Amorphous-nanocrystalline soft magnetic material, preparation method and application thereof, amorphous strip, amorphous-nanocrystalline strip and amorphous-nanocrystalline magnetic sheet

An amorphous nanocrystalline, soft magnetic material technology, applied in magnetic materials, inductance/transformer/magnet manufacturing, magnetic objects, etc., can solve the problems of high cost, low saturation magnetic induction intensity, etc., and achieve balanced saturation magnetic induction intensity and coercivity. force, improve the ability to form amorphous, improve the effect of comprehensive magnetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

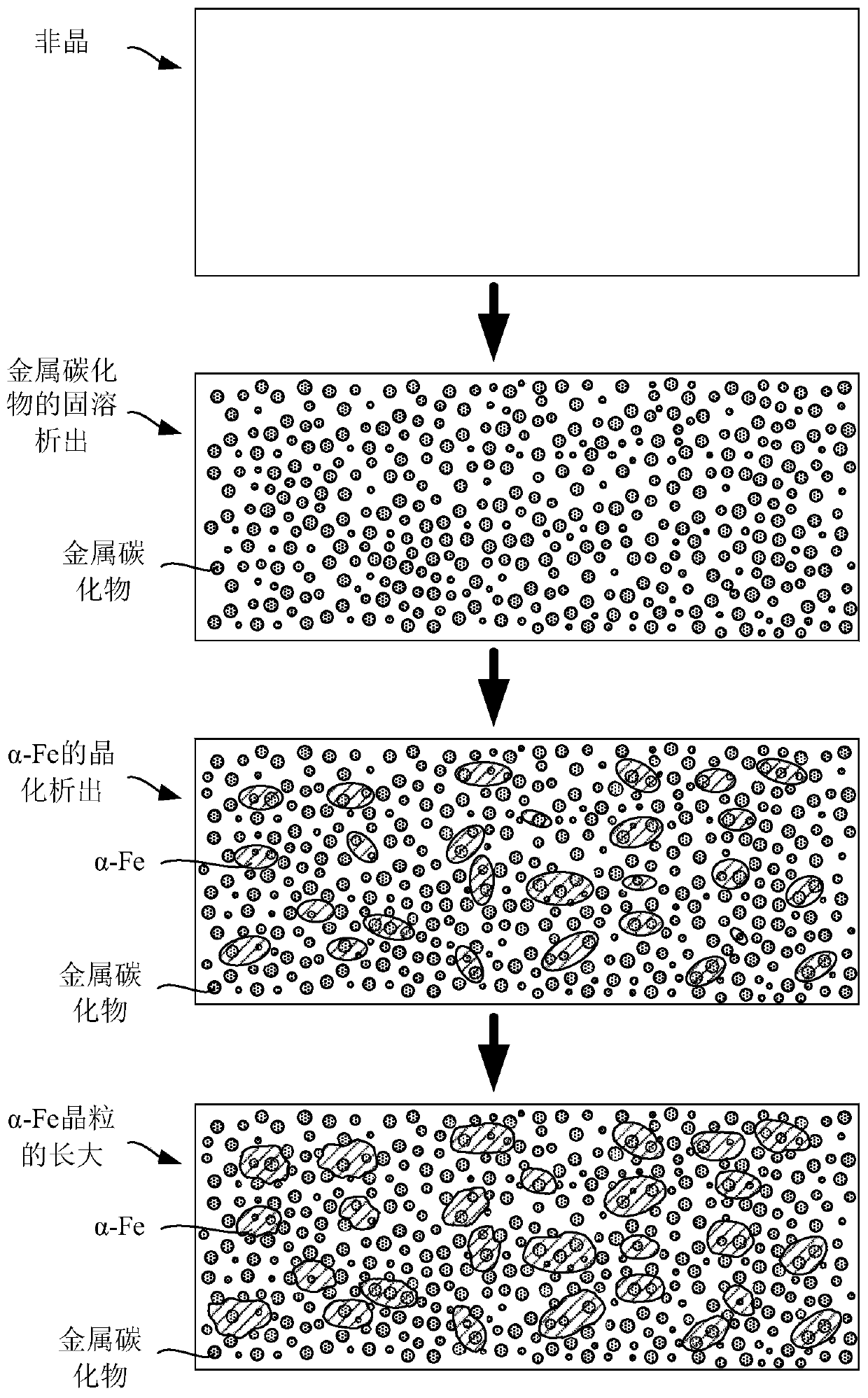

Method used

Image

Examples

Embodiment 1

[0076] This embodiment prepares amorphous nanocrystalline soft magnetic material according to the following method:

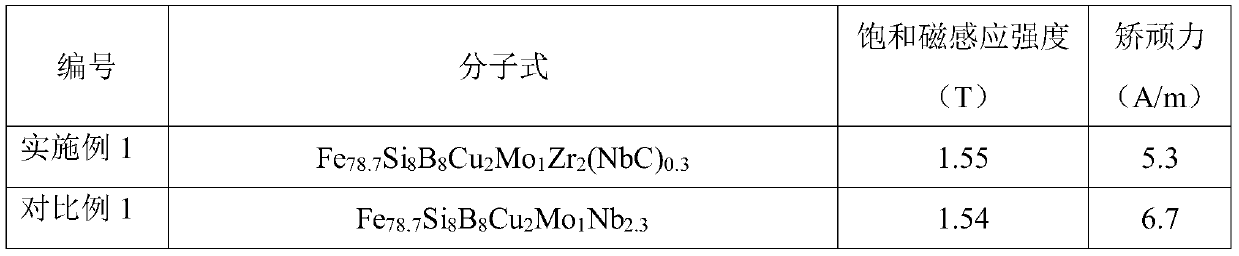

[0077] 1. Ingredients: raw materials with a purity greater than 99% 78.7 Si 8 B 8 Cu 2 Mo 1 Zr 2 (NbC) 0.3 The alloy components are mixed, wherein B is added in the form of boron-iron alloy, Nb in the form of niobium-iron alloy, and C in the form of iron-carbon alloy.

[0078] 2. Melting: Put the raw materials with a good ratio into the crucible of the melting furnace, and in a vacuum state, use the arc melting method to melt at 1300°C to obtain an alloy ingot with a uniform composition.

[0079] 3. Manufacturing of amorphous alloy: after the alloy ingot described in step 2 is re-melted, the strip-shaped amorphous alloy is produced by a single-roll quenching method.

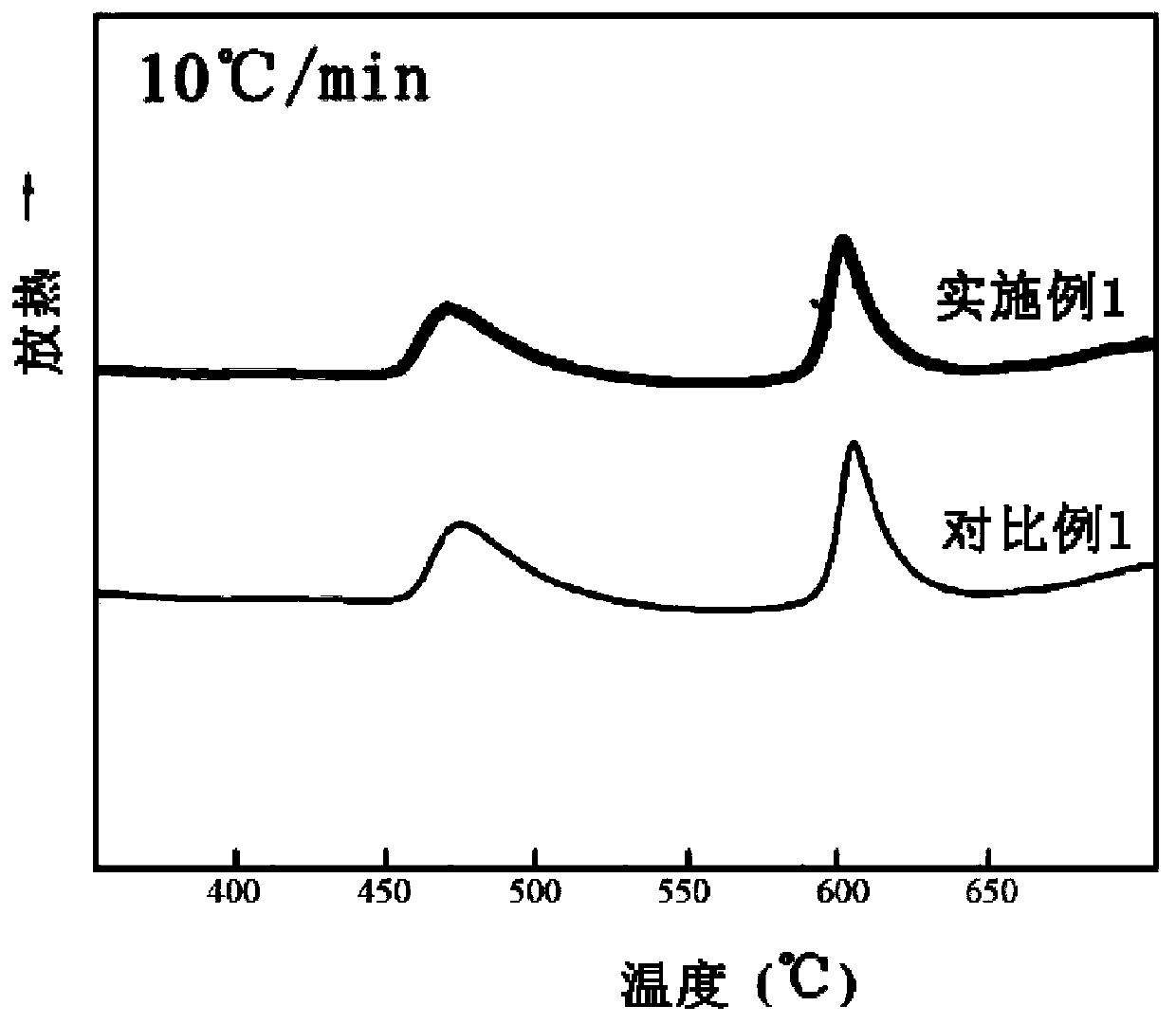

[0080] DSC (Differential Scanning Calorimeter, Differential Scanning Calorimeter) detection is carried out to the amorphous alloy that prepares, obtain as follows figure 2 The DSC curve s...

Embodiment 2

[0095] The amorphous nanocrystalline soft magnetic material of this comparative example is with reference to embodiment 1, and difference is, in step 1, the raw material with purity greater than 99% is pressed Fe 80.7 Si 8 B 8 Cu 2 Mo 1 (NbC) 0.3Alloy components are batched; in step 4, the crystallization temperature of the first stage and the crystallization temperature of the second stage are the initial temperature (456.60°C) of the first crystallization peak of the amorphous alloy obtained in step 3 in this comparative example Based on the calculation, put the amorphous alloy into the heat treatment furnace, and under the protection of high vacuum, raise the temperature in the heat treatment furnace to 448°C at a heating rate of 7°C / min, and keep it for 25min to carry out the first stage of crystallization. Then, at a heating rate of 7°C / min, the temperature in the heat treatment furnace was raised to 540°C and kept for 25 minutes to carry out the second stage of cryst...

Embodiment 3

[0100] This embodiment prepares amorphous nanocrystalline soft magnetic material according to the following method:

[0101] 1. Ingredients: raw materials with a purity greater than 99% 76.5 Si 10 B 6 Cu 1 Ta 1 W 2 Ge 1 Zr 2 (NbC) 0.5 The alloy components are mixed, wherein B is added in the form of boron-iron alloy, Nb in the form of niobium-iron alloy, and C in the form of iron-carbon alloy.

[0102] 2. Melting: Put the raw materials with a good ratio into the crucible of the melting furnace, and use the arc melting method at 1400°C to melt in a vacuum state to obtain an alloy ingot with a uniform composition.

[0103] 3. Manufacturing of amorphous alloy: after the alloy ingot described in step 2 is re-melted, the strip-shaped amorphous alloy is produced by a single-roll quenching method. DSC (Differential Scanning Calorimeter, Differential Scanning Calorimeter) detection is carried out to the prepared amorphous alloy, and the DSC curve is obtained, and the DSC curv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com