Mixed soft magnetic material and integrally molded inductor prepared thereby

A soft magnetic material, integrated technology, applied in the direction of inorganic material magnetism, inductance/transformer/magnet manufacturing, circuits, etc., can solve the problems of high compressibility, difficult stamping, low forming density, etc., to achieve low product loss, High efficiency, good saturation characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

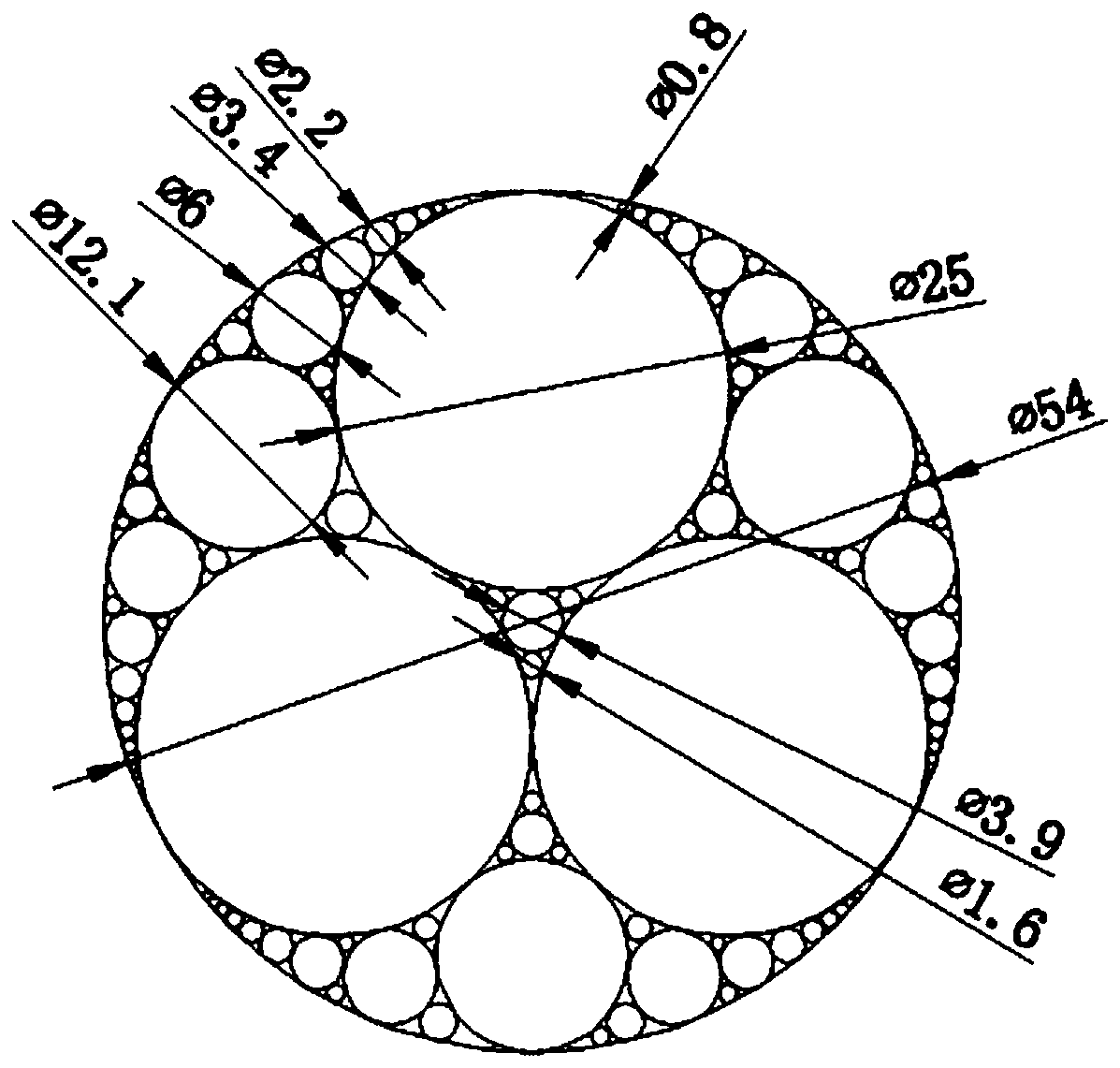

[0043] Take 1KG mixed soft magnetic powder with particle size grading (70 parts of carbonyl iron powder with a particle size of D50=5 μm and 30 parts of amorphous FeSiBCr powder with a particle size of D50=25 μm), and carry out passivation insulation treatment , and then mix and granulate the soft magnetic powder after the passivation insulation treatment and the binder.

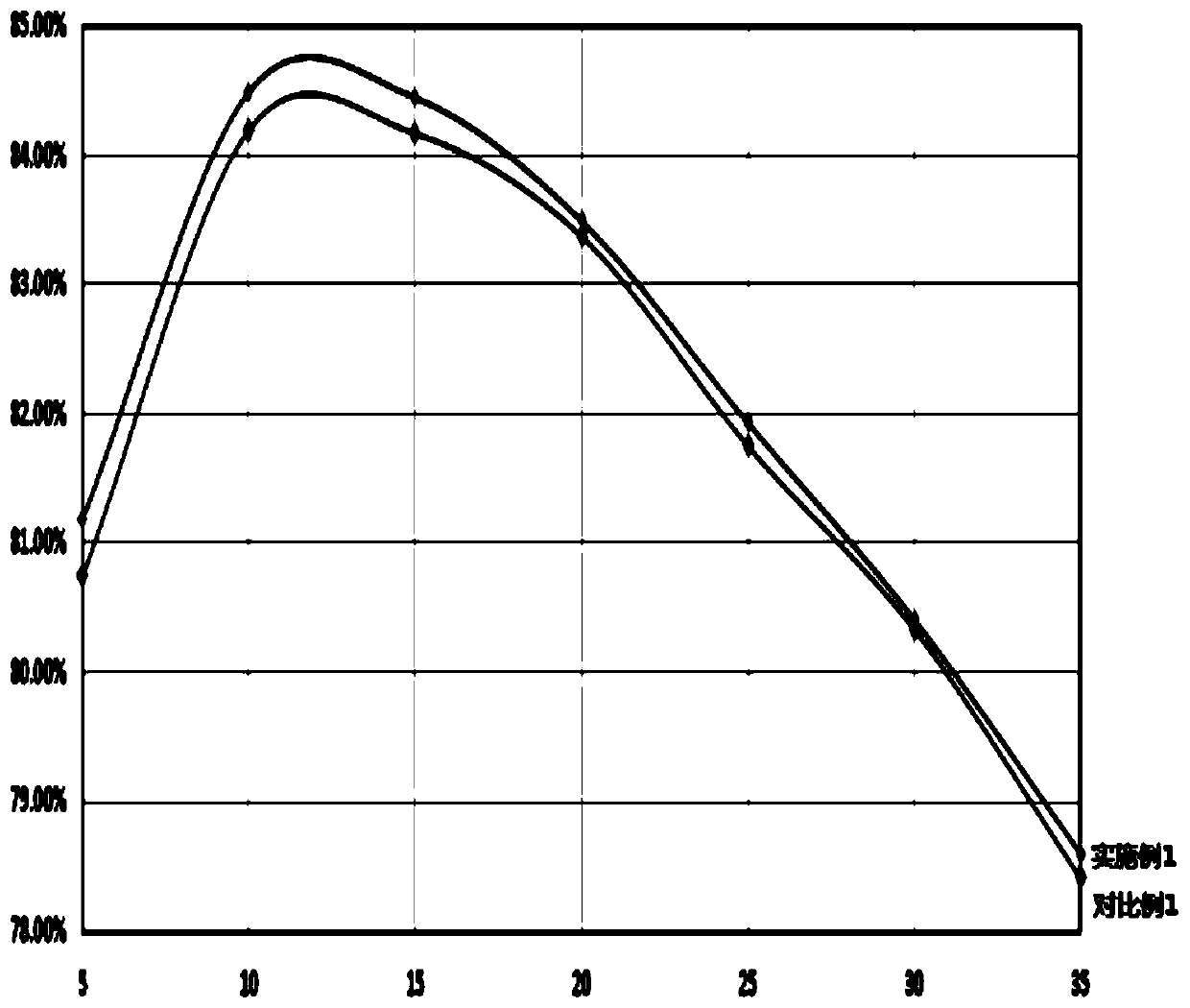

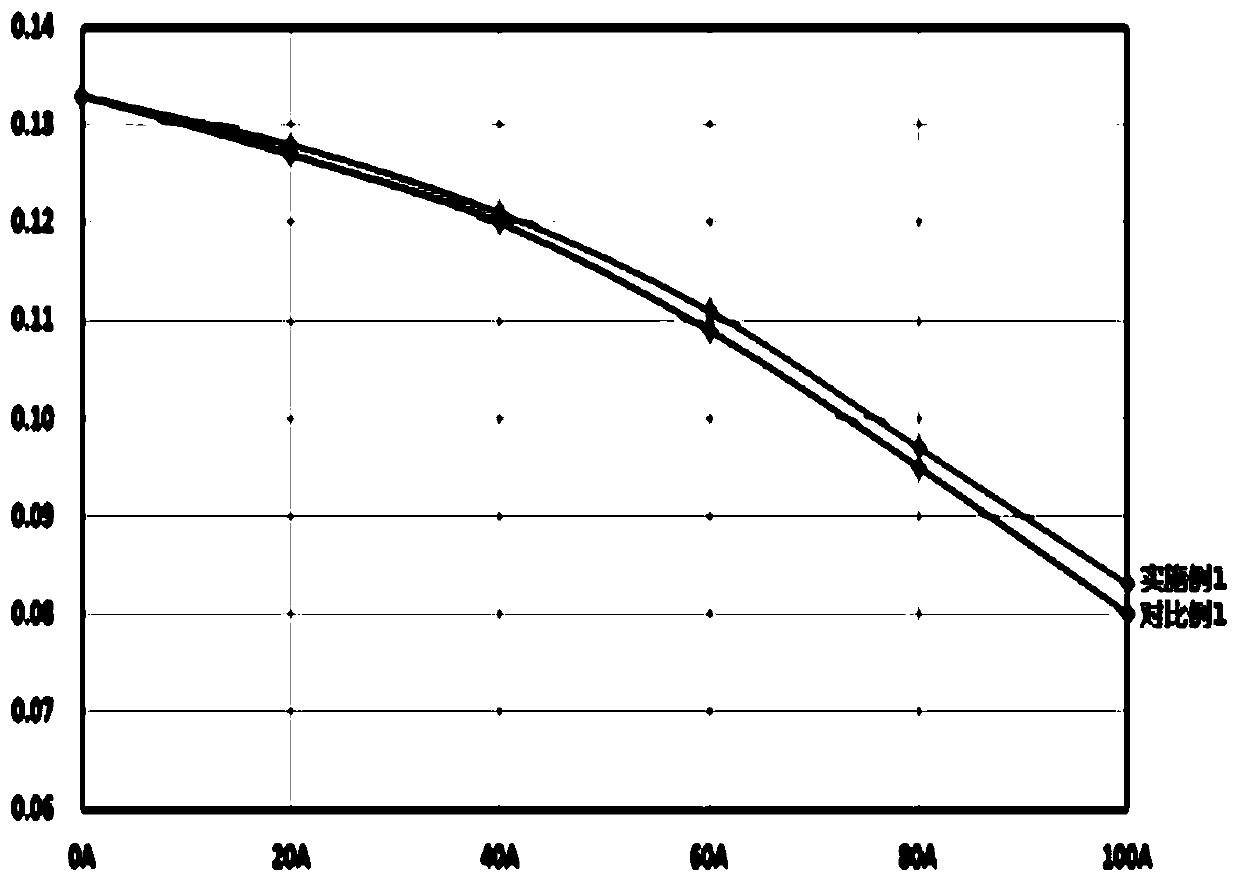

[0044] Comparative Example 1 and Example 1 respectively use the same coil 1.4mm×2.8mm(OD)×1.5Ts to press the integrally formed inductor with the same size of 8mm×8mm×5mm, and the inductance range is 0.14uH±20%. Comparative Example 1 is 1L: 0.133uH powder 1, Example 1 is 2L: 0.133uH powder 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com