Soft capsule shell and soft capsule

A technology of soft capsules and capsule shells, which is applied in the directions of capsule transportation, food forming, medical preparations with inactive ingredients, etc., can solve problems such as poor formability, easy pre-gelling, rough and uneven rubber skin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

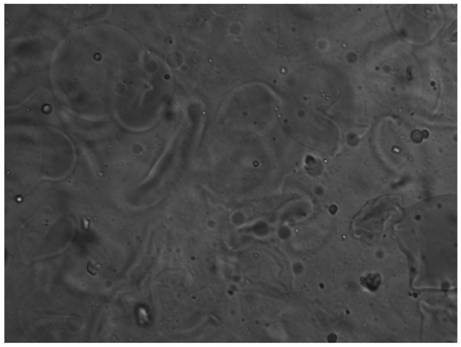

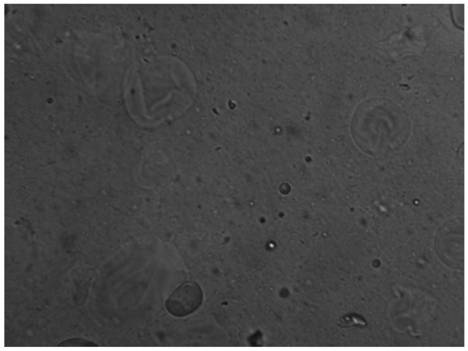

Image

Examples

Embodiment 1-8

[0078] Soft capsules were prepared with ingredients and contents as described in Table 2, and tested and scored. The measurement results are shown in Table 2.

[0079] According to Table 2, it can be known that Examples 1-8 use specific viscosity gellan gum and starch in combination, and the formed rubber has better strength, toughness and molding adhesion, while Comparative Examples 1-2 use the same combination of the film-forming composition of the present invention. content, when comparative example 1 adopts gellan gum with higher viscosity and starch combination, the rubber skin strength formed is weaker, has certain toughness, but molding bonding is general; comparative example 2 adopts gellan gum and starch with lower viscosity When combined, the rubber is basically viscous and has poor toughness, so it cannot be pressed and molded into soft capsules.

Embodiment 9-23

[0081] Soft capsules were prepared with ingredients and contents described in Table 3 and Table 4, and tested and scored. The measurement results are shown in Table 3 and Table 4. The soft capsules prepared in Example 9, Example 10 and the above-mentioned Example 4 can all achieve the enteric-coating effect. Compared with Example 9, due to the addition of granular starch, the comprehensive evaluation of the soft capsules made in Example 10 and the above-mentioned Example 4 becomes better, but when the granular starch is increased to 3%, the soft capsules made in the stomach All disintegrated. Therefore, the addition of less than 2% (such as 1.7%) of cross-linked starch, such as hydroxypropyl distarch phosphate, has achieved unexpected effects on the comprehensive evaluation and enteric solubility of soft capsules.

[0082]

[0083]

[0084]

[0085]

[0086]

[0087] Examples 9-23 illustrate that gellan gum of specific viscosity is combined with various types ...

Embodiment 24-31

[0090] The ingredients and contents described in Table 5 were prepared into soft capsules, and tested and scored. The measurement results are shown in Table 5.

[0091]

[0092]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com