Rotational viscometer based on velocity attenuation

A technology of rotational viscosity and viscometer, which is applied in flow characteristics, measuring devices, instruments, etc. It can solve the problems of large measuring range and achieve the effects of long life, small starting current and small vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention can be understood more clearly through the specific examples of the present invention given below, but the present invention is not limited thereto.

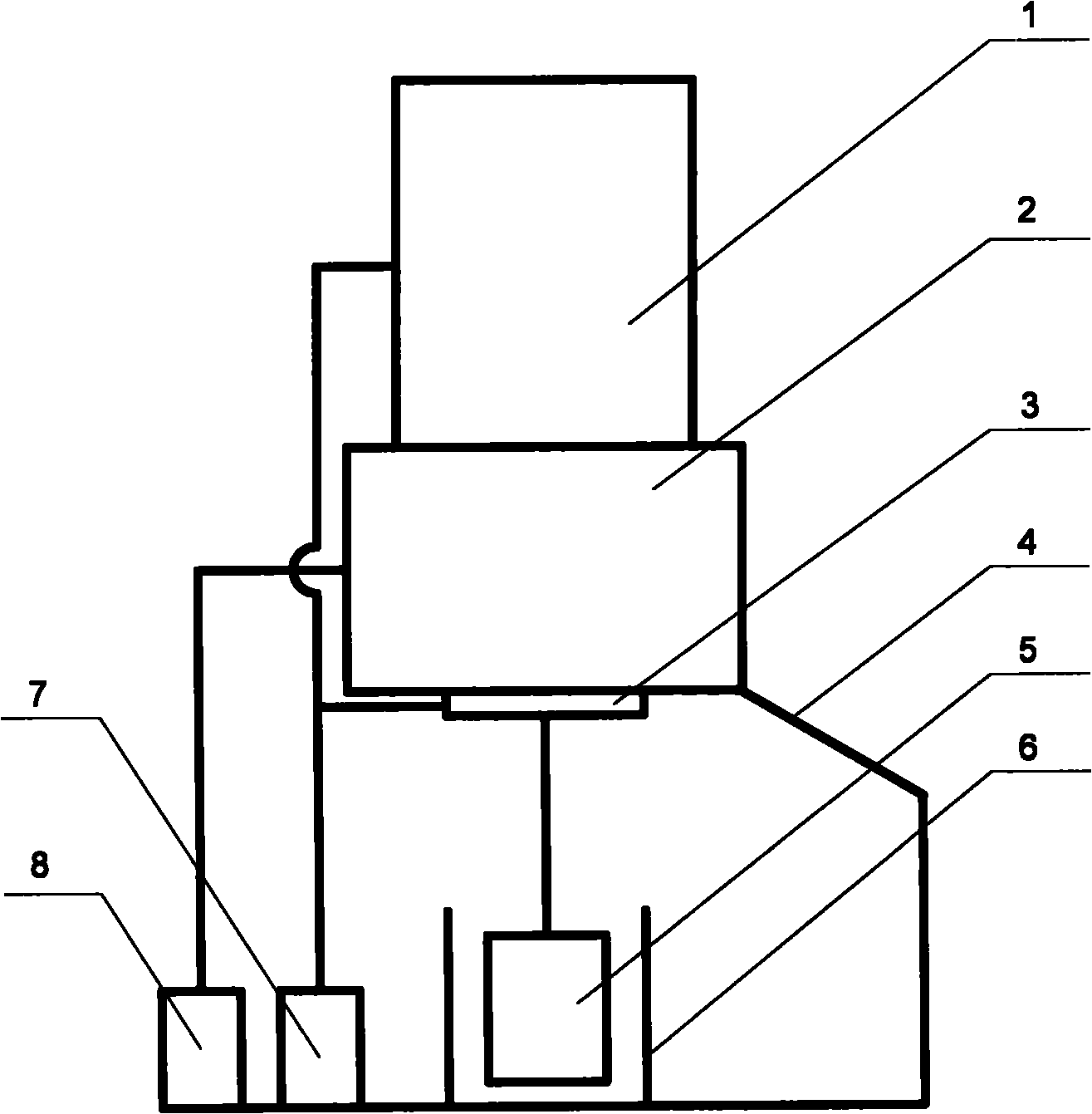

[0030] The rotational viscometer based on velocity decay, its shape is as follows figure 1 As shown, it consists of a cascaded motor 1, an air bearing 2, a speed sensor 3, a bracket 4, a probe rotor 5, an outer cylinder 6, a calculation and display unit 7, and an air source 8.

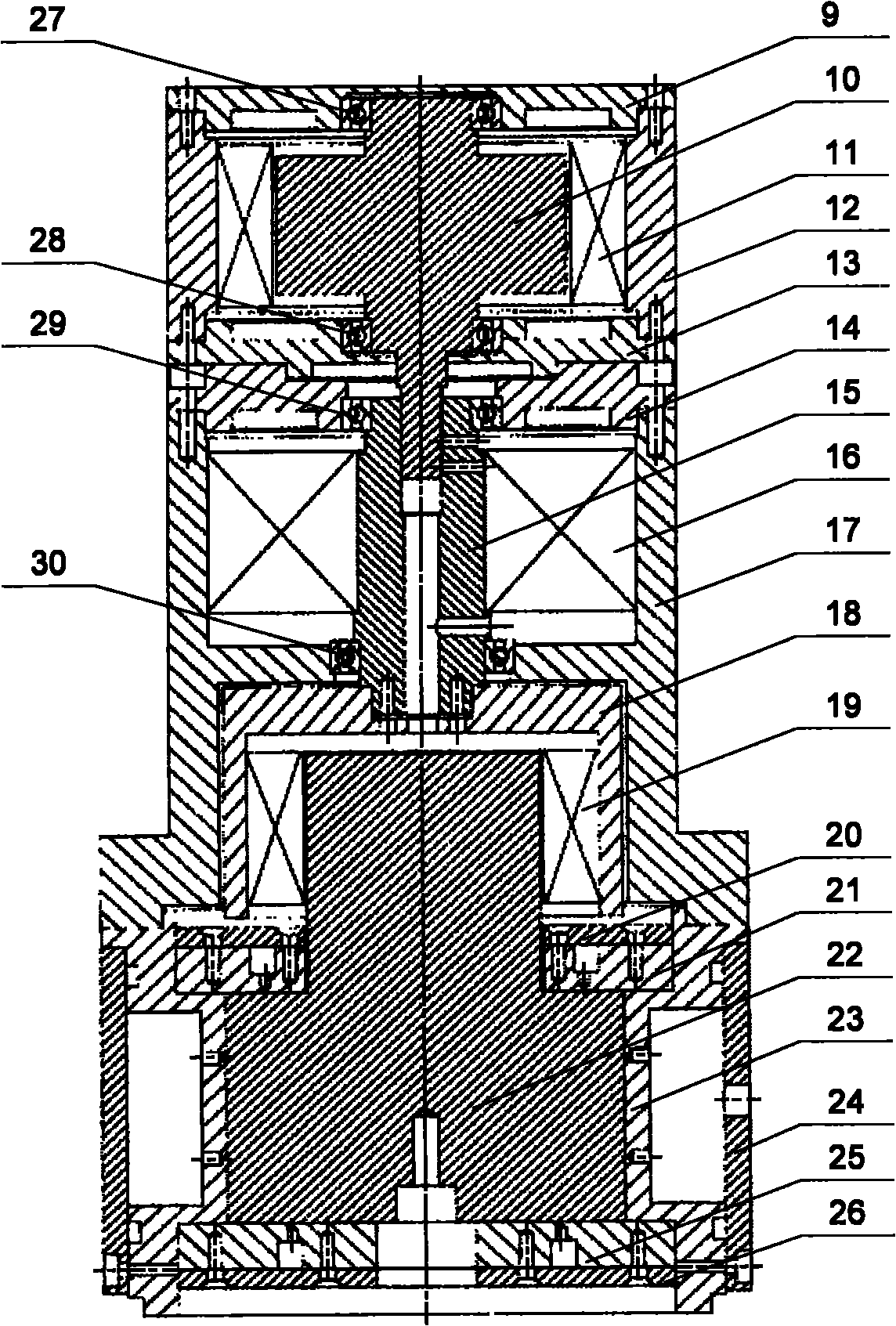

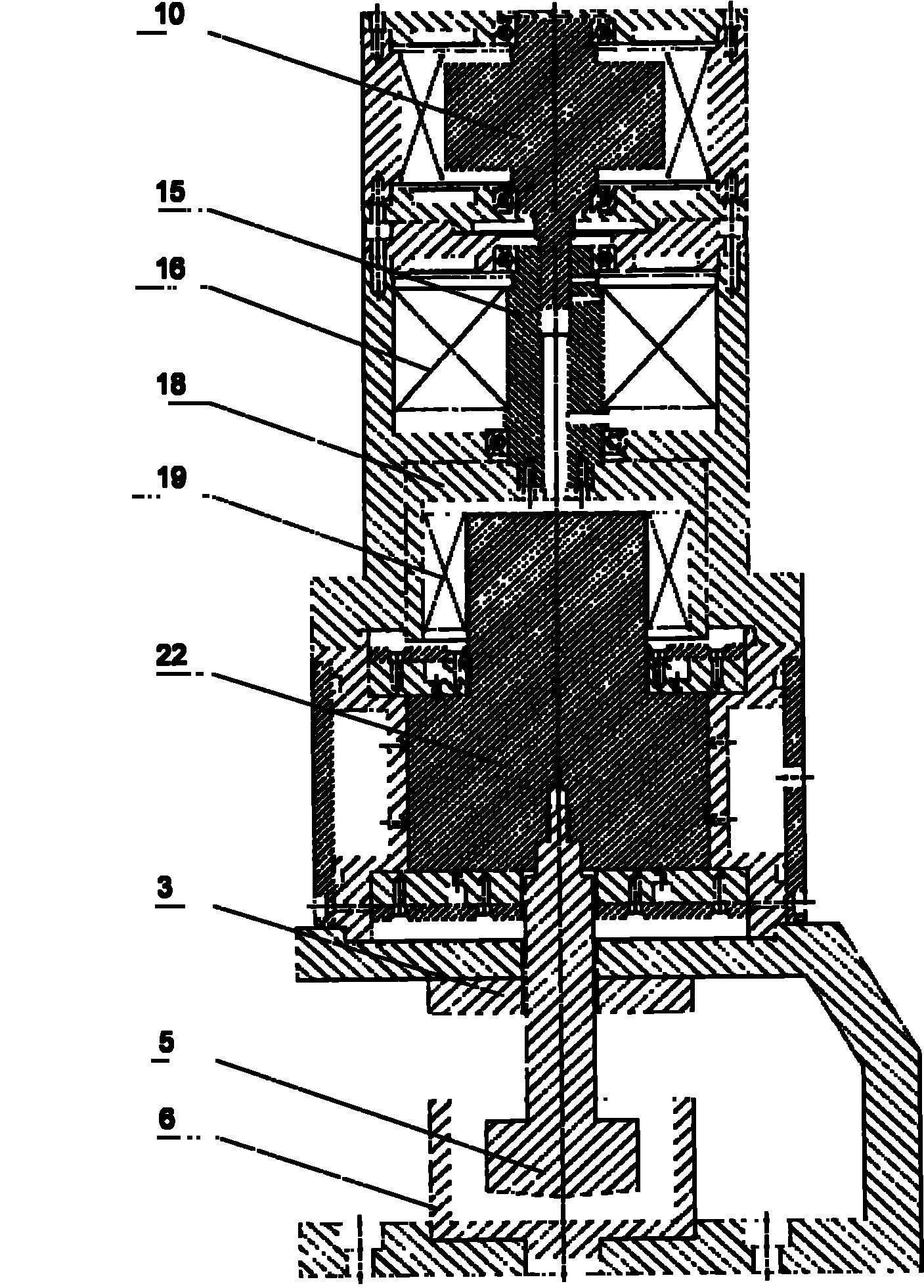

[0031] The cascaded motor 1 is composed of two motors in series, wherein the first motor is a synchronous motor with adjustable speed, the second motor is an adjustable speed slotless cylindrical solid rotor asynchronous motor, and the rotor of the second motor is the torque output shaft And supported by the air bearing 2 connected in series, the output torque is used to drive the probe rotor 5 to rotate in the fluid. The measuring probe rotor 5 is likewise supported by the air bearing 2 . The bracket 4 mainly plays a suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com