Microwave and ultrasound combined assisted ball-milling device and process for preparing high-performance nanopowder

A nano-powder, microwave ultrasonic technology, applied in the field of grinding and pulverization, can solve the problems of long ball milling action time, uneven particle size, poor repeatability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

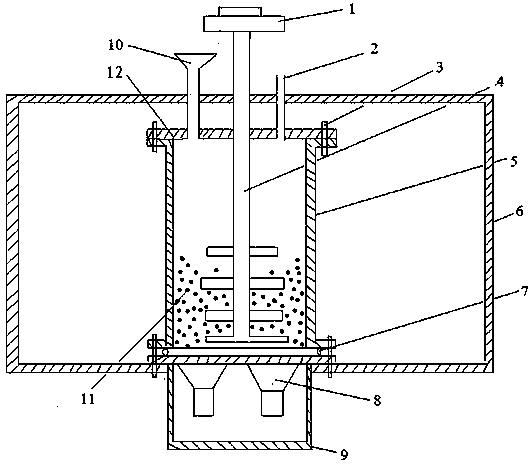

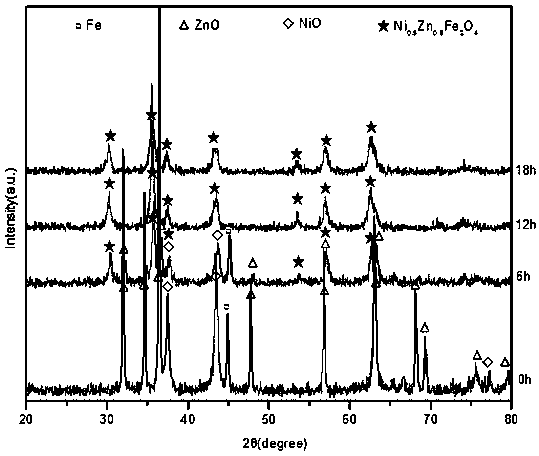

[0040] Example 1: Microwave ultrasonic combined with assisted ball milling to prepare high-performance nano-nickel-zinc composite ferrite

[0041] The reactants are analytically pure nickel oxide, zinc oxide and iron powder, which are first prepared according to a certain chemical ratio, mixed evenly, and then the reactants are put into a Ф135×215mm ball mill tank with a ball-to-material ratio of 100:1 , then add deionized water to 2 / 3 of the jar. Turn on the motor 1 and the ultrasonic generator, the power of the ultrasonic generator is 200W, the frequency is 20KHz, start to stir the ball mill, the stirring speed is 235 revolutions per minute, carry out the aqueous solution ball milling of the reactant for 15 minutes, and then turn on the microwave generator to work together, The power of the microwave generator is 1KW, the frequency is 2450MHz, irradiate for 15 minutes, and then ultrasonic ball milling for 15 minutes, and so on and so forth; after a certain period of time, ta...

Embodiment 2

[0046] Example 2: Microwave Ultrasound Combined with Assisted Ball Milling to Prepare Nano Zinc Oxide

[0047] Using basic zinc carbonate as raw material and ethylene glycol as an organic solvent as a ball milling medium, we also prepared zinc oxide nano-oxides by the same method as in Example 1.

[0048] from up Figure 7 It can be seen that after 10 hours of microwave ultrasonic combined with assisted ball milling, all basic zinc carbonate was converted to zinc oxide. This proves that microwave ultrasonic combined with assisted ball milling is an effective means to effectively decompose basic zinc carbonate into zinc oxide. Moreover, in this process, the product is not subjected to heat treatment such as calcination, and in the whole process, all reactions are carried out in an organic solvent, and the reaction temperature does not exceed 100 ° C, which proves that this equipment is a kind of equipment that can be used to quickly realize salt It is a new equipment for the ...

Embodiment 3

[0051] Example 3: Microwave Ultrasound Combined with Assisted Ball Milling to Prepare Nanoscale Tin Oxide Powder

[0052] We used 100-mesh tin powder as the raw material and organic solvents such as acetic acid as the ball milling medium to prepare tin oxide nanopowder with a particle size of 10-20nm within 10 hours by the same method as in Example 1. This method has the characteristics of high efficiency, and is an ideal device and process method for industrial production of nano tin oxide powder.

[0053] We also carried out microwave-assisted ball milling and ultrasonic-assisted ball-milling experiments with the same raw materials, and found that no matter whether ultrasonic-assisted ball milling or microwave-assisted ball milling, nano-tin oxide powder could not be prepared for a long time.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Saturation magnetization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com