Magnesium-zinc soft magnetic ferrite and preparation method thereof

A soft ferrite, magnesium-zinc technology, applied in the field of magnesium-zinc soft ferrite and its preparation, can solve the problems of low cost, high cost, high loss of soft ferrite, etc., achieve low cost, improve Q value, improve The effect of resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The preparation method of above-mentioned magnesium-zinc soft magnetic ferrite comprises the following steps:

[0045] Step 1, ingredients: Weigh the raw materials of magnesium-zinc soft magnetic ferrite in proportion, and the raw materials include: iron oxide 68.92wt%-70.59wt%; zinc oxide 16.03wt%-18.52wt%; magnesium oxide 8.07wt%-9.83 wt%; copper oxide 3.62wt%-3.86wt%; bismuth trioxide 0.1wt%-0.3wt%; vanadium pentoxide 0.1wt%-0.3wt%; cobalt oxide 0.05wt%-0.3wt%; calcium carbonate 0.03 wt% - 0.10 wt%.

[0046] Step 2, the first ball mill: put the weighed iron oxide, zinc oxide, magnesium oxide, copper oxide, bismuth trioxide and vanadium pentoxide in a dry ball mill mixer and mix them for 4-6 hours After fully mixing, the material is discharged, and the mixed powder is obtained and then put into the sagger;

[0047] Step 3. Pre-sintering: Put the above-mentioned sagger containing the mixed powder into a pre-sintering furnace for pre-sintering, heat up from room tempe...

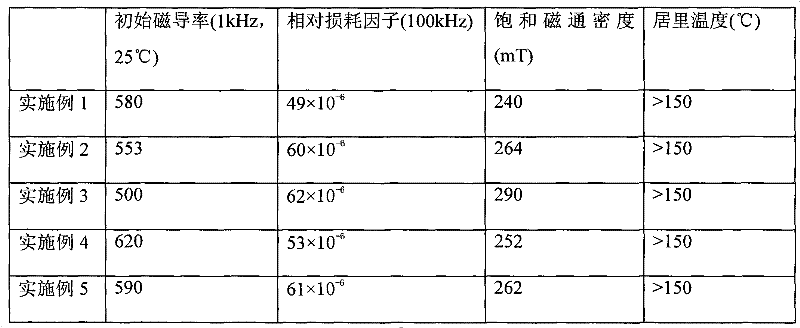

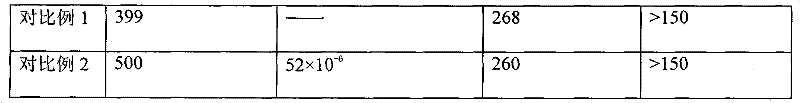

Embodiment 1-5

[0055] The preparation method of the magnesium-zinc soft magnetic ferrite of embodiment 1-5 of the present invention comprises the following steps:

[0056] 1), ingredients: weigh the raw materials of magnesium-zinc soft magnetic ferrite according to the components and ratios of Examples 1-5 in Table 1 respectively (the contents of the raw materials are all in weight percent wt%);

[0057] 2), ball milling for the first time: place the weighed iron oxide, zinc oxide, magnesium oxide, copper oxide, bismuth trioxide and vanadium pentoxide in a dry ball mill mixer and mix them thoroughly for 5 hours, then Discharge, put into the sagger;

[0058] 3) Pre-firing: Put the sagger into the pre-burning furnace for pre-firing, that is, raise the temperature from room temperature to about 800°C after 3 hours, then raise the temperature to about 900°C after 1 hour, and keep warm at 900°C for 3 hours. hours, and then cooled to below 200°C after 2 hours;

[0059] 4), the second ball millin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com