Microwave rapid sintering method for high-quality aluminum nitride ceramic substrates

An aluminum nitride ceramic and rapid sintering technology, which is applied in the sintering field of inorganic non-metallic material aluminum nitride ceramics, can solve the problem that the quality of aluminum nitride ceramic substrates cannot be guaranteed, the cost of aluminum nitride ceramic substrates is high, and it is difficult to adapt to the market. Competition and other problems, to achieve the effect of improving the sintering environment, long sintering time and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

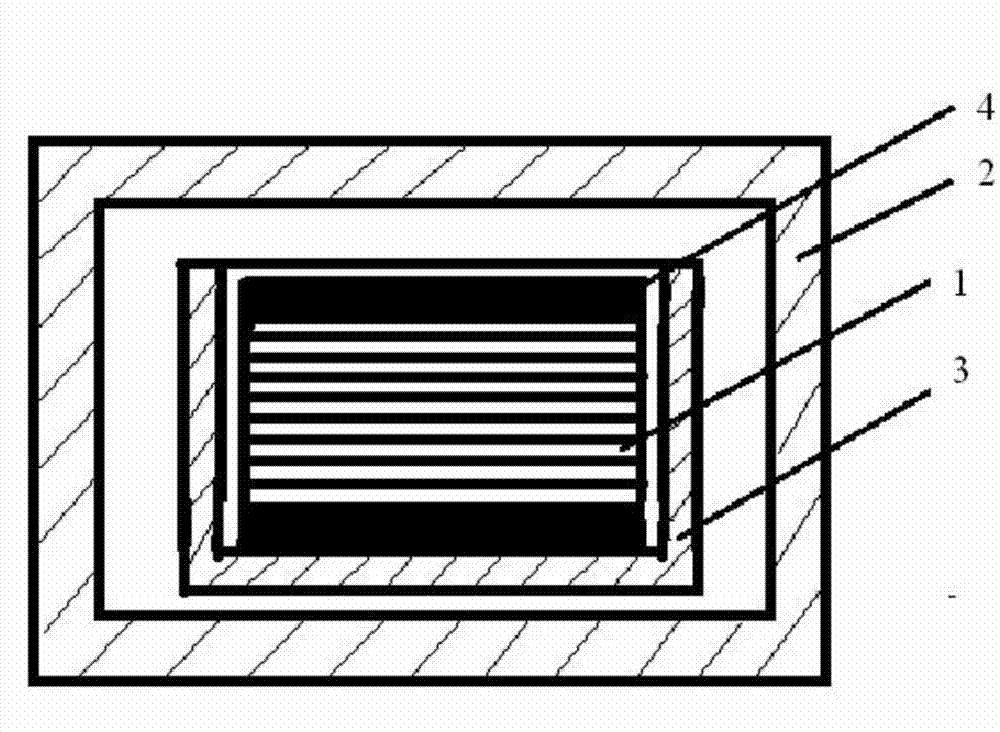

[0014] The aluminum nitride ceramic substrate green body 1 after debinding is put into the auxiliary heat preservation structure in the microwave sintering cavity, stacked neatly, and the boron nitride powder is evenly sprinkled between the sheets, and the aluminum nitride ceramic substrate The size of green body 1 is 150mm×150mm×3mm, and the microwave sintering cavity is a spherical cavity, which rotates at a constant speed of 30 rpm. The auxiliary thermal insulation structure is composed of alumina fiber board 2, boron nitride sagger 3 and high-purity graphite board 4, such as figure 1 As shown, the inner size of the boron nitride sagger 3 is 180 mm × 180 mm × 100 mm, the size of the high-purity graphite plate 4 is 150 mm × 150 mm × 8 mm, the distance between the upper and lower graphite plates is 75 mm, and the upper graphite plate is directly pressed on the nitriding plate. On the green body 1 of the aluminum ceramic substrate. The frequency of microwave sintering is 2.45...

Embodiment 2

[0016] The aluminum nitride ceramic substrate green body 1 after debinding is put into the auxiliary heat preservation structure in the microwave sintering cavity, stacked neatly, and the boron nitride powder is evenly sprinkled between the sheets, and the aluminum nitride ceramic substrate The size of the green body is Φ80mm×2mm, and the microwave sintering cavity is a cylindrical cavity, which rotates at a constant speed of 30 rpm. The auxiliary thermal insulation structure is composed of alumina fiber board 2, boron nitride sagger 3 and high-purity graphite board 4, such as figure 1 As shown, the inner size of the boron nitride sagger 3 is Φ100mm×60mm, the size of the high-purity graphite plate 4 is Φ80mm×5mm, the distance between the upper and lower graphite plates is 40mm, and the upper graphite plate is directly pressed on the aluminum nitride ceramic substrate On the green body. The frequency of microwave sintering is 2.45GHz, a nitrogen atmosphere containing 6% hydrog...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com