Composite material with capacitance and inductance performance and its preparing method

A composite material, capacitor-inductor technology, applied in the direction of fixed capacitor dielectrics, fixed capacitor components, etc., can solve the problems of high temperature co-firing, high energy consumption, easy cracking in ceramic technology, and achieve lower molding temperature, good performance, high The effect of dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

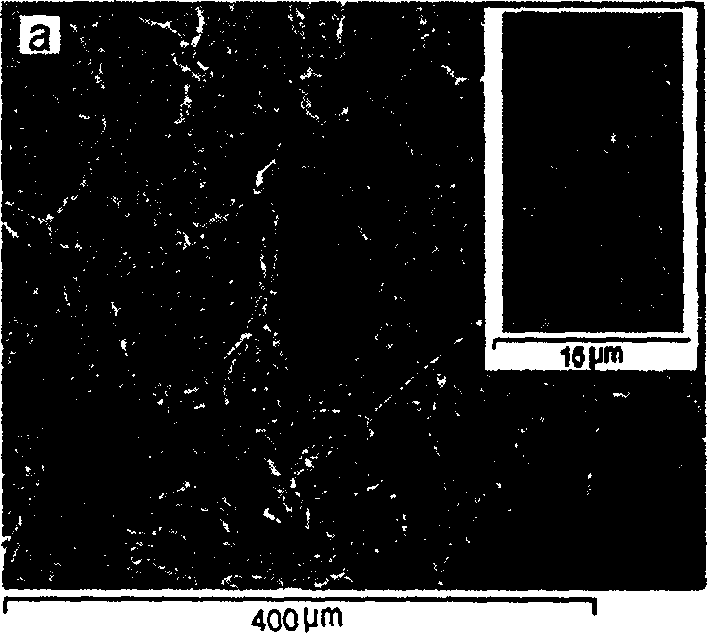

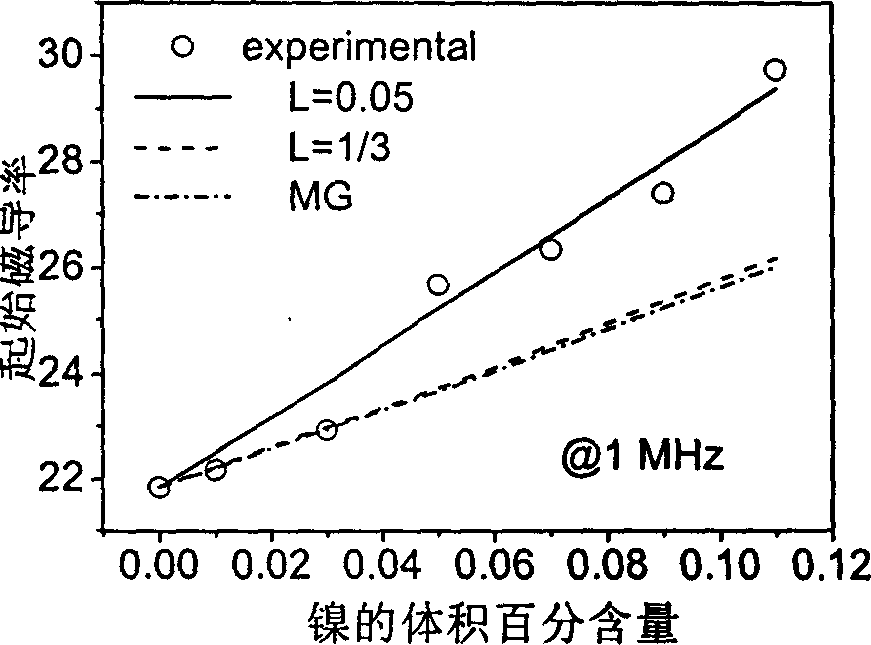

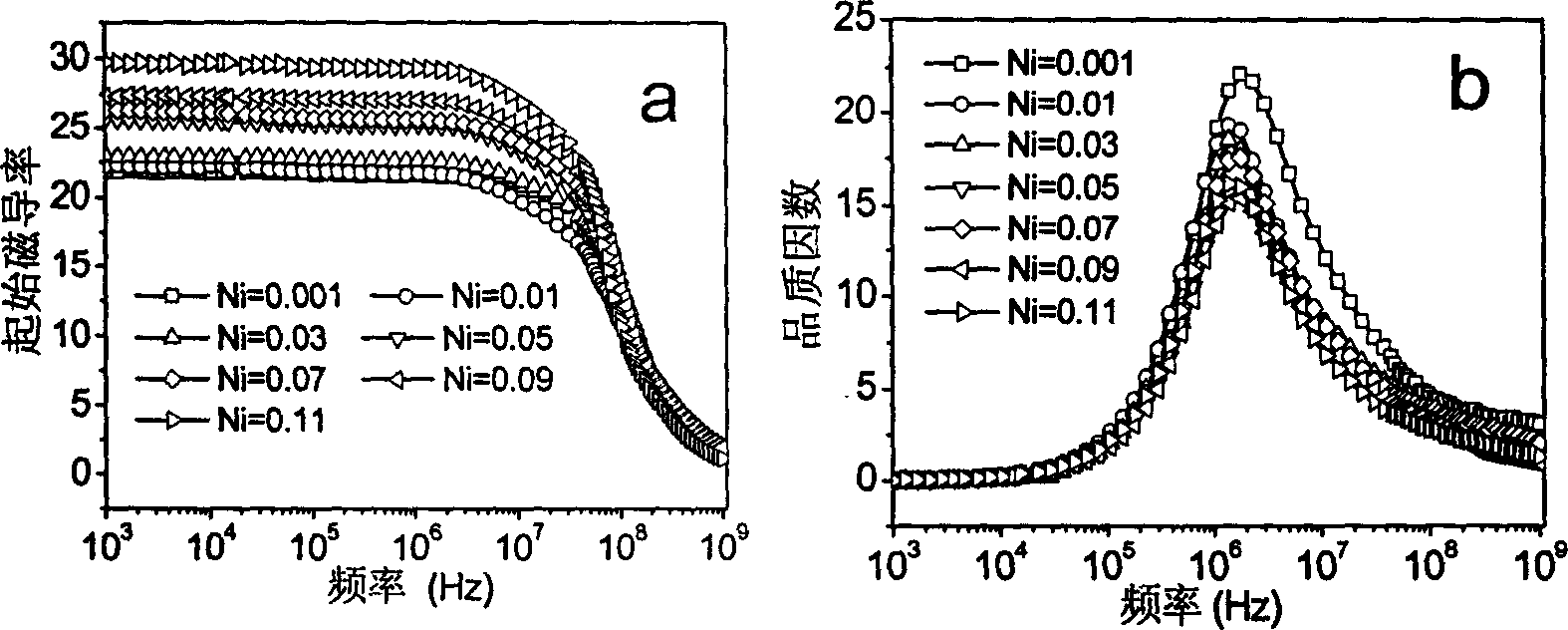

[0028] According to the formula listed in Table 1, weigh appropriate amount of nickel powder, polyvinylidene fluoride and 2.4g of nickel-zinc ferrite powder, mix them evenly, place them in a mold, and heat-press at 200°C and 15MPa for 15 minutes to form. Series samples. The double percolation structure can be verified from the microstructure photos of the sample, such as figure 1 Shown. The initial magnetic permeability of the sample varies with the volume percentage of nickel particles as follows: figure 2 As shown, the simulation results using Maxwell-Garnett formula and Bruggeman-Hanai formula are also shown in figure 2 in. The law of initial permeability and quality factor changing with frequency is as follows image 3 Shown. The sample conductivity and dielectric constant change with the volume percentage of nickel particles as follows: Figure 4 Shown in.

[0029] serial number

[0030] Note: Each composite material contains 60vol% nickel-zinc ferrite with a we...

Embodiment 2

[0032] According to the formula listed in Table 2, weigh the appropriate amount of nickel powder, polyvinylidene fluoride and 1.65g Z-type flat hexagonal ferrite powder, mix them uniformly, and place them in the mold, and heat-press at 200°C and 15MPa for 15 minutes. A series of samples can be obtained. The double percolation structure can be verified from the microstructure photos of the sample, such as Figure 5 Shown. The initial permeability of the sample changes with the volume percentage of nickel particles as follows: Figure 6 As shown, the simulation results using Maxwell-Garnett formula and Bruggeman-Hanai formula are also shown in Figure 6 in. The initial permeability and quality factor of the sample change with frequency as followsFigure 7 Shown. The electrical conductivity and dielectric constant of the sample change with the volume percentage of nickel particles as follows: Figure 8 Shown in.

[0033] serial number

[0034] Note: Each composite materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com