Nano crystal soft magnetic alloy superthin belt and mfg method thereof

A nanocrystalline soft magnetic and ultra-thin ribbon technology, which is applied in the direction of magnetic materials, magnetic objects, and inorganic materials, can solve problems such as poor fluidity of molten alloys, increased material costs, and difficult preparation of original amorphous ribbons, reducing production. Effects of cost, increased liquidity, broad research and market application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

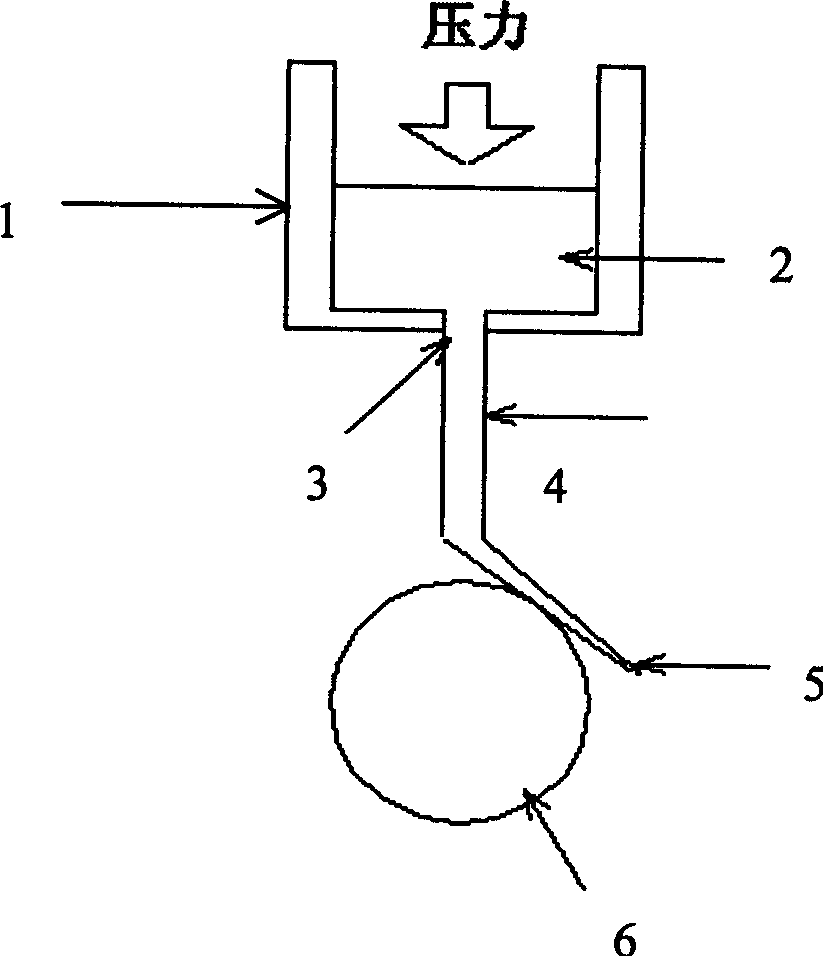

[0024] The preparation process of the soft magnetic alloy ultra-thin strip is as described above. During vacuum smelting, the vacuum degree is 6×10 -3 Pa, the smelting temperature is 1000°C, and the master alloy is prepared. In the preparation of the amorphous ribbon, a single-roll quenching device is used, as shown in Fig. 1 . The shielding gas is Ar, the pressure is 500Pa, and the linear speed of the roller is 40-70m / s, and the thickness of the obtained nanocrystalline ultra-thin ribbon is 14 microns, and the width is 20 mm. When the annealing temperature is 540°C, the content of nanocrystals in the ultrathin ribbon is 63.2%, and when the annealing temperature is 600°C, the content of nanocrystals is 73.9%. Its magnetic properties are as follows:

[0025] Saturation flux density: B 30 = 1.4T; B 10 =1.3T,B s Up to 1.7T

[0026] Magnetic permeability: μ i =3.8×10 4

[0027] Coercivity: H c =0.12Oe=9.6A / m

[0028] Iron loss: P 10 / 400 = 1.9097w / kg; P 2 / 100K ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com