Method for determining gluing viscosity of water-based adhesive and application thereof

A determination method and technology for water-based adhesives, which are applied in measurement devices, flow characteristics, instruments, etc., can solve the problems of difficulty in implementation and promotion, high cost, unsuitable for viscosity judgment of water-based adhesive products, etc., and meet the requirements of low cost and equipment. Low, easy-to-use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

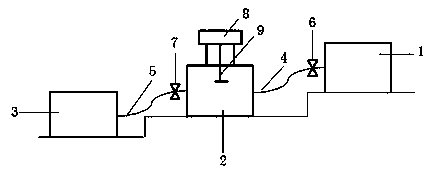

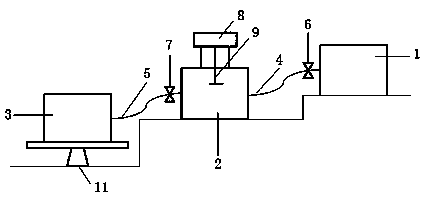

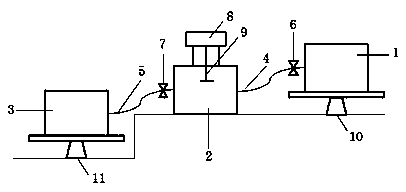

[0037] In this embodiment, a detection device is designed according to the detection method of the present invention as attached figure 1 , attached figure 2 or attached image 3 shown.

[0038] attached figure 1 Among them, 1 is the water-based glue supplement tank, 2 is the rotational viscometer method measuring tank, 3 is the water-based glue collection tank, 8 is the rotational viscometer, and 9 is the rotor;

[0039] attached figure 2 Among them, 1 is a water-based glue supplement tank, 2 is a rotational viscometer measuring tank, 3 is a water-based glue collection tank, 8 is a rotational viscometer, 9 is a rotor, and 11 is a support;

[0040] attached image 3 Among them, 1 is the water-based glue supplement tank, 2 is the rotational viscometer method measuring tank, 3 is the water-based glue collection tank, 8 is the rotational viscometer, 9 is the rotor, 10 and 11 are supports.

[0041] The measuring tank 2 of the rotational viscometer method is a cylinder with a...

Embodiment 2

[0050] The difference from Example 1 is that the test temperature of the water-based adhesive was adjusted to 27°C. Measure three times, take the minimum reading value of three times as 2025. Replace the same sample glue and repeat the operation twice according to the above steps, and the standard deviation of the three measurement results is 0.014.

Embodiment 3

[0052] The difference from Example 1 is that the flow pipeline is opened and the flow rate is adjusted to 5.7 liters / hour. Measure three times, take the minimum reading value of three times as 2177. Replace the same sample glue and repeat the operation twice according to the above steps, the standard deviation of the three measurement results is 0.017.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity value | aaaaa | aaaaa |

| Viscosity value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com