Method for manufacturing chip inductance element from low-temperature cofired ferrite raw material belt

A ferrite raw material, low temperature co-firing technology, applied in electrical components, inductors, fixed inductors, etc., can solve the problem of high Curie temperature, achieve high Curie temperature, uniform distribution, and prevent device failure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

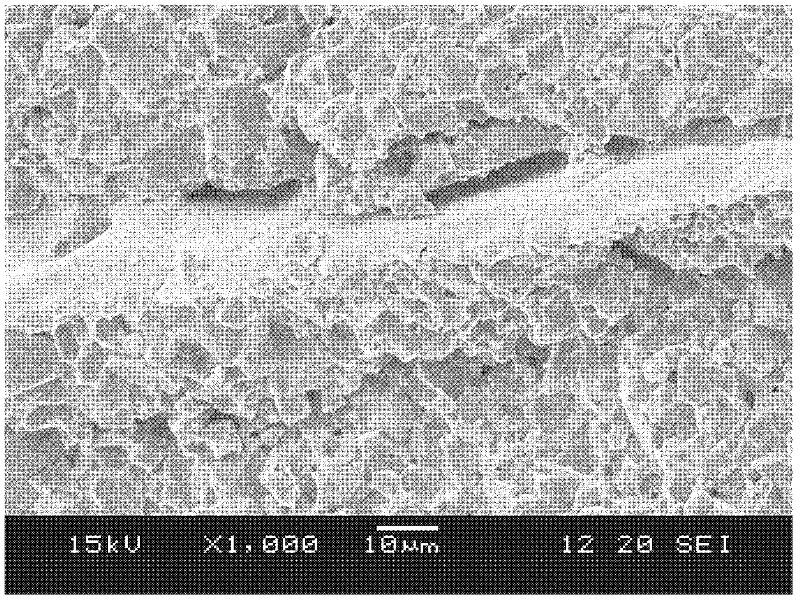

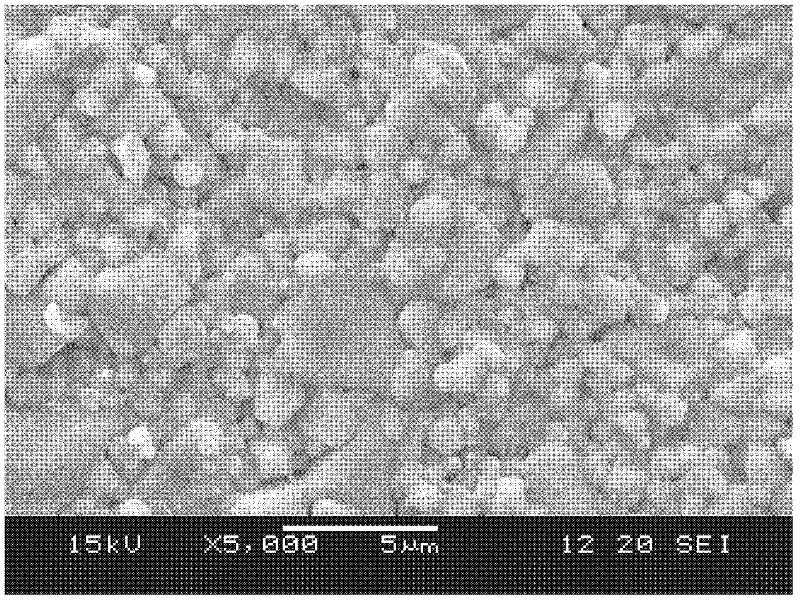

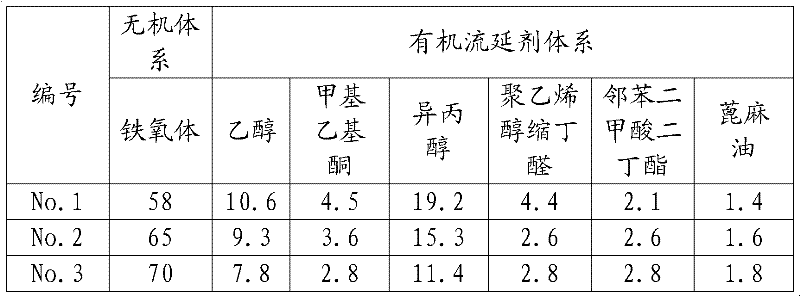

[0031] Table 1 shows the content of each component of the specific example 1 of the present invention. Weigh the calcined ferrite powder according to the formula in Table 1, add solvent and dispersant and ball mill for 3-6 hours, add binder and plasticizer and ball mill for 3-6 hours, vacuum defoaming, tape casting, and drying to obtain The low-temperature co-fired ferrite raw tape of the present invention.

[0032] In the present invention, the prepared raw material tape is engraved to make a standard test ring, the temperature is raised at 2°C / min to 450°C for 3 hours to remove glue, and then the temperature is raised from 450°C to 900°C for 3 hours at 2.5°C / min for sintering. During the cooling process, the temperature was controlled to drop to 250°C for 10 hours, and then cooled naturally with the furnace, and the performance of the sintered body was tested (see Table 2).

[0033] Table 1 The content of each component of low temperature co-fired ferrite raw tape (wt%)

...

Embodiment 2

[0038] Table 4 shows the content of each component of the specific example 2 of the present invention. Weigh the calcined ferrite powder according to the formula in Table 4, add solvent and dispersant and ball mill for 3-6 hours, add binder and plasticizer and ball mill for 3-6 hours, vacuum defoaming, tape casting, and drying to obtain The low-temperature co-fired ferrite raw tape of the present invention.

[0039] In the present invention, ring-cutting is performed on the prepared raw material tape, the temperature is raised to 450°C at 2°C / min and kept for 3 hours to remove glue, and then the temperature is raised from 450°C to 900°C for 3 hours at 2.5°C / min for sintering. During the cooling process, the temperature was controlled to drop to 250°C for 10 hours, and then cooled naturally with the furnace, and the performance of the sintered body was tested (see Table 5).

[0040] Table 4 The content of each component of low temperature co-fired ferrite raw tape (wt%)

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com