Underground gas cut intelligent control system

An intelligent control system and gas intrusion technology, applied in the field of downhole gas intrusion intelligent control system, can solve problems such as delayed well kill operations, catastrophic accidents, inaccurate gas intrusion, etc. simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

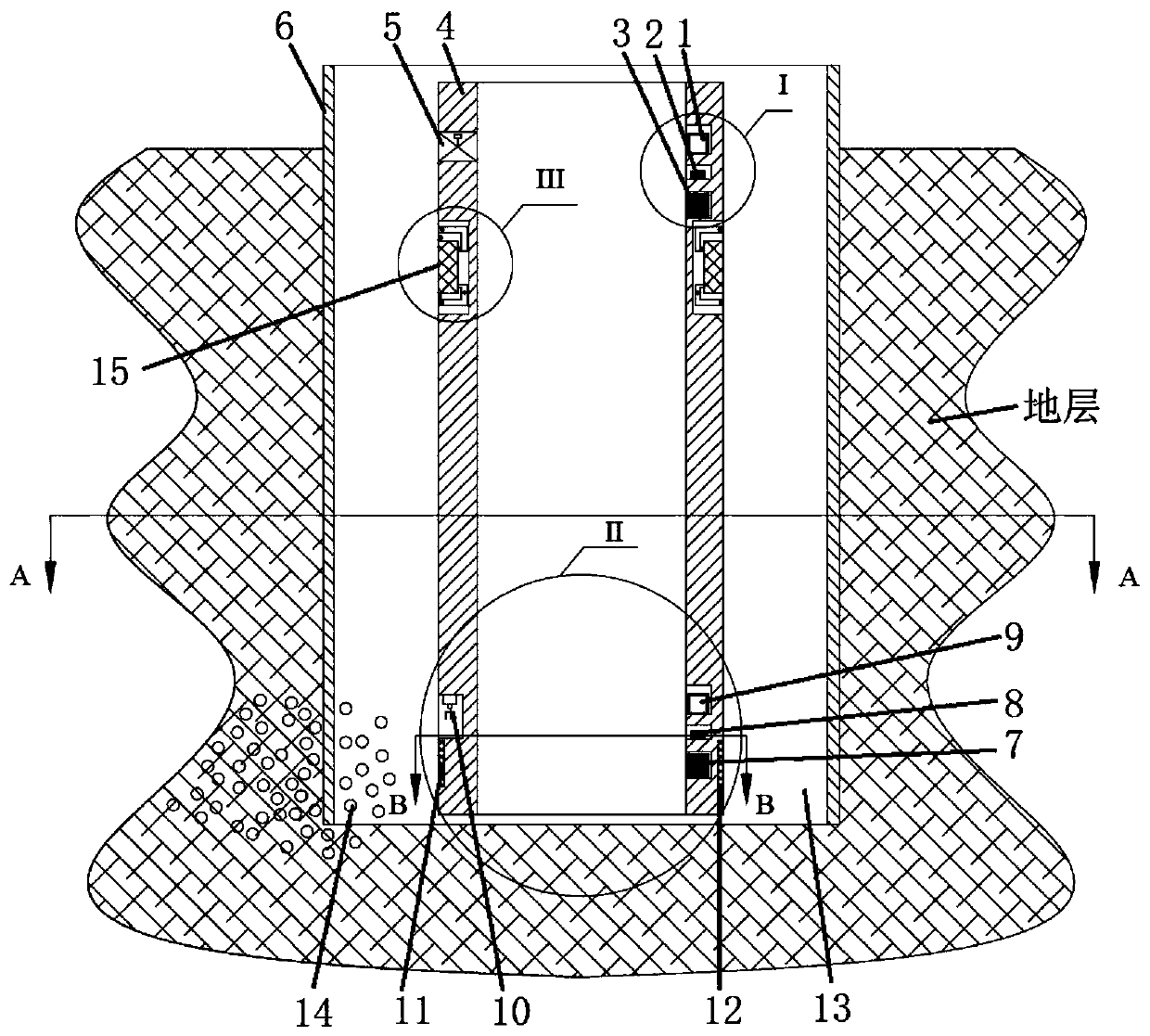

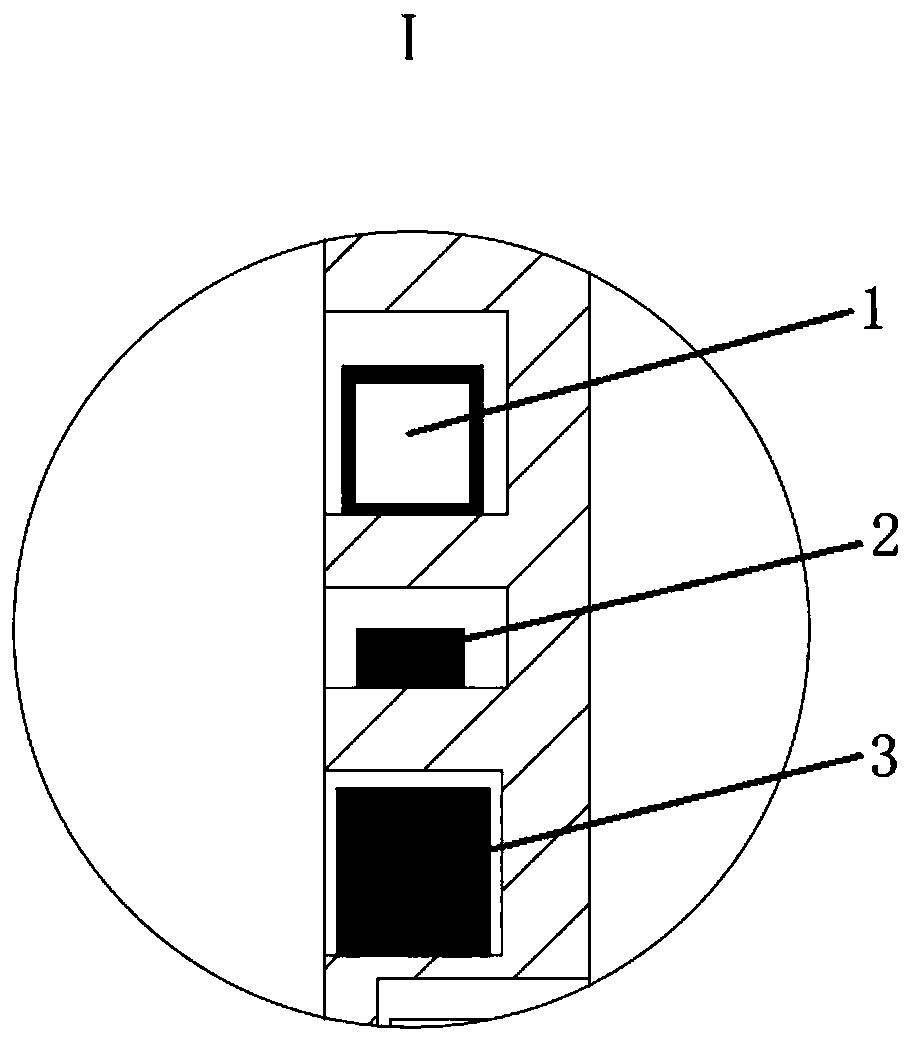

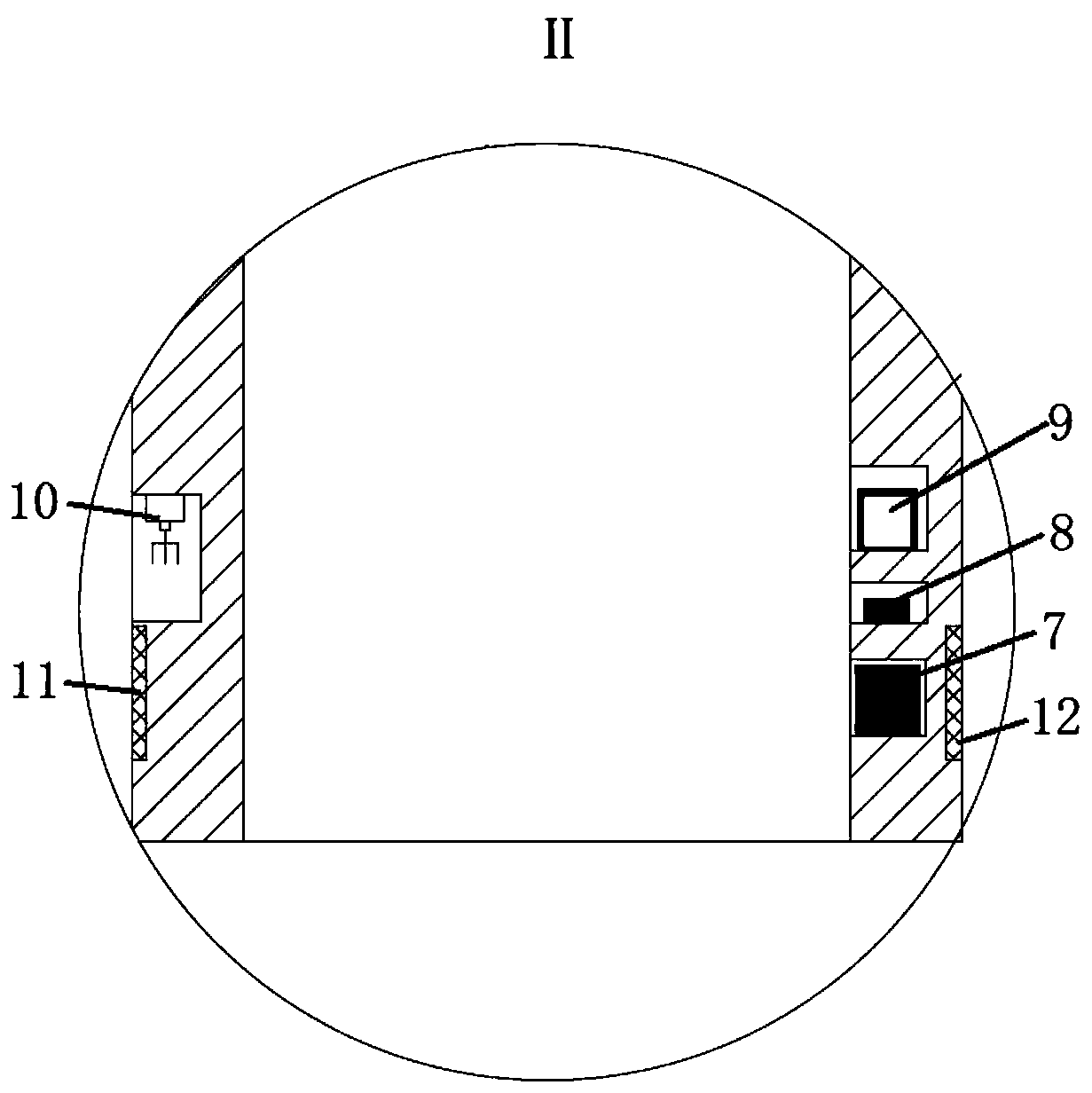

[0030] Combine below figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 with Image 6 Explaining this embodiment, the present invention relates to the field of downhole gas intrusion monitoring and control engineering, more specifically it is a downhole gas intrusion intelligent control system, including a control assembly microcomputer 1, a control assembly battery 2, a signal receiver 3, and a drilling well Bottom string 4, bypass solenoid valve 5, well wall (casing) 6, signal transmitter 7, monitoring assembly battery 8, monitoring assembly microcomputer 9, rotational viscometer 10, positive electrode for measuring resistivity 11, measuring Resistivity negative electrode 12, packer 15, check valve A 151, upper inner flow passage 152, solenoid valve A 153, lower inner flow passage 154, check valve B 155, solenoid valve B 156, pressure sensor A 157, Airbag 158 and pressure sensor B 159; control assembly microcomputer 1, control assembly battery 2, signal receiver 3, bypass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com