Carbon negative electrode material for sodium ion battery and preparation method of carbon negative electrode material

A carbon negative electrode material and sodium-ion battery technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as low degree of graphitization, weak sodium storage capacity, and mismatched layer spacing, achieving good repeatability and low cost. Inexpensive, well-sourced effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] First weigh 3.0kg of gelatin and dissolve it in 5L of deionized water, heat it to 80°C with stirring in an oil bath to form a transparent gelatin solution; then weigh 1.36kg of zinc chloride, 0.15kg of N-methylpyrrolidone, 0.81 kg of nickel chloride was dissolved in water to form a solution; the latter was slowly added to the gelatin solution under magnetic stirring conditions, and after stirring evenly, the resulting mixed solution was sprayed and pyrolyzed at 900°C; the obtained pyrolysis product was used Washed with ion water and alcohol, placed under the temperature condition of 80° C., and vacuum-dried for 10 hours to obtain a composite structure carbon negative electrode material.

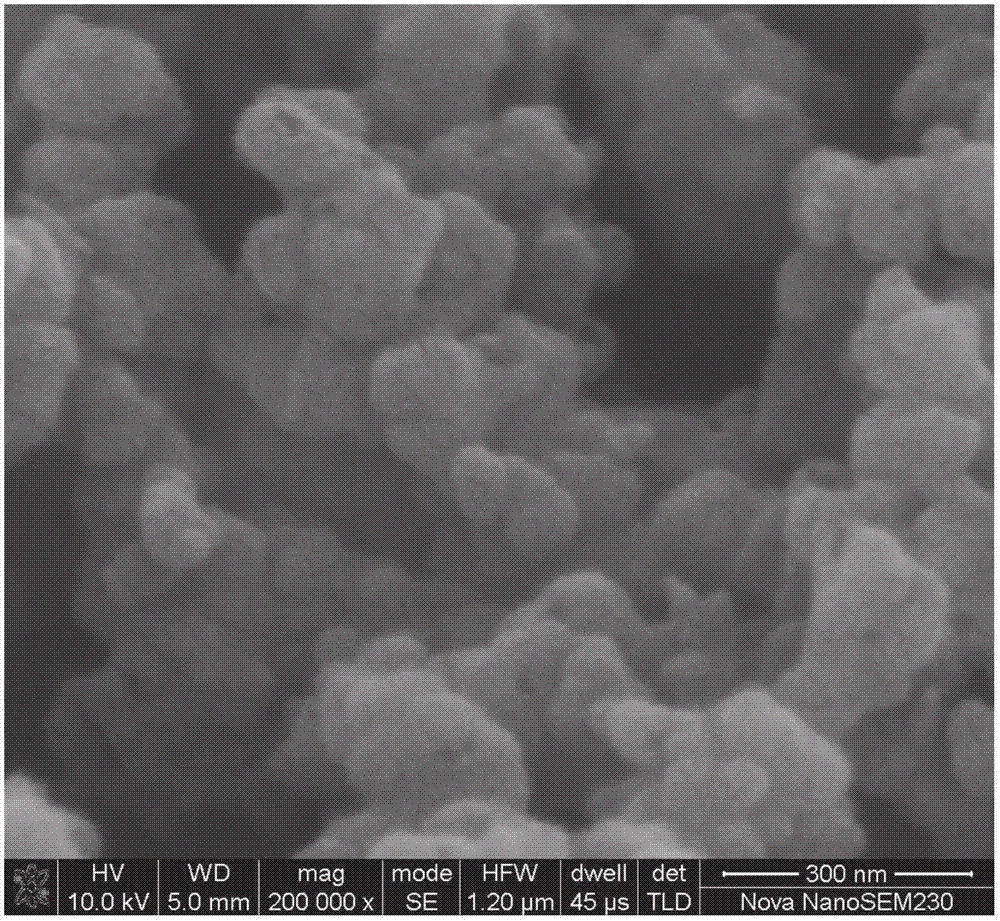

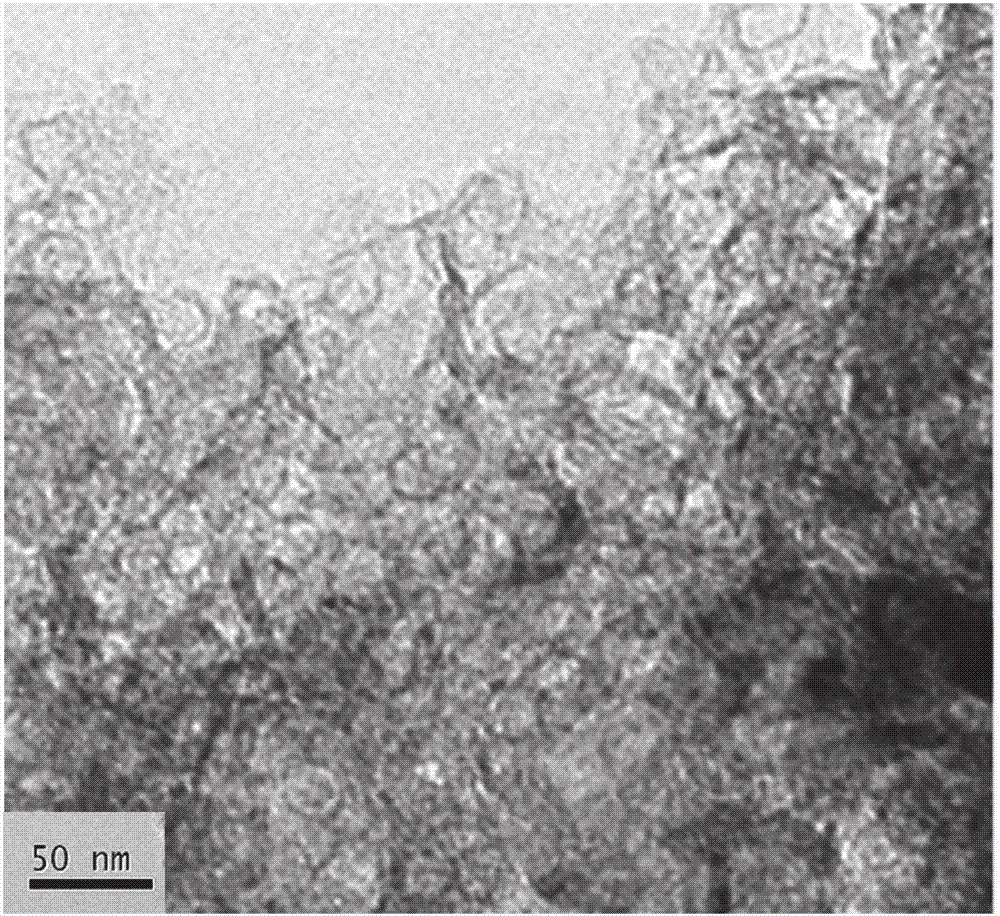

[0058] The nickel carbonate nano-electrode material of the sodium ion battery prepared in this example and the sodium sheet are assembled into a button battery, and its material structure characterization and electrochemical performance are shown in the figure:

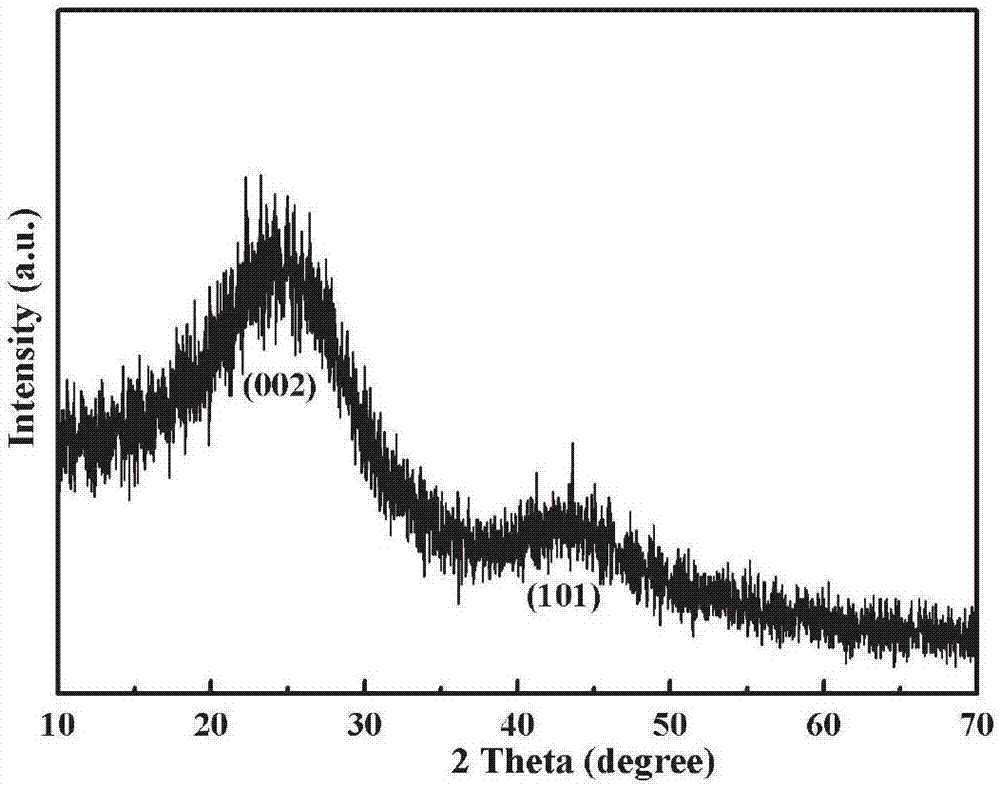

[0059] figure 1 The c...

Embodiment 2

[0065] First weigh 3.0kg of gelatin and dissolve it in 5L of deionized water, heat it to 80°C with stirring in an oil bath to form a transparent gelatin solution; then weigh 1.02kg of zinc chloride, 0.1kg of N-methylpyrrolidone, 0.60 kg of nickel chloride was dissolved in water to form a solution; the latter was slowly added to the gelatin solution under magnetic stirring conditions, and after stirring evenly, the resulting mixed solution was sprayed and pyrolyzed at 1000°C; the obtained pyrolysis product was used Washed with ion water and alcohol, placed at 80° C., and vacuum-dried for 12 hours to obtain a carbon negative electrode material with a composite structure.

[0066] The composite structure carbon negative electrode material prepared by this method is a loose, porous, spherical material with a rough surface, wherein the carbon composite nanoparticle (the composite structure carbon negative electrode material prepared in this embodiment) has a size of 120-600 nm.

[...

Embodiment 3

[0069] First weigh 3.0kg of gelatin and dissolve it in 5L of deionized water, heat it to 80°C under stirring in an oil bath to form a transparent gelatin solution; then weigh 1.02kg of zinc chloride, 0.1kg of N-methylpyrrolidone, 0.81 kg of nickel chloride was dissolved in water to form a solution; the latter was slowly added to the gelatin solution under magnetic stirring conditions, and after stirring evenly, the resulting mixed solution was sprayed and pyrolyzed at 800°C; the obtained pyrolysis product was used Washed with ion water and alcohol, placed at 80° C., and vacuum-dried for 8 hours to obtain a composite structure carbon negative electrode material.

[0070] The composite structure carbon negative electrode material prepared by this method is a loose, porous, spherical material with a rough surface, wherein the carbon composite nanoparticle (the composite structure carbon negative electrode material prepared in this embodiment) has a size of 100-800 nm.

[0071] Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com