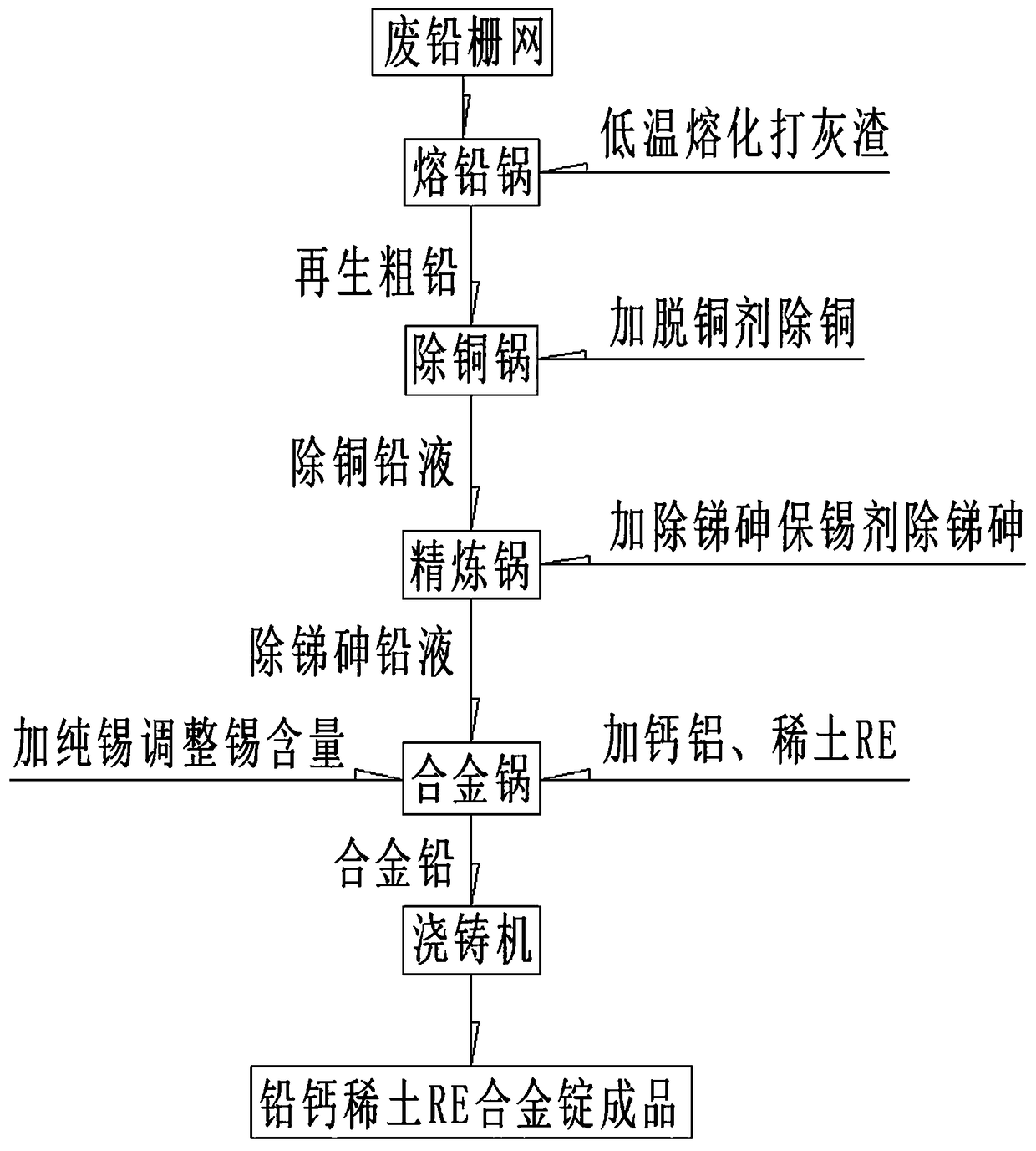

Technological method for producing lead-calcium rare earth alloy based on waste lead grid mesh of waste lead-acid batteries

A technology of waste lead-acid batteries and rare earth alloys, which is applied in battery recycling, process efficiency improvement, waste collector recycling, etc. It can solve the problems of not being able to use metal tin in waste lead grids, etc., and achieve good reaction effect and simple operation , The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Example 1: The waste lead grid is melted at 420±20°C in the melting pot, and the lead liquid is pumped into the copper removal pot with a lead pump after the ash is removed, and the sampling spectrum is analyzed. The composition: Sb 0.112%, As 0.0072%, Sn 0.61 %, Cu 0.011%, Bi 0.0038%, Ag0.00068%, Pb balance; heat up to 500±20°C, add sulfur and pyrite powder mixture to remove copper, of which weight percentage, sulfur 13%, pyrite powder 87%, sampling direct reading spectroscopic analysis, the composition is as follows: Sb 0.098%, As 0.0069%, Sn 0.595%, Cu 0.0005%, Bi 0.0038%, Ag 0.00069%, Pb balance.

[0038] After the ash and slag are crushed, the copper and lead liquid is pumped into the refining pot with a lead pump.

[0039] Raise the temperature of the copper and lead removal solution in the refining pot to 560±20°C, calculate the amount of antimony, arsenic and tin retention agent used as 1.3 times the total amount of antimony and arsenic, turn on the mixer, stir th...

Embodiment 2

[0043] Example 2: The waste lead grid is melted in the melting pot at 410±20°C. After the ash is removed, the lead liquid is pumped into the copper removal pot with a lead pump, and the sampling spectrum is analyzed. The composition: Sb 0.152%, As 0.011%, Sn 0.70 %, Cu 0.008%, Bi 0.0037%, Ag0.00068%, Pb balance; heating up to 480±20°C, adding pyrite powder to remove copper, sampling direct reading spectral analysis, the composition is as follows: Sb 0.150%, As 0.011 %, Sn 0.70%, Cu 0.0005%, Bi 0.0037%, Ag 0.00068%, Pb balance.

[0044] After the ash and slag are crushed, the copper and lead liquid is pumped into the refining pot with a lead pump.

[0045] Raise the temperature of the copper and lead removal solution in the refining pot to 570±20°C, calculate the amount of antimony, arsenic and tin retention agent used as 1.2 times the total amount of antimony and arsenic, turn on the mixer, stir the lead solution to generate a vortex, and the input speed should not affect the ...

Embodiment 3

[0050] Example 3: The waste lead grid is melted in the melting pot at 380±20°C, and the lead liquid is pumped into the copper removal pot with a lead pump after the ash is removed, and the sampling spectrum is analyzed. The composition: Sb 0.085%, As 0.011%, Sn 0.51 %, Cu 0.008%, Bi 0.004%, Ag0.00078%, Pb balance; cool down to 360±20°C, add red phosphorus to remove copper, sample direct reading spectrum analysis, the composition is as follows: Sb0.083%, As 0.011%, Sn 0.492%, Cu 0.0005%, Bi 0.004%, Ag 0.00078%, Pb balance;

[0051] After the ash and slag are crushed, the copper and lead liquid is pumped into the refining pot with a lead pump.

[0052] Raise the temperature of the copper and lead removal solution in the refining pot to 570±20°C, calculate the amount of antimony, arsenic and tin retention agent used as 1.5 times the total amount of antimony and arsenic, turn on the mixer, stir the lead solution to produce a vortex, and the input speed should not affect the vortex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com