Denture dyeing process

A denture and process technology, applied in the field of denture dyeing process, can solve the problems of denture structural strength and surface quality poor, secondary dyeing, fading, etc., to improve the surface quality and structural strength, simple and reliable operation method, high degree of operation automation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

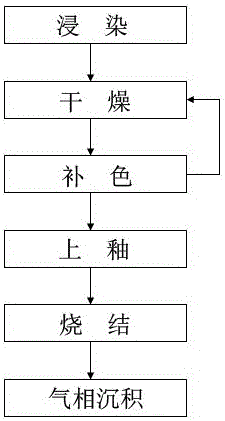

[0017] like figure 1 Shown, a kind of denture dyeing process comprises the steps:

[0018] The first step is dip dyeing. Soak the denture base in the dyeing solution, let it sit for 10 seconds, take it out of the dyeing solution and use the liquid absorbent material to absorb and wipe off the excess dyeing solution on the surface of the denture base. The temperature of the dyeing solution is 30°C ;

[0019] The second step is drying. The denture base treated in the first step is forced to ventilate and dry, where the air velocity is 5m / s and the air temperature is -10°C;

[0020] The third step, color complementing, checks the color of the denture base after drying, and performs color complementing treatment with a porcelain pen on the position where there is color difference after drying, and then returns to the second step for drying until the color of the denture base is unified;

[0021] The fourth step is glazing. The outer surface of the denture base treated in the thi...

Embodiment 2

[0025] A denture dyeing process, comprising the steps of:

[0026] The first step is dip dyeing. Soak the denture base in the dyeing solution, let it sit for 25 seconds, take it out of the dyeing solution and use the liquid absorbent material to absorb and wipe off the excess dyeing solution on the surface of the denture base. The temperature of the dyeing solution is 50°C ;

[0027] The second step is drying. The denture base treated in the first step is forced to ventilate and dry, where the air velocity is 8m / s and the air temperature is 50°C;

[0028] The third step, color complementing, checks the color of the denture base after drying, and performs color complementing treatment with a porcelain pen on the position where there is color difference after drying, and then returns to the second step for drying until the color of the denture base is unified;

[0029] The fourth step is glazing. The outer surface of the denture base treated in the third step is glazed, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com