Oil pipe butt joint packer

A technology for packers and tubing joints, applied in the direction of sealing/packing, drilling pipes, casings, etc., which can solve problems such as failure of stimulation operations, failure of hanging packers, and lack of sealing at joints, etc. Simple and reliable, reduced tool cost, and low processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

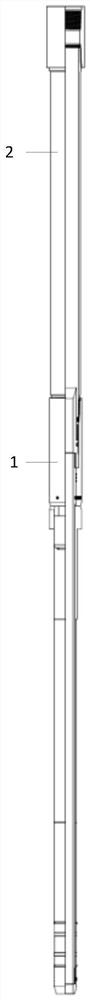

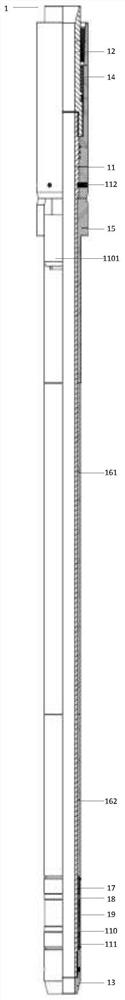

[0047] Reference attached figure 1 - attached Figure 21 , Embodiment 1 of the present invention proposes a tubing butt joint packer, which includes: a tubing joint 2 and a packer body 1; the tubing joint 2 includes opposite first ends and second ends, respectively used to connect the upper Butt the oil pipe and the packer body 1; the packer body 1 includes: a mandrel 11, the mandrel 11 includes opposite first ends and second ends, and the outer peripheral surface of the mandrel 11 is close to The position of the first end is provided with two bosses 1101 distributed in the circumferential direction and extending in the axial direction, which are used to press the upper end surface of the lower butt joint oil pipe 3; the long pressing cap 12 is connected to the mandrel The first end of 11; guide shoes 13, connected to the second end of the mandrel 11; the outside of the mandrel 11 is sequentially sleeved with Compression cylinder 14, opening pressure sleeve 15, spacer sleeve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com