Mn-Zn ferrite material with wide temperature and high initial magnetoconductivity and preparation method thereof

A technology of initial magnetic permeability and ferrite material, applied in the field of Mn-Zn ferrite material and its preparation, can solve problems such as low magnetic permeability and device failure, and achieve strong adaptability of raw materials, simple process, and expansion. Application-wide effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

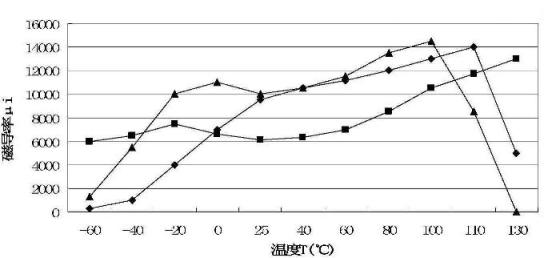

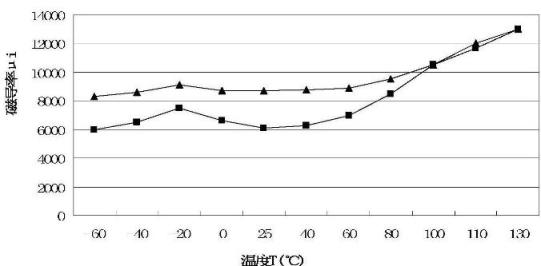

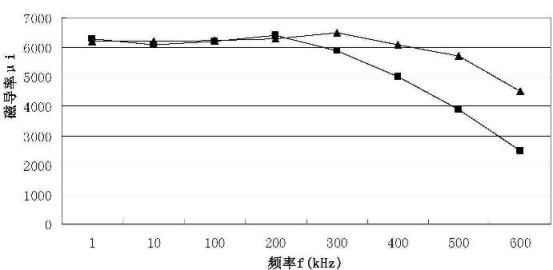

[0041] The ratio is Fe 2 o 3 The three main component materials of 51.5mol%, ZnO17.5mol%, and MnO31.0mol% are weighed, mixed in a ball mill, and then pre-fired at 750°C for 4 hours, and the auxiliary component CaO is added based on the total weight of the three main components. (450ppm), Bi 2 o 3 (950ppm), through 2 hours of sand grinding, and then spray granulation to obtain ferrite powder. Press the powder into blank samples of H25×15×10 with a fully automatic dry press machine, divide 100 samples into 5 groups, and keep warm at 1380°C for 8 hours under the protection of nitrogen to obtain the desired magnetic core. The sample number is 1. The test data of each group takes 10 samples to calculate the average value, and the test results of magnetic permeability μi are shown in Table 1. The magnetic permeability μ i of embodiment 1 product and temperature T curve figure such as figure 1 , figure 2 , image 3 , Figure 4 or Figure 5 shown.

Embodiment 2

[0043] The ratio is Fe 2 o 3 The three main component materials of 55.5mol%, ZnO17.5mol%, and MnO27.0mol% are weighed, mixed in a ball mill, and then pre-fired at 950°C for 1.5 hours, and the auxiliary component CaO is added based on the total weight of the three main components. (450ppm) and MoO 3 (750ppm), through 2 hours of sand grinding, and then spray granulation to obtain ferrite powder. Press the powder into blank samples of H25×15×10 with a fully automatic dry press machine, divide 100 samples into 5 groups, and keep warm at 1320°C for 14 hours under the protection of nitrogen to obtain the desired magnetic core. The sample number is 2. The test data of each group takes 10 samples to calculate the average value, and the test results of magnetic permeability μi are shown in Table 1.

Embodiment 3

[0045] The ratio is Fe 2 o 3 The three main components of 51.5mol%, ZnO25.5mol%, and MnO23.0mol% are weighed, mixed in a ball mill, and then pre-fired at 1000°C for 1 hour, and the auxiliary component CaO is added based on the total weight of the three main components. (50ppm) and V 2 o 5 (750ppm), through 2 hours of sand grinding, and then spray granulation to obtain ferrite powder. Use a fully automatic dry press to press the powder into H25×15×10 blank samples, divide 100 samples into 5 groups, and keep warm at 1400°C for 4 hours under the protection of nitrogen to get the desired magnetic core. The sample number is 3. The test data of each group takes 10 samples to calculate the average value, and the test results of magnetic permeability μi are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com