Mn-Zn wide-temperature soft magnetic ferrite material and preparation method thereof

A soft magnetic ferrite and magnetic ferrite technology, applied in the field of Mn-Zn wide temperature soft magnetic ferrite material and its preparation, can solve problems such as backwardness, and achieve the effects of low production cost, low power consumption and superior performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Weighing; 71wt% iron red (Fe 2 o 3 ), 22wt% Mn 3 o 4 , 7wt% ZnO, put it into a vibrating ball mill and vibrate for 20min, then put it into a rotary kiln, pre-fire at a temperature of 1010°C, and the output is 2Kg / min, go to the sand mill and add additives

[0045] NiO: 0.0125wt%

[0046] co 2 o 3 : 0.0275wt%

[0047] CaCO 3 : 0.025wt%

[0048] SiO 2 : 0.0025wt%

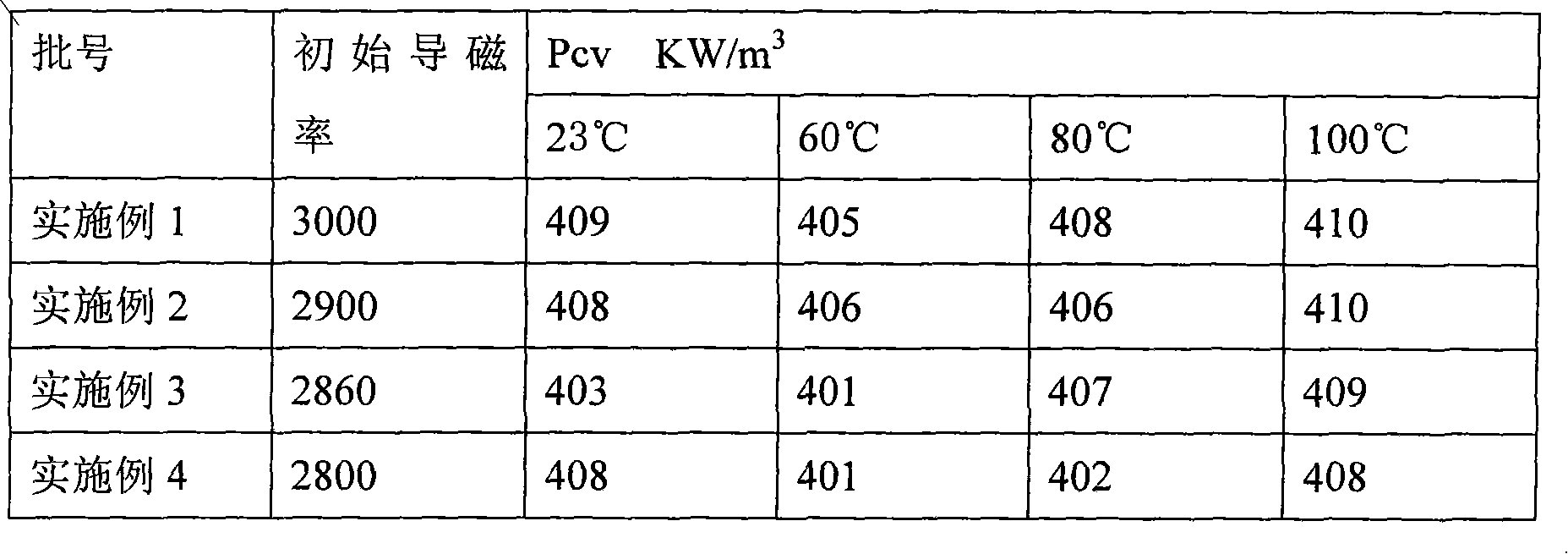

[0049] Finally, the Mn-Zn ferrite powder is obtained by spraying and granulating through a spray granulation tower at an outlet temperature of 110°C. Take the powder to make T-30*20*8, set density 3.0g / cm 3 , placed in a nitrogen tunnel kiln for sintering, and kept at 1360°C for 4 hours in the high temperature zone of the heating zone. A mixture of nitrogen and oxygen is added to the dense zone, the oxygen content is controlled at 5%, and the temperature in the cooling zone is controlled at 1200-1100°C, and the oxygen content is controlled below 0.4%. Tested with an impedance analyzer and a power c...

Embodiment 2

[0051] Weighing; 70t% Fe 2 o 3 , 22wt% Mn3 o 4 , 8wt% ZnO was put into a vibrating ball mill for 20 minutes, then put into a rotary kiln, pre-fired in a 1040°C rotary kiln, and the pre-fired material was ball-milled for 20 minutes, and then put into a sand mill together with additives for sand grinding. Portions are as follows

[0052] Nb 2 o 5 : 0.025wt%

[0053] NiO: 0.0125wt%

[0054] co 2 o 3 : 0.0275wt%

[0055] CaCO 3 : 0.02wt%

[0056] SiO 2 : 0.0025wt%

[0057] Finally, the Mn-Zn ferrite powder was obtained by spraying and granulating at an outlet temperature of 110°C. Take the powder to make T-30*20*8, set density 3.0g / cm 3 , put into nitrogen tunnel kiln and carry out sintering according to Example 1, and the obtained data are listed in Table 4.

Embodiment 3

[0059] Take the powder of Example 1 to make a T-30*20*8 blank, put it in a nitrogen tunnel kiln for sintering, add a mixture of nitrogen and oxygen in the dense area, control the oxygen content at 5%, and keep the high temperature area for 4 hours. The temperature in the cooling zone is controlled at 1200-1100°C and the oxygen content is controlled below 0.7%. The properties obtained are listed in Table 4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com