SBS modified asphalt construction temperature determination method

A technology for temperature measurement and modification of asphalt, applied in thermometers, thermometers based on physical/chemical changes, flow characteristics, etc. The effect of reducing the construction temperature of the asphalt, the simple and reliable operation method, and the effect of good engineering practice

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

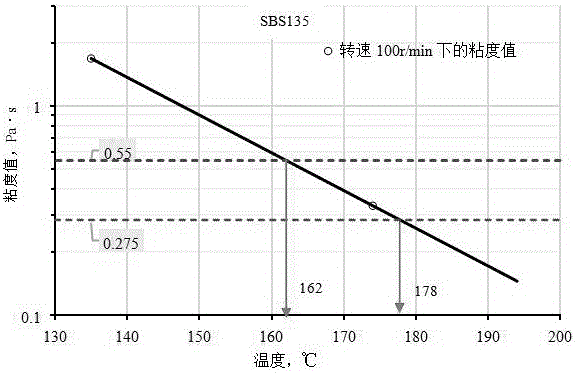

[0026] Example 1 (1-D grade SBS135 modified asphalt is selected as the asphalt binder)

[0027] Determination steps:

[0028] A. According to the T0601 and T0602 standard methods in JTG E20-2011 "Test Regulations for Asphalt and Asphalt Mixtures in Highway Engineering", the 1-D grade SBS modified asphalt was sampled and the asphalt sample was prepared.

[0029] B. According to T0625 "asphalt rotational viscosity test" in JTG E20-2011 "Test Regulations for Asphalt and Asphalt Mixtures in Highway Engineering", the sample is prepared in the viscosity sample bottle. Then, using a rotational viscometer, using a No. 27 rotor, at a speed of 100 RPM, the viscosity values of the modified asphalt at 135°C and 174°C were collected. The obtained viscosity values are shown in Table 1.

[0030] Table 1 Temperature and corresponding viscosity values of asphalt samples

[0031]

[0032] C. Take the temperature as the abscissa, and the logarithm of the viscosity as the ordinate, dr...

Embodiment 2

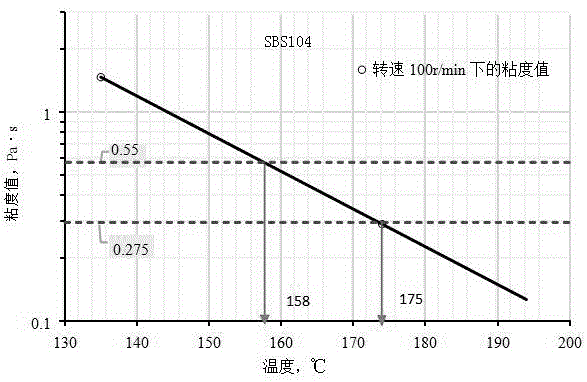

[0035] Embodiment 2 (the SBS104 modified asphalt viscosity that asphalt binder selects is slightly lower)

[0036] Measuring procedure is identical with embodiment one, utilizes the viscosity data that rotational viscometer detects to obtain as shown in table 2, and viscosity-temperature curve and construction temperature are determined as follows figure 2 shown.

[0037] Table 2 Temperature and corresponding viscosity value of asphalt samples

[0038]

[0039] From figure 2 It can be seen from the figure that the construction temperature of sample 2 modified asphalt is: the mixing temperature is 174°C, and the compaction temperature is 158°C.

Embodiment 3

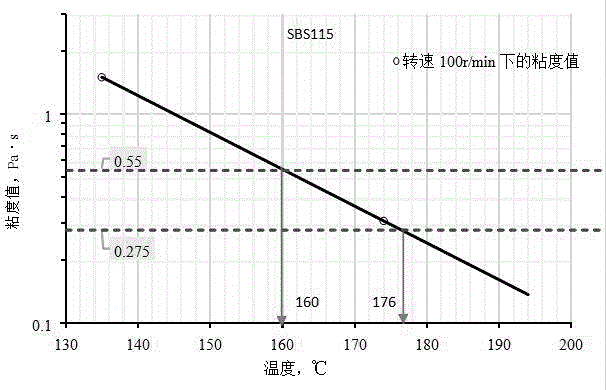

[0040] Embodiment 3 (asphalt binder selects 1-D grade SBS115 modified asphalt)

[0041] The measurement procedure is the same as that of Example 1, and the viscosity data obtained by utilizing the rotational viscometer to detect is as shown in Table 3, and the viscosity-temperature curve and construction temperature are determined as follows: image 3 shown.

[0042] Table 3 Temperature and corresponding viscosity values of asphalt samples

[0043]

[0044] From image 3 It can be seen from the figure that the construction temperature of sample 3 modified asphalt is: the mixing temperature is 176°C, and the compaction temperature is 160°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com