Soft-magnetic nickel-copper-zinc ferrite material and preparation method thereof

A nickel-copper-zinc ferrite and soft-magnetic technology, applied in the field of soft-magnetic nickel-copper-zinc ferrite materials and their preparation, can solve problems such as large specific loss, achieve high Curie temperature, simple preparation process and low specific temperature The effect of coefficients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

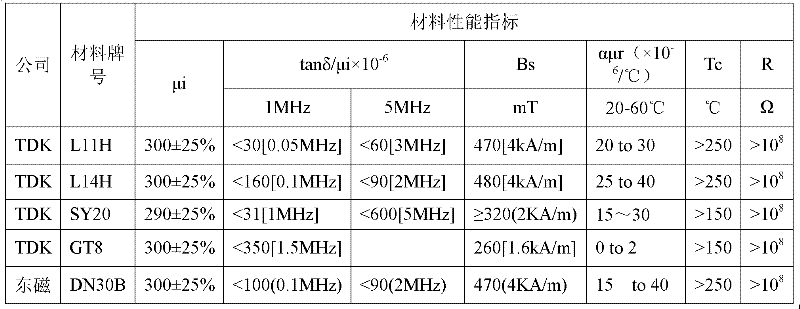

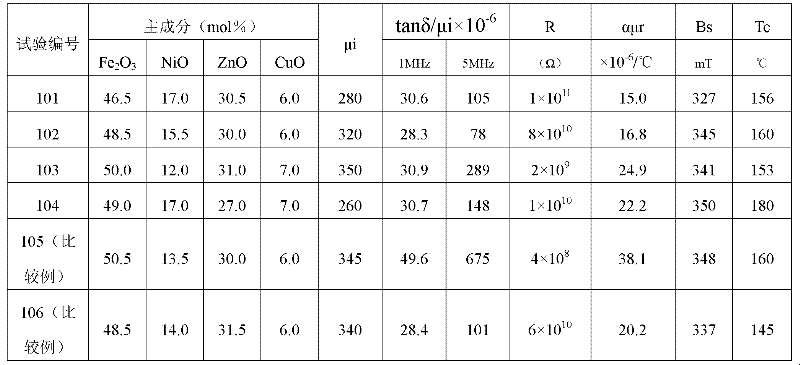

[0046] Weigh Fe with the main component content shown in Table 1 2 o 3 , NiO, ZnO and CuO raw materials, relative to the total weight of the main components, the weight percentage content of the secondary components in terms of their respective standards is: MnO: 0.2wt%, Bi 2 o 3 : 0.2wt%, Co 2 o 3 : 0.3wt%, V 2 o 5 : 0.05wt%, ZrO 2 : 0.05wt%, SiO 2 : 0.1wt%, TiO 2 : 0.01wt%, Nb 2 o 5 : 0.02wt%, secondary component manganese oxide MnO with Mn 3 o 4 Add in the form of raw materials, mix and vibrate the raw materials of the main component and each auxiliary component, and then pre-fire in an air kiln at 950°C for 120 minutes to obtain pre-fired powder after preliminary reaction. According to the weight of the calcined powder, add 0.2wt% n-zinc alcohol to the calcined powder for sand grinding, discharge and stir and add 0.8wt% binder polyvinyl alcohol, and spray dry to obtain the average particle size In 200μm pellets. According to the weight of the pellets, add 0.0...

Embodiment 2

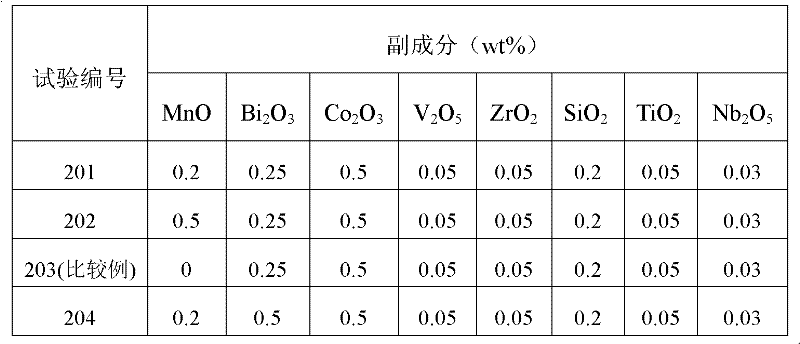

[0052] The preparation process of the magnetic core is the same as that of Example 1. Only Fe in the main ingredient formula 2 o 3 , NiO, ZnO, CuO content fixed at 48.5mol% Fe 2 o 3 , 15.5 mol% NiO, 30 mol% ZnO and 6 mol% CuO. The contents of subcomponents are shown in Table 2.

[0053] Table 2

[0054]

[0055]

[0056] table 3

[0057]

[0058] It can be seen from Table 2 and Table 3 that when the content of the auxiliary components is within the scope of the present invention, the specific loss of the magnetic core is low, and the saturation magnetic flux density at 25°C is above 320mT; the specific loss at 1MH tanδ / μi-6 、Specific loss tanδ / μi-6 ;Surface resistance R>10 9 Ω, Curie temperature Tc>150°C. When the content of subcomponents deviates from the scope of the present invention, there will be one or several performance indicators among the magnetic permeability μi, saturation magnetic flux density Bs, tanδ / μi, αμr, and surface resistance R.

Embodiment 3

[0060] The composition of the magnetic core is the same as that of test number 102#, and the preparation process is the same as that of Example 1. Only the sintering temperature is shown in Table 4.

[0061] Table 4

[0062]

[0063] It can be seen from Table 4 that when the sintering temperature is 1050-1150°C, the performance indicators of the magnetic core are better, and the temperature is lower when sintering at 1030°C, resulting in magnetic permeability μi, saturation magnetic induction Bs, 5MHz The lower tanδ / μi and other characteristics become worse.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com