Preparation method of cell-entrapped ultrathin cavity composite microfiber material

A technology of microfibers and cells, applied in the manufacture of hollow filaments, fiber chemical characteristics, cellulose/protein conjugated artificial filaments, etc., can solve problems such as shortage of organ supply, ethical disputes and constraints of immune rejection, etc., and achieve simple operation methods The effect of reliability, high efficiency and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

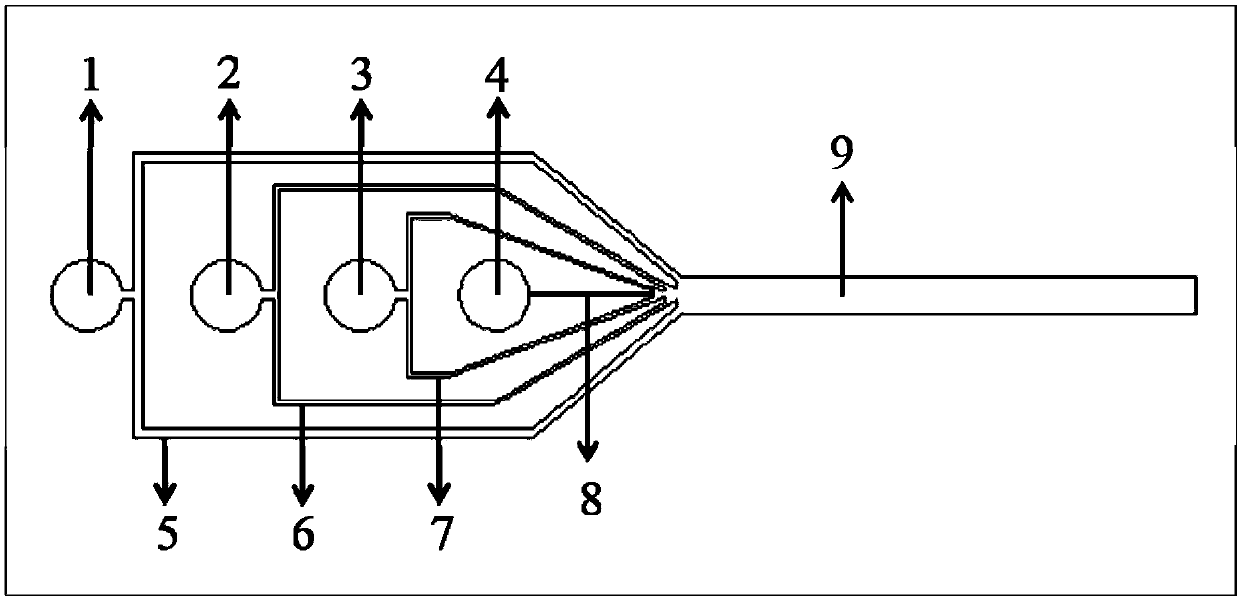

Image

Examples

Embodiment 1

[0058] A solution containing NaCl and sodium alginate is used as the sample fluid in advance; wherein the mass volume concentration of NaCl is 0.85% g / ml, and the mass volume concentration of sodium alginate is 1% g / ml;

[0059] Methylcellulose with a mass volume concentration of 2% g / ml is used as an inert fluid;

[0060] Prepare a chitosan solution with a mass volume concentration of 4% g / ml with a volume concentration of 2% acetic acid as a modification fluid; or mix chitosan and methylcellulose to obtain methylcellulose solutions containing different chitosan concentrations as a modifying fluid;

[0061] Contains Sucrose and CaCl 2 The solution is used as a sheath fluid; the mass volume concentration of sucrose is 3% g / ml, CaCl 2 The mass volume concentration of 1% g / ml;

[0062] Using a microfluidic chip, the ultra-clean table was irradiated with ultraviolet light for more than 2 hours in advance, and then the cavity composite microfiber material embedded with cells wa...

Embodiment 2

[0066] A solution containing NaCl and sodium alginate is used as the sample fluid in advance; wherein the mass volume concentration of NaCl is 0.85% g / ml, and the mass volume concentration of sodium alginate is 2% g / ml;

[0067] Methylcellulose with a mass volume concentration of 3% g / ml is used as an inert fluid;

[0068] Prepare a chitosan solution with a mass volume concentration of 5% g / ml with a volume concentration of 2.5% acetic acid as a modification fluid; or mix chitosan and methylcellulose to obtain methylcellulose solutions containing different chitosan concentrations as a modifying fluid;

[0069] Contains Sucrose and CaCl 2 The solution is used as a sheath fluid; the mass volume concentration of sucrose is 3% g / ml, CaCl 2 The mass volume concentration of 1% g / ml;

[0070] Using a microfluidic chip, the ultra-clean table was irradiated with ultraviolet light for more than 2 hours in advance, and then the cavity composite microfiber material embedded with cells ...

Embodiment 3

[0074] A solution containing NaCl and sodium alginate is used as the sample fluid in advance; wherein the mass volume concentration of NaCl is 0.85% g / ml, and the mass volume concentration of sodium alginate is 5% g / ml;

[0075] Methylcellulose with a mass volume concentration of 5% g / ml is used as an inert fluid;

[0076] Prepare a chitosan solution with a mass volume concentration of 10% g / ml with a volume concentration of 5% acetic acid as a modification fluid; or mix chitosan and methylcellulose to obtain methylcellulose solutions containing different chitosan concentrations as a modifying fluid;

[0077] Contains Sucrose and CaCl 2 The solution is used as a sheath fluid; the mass volume concentration of sucrose is 3% g / ml, CaCl 2 The mass volume concentration of 4% g / ml;

[0078] Using a microfluidic chip, the ultra-clean table was irradiated with ultraviolet light for more than 2 hours in advance, and then the cavity composite microfiber material embedded with cells w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com