Amorphous nano crystal soft magnet alloy strip with surface insulation coating and its preparation method

A technology of soft magnetic alloy strips and amorphous nanocrystals, applied in the direction of coating liquid devices, coatings, insulators, etc., can solve the problem of hard coatings, insulating coatings that cannot withstand higher temperatures, and affect magnetic properties and other issues to achieve the effect of reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

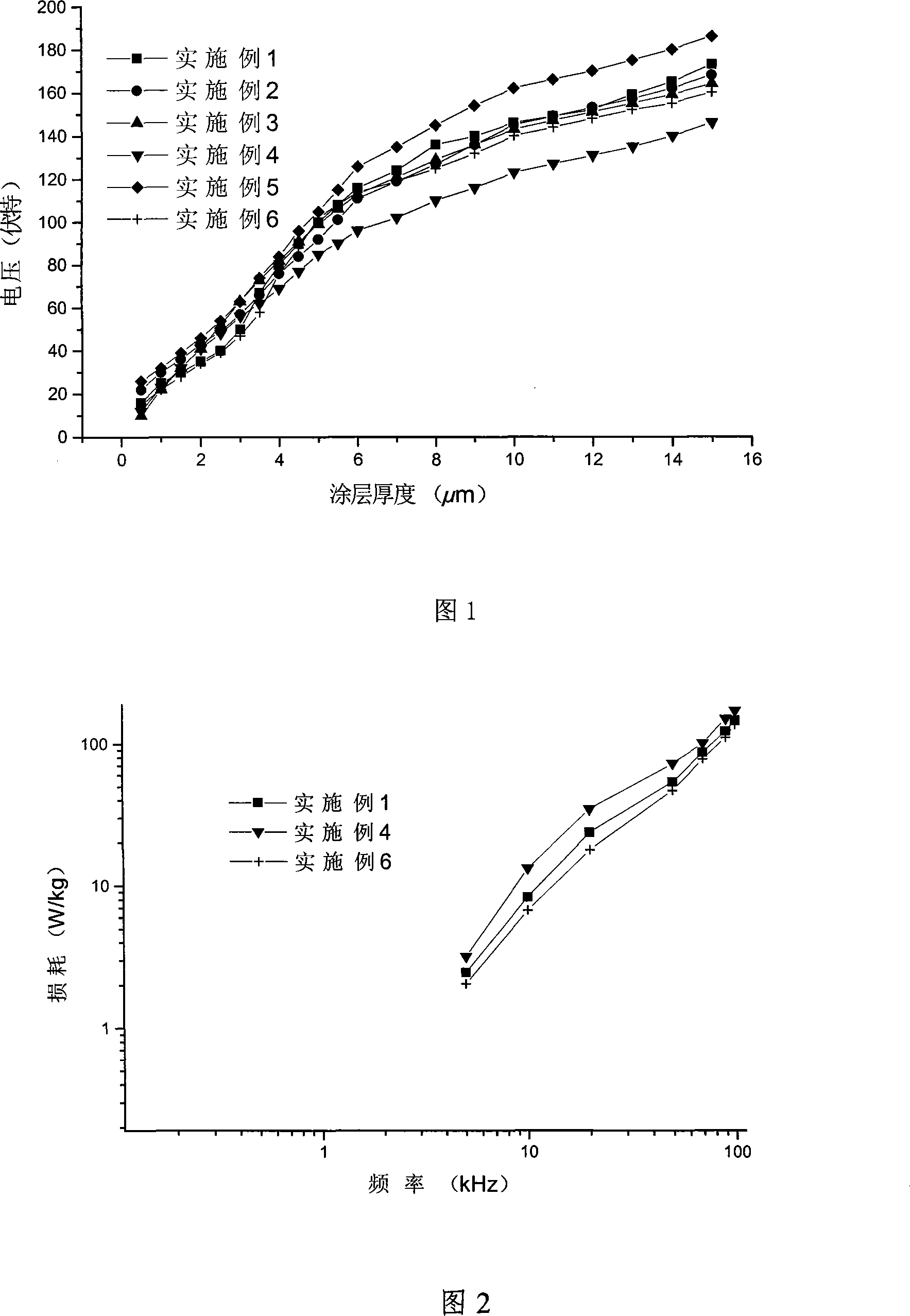

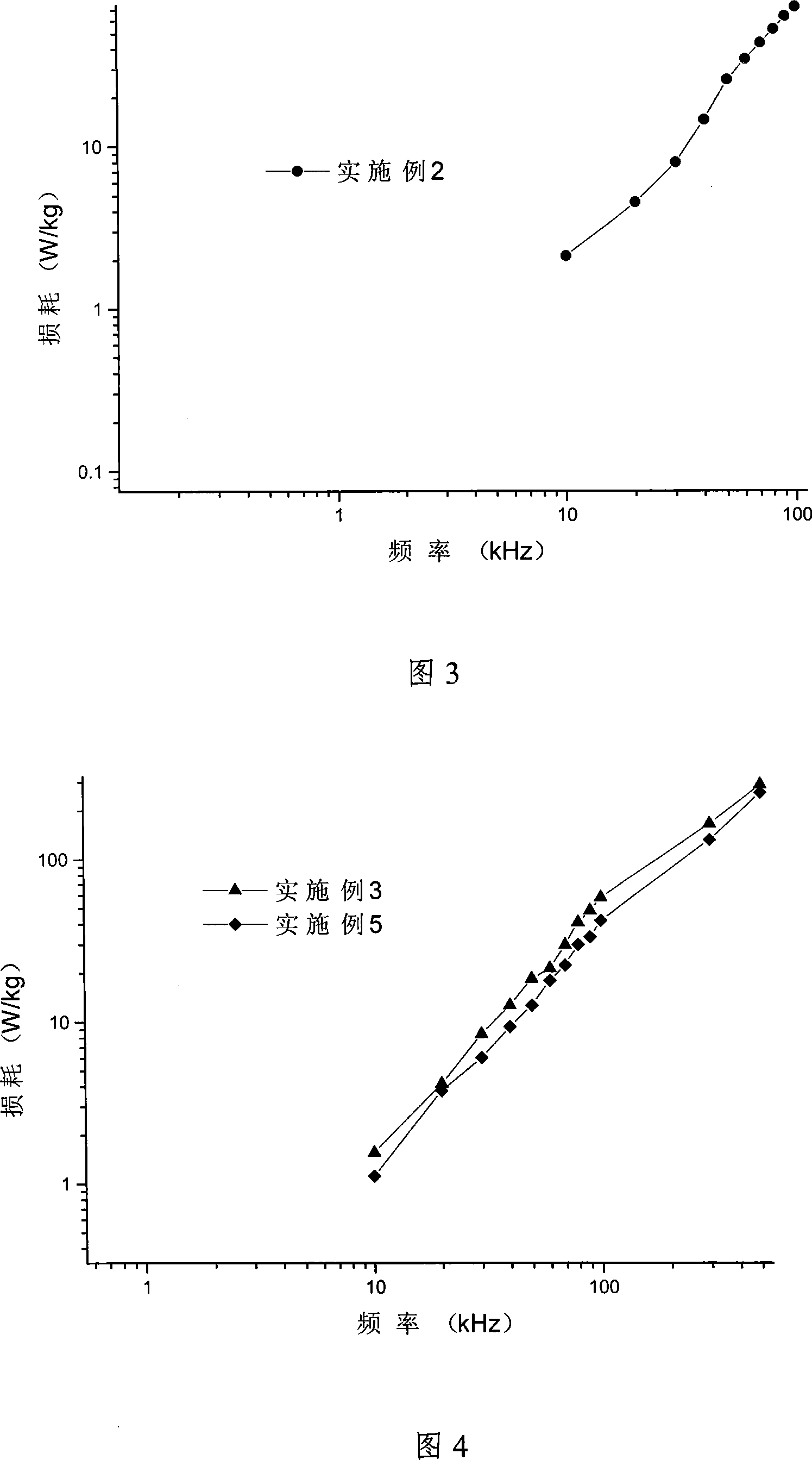

[0057] After mixing 125g of silicon carbide powder with an average particle size of 50 μm and 375 g of alumina powder with an average particle size of 200 μm, add 5 kg of deionized water and stir continuously to form a suspension. 82.5 Mo 2.5 Si 5 B 10 Dip-coat the amorphous strip in the suspension for 90s, then bake the amorphous strip at 160°C for 300s to form an insulating layer with a thickness of 7μm on both surfaces, then test its breakdown voltage, and then Wind it into a φ64-40-20mm magnetic core, keep it warm for 360 minutes under the protection of nitrogen at 380°C, and then test the loss of the magnetic core. At 20kHz, 0.2T, the loss is 24W / kg, and the breakdown voltage is 172V. This method The raw materials used are cheap, easy to operate, Fe 82.5 Mo 2.5 Si 5 B 10 Amorphous strips have lower loss after coating and higher breakdown voltage.

Embodiment 2

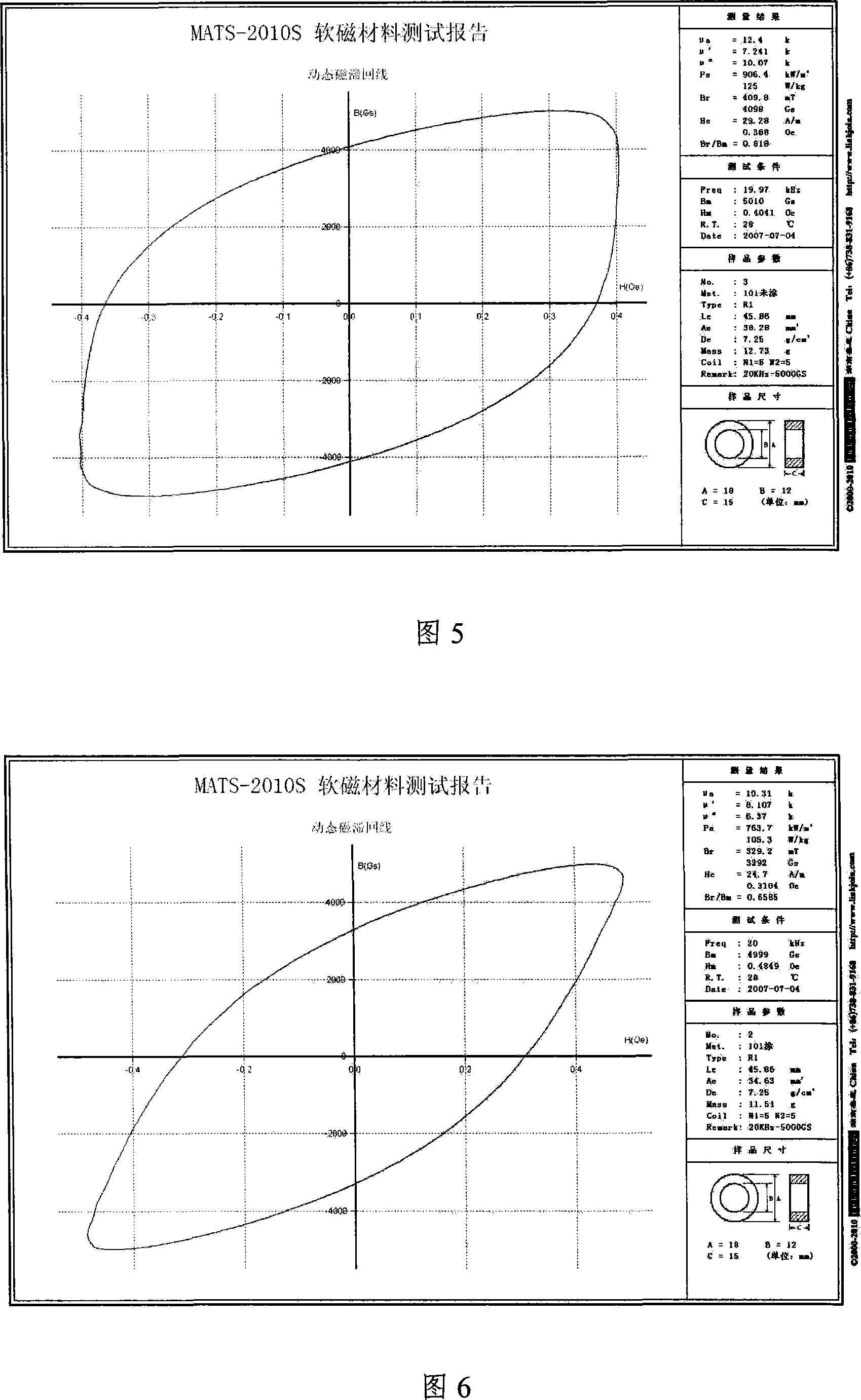

[0059]Take 35g of boron trioxide powder with an average particle size of 90μm, 45g of magnesium oxide powder with an average particle size of 150μm, and 30g of silicon dioxide powder with an average particle size of 400μm, mix them uniformly, add 4.2kg of 20% ethanol aqueous solution and keep stirring Uniformly form a suspension, the 10mm wide Fe 75 Cu 1 Mo 3 Si 15 B 6 Soak the nanocrystalline strip in the suspension for 60s, and bake the amorphous nanocrystalline strip with an insulating layer at 150°C for 1200s to form an insulating layer with a thickness of 1.5μm on each of its two surfaces; Wind it into a magnetic core of φ18-12-10mm, keep it warm for 30 minutes under the protection of argon at 580°C, and then test the loss of the magnetic core and the breakdown voltage of the strip. The loss is 30W / kg at 0.5T at 20kHz before coating. After coating, the loss is 20W / kg at 20kHz, 0.5T, 10W / kg at 20kHz, 0.2T, and the breakdown voltage is 60V. The raw materials used in th...

Embodiment 3

[0061] Take 300g tetraethyl orthosilicate, 100g polyester modified silicone resin, add to 4.6kg ethanol, stir to form an organic solution, put 10mm wide Co 78 Fe 4 Ni 2 Si 6 B 10 The amorphous strip was soaked in the organic solution for 120s, and then baked at 120°C for 600s. Take another 1.5kg of K with a modulus of 2.5 2 O SiO 2 , dissolved in 3.5kg of deionized water at 60°C, stirred evenly, and then the above-mentioned 10mm wide Co 78 Fe 4 Ni 2 Si 6 B 10 The amorphous strip is soaked in the coating solution for 70s, baked at 160°C for 300s, so that an insulating layer with a thickness of 1.5μm and 2μm is formed on the two surfaces of the strip, and it is wound into a φ18-12-10mm The magnetic core was kept at 450°C for 50 minutes under the protection of nitrogen. Then test the loss of the magnetic core and the breakdown voltage of the strip, 20kHz before coating, the loss at 0.5T is 18W / kg, 20kHz after coating, the loss at 0.5T is 16W / kg, 20kHz, the loss at 0.2T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com