Inductive heat treatment method of low-speed large-torque drive axle

A technology of induction heat treatment, low speed and high torque, applied in heat treatment furnaces, heat treatment equipment, heat treatment process control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

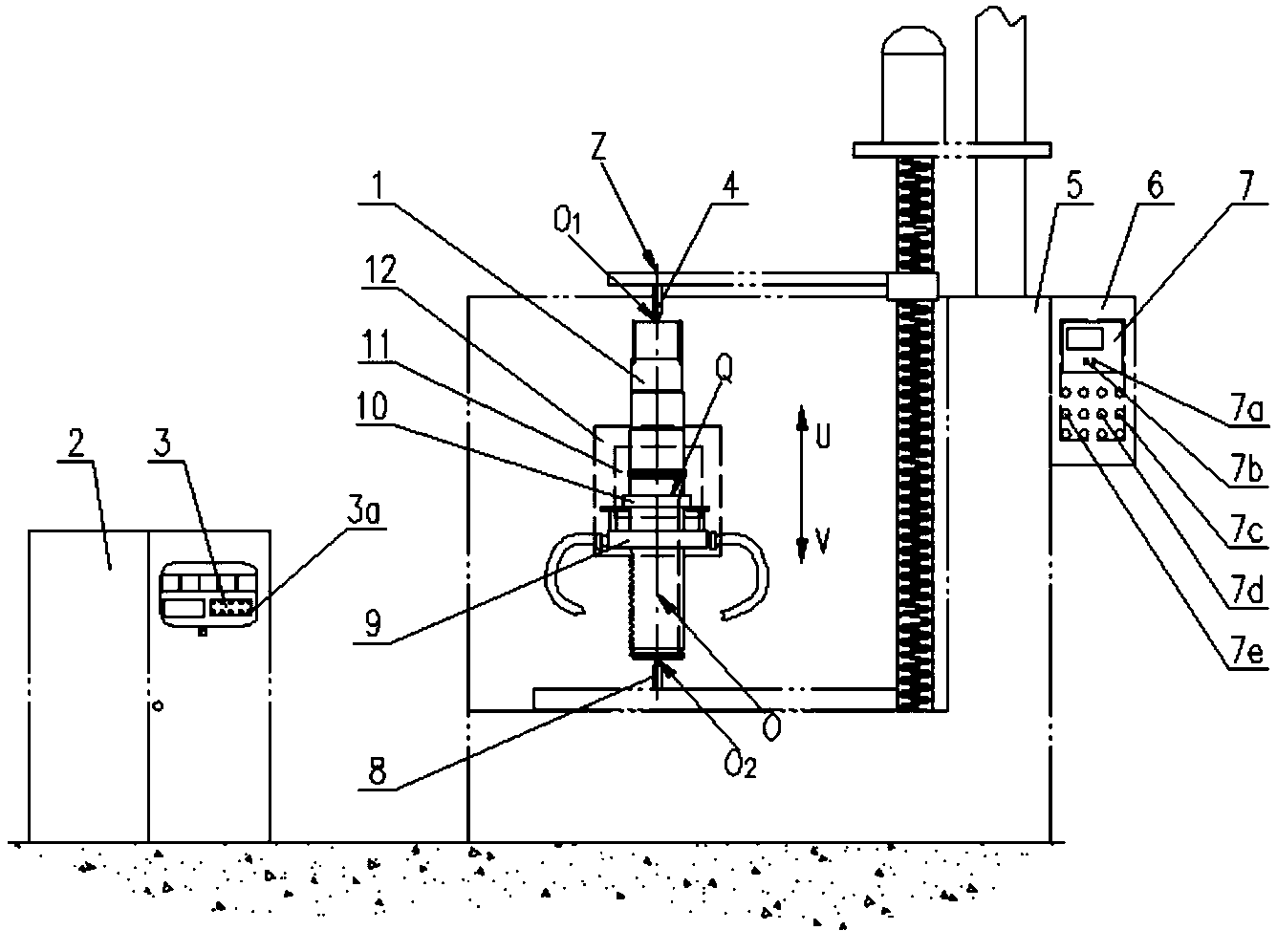

Method used

Image

Examples

Embodiment

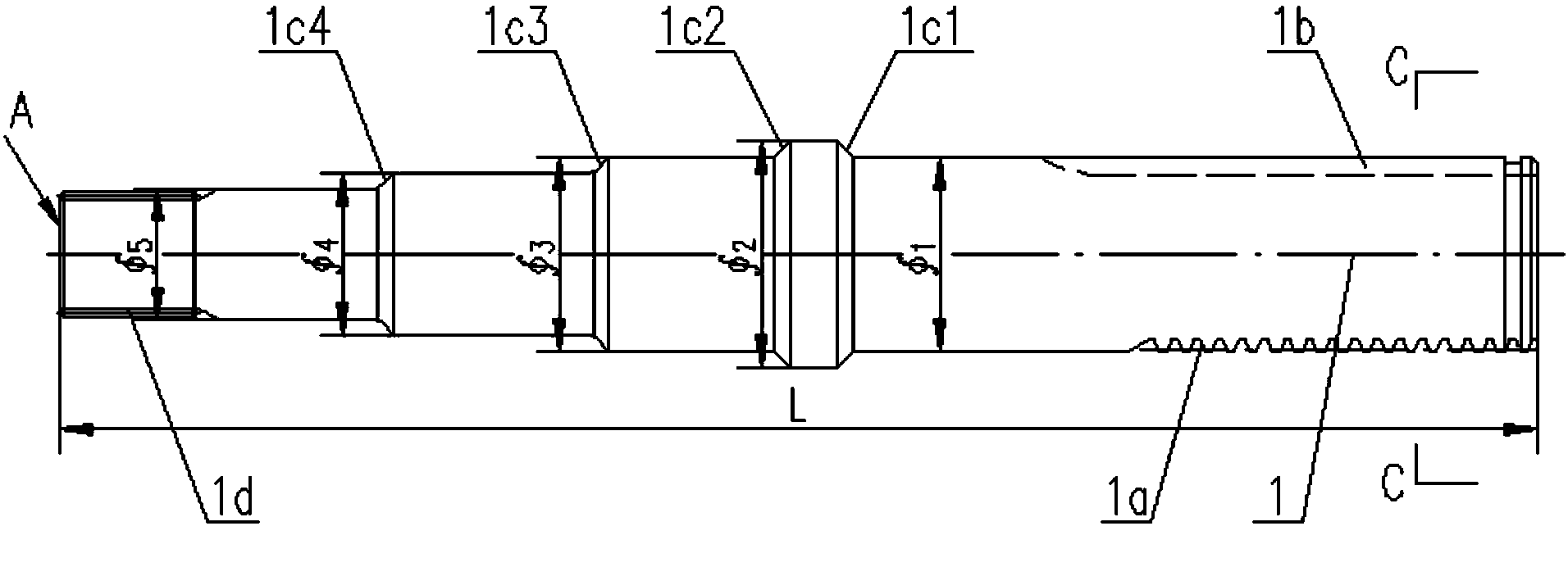

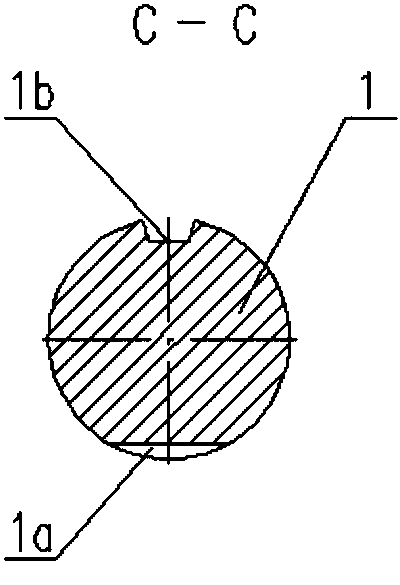

[0132] Drive axle 1 is the low-speed high-torque drive axle of 160 horsepower wheeled tractor, by figure 1 , figure 2 It is known that the driving wheel shaft 1 has several structural types such as a rack 1a, a keyway 1b, a first step 1c1, a second step 1c2, a third step 1c3, a fourth step 1c4 and a spline 1d, and the size of the parts is relatively large. Large, and the rack 1a and the keyway 1b are in the same shaft section, the overall length dimension L is 925mm, and the shaft diameter dimension of the keyway section∮ 1 95mm, the shaft diameter dimension of the first stage stage∮ 2 is 100mm, the shaft diameter dimension of the second stage stage∮ 3 95mm, the shaft diameter dimension of the third stage stage∮ 4 94mm, the shaft diameter dimension of the fourth stage stage∮ 5 is 90mm.

[0133] The material of the driving wheel shaft 1 is 42CrMo, and the depth of the hardened layer in each area is: the bottom of the rack 1a ≥ 2mm; the bottom of the keyway 1b ≥ 2mm; the d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com