MnZn ferrite material and method for preparing magnet core

A technology of ferrite material and iron oxide, which is applied in the direction of magnetism of inorganic materials, can solve problems such as poor power conversion efficiency, achieve low power loss characteristics, and improve technical grades

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

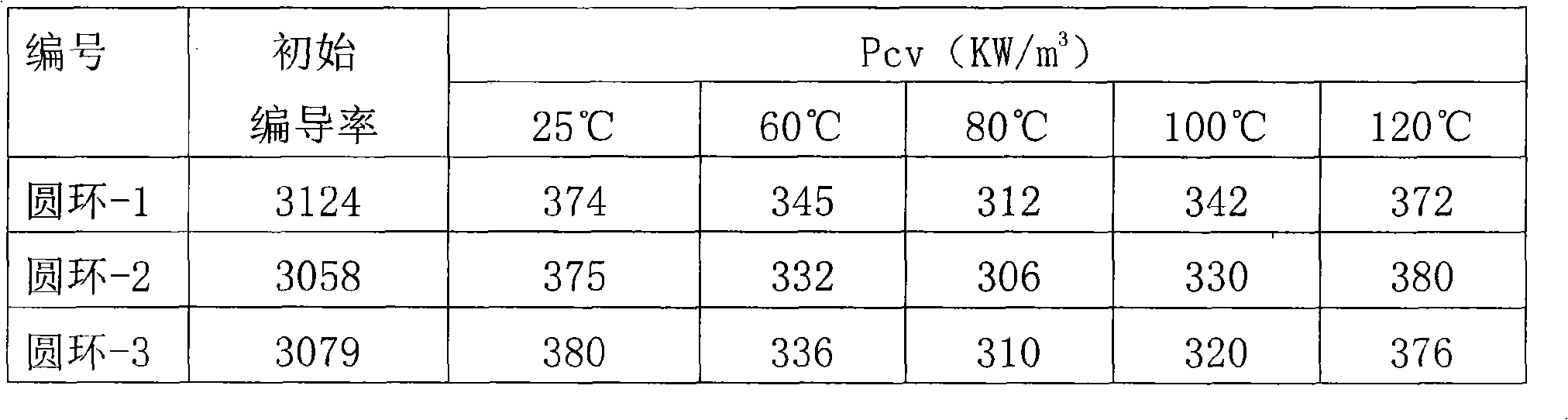

Examples

Embodiment 1

[0015] A kind of MnZn ferrite material, its method for preparing magnetic core is as follows:

[0016] (1) by Fe 2 o 3 : MnO: ZnO = 53.5: 35.6: 10.9mol% of the formula for a batching, where Fe 2 o 3 Using German ThyssenKrupp iron red (purity ≥ 99.3wt%), MnO is converted into Mn 3 o 4 , using high-purity Mn from Hunan Jinrui 3 o 4 (purity ≥ 98.8wt%), ZnO adopts ZnO (indirect method, purity ≥ 99.7wt%) in Haimen, Zhejiang; three kinds of raw materials are poured into the mixing tank, and dispersant and deionized water are added, and the dispersant is water The mixture of citric acid, acrylic acid and ammonia water has a weight ratio of 0.31-0.45:0.45-0.58:0.11-0.24; polyvinyl alcohol is added in a weight percentage of 0.6wt%-1.5wt%. Thoroughly stir and mix, and carry out ball milling for 2 hours;

[0017](2) Perform conventional spray drying on the above slurry, and then pre-calcine, the pre-fire temperature is 800°C, and the pre-fire time is 180 minutes, to obtain the pr...

Embodiment 2

[0023] A kind of MnZn ferrite material, its method for preparing magnetic core is as follows:

[0024] (1) by Fe 2 o 3 : MnO: ZnO = 51.8: 37.8: 10.4mol% of the formula for a batching, where Fe 2 o 3 Using German ThyssenKrupp iron red (purity ≥ 99.3wt%), MnO is converted into Mn 3 o 4 , using high-purity Mn from Hunan Jinrui 3 o 4 (purity ≥ 98.8wt%), ZnO adopts ZnO (indirect method, purity ≥ 99.7wt%) in Haimen, Zhejiang; three kinds of raw materials are poured into the mixing tank, and dispersant and deionized water are added, and the dispersant is water The mixture of citric acid, acrylic acid and ammonia water has a weight ratio of 0.31-0.45:0.45-0.58:0.11-0.24; polyvinyl alcohol is added in a weight percentage of 0.6wt%-1.5wt%. Thoroughly stir and mix, and carry out ball milling for 6 hours;

[0025] (2) Perform conventional spray drying on the above slurry, and then pre-calcine, the pre-fire temperature is 940°C, and the pre-fire time is 90 minutes, to obtain the pr...

Embodiment 3

[0032] A kind of MnZn ferrite material, its method for preparing magnetic core is as follows:

[0033] (1) by Fe 2 o 3 : MnO: ZnO = 52.5: 36.2: 11.3mol% of the formula for a batching, where Fe 2 o 3 Using German ThyssenKrupp iron red (purity ≥ 99.3wt%), MnO is converted into Mn 3 o 4 , using high-purity Mn from Hunan Jinrui 3 o 4 (purity ≥ 98.8wt%), ZnO adopts ZnO (indirect method, purity ≥ 99.7wt%) in Haimen, Zhejiang; three kinds of raw materials are poured into the mixing tank, and dispersant and deionized water are added, and the dispersant is water The mixture of citric acid, acrylic acid and ammonia water has a weight ratio of 0.31-0.45:0.45-0.58:0.11-0.24; polyvinyl alcohol is added in a weight percentage of 0.6wt%-1.5wt%. Thoroughly stir and mix, and carry out ball milling for 5 hours;

[0034] (2) Perform conventional spray drying on the above slurry, and then pre-calcine, the pre-fire temperature is 940°C, and the pre-fire time is 120 minutes, to obtain the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com