A large-scale steam test system and method based on auxiliary steam system of thermal power plant

A technology for test systems and thermal power plants, applied in pipeline systems, mechanical equipment, gas/liquid distribution and storage, etc., can solve problems such as no measurement of steam enthalpy, inability to achieve stability, and inability to meet the steam requirements of large-scale steam tests. Achieve the effects of simple and reliable overall system design, simple and reliable operation method, and safe and efficient operation results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

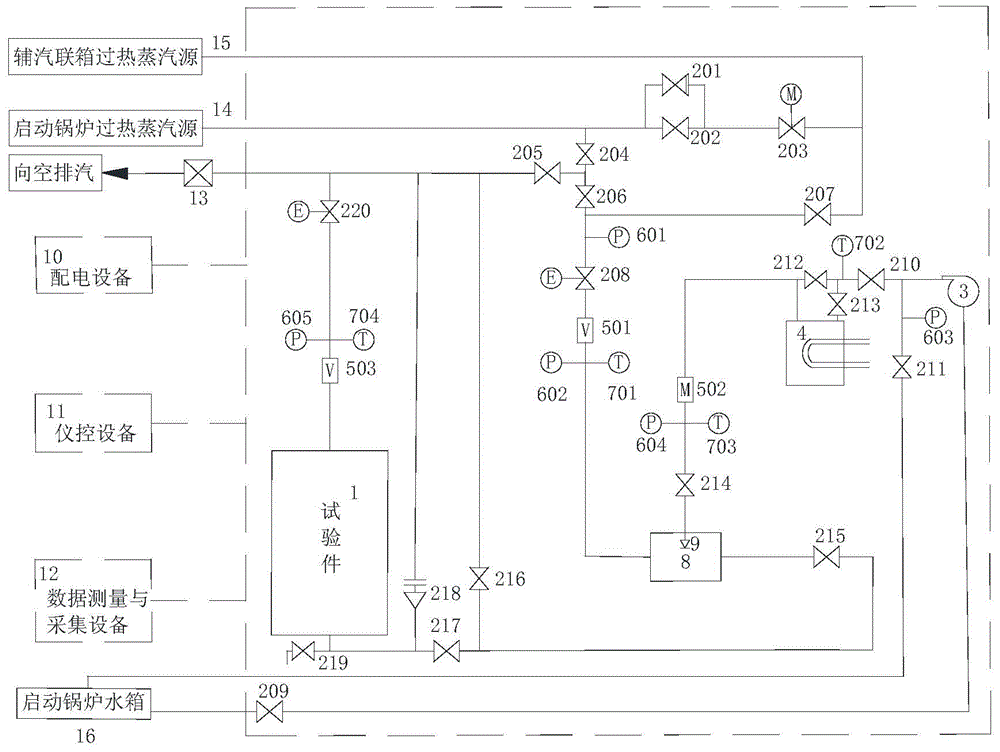

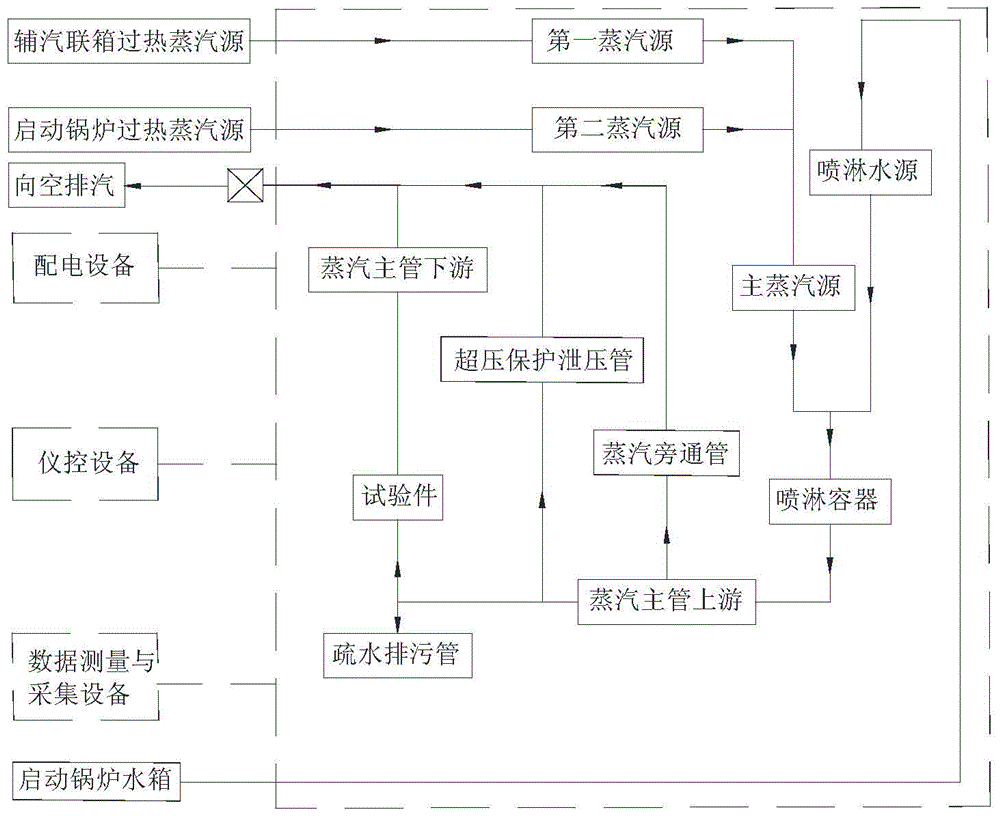

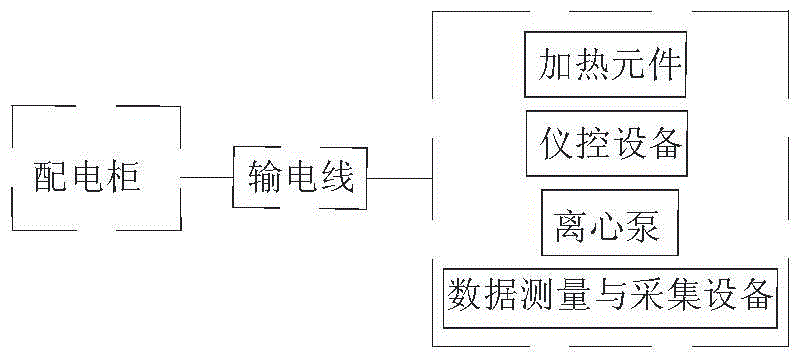

[0034] Such as figure 1 with figure 2 As shown, the present invention is a large-scale steam test system based on the auxiliary steam system of a thermal power plant, including the first steam source connected to the pipeline behind the check valve 201, the first valve 202, and the electric valve 203 of the boiler superheated steam source 14 Valve 207, the first steam source valve 207 communicates with the superheated steam source 15 of the auxiliary steam header, forming the first steam source of the system; the second valve 205 installed behind the valve 204 of the exhaust steam pipe of the boiler superheated steam source 14 , the second steam source valve 206 installed on the pipeline between the empty steam exhaust pipe valve 204 and the second valve 205, the empty steam exhaust pipe valve 204 and the second steam source valve 206 communicated with the starting boiler superheated steam source 14 , forming the second steam source of the system; connected by pipelines, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com