Patents

Literature

40results about How to "The operation method is simple and reliable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

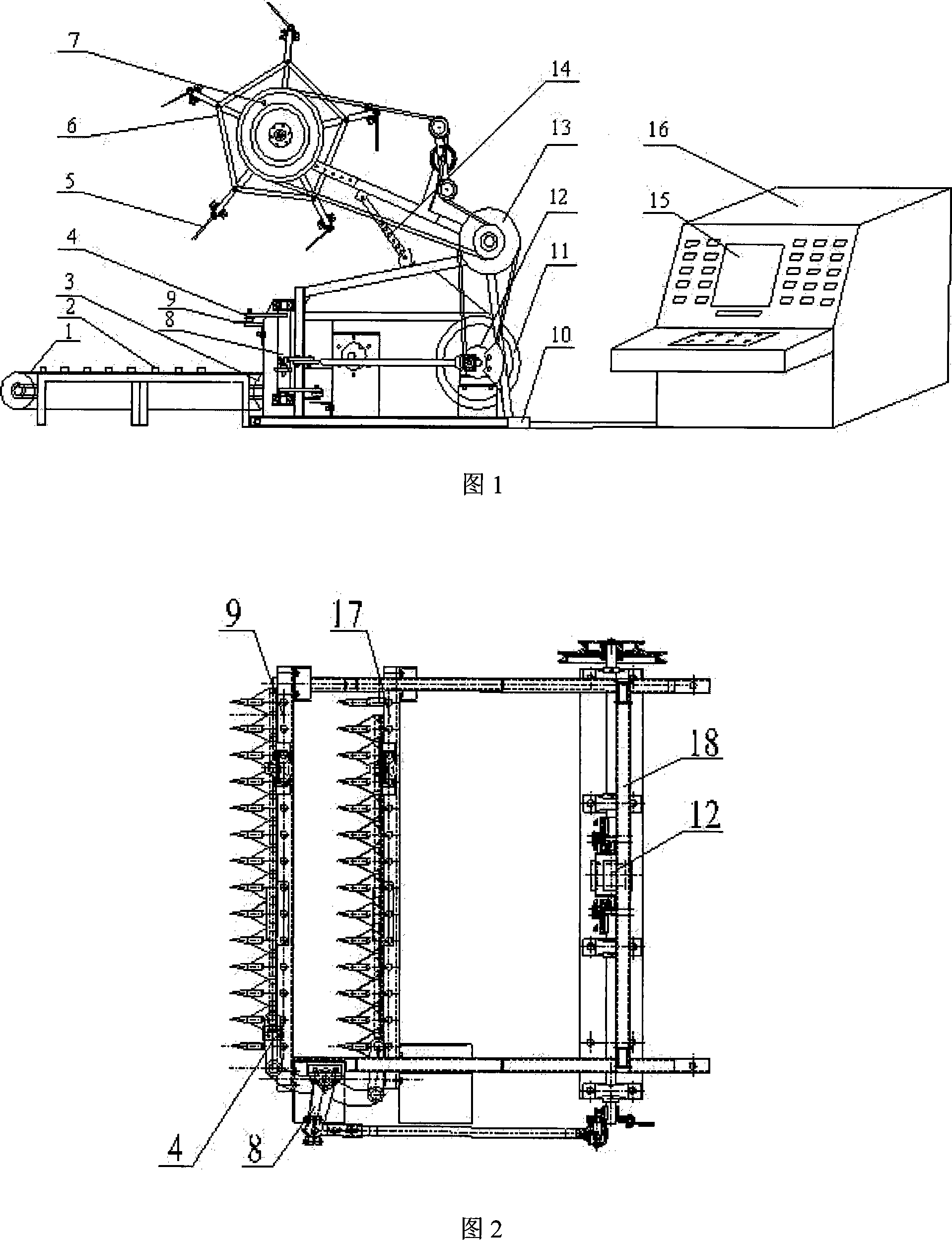

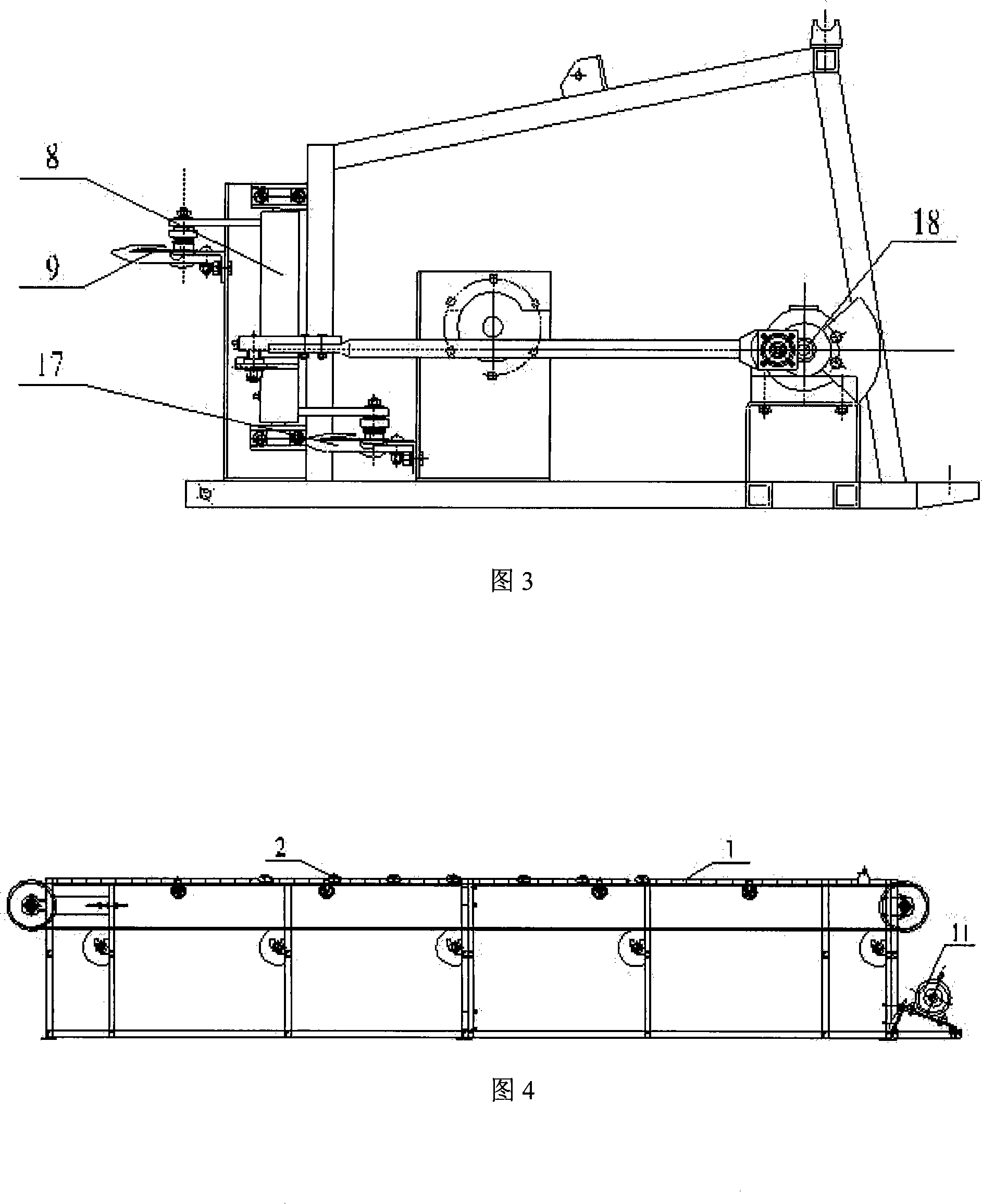

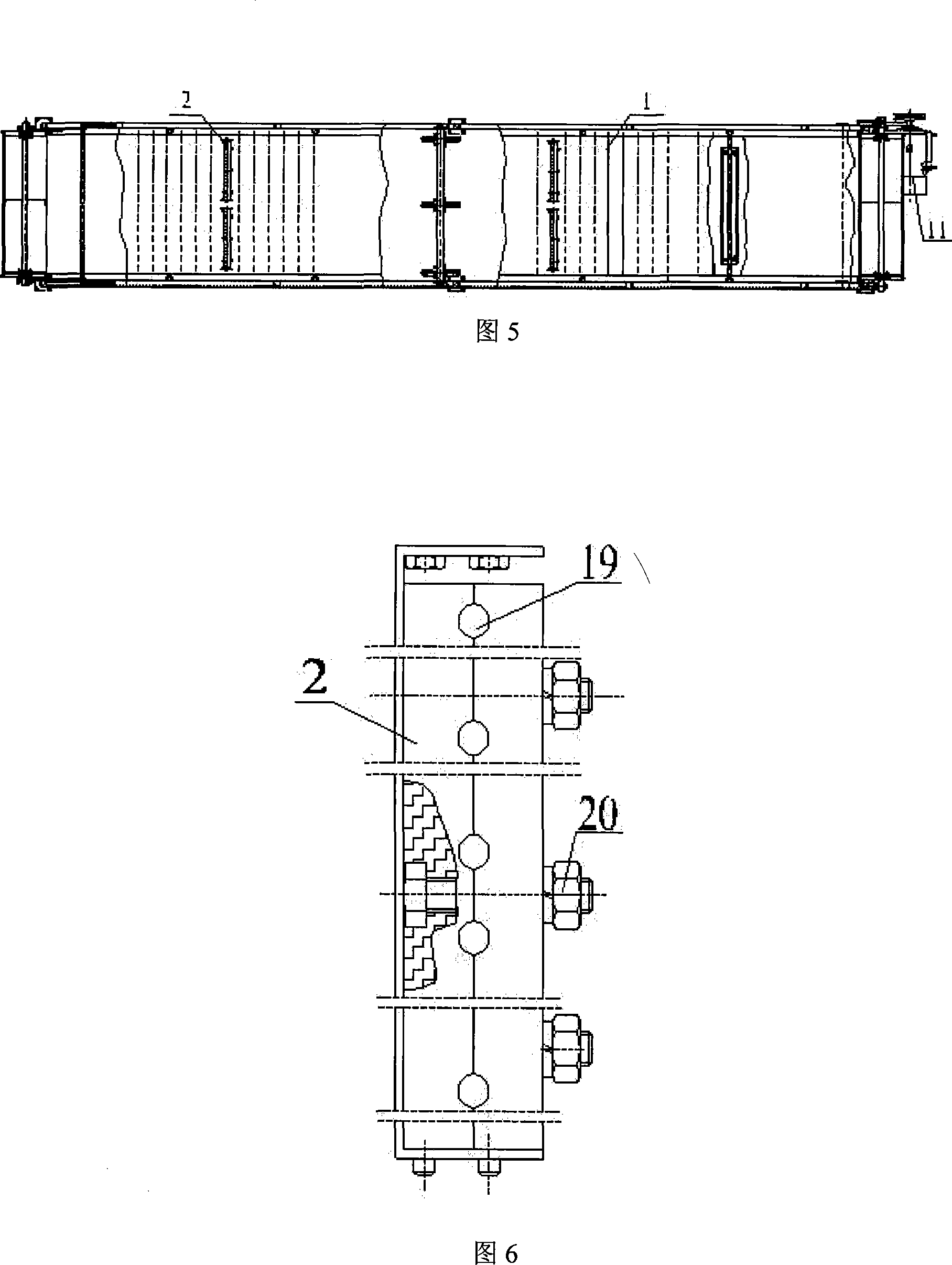

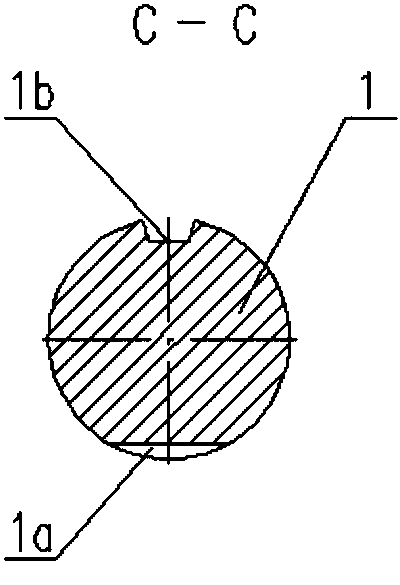

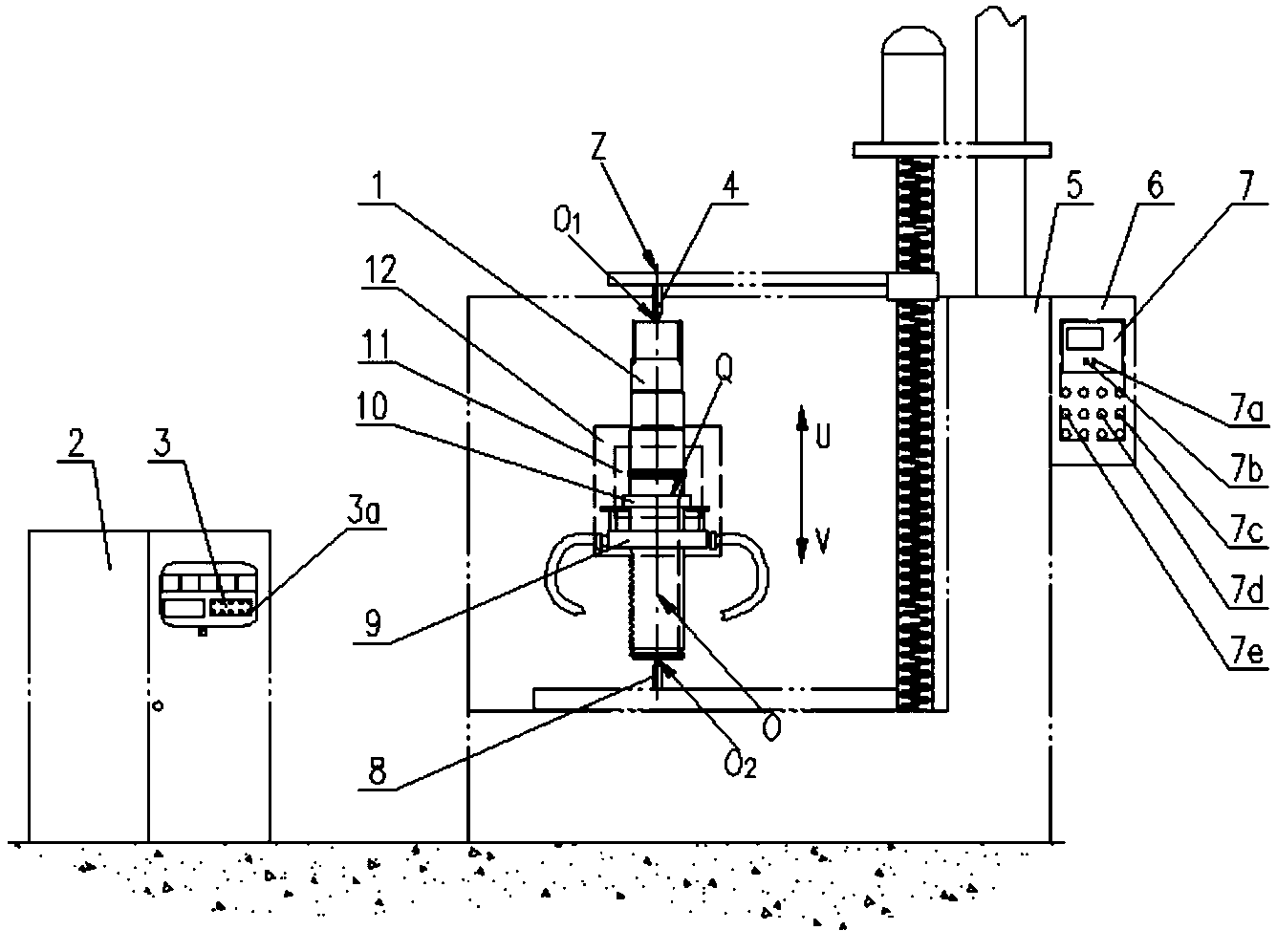

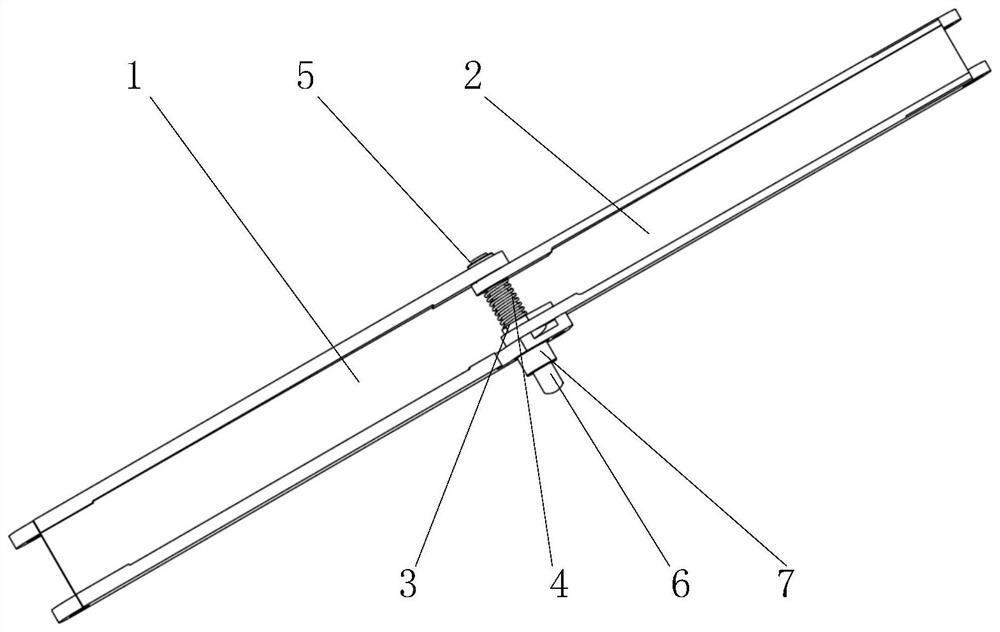

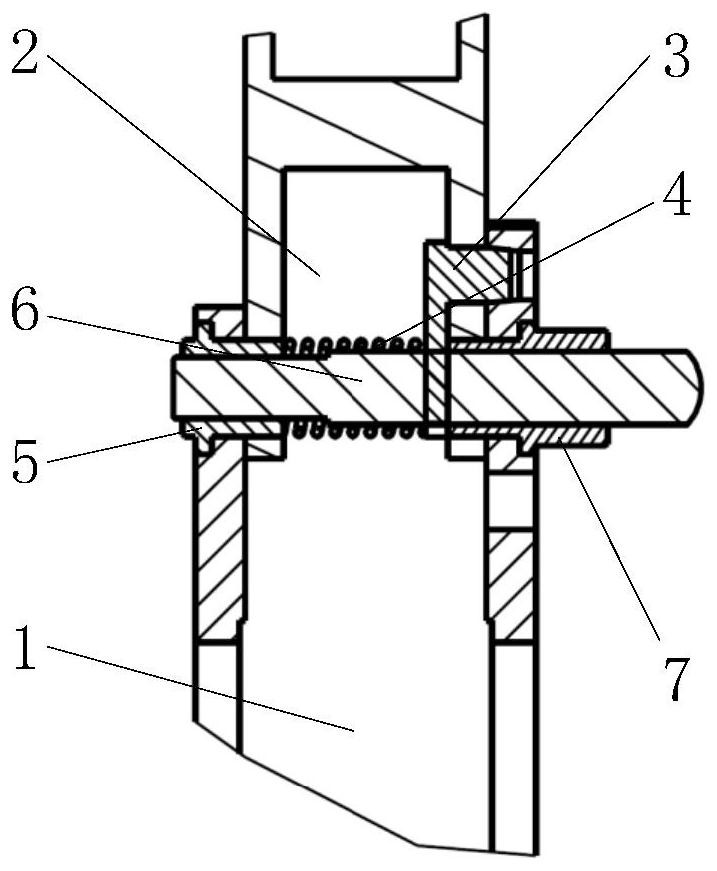

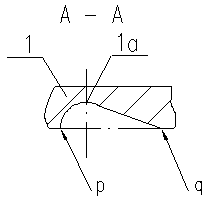

Stalk cutting test device and method

InactiveCN101216379AThe device is simple and reasonableThe operation method is simple and reliableCuttersStructural/machines measurementTorque sensorEngineering

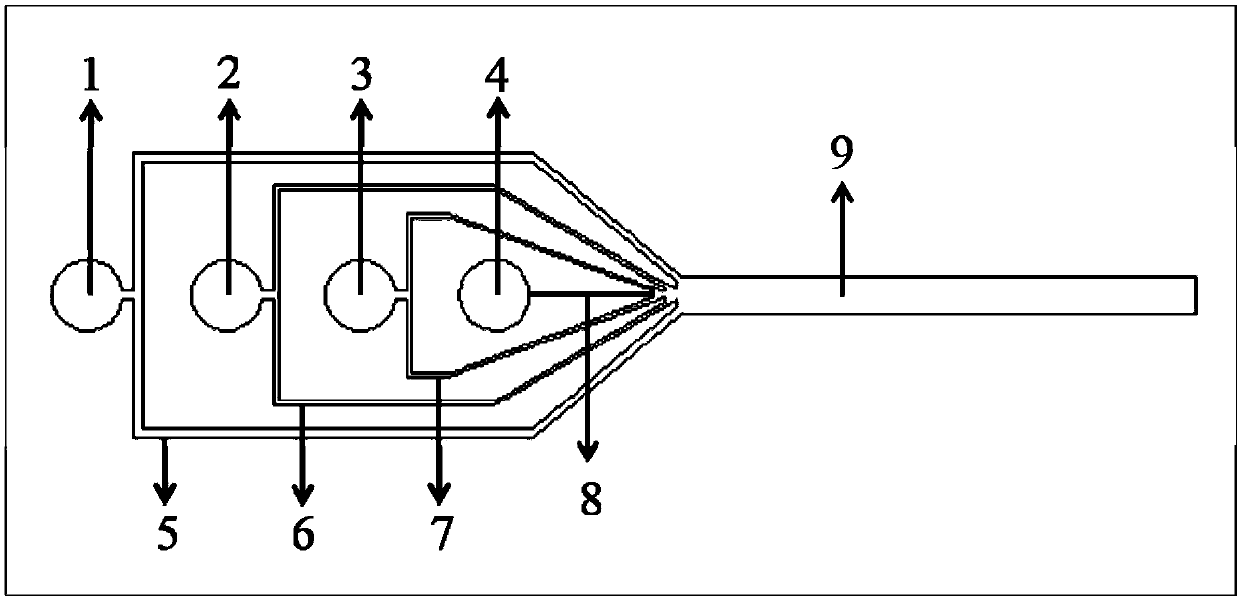

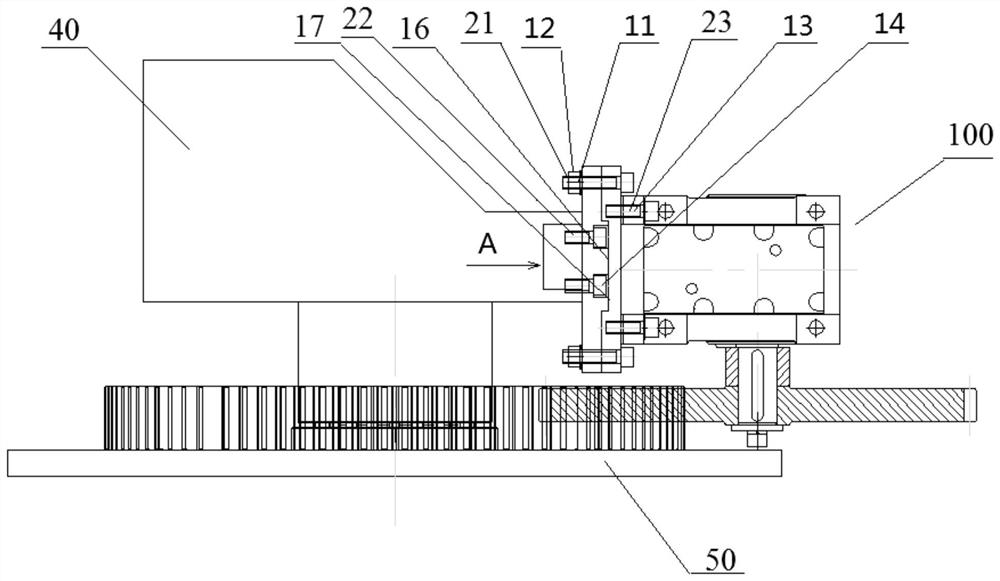

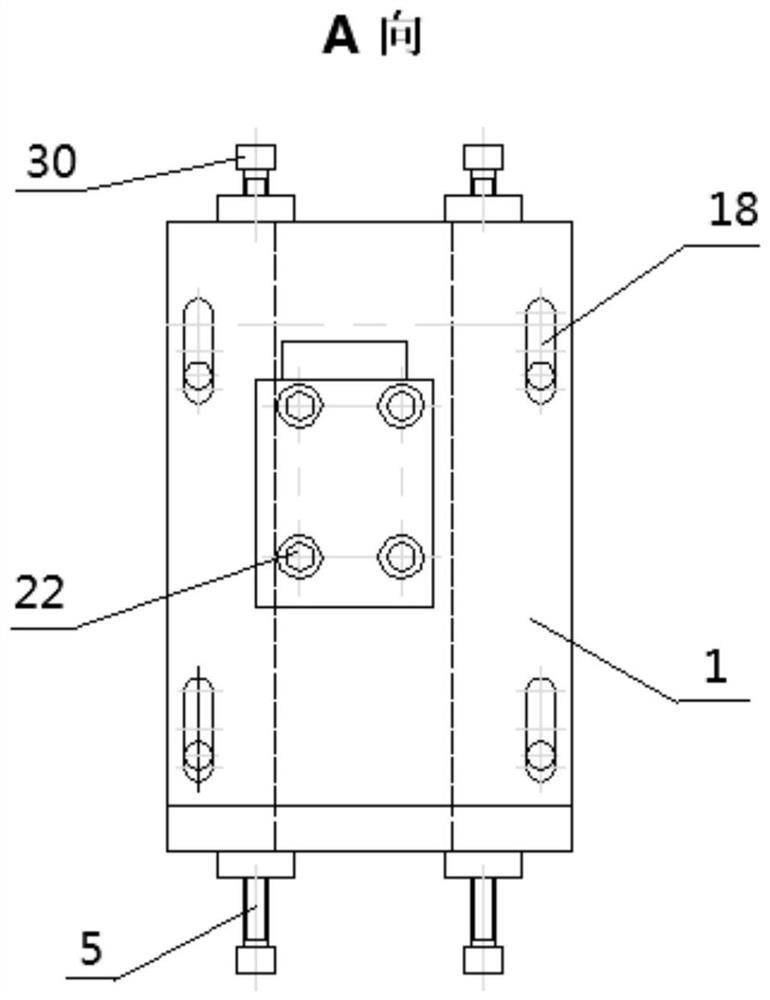

The invention discloses a test device for simulating indoor cutting of crop stalk and a test method thereof. The device comprises a stalk clamping device arranged on a conveying device, a grain pulling device on the stalk clamping device, a cutting device connected with a blade driving mechanism and arranged on one side of the stalk clamping device, a rotation speed sensor arranged on the drum shaft end of a conveying belt, a torque sensor arranged on a power input shaft, a pressure sensor arranged at the joint of the blade of the cutting device and a rocker connection rod. The cutting test can be conducted by collecting, recording and displaying data collected by the rotation speed sensor, the pressure sensor and the torque sensor by a test control system of a computer. The device has simple and reasonable structure and stable and reliable operation method, thus radically solving problems of the prior stalk cutting test such as parameter adjustment and realtime sampling and processing of test data.

Owner:JIANGSU UNIV

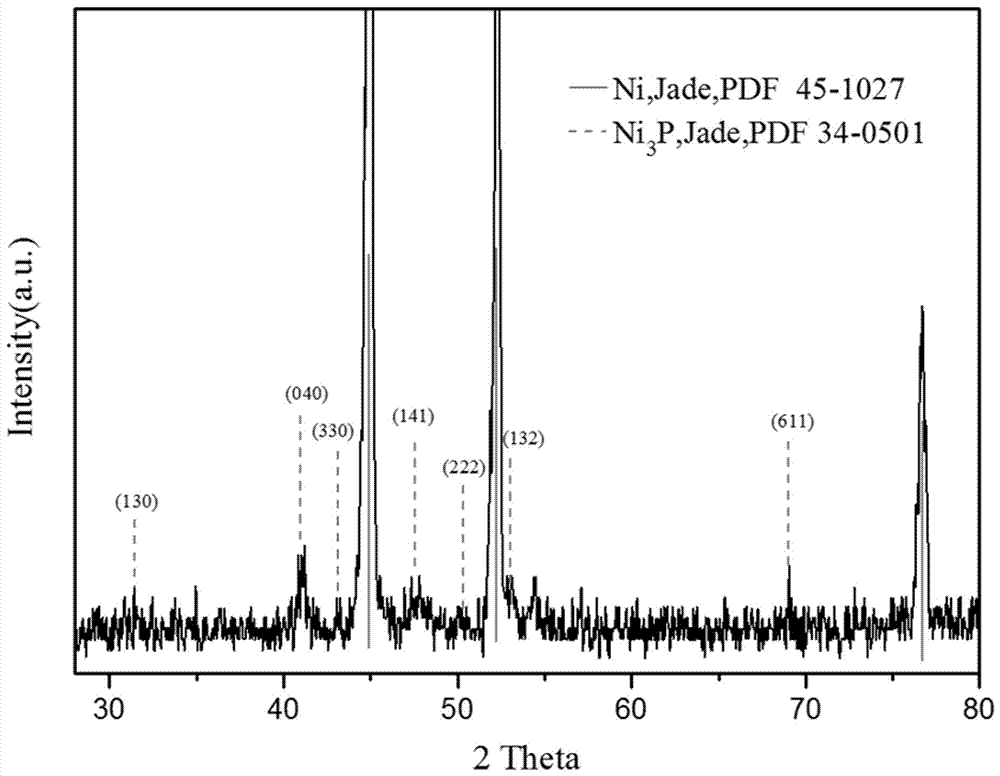

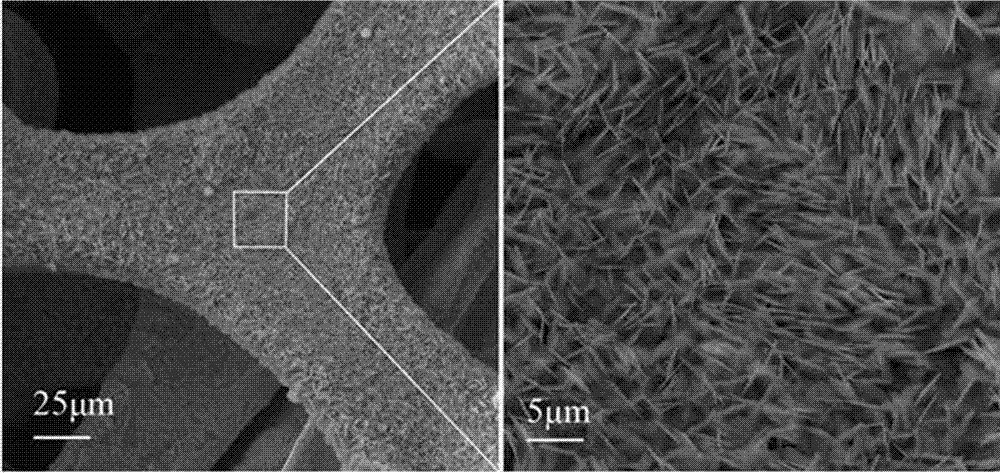

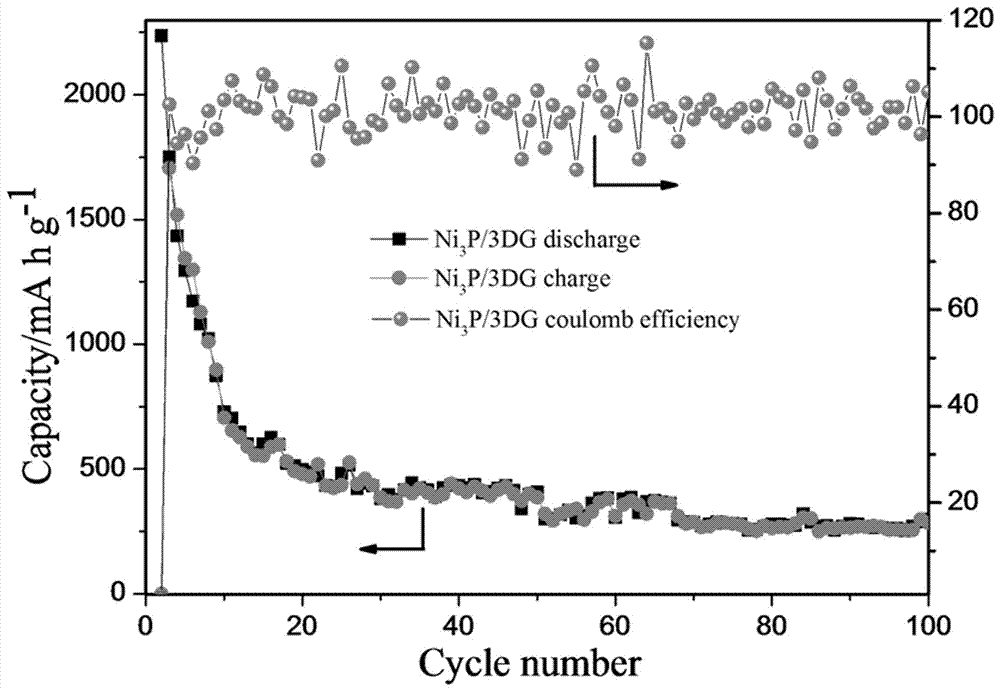

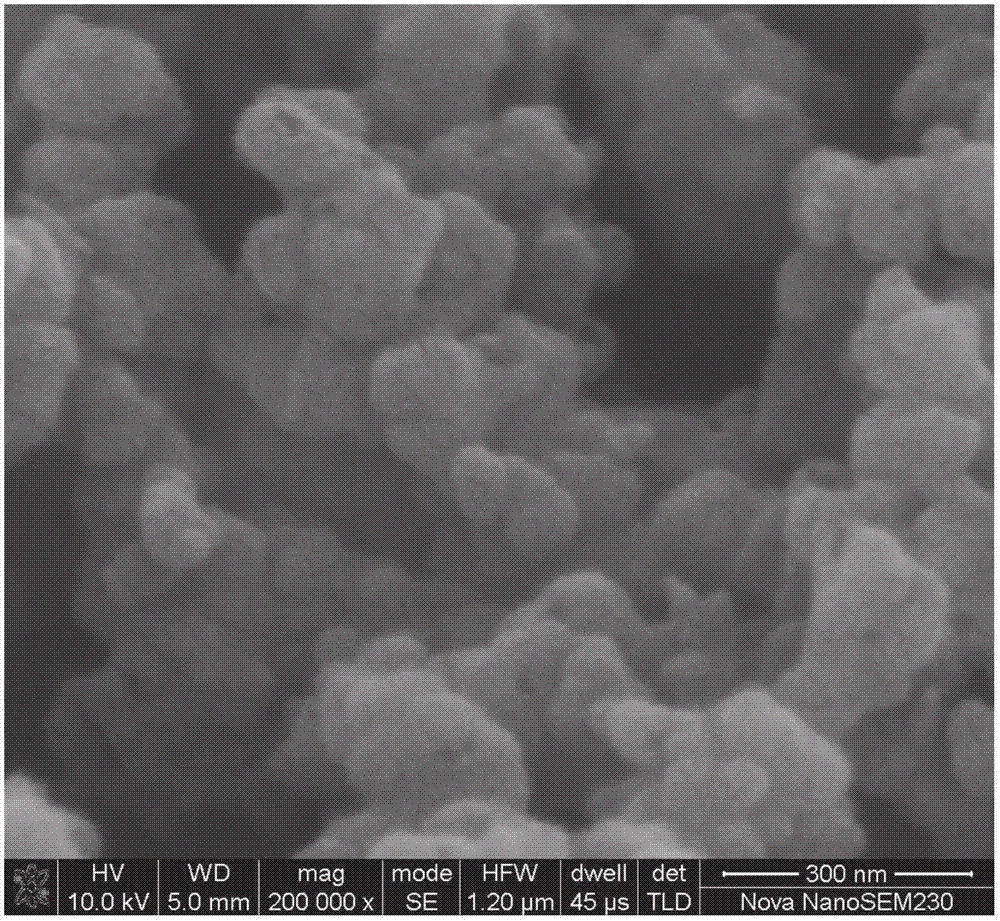

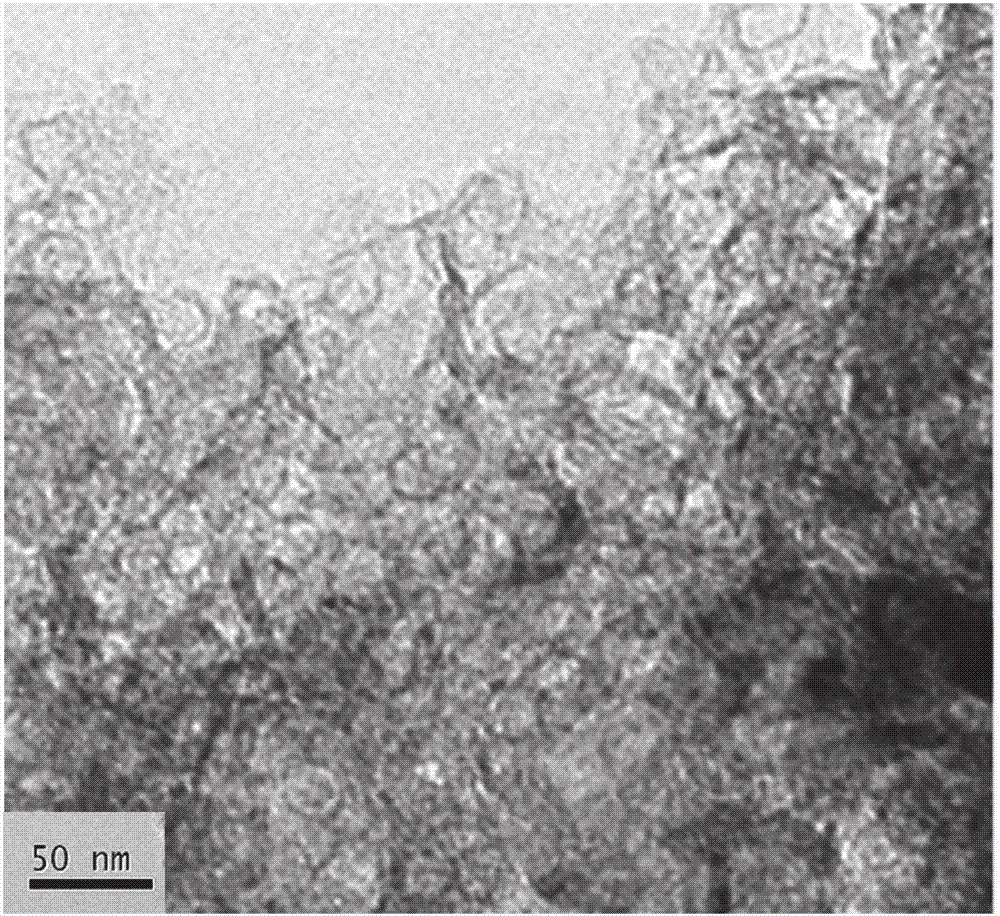

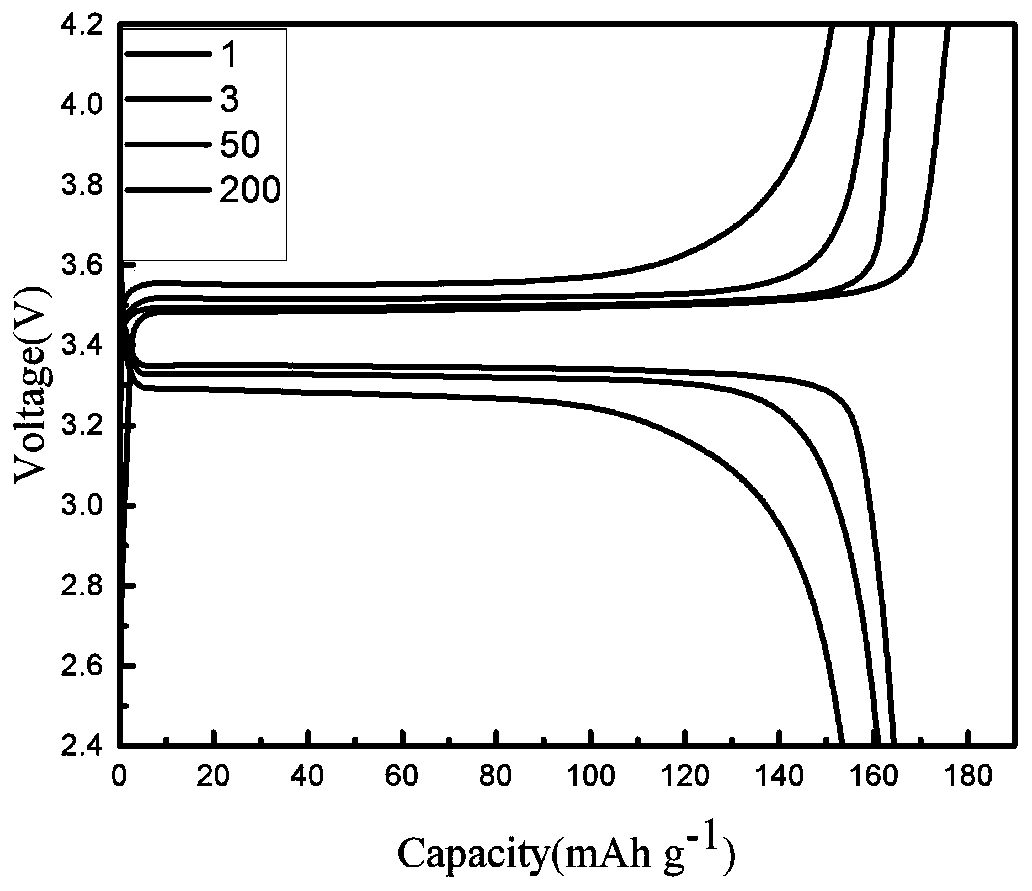

Sodium ion battery nanosheet array nickel phosphide/three-dimensional (3D) graphene composite material and preparation method thereof

ActiveCN107331851AImprove cycle stabilityImproved magnification performanceMaterial nanotechnologyCell electrodesSodium-ion batteryInorganic phosphorus

The invention discloses a sodium ion battery nanosheet array nickel phosphide / three-dimensional (3D) graphene composite material and a preparation method thereof. The preparation method comprises the steps of preparing 3D graphene by using foam nickel and a chemical vapor deposition (CVD) method, enabling the 3D graphene and deionized water having a pH value of 3 to be subjected to a hydrothermal reaction, and generating an Ni(OH)2 nanosheet array structure on a foam nickel substrate loaded with the 3D graphene; respectively placing nanosheet array Ni(OH)2 / 3D graphene composite material and a phosphorus source at the two ends of a tube furnace, heating the tube furnace, replenishing one end of the tube furnace, where the inorganic phosphorus source is placed, with flowing inert gas, and carrying out heat treatment; cooling the product of the reaction to room temperature to obtain the nanosheet array nickel phosphide / 3D graphene composite material. The whole preparation method provided by the invention is simple and environmentally-friendly; nickel phosphide is compounded with the 3D graphene, so that the material performance is improved; when the composite material is used as a self-supported sodium ion battery anode material, a conductive additive is not needed; the sodium ion battery nanosheet array nickel phosphide / 3D graphene composite material has high specific capacity and good rate performance, thus having a wide industrial application prospect.

Owner:TAIYUAN UNIV OF TECH

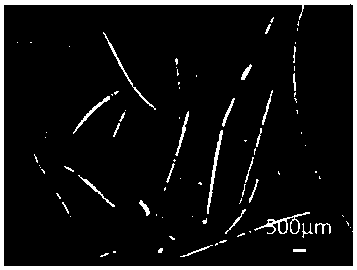

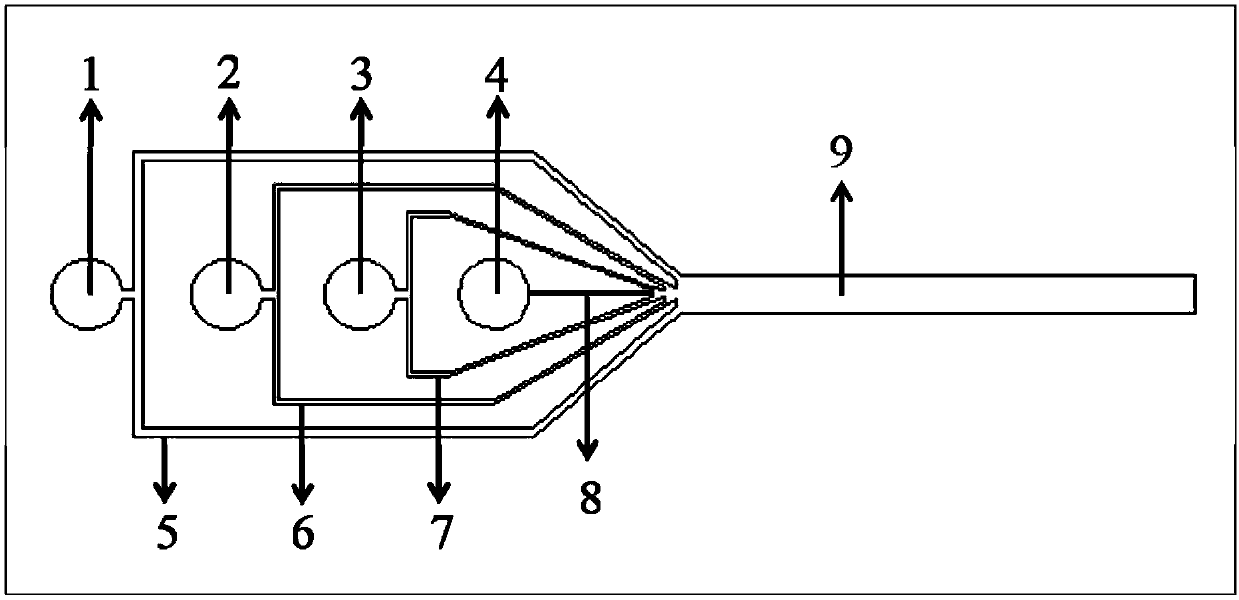

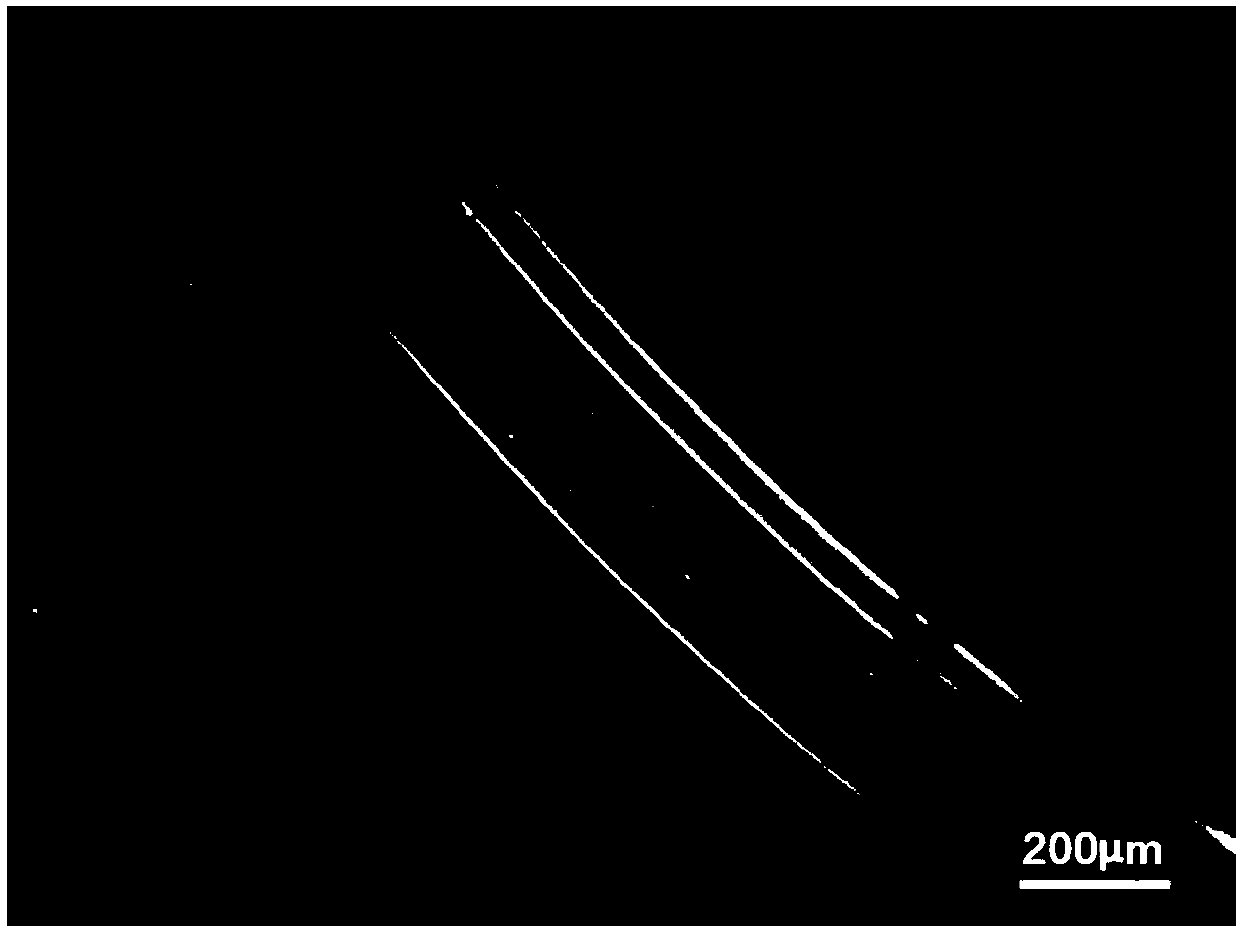

Preparation method of composite cavity microfibers based on micro-fluidic technology

ActiveCN108149342AStable growthPrecise Density ControlConjugated cellulose/protein artificial filamentsArtificial cell constructsCell adhesionAdhesion process

The invention relates to a preparation method of composite cavity microfibers based on a micro-fluidic technology. The preparation method is characterized in that in the preparation process of cavitymicrofibers, a modified material capable of promoting the cell wall adhesion growth is introduced in a microfiber inner cavity; while the cavity is formed, the modified material is adhered onto the cavity to form a modified coating layer, so that a promoting effect on late cell adhesion and culture is provided. By utilizing the micro-fluidic technology, a micron-sized channel capable of generatinga coaxial laminar flow pattern is formed, the flow pattern control on a sample fluid is realized, and the sample fluid is finally solidified into a micron-sized hollow fiber material with a specificinner coating structure. The microfiber material can simulate a microstructure in a human body tissue, and a new method and a new concept are provided for tissue engineering and organ regeneration. The preparation method provided by the invention is simple and reliable to operate, high in efficiency and excellent in technical effect; convenient conditions are provided for the modification of the microfibers; an internal finish coating is uniform, stable, simple and controllable to facilitate the cell wall adhesion growth.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

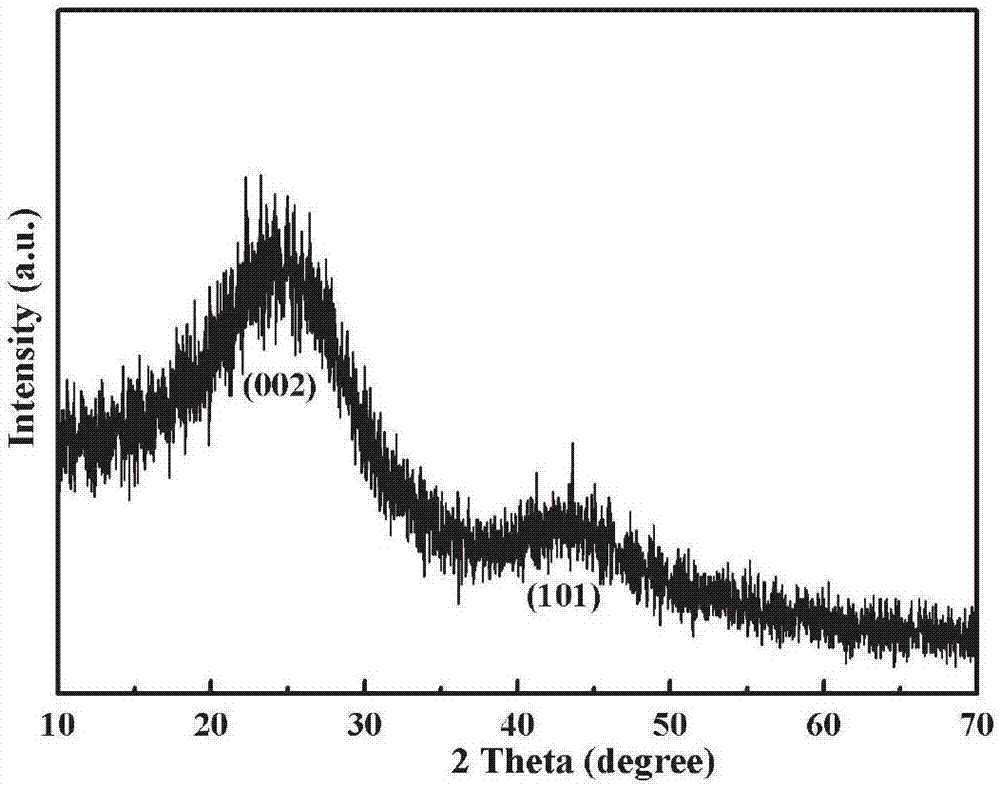

Carbon negative electrode material for sodium ion battery and preparation method of carbon negative electrode material

ActiveCN106935861AGuaranteed electrical conductivityIncreased wetted contact areaCell electrodesNickel saltElectrical battery

The invention discloses a preparation method of a carbon negative electrode material for a sodium ion battery. The preparation method comprises the steps of performing spray pyrolysis on solution of a carbon-containing nitrogen source, an activating agent, a surfactant and a nickel salt, and washing and drying the obtained product to prepare the carbon negative electrode material. Moreover, the invention also discloses the carbon negative electrode material obtained by employing the preparation method. The composite structure carbon negative electrode material prepared by the method is a carbon sphere with certain graphitized degree and rich pores, and the carbon negative electrode material has low potential, high specific capacity and excellent cycle performance when used as a negative electrode material of the sodium ion battery; and moreover, the preparation method is simple and is low in cost and has wide industrial application prospect.

Owner:CENT SOUTH UNIV

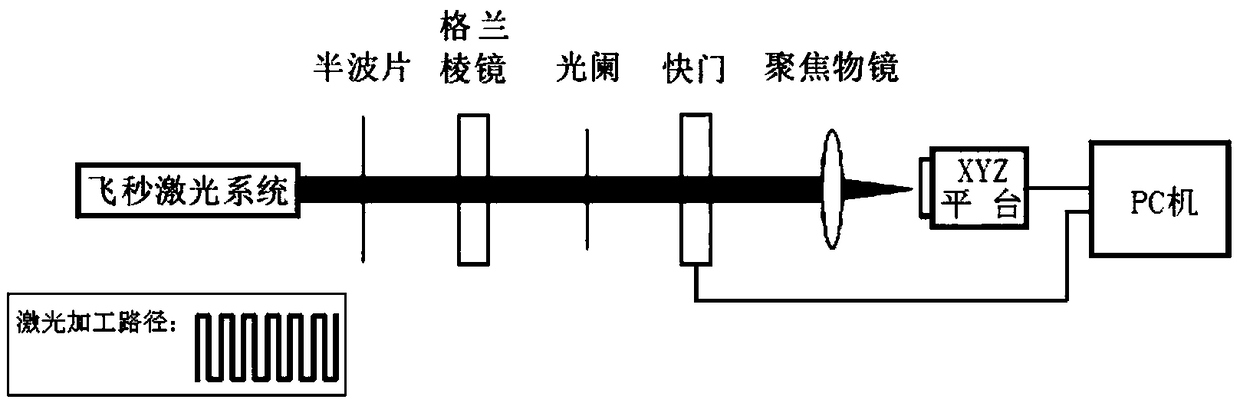

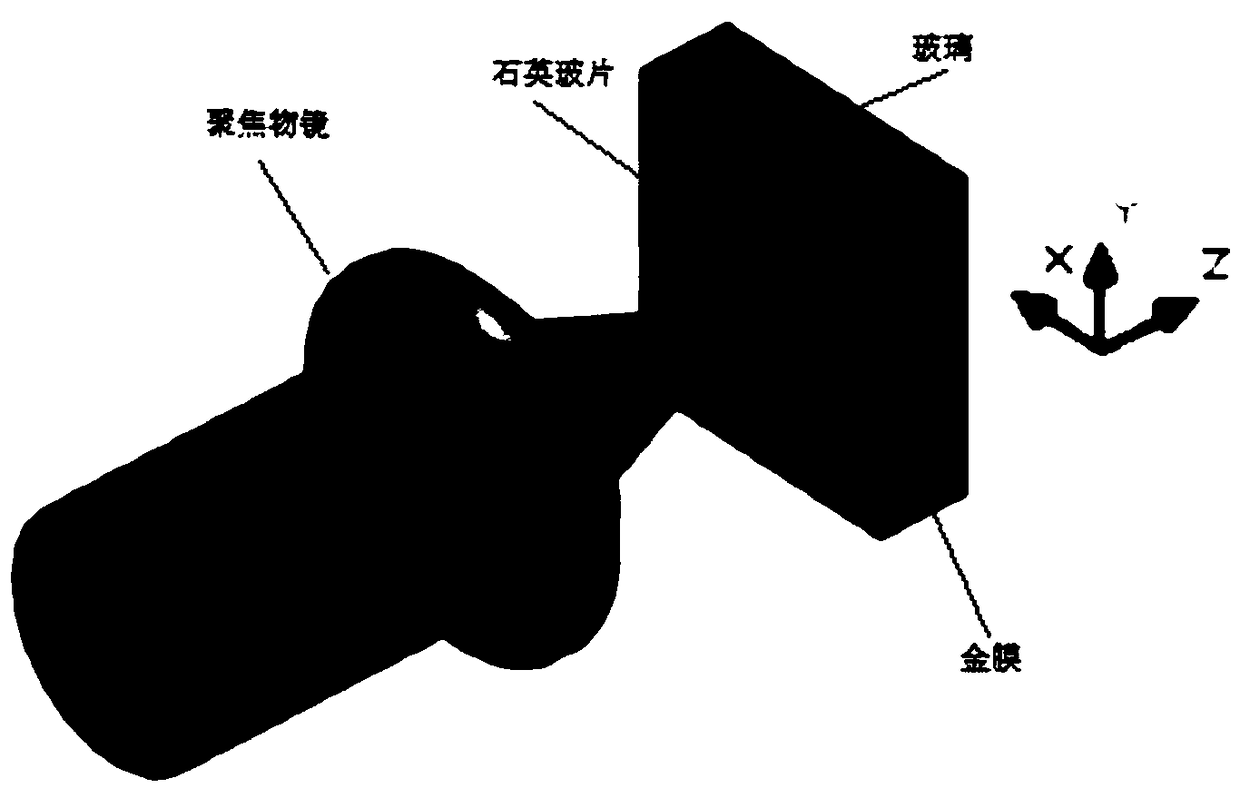

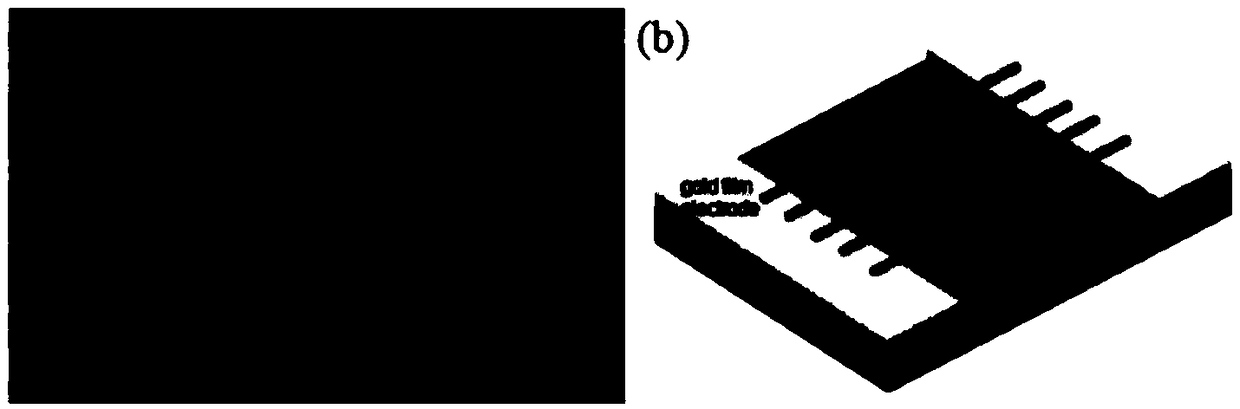

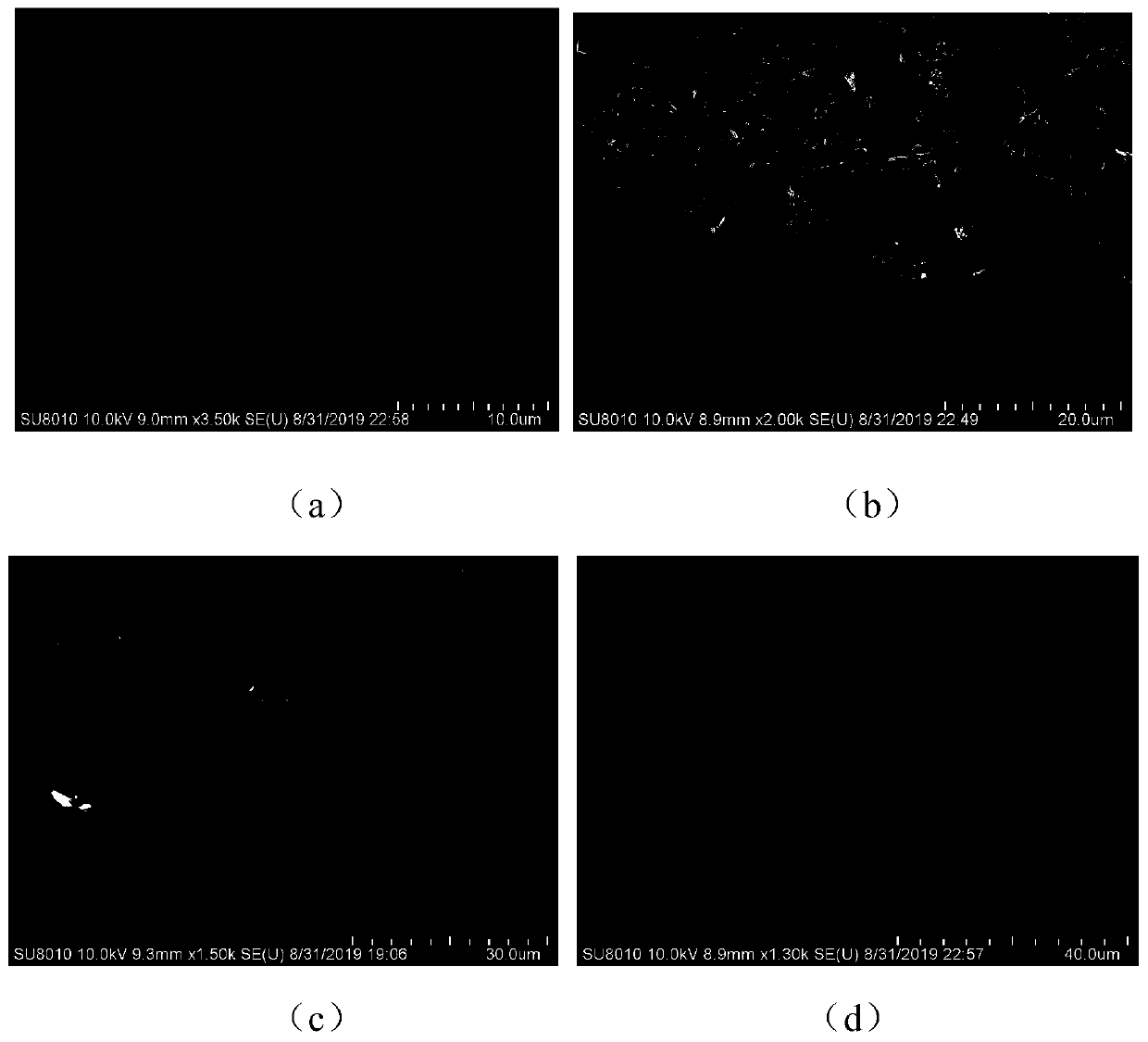

Preparation method of nanoparticle linear array resistor

ActiveCN108648890AEasy transferAchieving controllable equipmentResistor manufactureMicro nanoFemtosecond pulsed laser

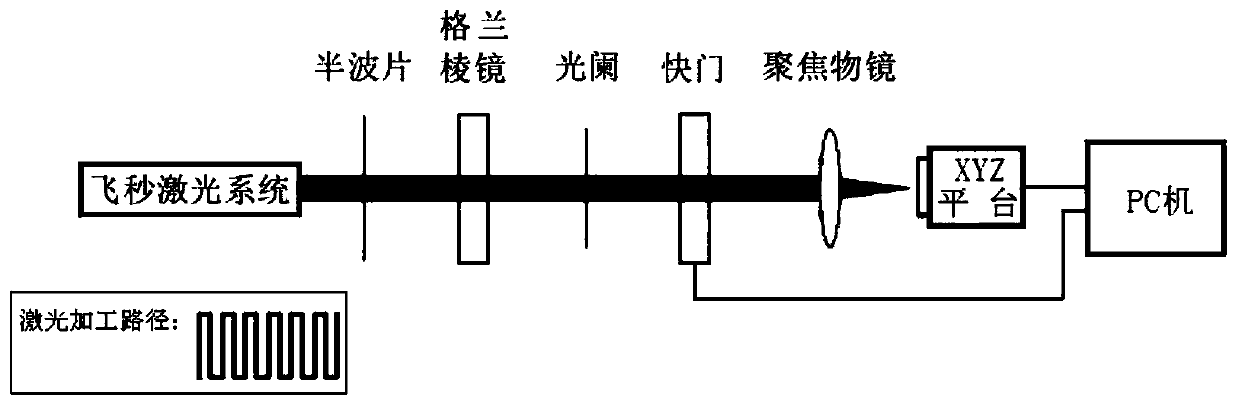

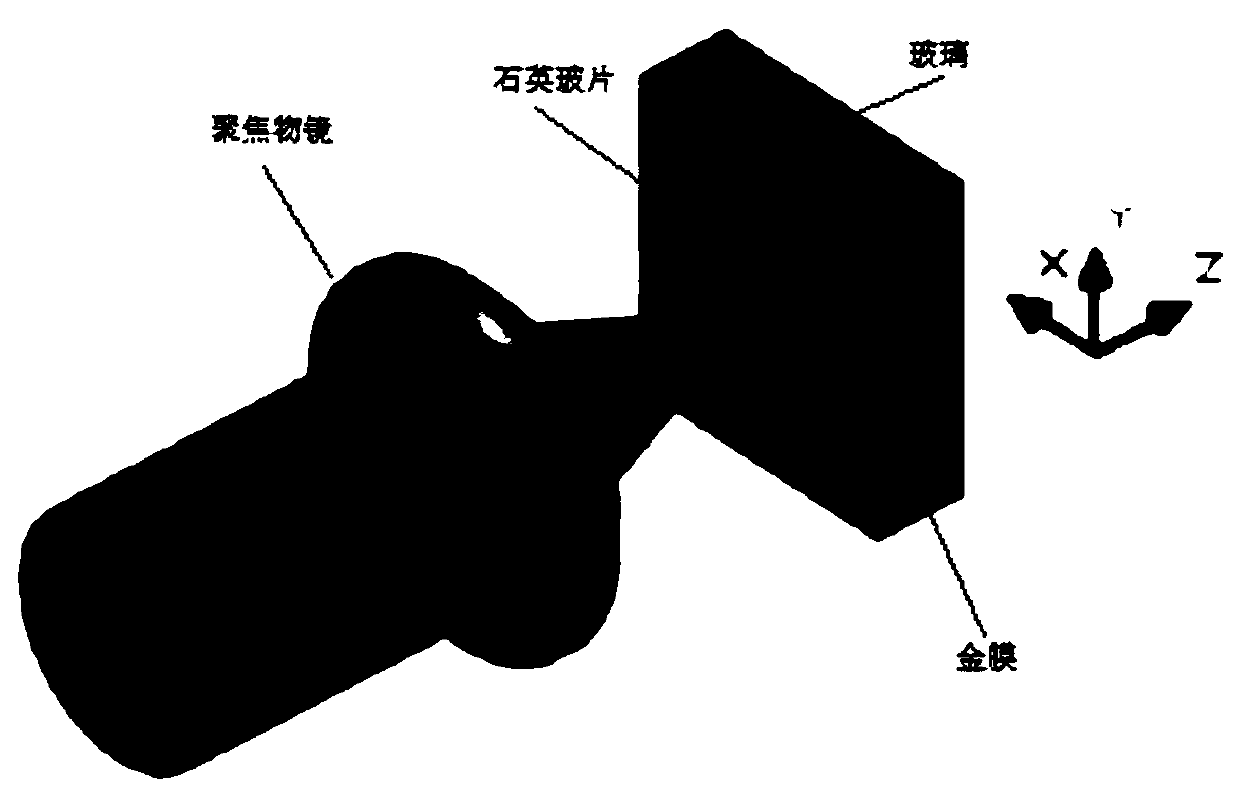

The invention provides a preparation method of a nanoparticle linear array resistor. The preparation method comprises the steps: a prepared sample is obtained; the prepared sample is put on a three-dimensional micro displacement platform; femtosecond pulse laser passes through an optical path system to transmit a quartz slide to be focused on the surface of a gold film; a PC controls the three-dimensional micro displacement platform to move in the directions of a Y axis and a Z axis; the gold film is subjected to ablation by the focused laser to form plasma spray in a constraint space; the spayed gold nanoparticles are received by the covered glass, and the gold nanoparticle linear array resistor is obtained on the glass surface; and the morphology features of the gold nanoparticle lineararray resistor are represented. The method is based on a femtosecond laser micro-nano processing platform and is combination with a laser induced backward transfer technology; by controlling femtosecond pulse laser energy density, scanning speed and processing number of branches, the linear array resistor formed by the gold nanoparticles is prepared; and the gold nanoparticle morphology features of different processing parameters are represented by a scanning electron microscope and an atomic force microscope.

Owner:GUANGZHOU UNIVERSITY

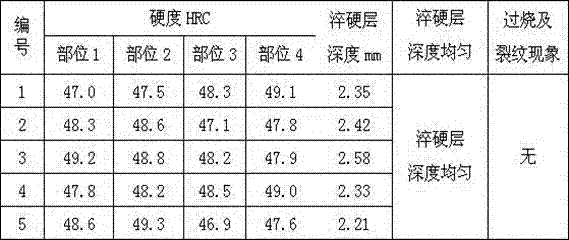

Inductive heat treatment method of low-speed large-torque drive axle

InactiveCN103667661AAddressing Induction Heat Treatment RequirementsThe operation method is simple and reliableFurnace typesIncreasing energy efficiencyElectricityCapacitance

The invention discloses an inductive heat treatment method of a low-speed large-torque drive axle and relates to the technical field of inductive heat treatment. The method comprises the specific steps as follows: an annular inductor and a quenching liquid spraying device are installed; a transformer ratio and the capacitance are determined; a run program is formulated according to specific technical requirements for a part; the part is clamped; a zero position and the rotational speed of the part are determined; an electrical parameter is adjusted and determined in coordination with the run program; an automatic run button is started, and the inductive heat treatment is performed on the part with a two-step method, that is, the first step is preheating, continuous heating is only performed in the annular inductor when the whole part is displaced from the head end to the tail end up and down, and the second step is to perform liquid spray cooling on the part to realize quenching of the part and the like while the part is heated in a manner identical with the first time. According to the inductive heat treatment method, the requirement for inductive heat treatment of the drive axle simultaneously provided with four structural types, namely, a rack, a keyway, steps and a spline is met; and the method in simple and reliable in operation, easy to implement, stable in quality and high in efficiency and has high application values.

Owner:FIRST TRACTOR

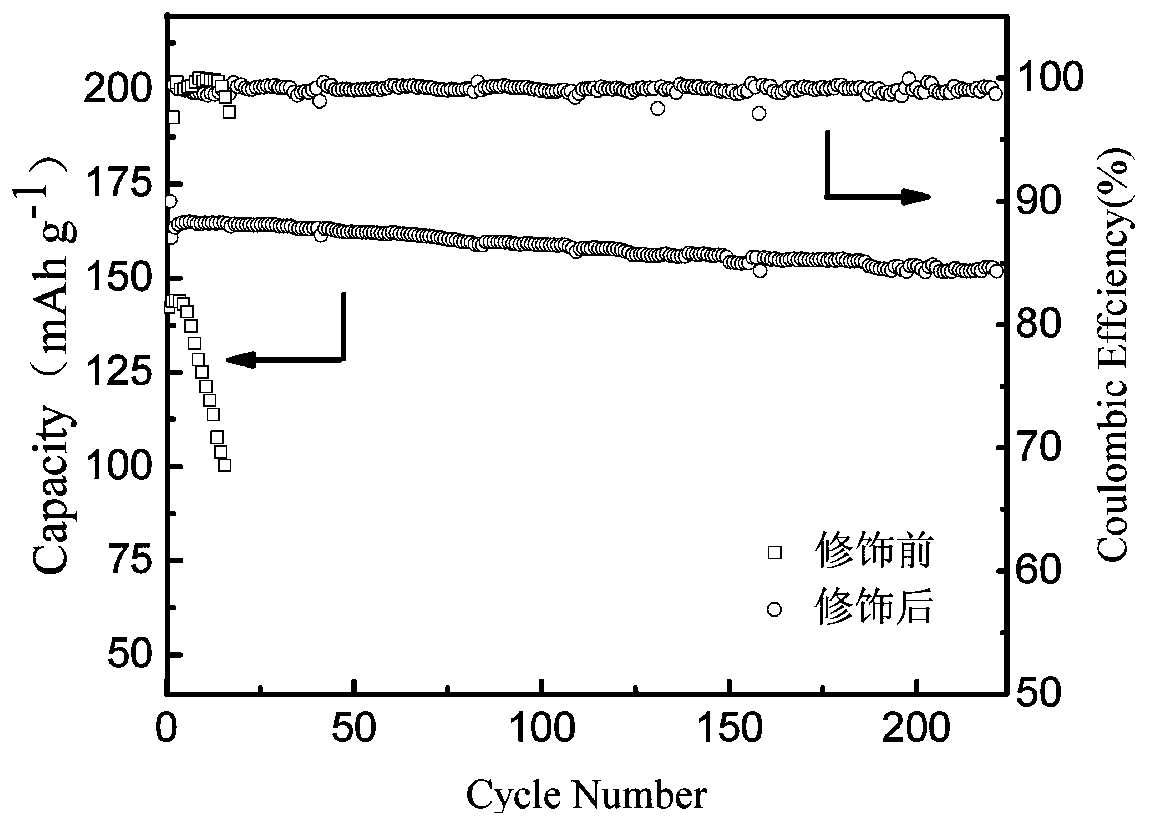

Method for improving lithium dendrite at solid electrolyte interface with carbon fluoride

ActiveCN110600808AThe operation method is simple and reliableShort timeFinal product manufactureElectrolyte accumulators manufactureAll solid stateSolid state electrolyte

The invention discloses a method for improving lithium dendrite at a solid electrolyte interface with carbon fluoride. The method comprises the following steps: step 1, polishing a garnet electrolytesheet with sandpaper; and step 2, modifying the carbon fluoride on the polished surface of the garnet electrolyte sheet so as to obtain the garnet electrolyte sheet modified with the carbon fluoride.The garnet electrolyte sheet modified with the carbon fluoride prepared by the method can be used for assembling an all-solid-state battery based on an inorganic solid electrolyte. Compared with the methods in the prior art, the method has the following advantages: (1) the operation method is simple and reliable and the time consumption is short without using high-end instruments; and (2) the improvement efficiency is excellent and large-scale production is feasible.

Owner:HARBIN INST OF TECH

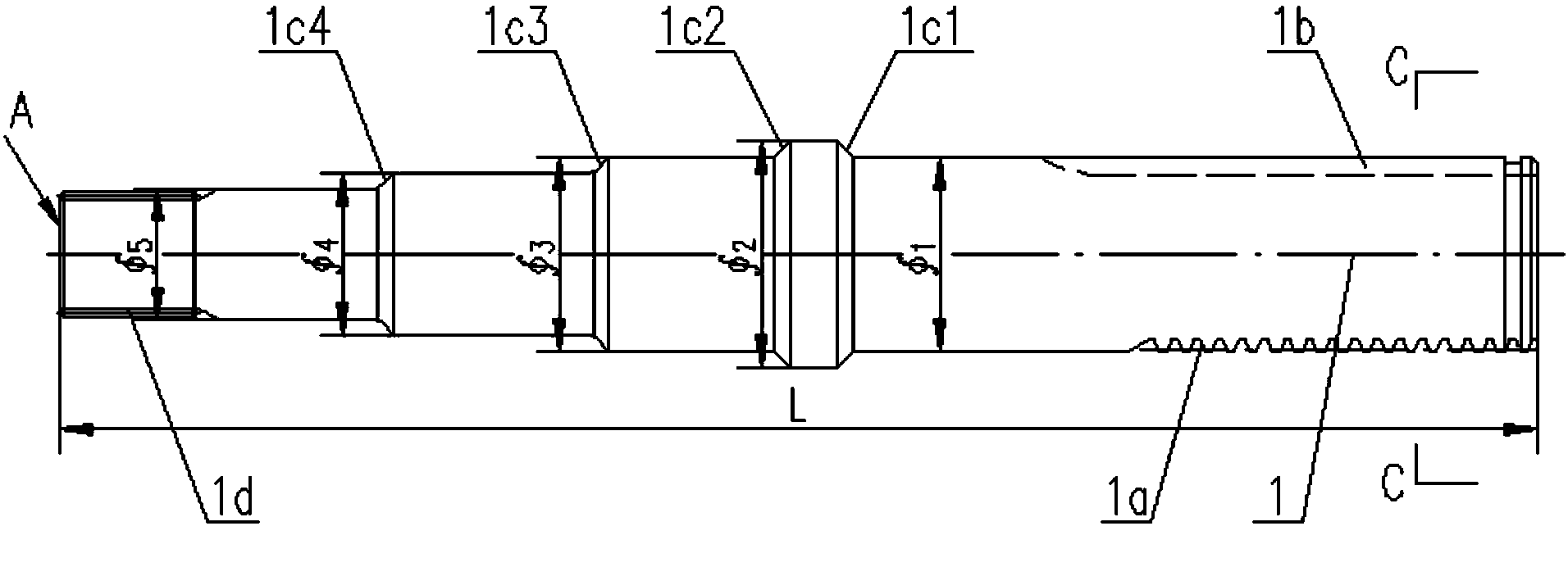

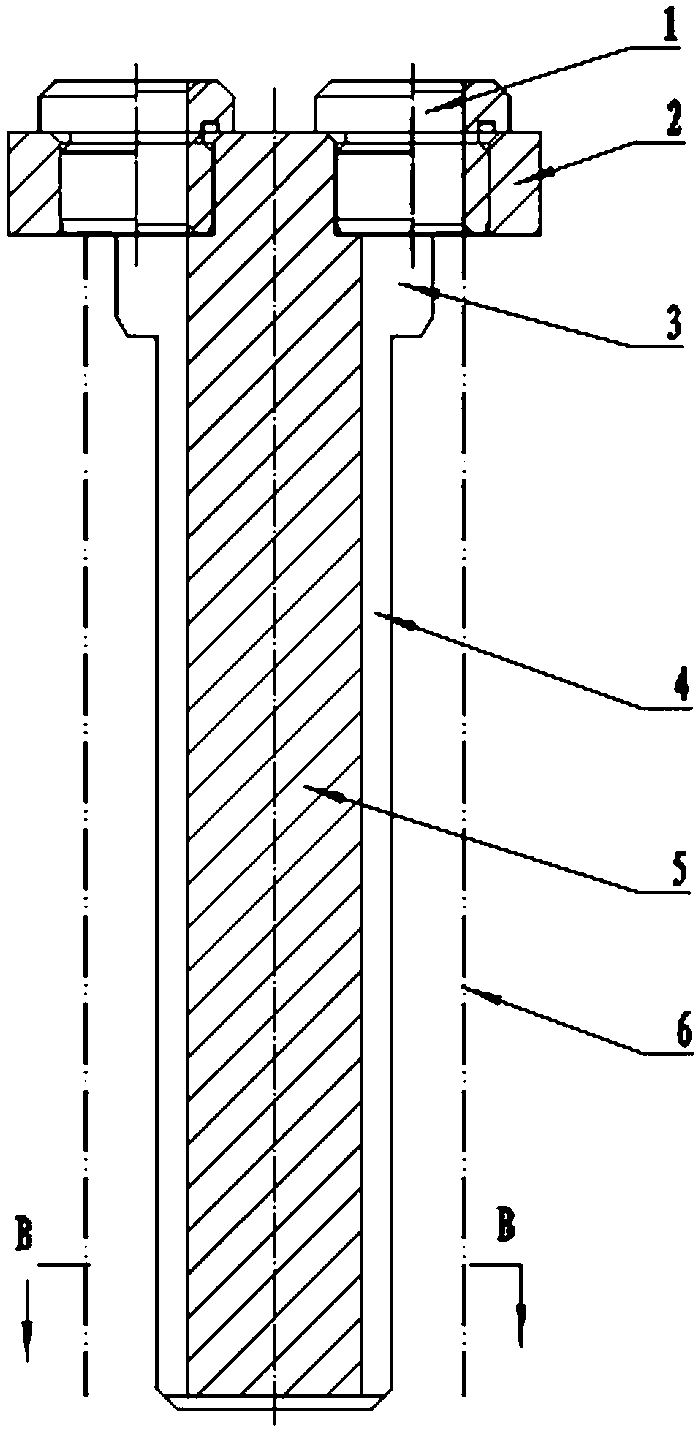

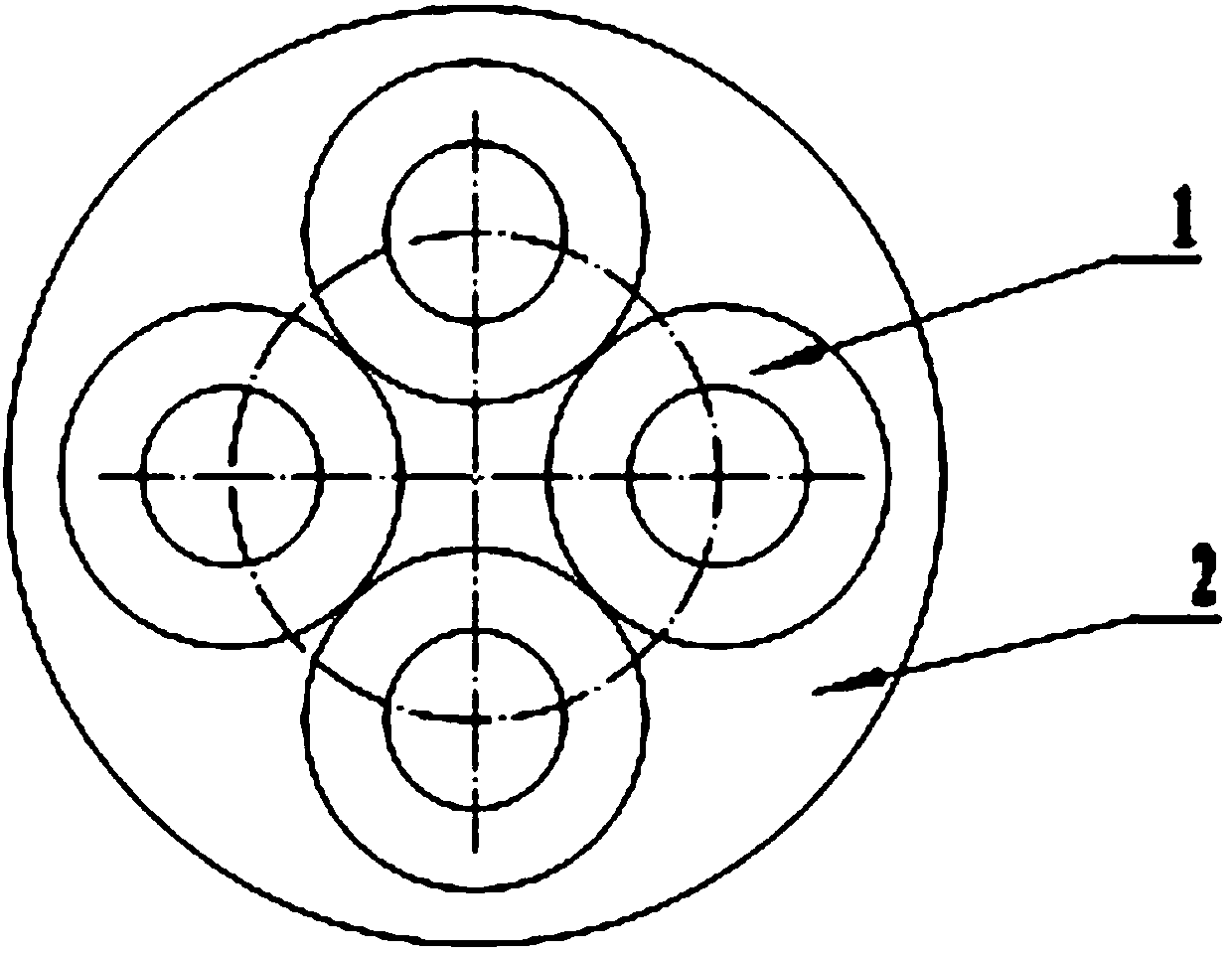

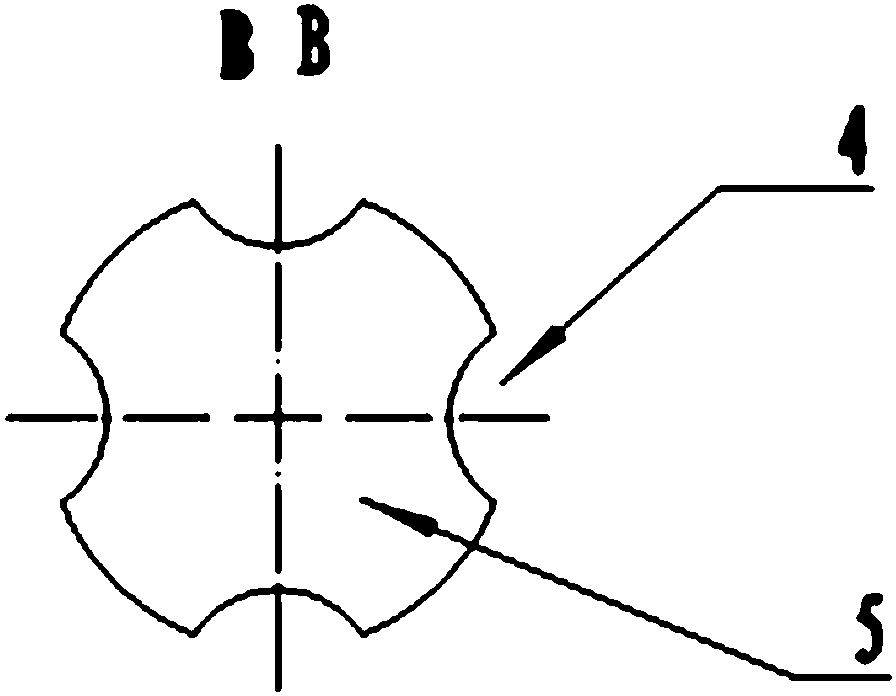

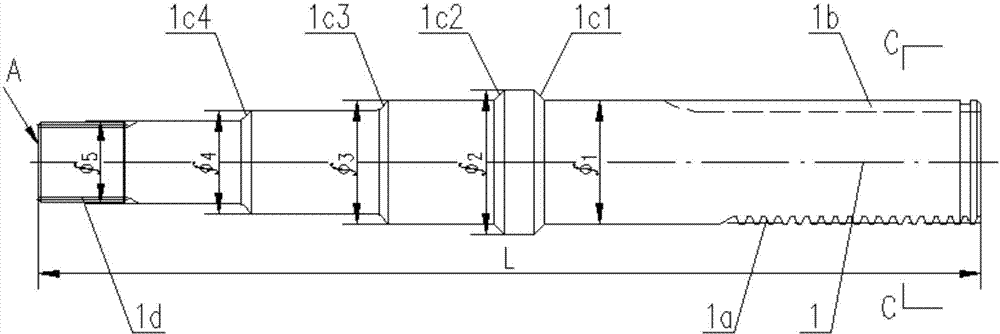

Method for rapidly cold-extracting scrapped nylon sleeve in concrete sleeper and special drill jig

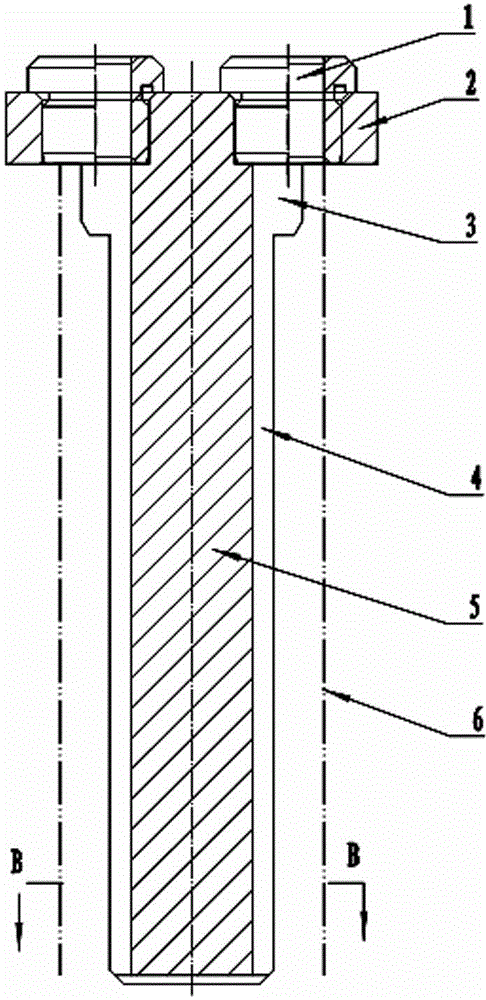

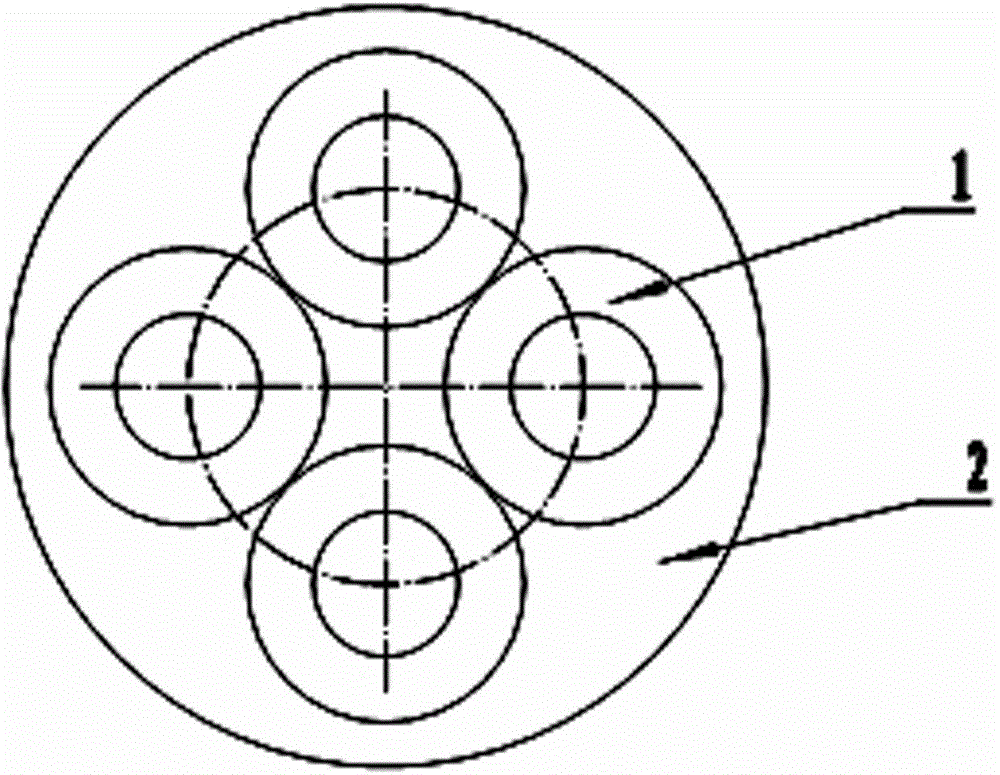

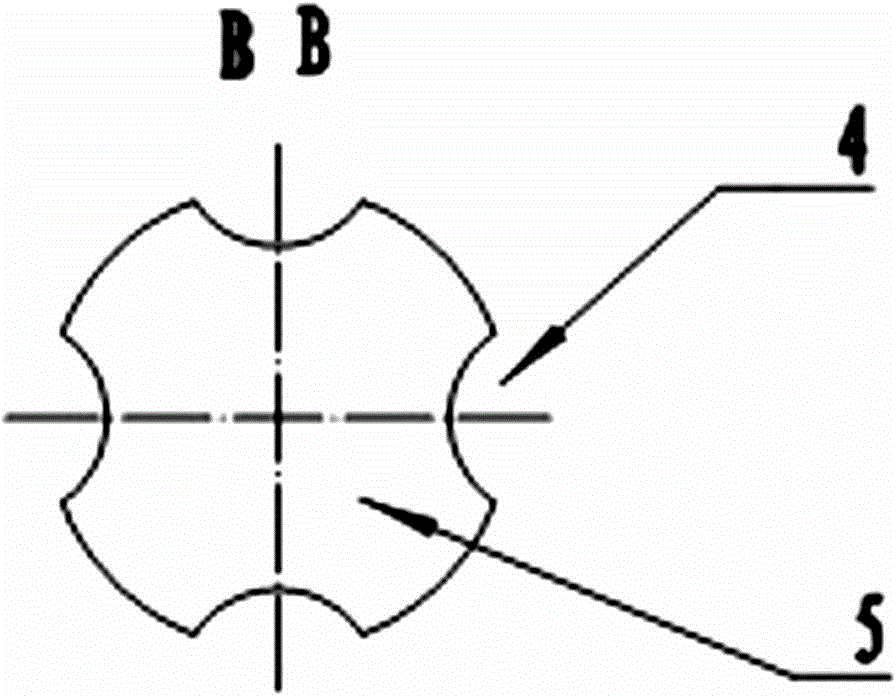

InactiveCN102995509AIntegrity guaranteedHigh strengthRailway track constructionScrew threadDrill bushing

The invention discloses a method for rapidly cold-extracting a scrapped nylon sleeve in a concrete sleeper and a special drill jig. The method comprises the following steps of: adopting a stepwise working method, namely, drilling a plurality of key slots in the inner wall of the scrapped nylon sleeve at first, and then clamping wedges in the inner cavity of the scrapped nylon sleeve along the plurality of key slots, then locking the wedges by a torque wrench to loosen the scrapped nylon sleeve relative to the concrete sleeper until the scrapped nylon sleeve is unscrewed out of the concrete sleeper. The special drill jig is provided with a drill jig body, wherein drill bushings are arranged on the drill jig body; and the special drill jig is characterized in that the drill bushings are uniformly distributed on the drill jig body, a location boss matched with an unthreaded hole in the upper part of the inner cavity of the nylon sleeve extends outwards from one side of the drill jig body, a guide rod inserted in the inner cavity of the nylon sleeve extends from the location boss, and arc-shaped grooves concentric with the drill bushings are formed in the periphery of the guide rod. The whole operation method is simple and reliable, and free from damages on cement internal threads in the nylon sleeve and the concrete sleeper, thus guaranteeing time-saving, labour-saving and high-efficiency replacement of a new nylon sleeve.

Owner:NANYANG INST OF TECH

Preparation method of ultrathin cavity composite microfiber material based on microfluidic technology

InactiveCN110725023AEasy to prepareNovel material structureHollow filament manufactureConjugated cellulose/protein artificial filamentsMicrofluidic chipOrgan regeneration

The invention provides a preparation method of an ultrathin cavity composite microfiber material based on a microfluidic technology. In the process of preparing common cavity microfibers, a modification material capable of being combined with a microfiber material on the outer layer is introduced into the cavity of the microfibers, the modification material is attached to the cavity while the cavity is formed to form a modification coating, and then an outer layer material is dissolved to obtain the ultrathin microfiber material. A micro-scale channel capable of generating a coaxial laminar flow pattern can be formed by utilizing a micro-fluidic chip technology, so that flow pattern control of sample fluid is realized, the sample fluid is finally solidified into a micro-scale cavity fibermaterial with a specific inner coating structure, and the ultra-thin cavity composite micro-fiber material is obtained by removing the outer layer material. The microfiber material can simulate microstructures in human tissues, and a new method and idea are provided for tissue engineering and organ regeneration.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

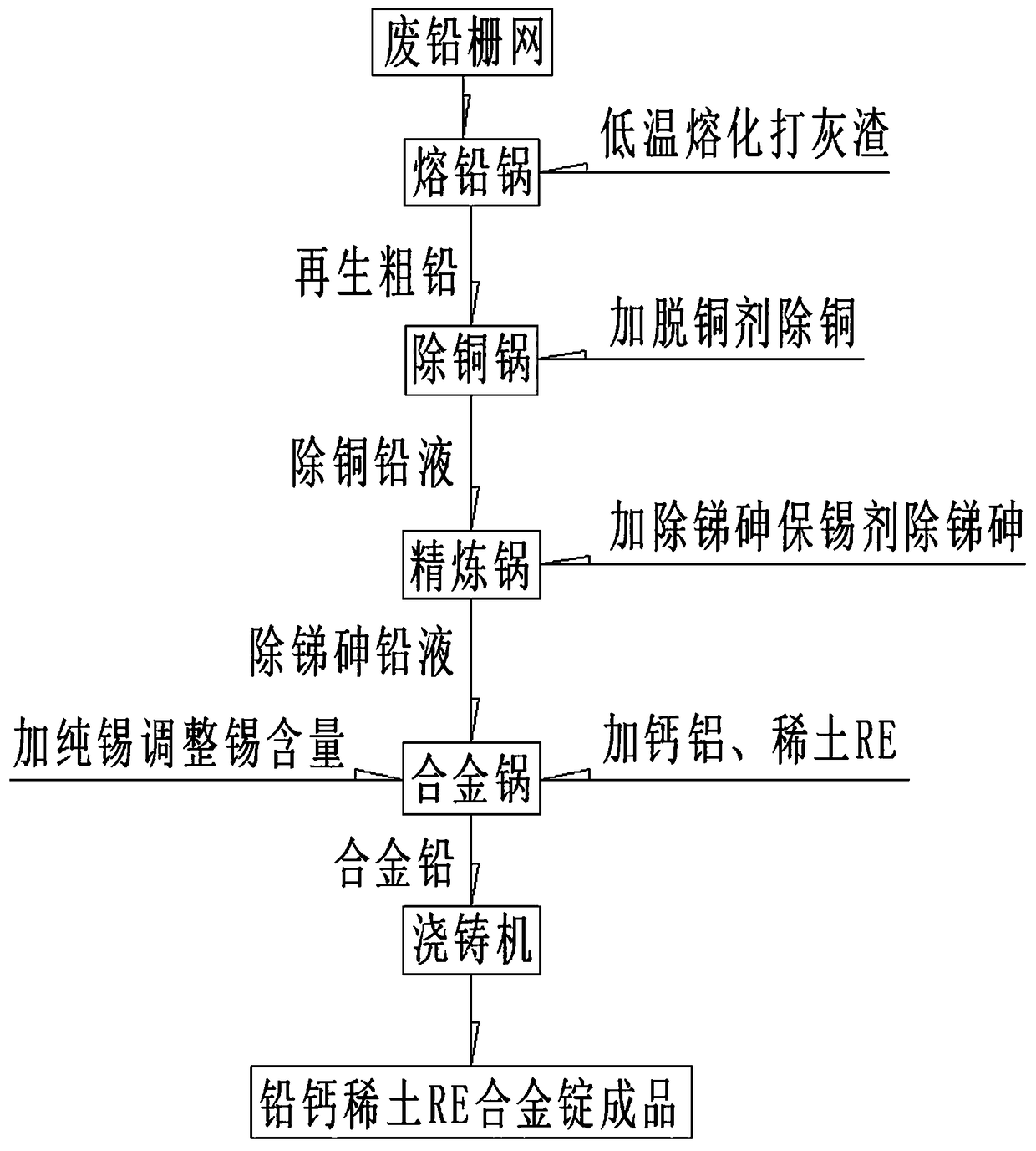

Selective antimony and arsenic removal tin retaining agent for refining regenerated crude lead and using method thereof

ActiveCN108707761AReduce manufacturing costHigh removal rateProcess efficiency improvementAlloyDross

The invention provides a selective antimony and arsenic removal tin retaining agent for refining regenerated crude lead and a using method thereof, and belongs to the field of refinement and impurityremoval of the regenerated crude lead. The selective antimony and arsenic removal tin retaining agent comprises 10-30wt% of aluminum, 65-85wt% of calcium, 1-10wt% of coke powder and 1-5wt % of lead powder on the basis of the total mass thereof. According to the content of antimony in lead, the antimony and arsenic removal tin retaining agent is added to lead liquid with the temperature of about 550-650 DEG C according to certain proportion so as to carry out antimony and arsenic removal reaction; at the end of reaction, antimony and arsenic scum is fished out by temperature reduction to obtainthe lead liquid without the antimony and arsenic; and the content of the antimony and arsenic is reduced to below 0.0005wt %, and the content of the tin is essentially unchanged. The selective antimony and arsenic removal tin retaining agent has a high removal rate for the antimony and arsenic in the lead liquid and realizes the deep removal of antimony and arsenic impurities, enables the valuable metal tin to be effectively retained, reduces the production cost of the lead alloy preparation, meanwhile is smokeless and tasteless in an antimony and arsenic removal reaction process and enablesworking environments to be good.

Owner:JIANGSU NEW CHUNXING RESOURCE RECYCLING CO LTD

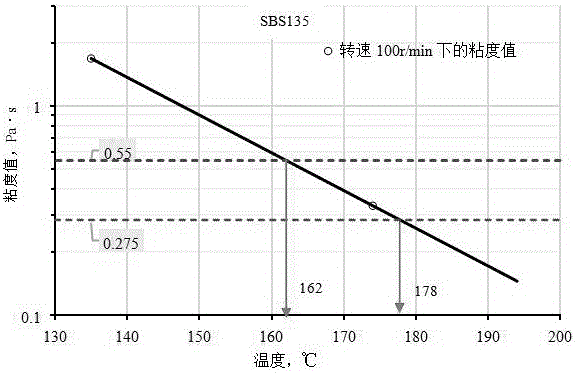

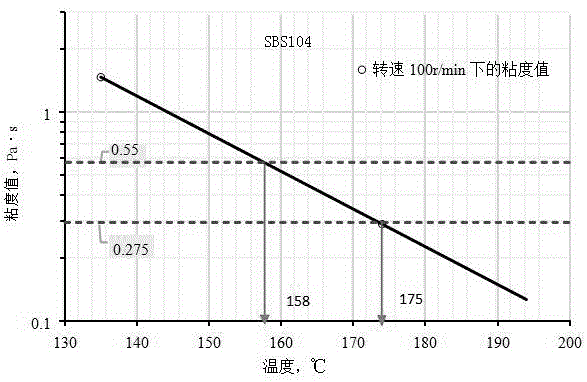

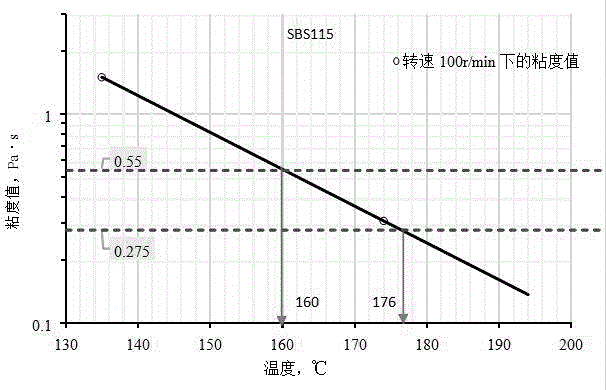

SBS modified asphalt construction temperature determination method

InactiveCN106556554AClear legal meaningThe experimental results are accurateFlow propertiesThermometers using physical/chemical changesRoad engineeringEngineering

The invention discloses a SBS modified asphalt construction temperature determination method and belongs to the field of road engineering. The method comprises the following steps: A, by the utilization of a rotational viscometer, by the adoption of a No. 27 rotor and at the revolving speed of 100 RPM, viscosity number of a SBS modified asphalt sample used in engineering practice is acquired at 135 DEG C and at 174DEG C; B, a relation curve of logarithmic viscosity and temperature is drawn; and C, with the temperature corresponding to 0.275 Pa.s as a mixing temperature and with the temperature corresponding to 0.55 Pa.s as a compaction temperature, corresponding mixing temperature and compaction temperature are calculated by interpolation algorithm. In comparison with existing design methods, the determination method has characteristics of clear physical significance, accurate experimental results and the like, and also has good engineering practice effects.

Owner:SHANDONG TRANSPORTATION INST +1

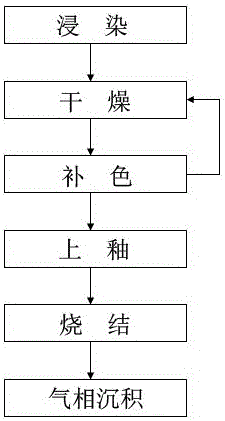

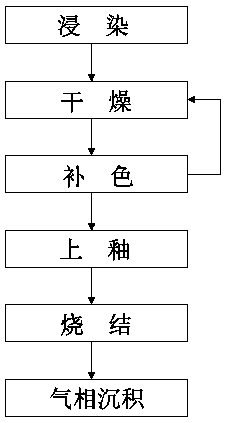

Denture dyeing process

ActiveCN106278386AThe operation method is simple and reliableHigh degree of automationImpression capsMedical preparationsDyeingEngineering

The invention discloses a denture dyeing process which includes dip-dyeing, drying, color-supplementing, glazing, sintering and vapor-depositing. The denture dyeing process is simple, convenient and reliable, high in operation automation, capable of flexibly adjusting color of dentures and meeting different using needs on the dentures, capable of effectively improving surface quality and structural strength of the dentures and conducive to prolonging service life of the dentures.

Owner:SHENZHEN JIAHONG DENTAL MEDICAL CO LTD

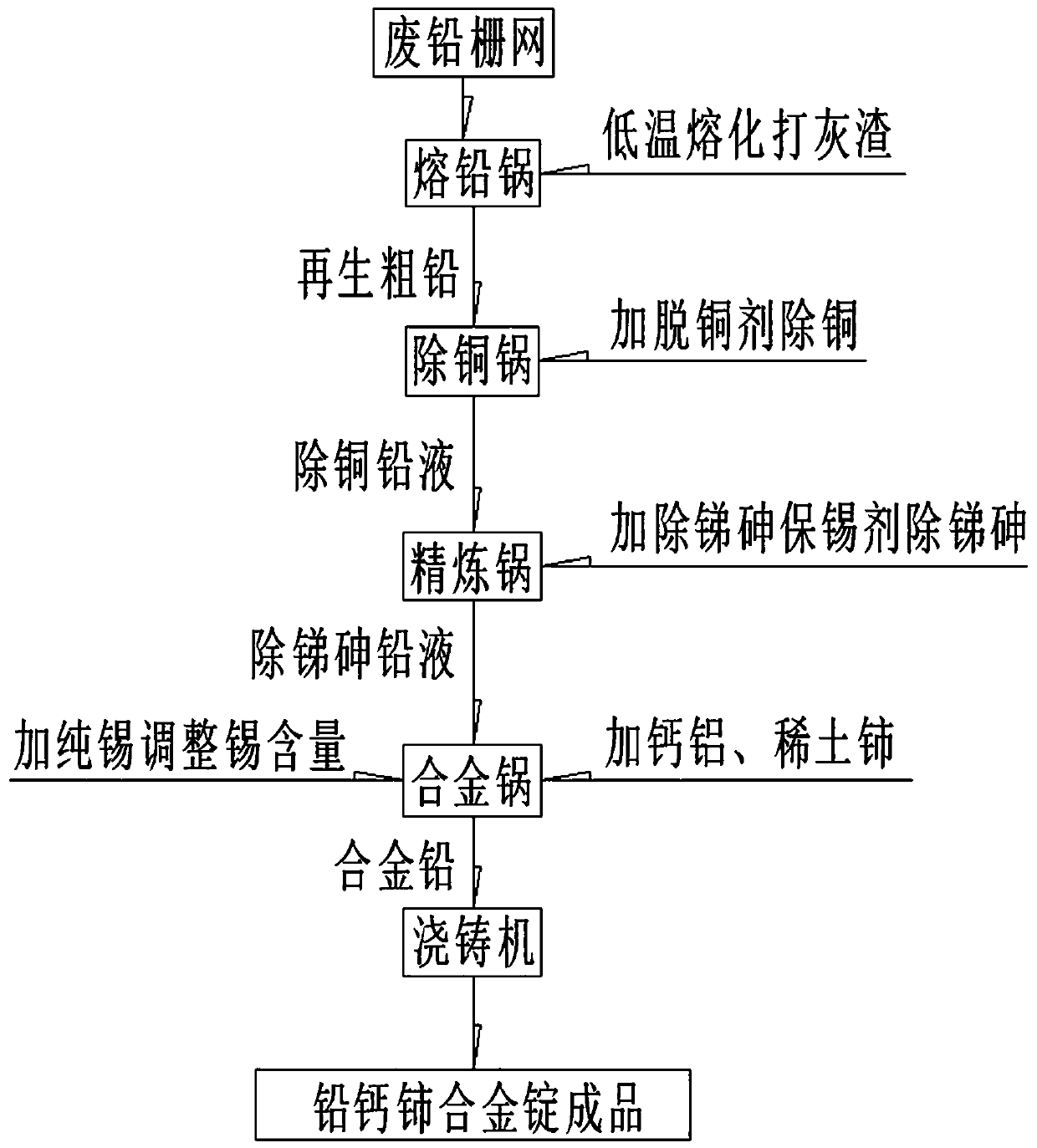

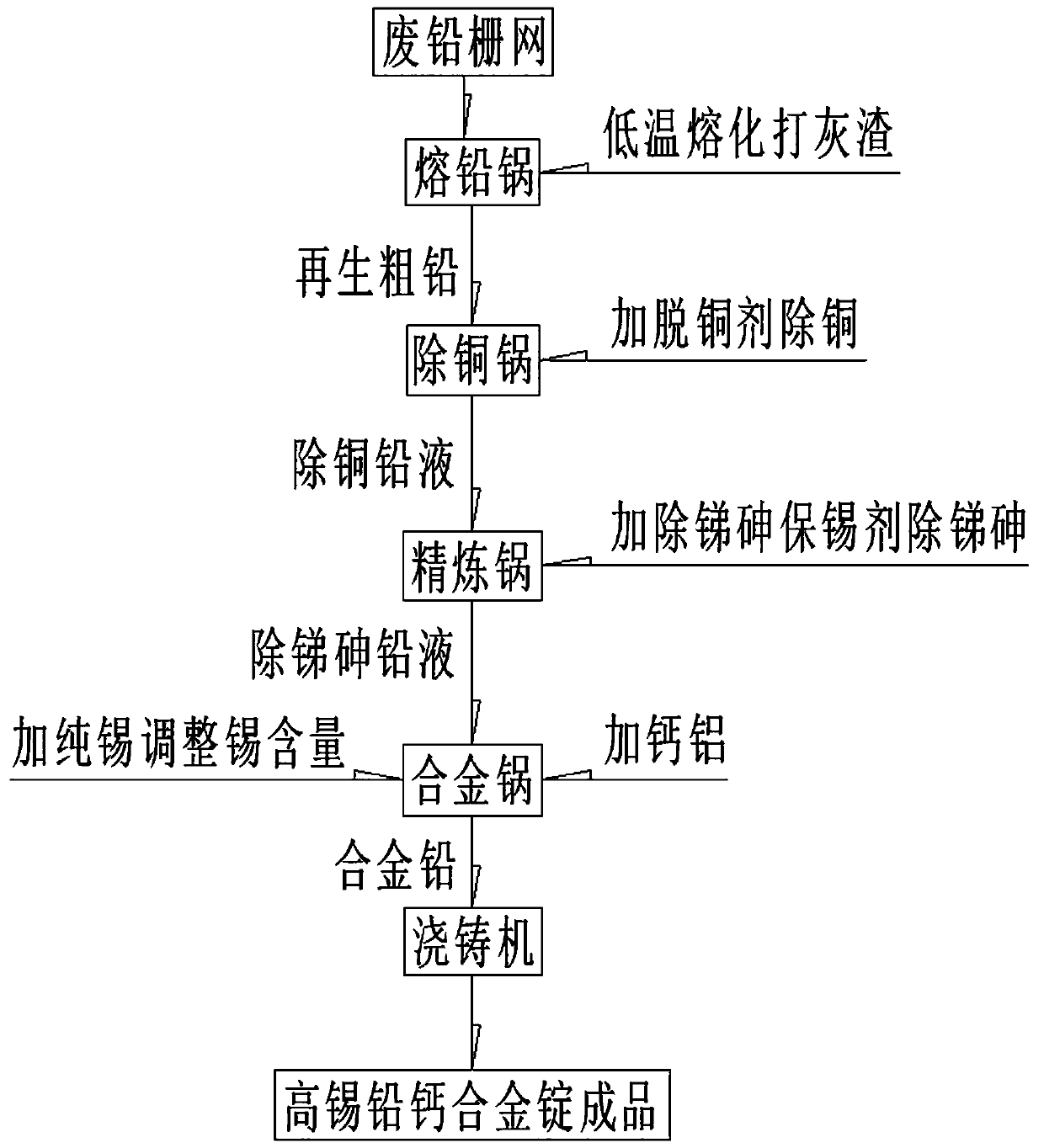

Technological method for producing lead-calcium rare earth alloy based on waste lead grid mesh of waste lead-acid batteries

ActiveCN108695572AHigh melting pointEfficient use ofWaste accumulators reclaimingProcess efficiency improvementElectrolysisSlag

The invention relates to a technological method for producing lead-calcium rare earth alloy based on waste lead grid mesh of waste lead-acid batteries, and belongs to the field of comprehensive recycling of waste lead-acid batteries. The technological method comprises the following steps: melting waste lead grid mesh at a low temperature in a smelting pot while controlling the melting temperatureat 350-500 DEG C, adding ash slag, adding a copper removal agent to remove copper and obtain a copper-lead liquid; heating the copper-lead liquid to 580-650 DEG C, adding an antimony-arsenic removal tin-retaining agent to remove antimony and arsenic and obtain a tin-containing lead liquid, and then purifying the tin-containing lead liquid, and adding tin-calcium-aluminum rare earth RE to prepare the lead-calcium rare earth RE alloy. The lead-calcium rare earth alloy produced has basically the same tensile strength, density, hardness and corrosion resistance as a lead-based alloy prepared by the original electrolytic lead, and meets the requirements for the use of a battery grid alloy. Advantages: The process is simple, the operation is convenient, the production efficiency is high, the valuable metallic tin in the waste lead grid mesh is effectively utilized, the production cost of the lead alloy preparation is reduced, the antimony-arsenic removal reaction process is smokeless and odorless, and the work environment is good.

Owner:JIANGSU NEW CHUNXING RESOURCE RECYCLING CO LTD

A method for induction heat treatment of a low-speed high-torque drive axle

InactiveCN103667661BAddressing Induction Heat Treatment RequirementsThe operation method is simple and reliableIncreasing energy efficiencyFurnace typesElectricityCapacitance

The invention discloses an inductive heat treatment method of a low-speed large-torque drive axle and relates to the technical field of inductive heat treatment. The method comprises the specific steps as follows: an annular inductor and a quenching liquid spraying device are installed; a transformer ratio and the capacitance are determined; a run program is formulated according to specific technical requirements for a part; the part is clamped; a zero position and the rotational speed of the part are determined; an electrical parameter is adjusted and determined in coordination with the run program; an automatic run button is started, and the inductive heat treatment is performed on the part with a two-step method, that is, the first step is preheating, continuous heating is only performed in the annular inductor when the whole part is displaced from the head end to the tail end up and down, and the second step is to perform liquid spray cooling on the part to realize quenching of the part and the like while the part is heated in a manner identical with the first time. According to the inductive heat treatment method, the requirement for inductive heat treatment of the drive axle simultaneously provided with four structural types, namely, a rack, a keyway, steps and a spline is met; and the method in simple and reliable in operation, easy to implement, stable in quality and high in efficiency and has high application values.

Owner:FIRST TRACTOR

Preparation method of cell-entrapped ultrathin cavity composite microfiber material

InactiveCN110721345AEasy to prepare in large batchesThe operation method is simple and reliableHollow filament manufactureConjugated cellulose/protein artificial filamentsMedicineOrgan regeneration

The invention provides a preparation method of a cell-entrapped ultrathin cavity composite microfiber material, which comprises the following steps: preparing a composite microfiber material with a coating in a cavity by using a microfluidic chip; by adding cells into the central fluid, obtaining the cavity composite microfiber material with cells embedded in the cavity; and dissolving off the outer layer material, and reserving the part with molecular interaction with the inner coating to form the ultrathin wall of the microfiber, thereby obtaining the cell-entrapped ultrathin microfiber material. The operation method is simple, reliable, high in efficiency and excellent in technical effect; the internal modification coating is uniformly, stably, simply and controllably adhered to the inner cavity, so that the convenient condition is provided for the preparation of the ultrathin microfibers; and an internal cavity structure is uniform, stable, simple and controllable, and is beneficial to embedding and culture of cells. Due to the characteristics of the ultra-thin wall, the exchange of nutrient substances can be accelerated, the proliferation of cells is promoted, and a new methodand thought are provided for tissue engineering and organ regeneration.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

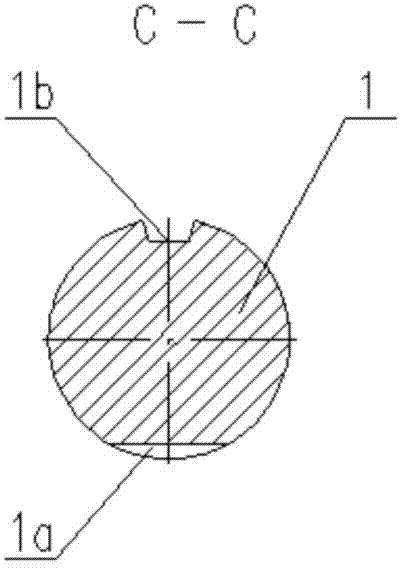

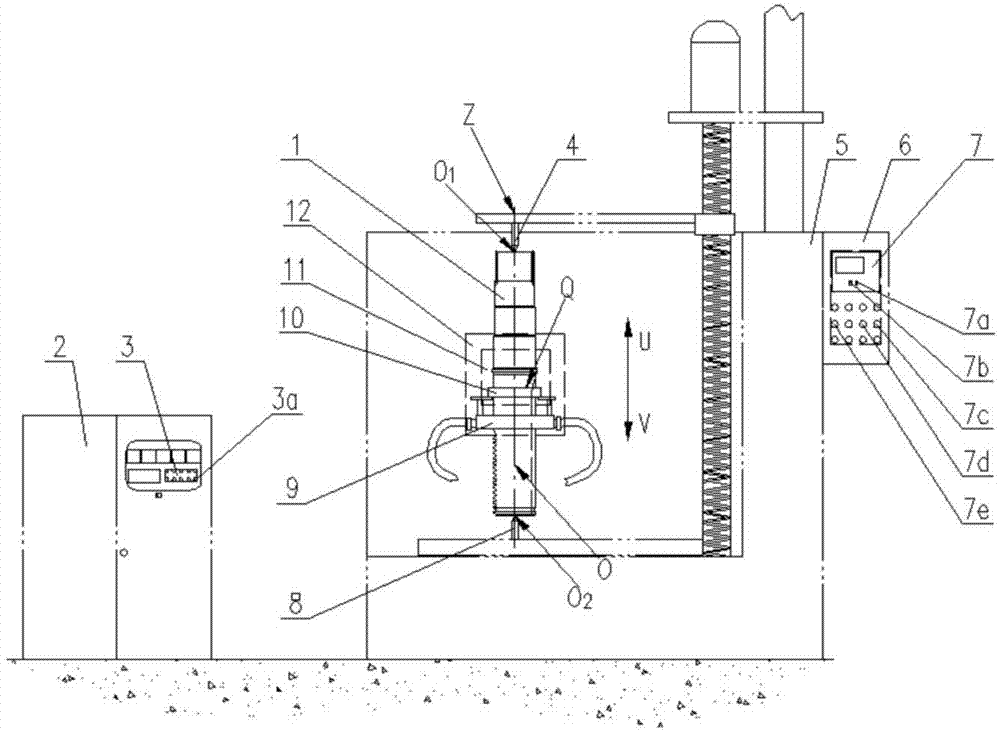

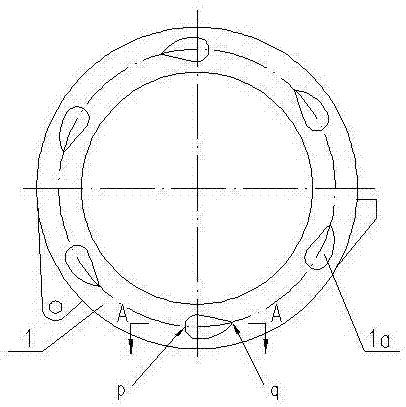

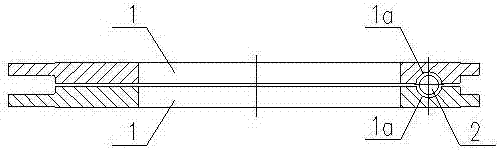

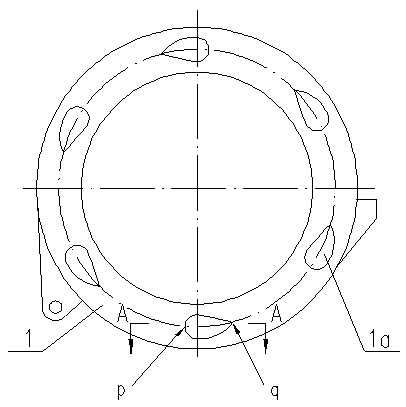

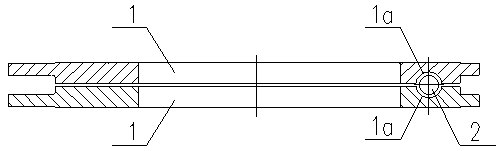

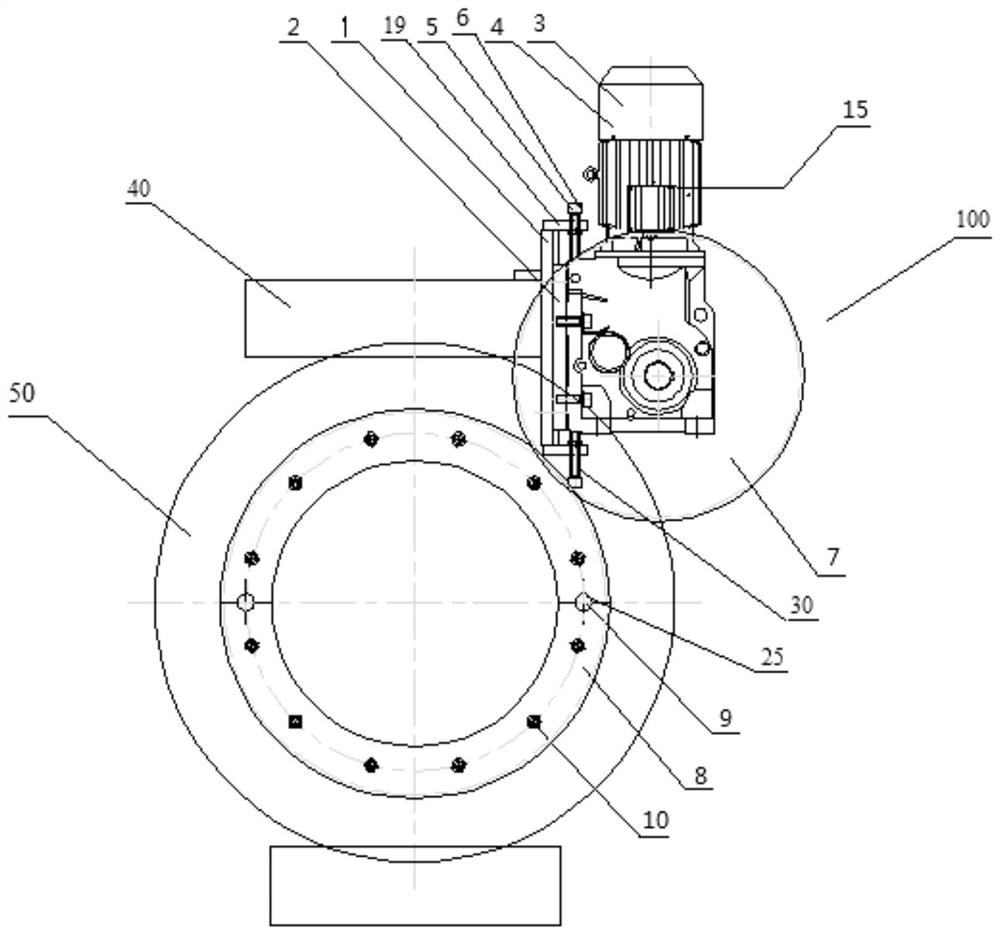

Induction quenching device used for cone sockets of brake platens and operation method

ActiveCN107312911AAvoid sharp corner effectSolve the problem that the sensing distance is difficult to controlFurnace typesIncreasing energy efficiencyHuman–machine interfaceInductor

Disclosed are an induction quenching device used for cone sockets of brake platens and an operation method. The induction quenching device comprises a quenching inductor, a revolution assembly, a cabinet body assembly and an electric control cabinet. The front end of the cabinet body assembly is fixedly connected with the quenching inductor, and the brake platens are placed at the upper end of the revolution assembly. In addition, the electric control cabinet is provided with a human-computer interface, a manual / automatic selecting knob and a heating button. A circular pipe is used for manufacturing the single-turn quenching inductor, so that the sharp corner effect is avoided during induction quenching of the cone sockets; the direction-adjustable and interval-adjustable lifting revolution tool assembly is arranged in the device, so that the problem that when induction quenching is conducted on the concave spherical surfaces of the cone sockets on arc surface wrapped with an effective induction coil, the induction interval is difficult to control is solved, the quenched layer is continuous and uniform in distribution, and accordingly the quenching quality is improved; the platens serves as the center for positioning, a height scale is used during induction quenching, and the position is precisely controlled through an index plate, so that the platens are rotationally positioned and heated in the induction quenching process, control over the quenching quality is guaranteed; and the operation method is simple, reliable and easy to carry out.

Owner:FIRST TRACTOR

A denture dyeing process

ActiveCN106278386BMeet the needs of different usesQuality improvementImpression capsMedical preparationsDenturesGas phase

The invention discloses a denture dyeing process which includes dip-dyeing, drying, color-supplementing, glazing, sintering and vapor-depositing. The denture dyeing process is simple, convenient and reliable, high in operation automation, capable of flexibly adjusting color of dentures and meeting different using needs on the dentures, capable of effectively improving surface quality and structural strength of the dentures and conducive to prolonging service life of the dentures.

Owner:SHENZHEN JIAHONG DENTAL MEDICAL CO LTD

Novel dry distillation method of oil shale

InactiveCN101760218ALess investmentEasy to handleSpecial form destructive distillationCombustionOil shale gas

The invention provides a novel dry distillation method of an oil shale. The existing dry distillation method is of heat accumulation type heating, the temperature and the pressure in a furnace are not stable, resulting in safety accidents easily and low oil yield. In the method, cold gas is introduced into a combustion fire layer in a dry distillation furnace in a circulating way to exchange heat, thereby enabling the temperature in the furnace to be stable, lowering the incidence of the safety accidents and enhancing the oil yield.

Owner:SHANDONG BOAOHUA SHALE OVEN R&D

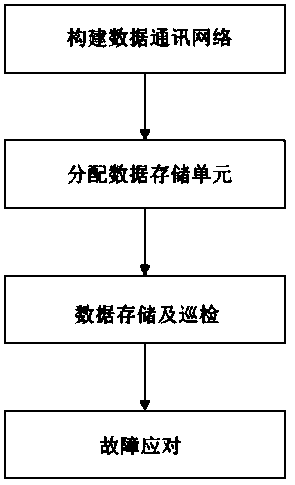

A power big data storage method capable of coping with n-5 storage medium failures

InactiveCN106201361BFound malfunctionImprove failure resilienceInput/output to record carriersData lossComputer science

Owner:南京华魄信息科技有限公司

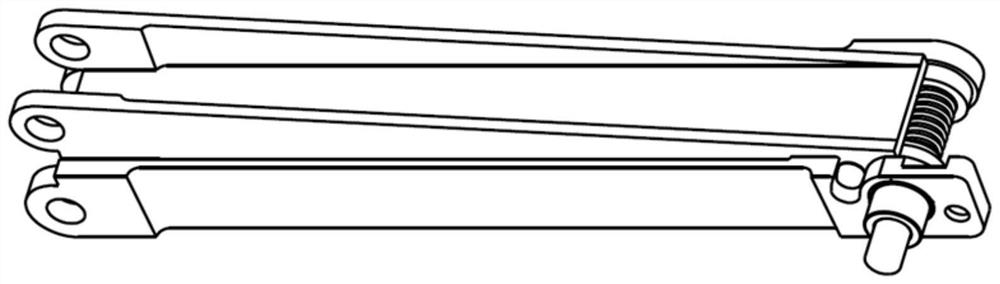

Hinge mechanism capable of being stacked and unfolded and folded and using method

PendingCN114715432AMeet the needs of multiple exhibitionsReliable lockingCosmonautic vehiclesCosmonautic power supply systemsEngineeringStructural engineering

The invention discloses a hinge mechanism capable of being stacked, unfolded and folded and a using method. The head end of an inner hinge rod assembly of each hinge unit in the hinge mechanism is located on the inner side of the tail end of an outer hinge rod assembly and connected through a mandrel. One end of the bolt is fixedly connected with the mandrel; in the unfolding state, the protruding shaft is matched with the inner locking hole and the outer locking hole at the same time, and unfolding locking is achieved. When the unfolding state is converted into the folding state, the mandrel is moved to drive the plug pin to move until the protruding shaft is unmatched with the outer locking hole, and unlocking is achieved; and when the folding state is converted into the unfolding state, the inner hinge rod assembly rotates around the mandrel until the inner locking hole corresponds to the outer locking hole, and the bolt is simultaneously matched with the inner locking hole and the outer locking hole again under the elastic force of the spring. The invention is applied to large spacecrafts such as space stations and satellites, can realize on-orbit multiple unfolding and folding of the solar wing, and can effectively reduce the outer envelope size of the spacecraft launched along with a carrier rocket in a launch state.

Owner:SHANGHAI AEROSPACE SYST ENG INST

Induction hardening device and operation method for brake pressure plate cone socket

ActiveCN107312911BAvoid sharp corner effectSolve the problem that the sensing distance is difficult to controlFurnace typesIncreasing energy efficiencyHuman–machine interfaceInduction hardening

Disclosed are an induction quenching device used for cone sockets of brake platens and an operation method. The induction quenching device comprises a quenching inductor, a revolution assembly, a cabinet body assembly and an electric control cabinet. The front end of the cabinet body assembly is fixedly connected with the quenching inductor, and the brake platens are placed at the upper end of the revolution assembly. In addition, the electric control cabinet is provided with a human-computer interface, a manual / automatic selecting knob and a heating button. A circular pipe is used for manufacturing the single-turn quenching inductor, so that the sharp corner effect is avoided during induction quenching of the cone sockets; the direction-adjustable and interval-adjustable lifting revolution tool assembly is arranged in the device, so that the problem that when induction quenching is conducted on the concave spherical surfaces of the cone sockets on arc surface wrapped with an effective induction coil, the induction interval is difficult to control is solved, the quenched layer is continuous and uniform in distribution, and accordingly the quenching quality is improved; the platens serves as the center for positioning, a height scale is used during induction quenching, and the position is precisely controlled through an index plate, so that the platens are rotationally positioned and heated in the induction quenching process, control over the quenching quality is guaranteed; and the operation method is simple, reliable and easy to carry out.

Owner:FIRST TRACTOR

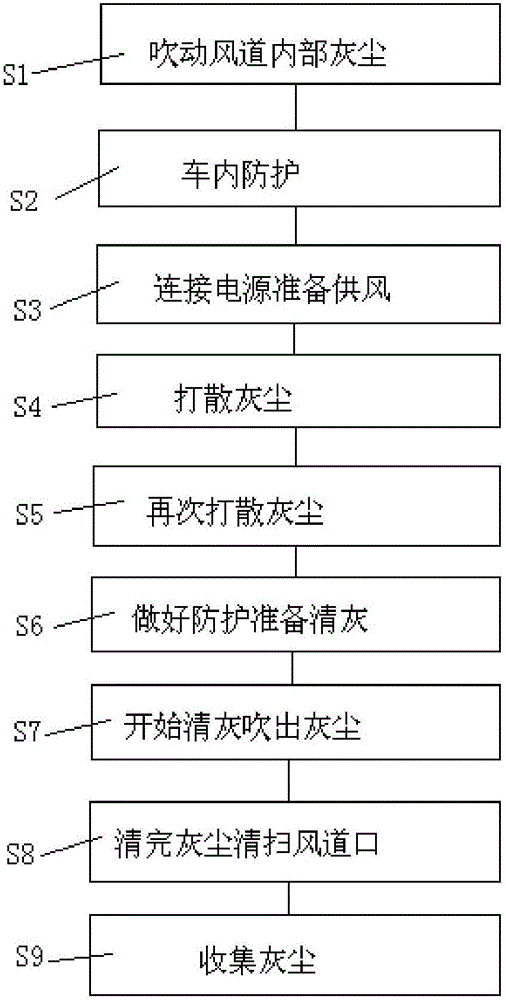

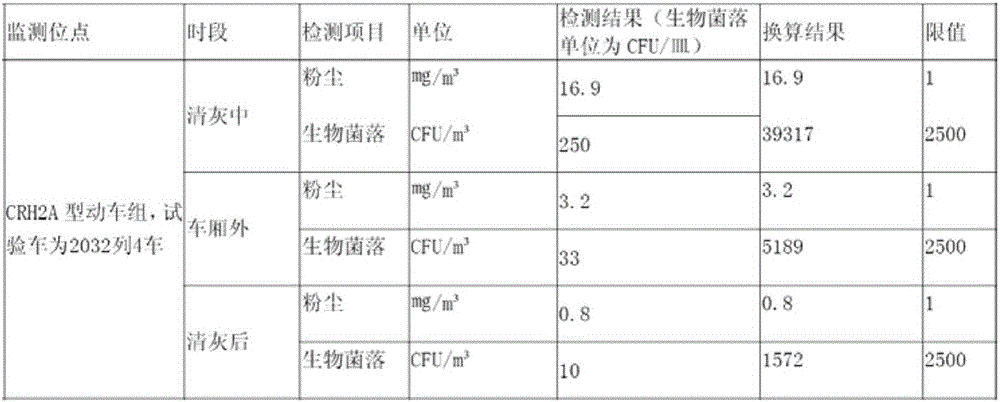

Technological method for cleaning dust in air duct in motor train unit floor

InactiveCN105964631AThe operation method is simple and reliableThe operation method is convenient and effectiveHollow article cleaningEngineeringMechanical engineering

The invention provides a technological method for cleaning dust in an air duct in a motor train unit floor. The technological method comprises the following steps: extending a long air gun into the air duct via an air duct inlet in a motor train unit to blow dust in the air duct; then withdrawing the long air gun, and using cloth bag devices to protect all air return holes in the motor train unit; putting a flexible shaft machine and a dust cleaning device into an air duct inlet below the motor train unit and connecting to an air supply power source; extending the flexible shaft machine from the air duct inlet below the motor train unit, so that a brush of the flexible shaft machine is in contact with the inner surface of an air duct, starting forward-direction rotation to scatter dust in the air duct, and then withdrawing from the air duct inlet; putting the brush of the flexible shaft machine to the air duct inlet below the motor train unit again, and starting reverse-direction rotation to scatter dust; connecting the dust cleaning device with an air duct inlet below the motor train unit at the end I, and plugging an air duct inlet below the motor train unit at the end II with the cloth bag device; starting the dust cleaning device to blow dust; loosening the dust cleaning device from the air duct inlet to clean dust at the air duct inlet; and removing the cloth bag device in the motor train unit and cleaning collected dust. The technological method can be used for cleaning adhesive dirt in the air duct, and the operation method is simple and reliable as well as convenient and effective.

Owner:CRRC QINGDAO SIFANG CO LTD

Process method for producing lead-calcium-cerium alloy based on waste lead grid of waste lead-acid battery

ActiveCN108711652BHigh melting pointEfficient use ofLead-acid accumulatorsWaste accumulators reclaimingElectrolysisCerium

A process method for producing lead calcium cerium alloy on the basis of a waste lead grid mesh of a waste lead-acid storage battery belongs to the field of integral recycling of waste lead-acid storage battery. The process comprises the steps of performing low-temperature melting on the waste lead grid mesh to remove copper, refining to remove impurity, selectively removing antimony and arsenic,adjusting tin content, adding calcium aluminum and rare-earth cerium for alloying, and casting ingot. The indexes such as tensile strength, density, hardness and corrosion resistance of the produced lead calcium cerium alloy are basically consistent with those of lead-based alloy prepared by original electrolytic lead, and the application requirement of storage battery grid alloy is met. The process method has the advantages that the process is simple, is convenient to operate and is high in production efficiency, valuable metal tin in the waste lead grid mesh is effectively utilized, the production cost of lead alloy preparation is reduced, meanwhile, no smoke and no favor are generated during the antimony and arsenic removal process, and the working environment is favorable.

Owner:JIANGSU NEW CHUNXING RESOURCE RECYCLING CO LTD

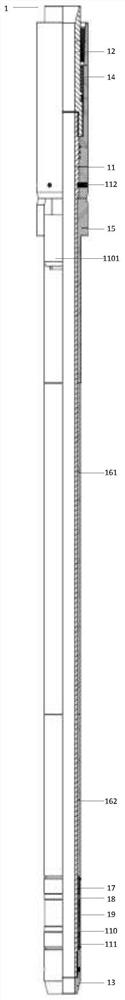

Oil pipe butt joint packer

PendingCN113622862AAvoid damageLow costDrilling rodsSealing/packingButt jointGeotechnical engineering

The invention provides an oil pipe butt joint packer, and relates to the technical field of oil exploitation. The oil pipe butt joint packer comprises an oil pipe joint and a packer body; the oil pipe joint comprises a first end and a second end which are opposite to each other and are used for connecting an upper butt joint oil pipe and the packer body correspondingly; the packer body comprises a mandrel, a long pressing cap and a guiding shoe, wherein the mandrel comprises a first end and a second end which are opposite to each other, and two bosses which are distributed in the circumferential direction and extend in the axial direction are arranged at the position, close to the first end, of the outer circumferential face of the core shaft and used for pressing the upper end face of a lower butt joint oil pipe; the long pressing cap is connected to the first end of the mandrel; the guide shoe is connected to the second end of the mandrel; and a pressing cylinder, an opening pressing sleeve, a spacer bush, an upper auxiliary rubber cylinder, an upper spacer ring, a sealing rubber cylinder, a lower spacer ring and a lower auxiliary rubber cylinder are sequentially sleeved outside the mandrel from the long pressing cap to the guide shoe.

Owner:ANTON OILFIELD SERVICES (GRP) LTD

Electric barring device for wind turbines

ActiveCN108869190BEnsure safetyImprove work efficiencyWind motor assemblyMachines/enginesMotor speedGear wheel

The invention discloses an electric barring device used for a wind generating set. The electric barring device used for the wind generating set comprises a fixing support, a movable base board, a plurality of first connection devices, a motor speed reducer, a control box, a displacement adjusting device, a pinion and a big gear, wherein the fixing support is in a groove shape and comprises a second connection device, a plurality of oblong holes and a threaded hole; a plurality of through holes are formed in the position, corresponding to the oblong holes, of the movable base board; the motor speed reducer is fixed to the movable base board through a third connection device; the displacement adjusting device comprises an adjusting screw rod and a locking nut; the pinion is installed on an output shaft of the motor speed reducer through a fourth connection device; and the big gear is installed on the side face of a brake disc of a high-speed shaft of a gear case of the wind generating set through a fifth connection device. By adjusting the adjusting screw rod, the motor speed reducer can drive the pinion to move up and down in the vertical direction to be engaged with or disengaged from the big gear. The electric barring device used for the wind generating set is safe, reliable, convenient to dismount and mount and good in universality, and improves the work efficiency.

Owner:TAIYUAN HEAVY IND

Operation method of network card MAC address under VxWorks

PendingCN113626094AImprove general performanceThe operation method is simple and reliableProgram loading/initiatingTransmissionConfigfsMaintainability

The invention discloses a method for operating a network card MAC address under VxWorks, and belongs to the technical field of computers. According to the method provided by the invention, a muxIoctl interface function in a VxWorks system kernel is utilized, and an EIOCGADDR command and an EIOCSADDR command of the interface are called to read and rewrite the MAC address of the network card, so that the method has high universality and is suitable for all types of network cards; According to the invention, the operation method is simple, reliable and high in execution efficiency, wherein the automatic setting of the network card MAC address when the VxWorks system is started can be completed by setting / modifying the script and the configuration file, separation of MAC address setting / modifying and program codes is achieved, and the maintainability of the system is greatly improved.

Owner:TIANJIN JINHANG COMP TECH RES INST

Preparation method of nanoparticle line array resistor

ActiveCN108648890BEasy transferAchieving controllable equipmentResistor manufactureFemto second laserScanning electron microscope

Owner:GUANGZHOU UNIVERSITY

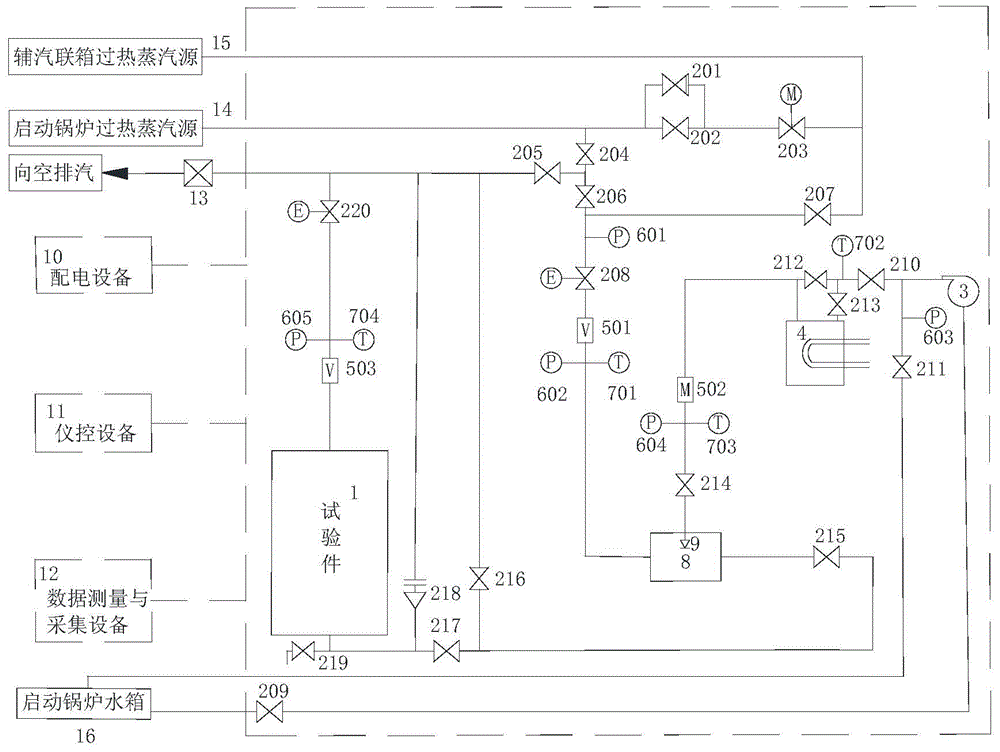

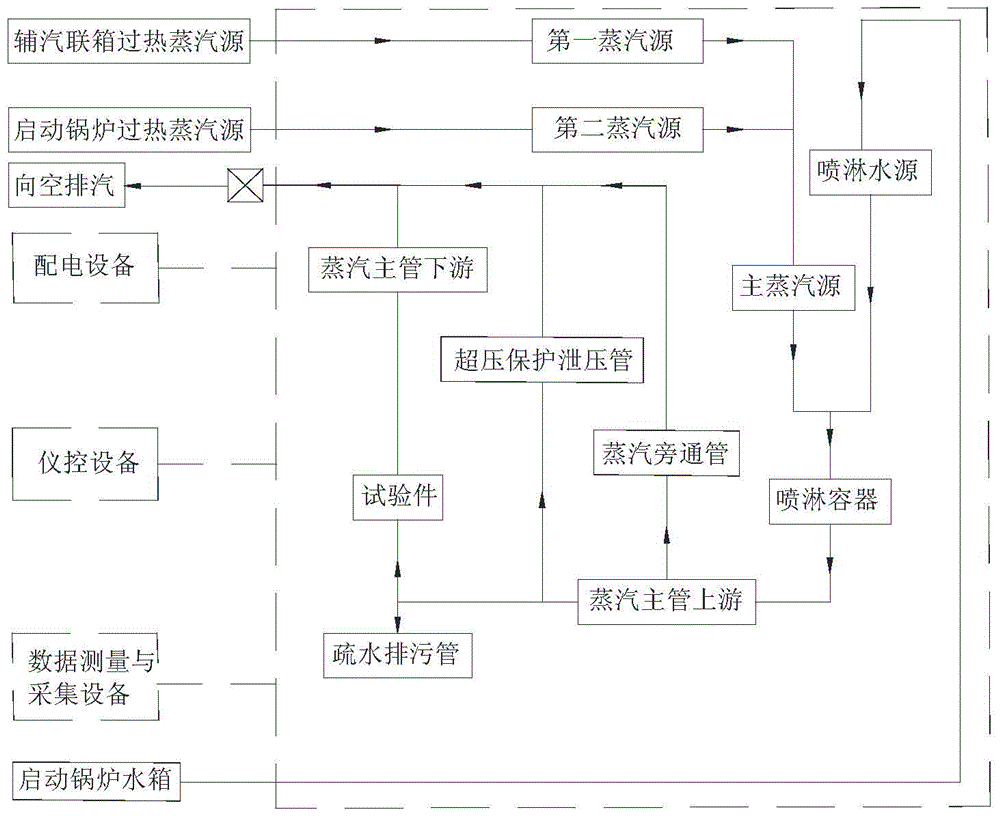

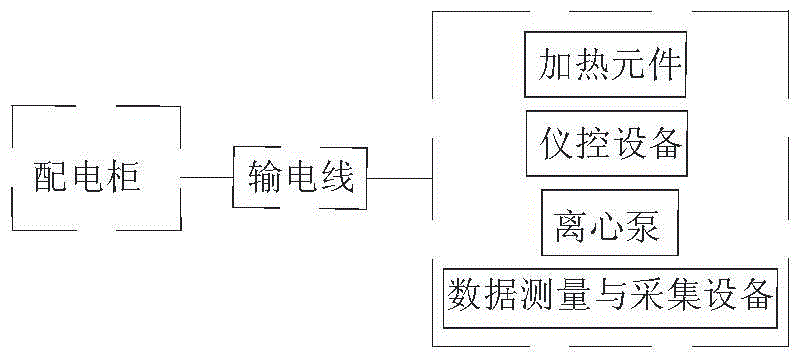

A large-scale steam test system and method based on auxiliary steam system of thermal power plant

ActiveCN104633451BTroubleshooting Superheated Steam SourcesImprove creativityPipeline systemsWater sourceEngineering

A large-scale steam test system and method based on the auxiliary steam system of a thermal power plant, the system includes a first steam source connected to the auxiliary steam header pipeline, a second steam source connected to the startup boiler pipeline, and the first steam source and the second steam source The main steam source where the steam source pipes merge together, the spray water source connected to the start-up boiler water tank, the spray container that connects the main steam source pipe and the spray water pipe, the steam main upstream that connects the spray container and the test piece, The steam bypass pipe connecting the spray container and the start-up boiler to the empty steam exhaust pipe, the downstream of the steam main pipe connecting the test piece and the start-up boiler to the empty steam exhaust pipe, and the super bypass pipe connecting the upstream of the steam main pipe and the empty steam exhaust pipe The pressure protection pressure relief pipe is located at the lowest level of the test piping system and is a drain pipe composed of traps and pipes; the present invention also provides a test method; the present invention uses the auxiliary steam system of the existing thermal power plant to provide large-scale thermal-hydraulic tests. High pressure and large flow can adjust the test steam.

Owner:XI AN JIAOTONG UNIV

A method for rapidly cooling scrapped nylon sleeves in concrete pillows

InactiveCN102995509BIntegrity guaranteedHigh strengthRailway track constructionScrew threadDrill bushing

The invention discloses a method for rapidly cold-extracting a scrapped nylon sleeve in a concrete sleeper and a special drill jig. The method comprises the following steps of: adopting a stepwise working method, namely, drilling a plurality of key slots in the inner wall of the scrapped nylon sleeve at first, and then clamping wedges in the inner cavity of the scrapped nylon sleeve along the plurality of key slots, then locking the wedges by a torque wrench to loosen the scrapped nylon sleeve relative to the concrete sleeper until the scrapped nylon sleeve is unscrewed out of the concrete sleeper. The special drill jig is provided with a drill jig body, wherein drill bushings are arranged on the drill jig body; and the special drill jig is characterized in that the drill bushings are uniformly distributed on the drill jig body, a location boss matched with an unthreaded hole in the upper part of the inner cavity of the nylon sleeve extends outwards from one side of the drill jig body, a guide rod inserted in the inner cavity of the nylon sleeve extends from the location boss, and arc-shaped grooves concentric with the drill bushings are formed in the periphery of the guide rod. The whole operation method is simple and reliable, and free from damages on cement internal threads in the nylon sleeve and the concrete sleeper, thus guaranteeing time-saving, labour-saving and high-efficiency replacement of a new nylon sleeve.

Owner:NANYANG INST OF TECH

Process method for producing high-tin-lead-calcium alloy by using waste lead-acid battery waste lead grid

ActiveCN108728648BHigh melting pointEfficient use ofWaste accumulators reclaimingProcess efficiency improvementElectrolysisAlloy

Owner:JIANGSU NEW CHUNXING RESOURCE RECYCLING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com