Manufacturing method of soft magnet silicon-aluminum alloy magnetic powder core with small amounts of rare earth element cerium or lanthanum

A rare earth element, silicon-aluminum alloy technology, used in the manufacture of inductors/transformers/magnets, electrical components, inorganic materials, etc., can solve the problems of not being widely used, easy to produce segregation and burning loss, etc. The effect of improving the resistance coefficient and reducing the power loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] 1) A 100Kg vacuum intermediate frequency induction furnace is used for iron-silicon-aluminum alloy smelting. First, industrial pure iron is melted, and then polysilicon, pure aluminum, and cerium-iron alloy are put into the vacuum induction furnace for smelting. Electromagnetic stirring is used to smelt FeSiAl alloy ingots. , The mass percentage content of the FeSiAl alloy ingot composition is: Si9%, Al 6.0%, Ce 0.02%, C 0.015%, O 2 0.010%, S 0.008%, P 0.035%, the rest is Fe.

[0015] 2) The alloy ingot is mechanically crushed into FeSiAl alloy powder, and sieved after high temperature heat treatment in a protective atmosphere, so that the mass percentage content of the FeSiAl alloy powder particle size composition is: -100~+140 mesh for 5%, -140~+200 The mesh accounts for 15%, -200~+300 mesh accounts for 45%, and -300 mesh accounts for 35%.

[0016] 3) Perform surface passivation treatment on the powder, extract 1000g of the above FeSiAl alloy powder, then pour 5g phosphor...

Embodiment 2

[0025] The production method is the same as that of Example 1. The alloy chemical composition is Si 9.56%, Al 5.4%, Ce 0.125%, C0.012%, O 2 0.010%, S 0.025%, P 0.032%, the rest is Fe, the pressing pressure is 23T / cm 2 , The heat treatment temperature is 690℃.

[0026] The alloy resistivity is 83.8×10 -6 Ω·m.

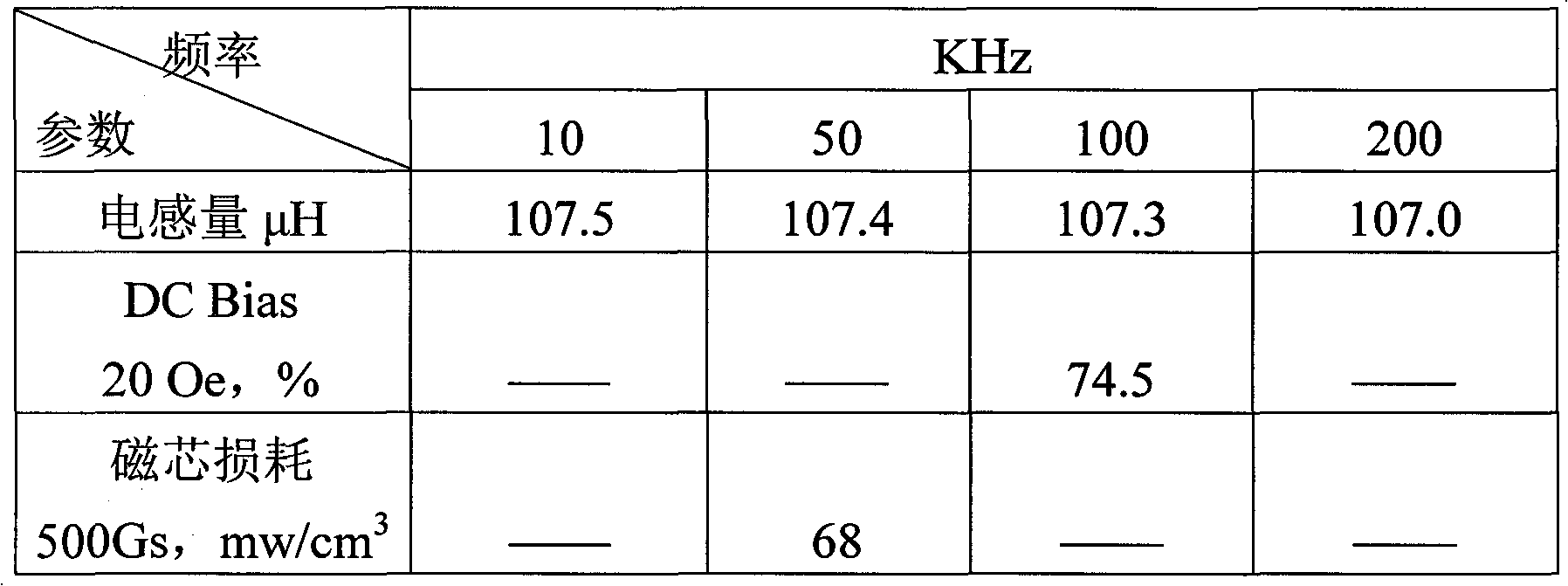

[0027] The magnetic parameters of the product of Example 2 are shown in Table 3.

[0028] Suppression ring size: outer diameter Φ16.50mm, inner diameter Φ10.15mm, height 6.35mm. Enameled wire wound inductance coil Φ0.5mm, 17 turns.

[0029] table 3

[0030]

[0031] Inductance 21.4μH corresponds to 74nH / N 2 Meets the permeability of 125.

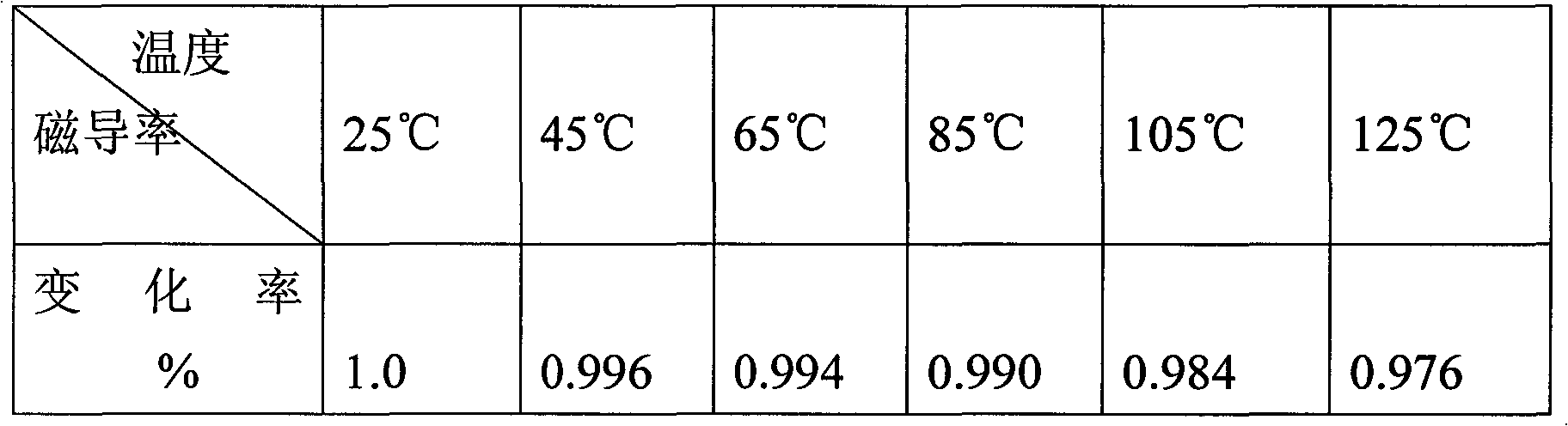

[0032] The rate of change of permeability with temperature is shown in Table 4

[0033] Table 4

[0034]

Embodiment 3

[0036] The production method is the same as that in Example 1. The chemical composition is Si 9.80%, Al 5.62%, Ce 0.250%, C 0.008%, O 2 0.008%, S 0.028%, P 0.030%, the rest is Fe, the pressing pressure is 25T / cm 2 , Heat treatment temperature 640℃

[0037] The alloy resistivity is 85.2×10 -6 Ω·m.

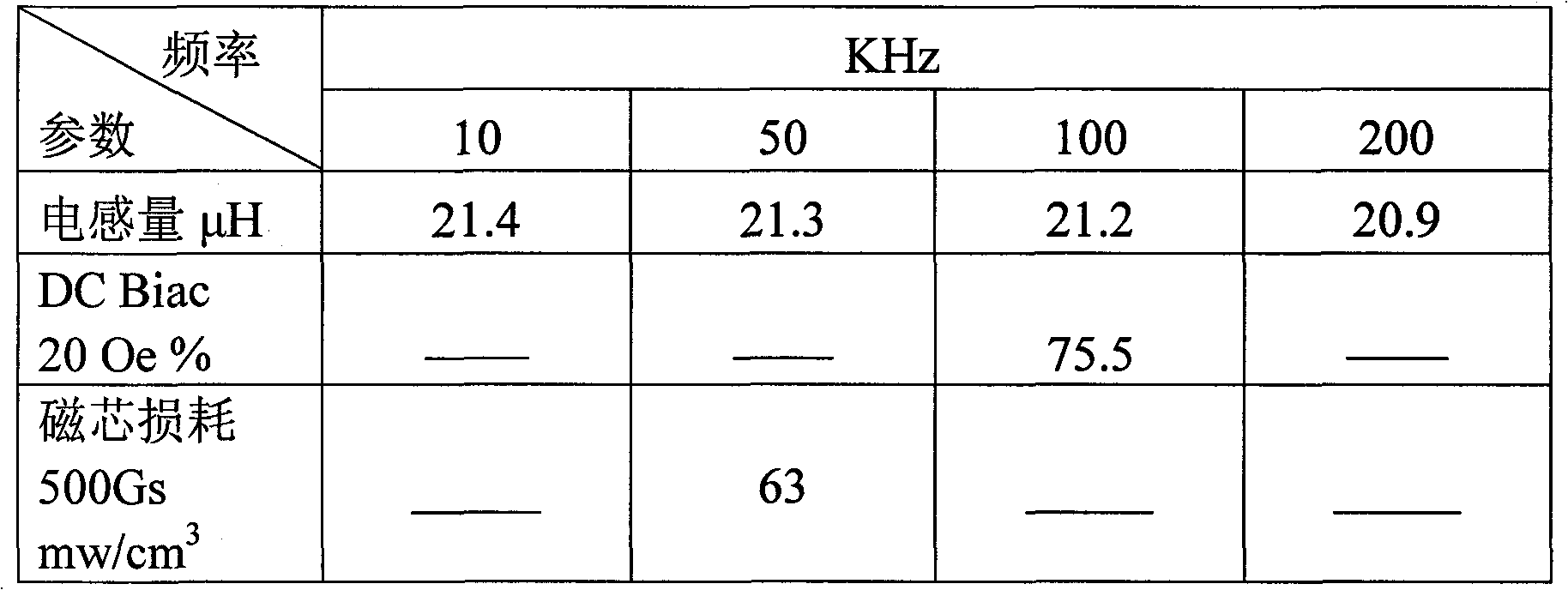

[0038] The magnetic performance parameters of magnetic powder core products are shown in Table 5

[0039] Press size: outer diameter Φ33.0mm, inner diameter Φ19.95mm, height 11.20mm. Winding enameled wire of inductance coil Φ0.5mm, 33 turns.

[0040] table 5

[0041]

[0042] Inductance 149.2μH corresponds to inductance coefficient 137nH / N 2 Corresponding to a permeability of 125.

[0043] The rate of change of permeability with temperature is shown in Table 6

[0044] Table 6

[0045]

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com