Method for rapidly cold-extracting scrapped nylon sleeve in concrete sleeper and special drill jig

A nylon casing, fast technology, applied in the direction of laying tracks, roads, tracks, etc., can solve the problems of operational safety threats, easy damage to cement threads, and low sleeve extraction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

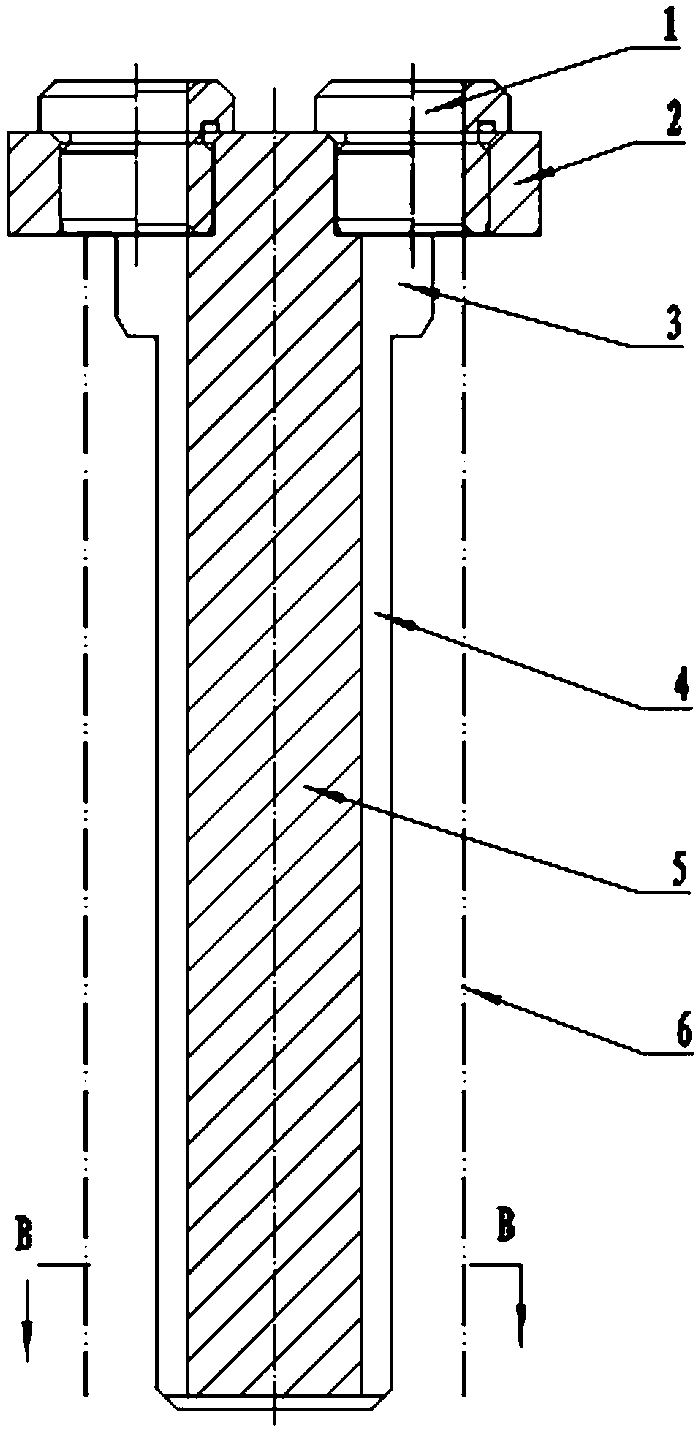

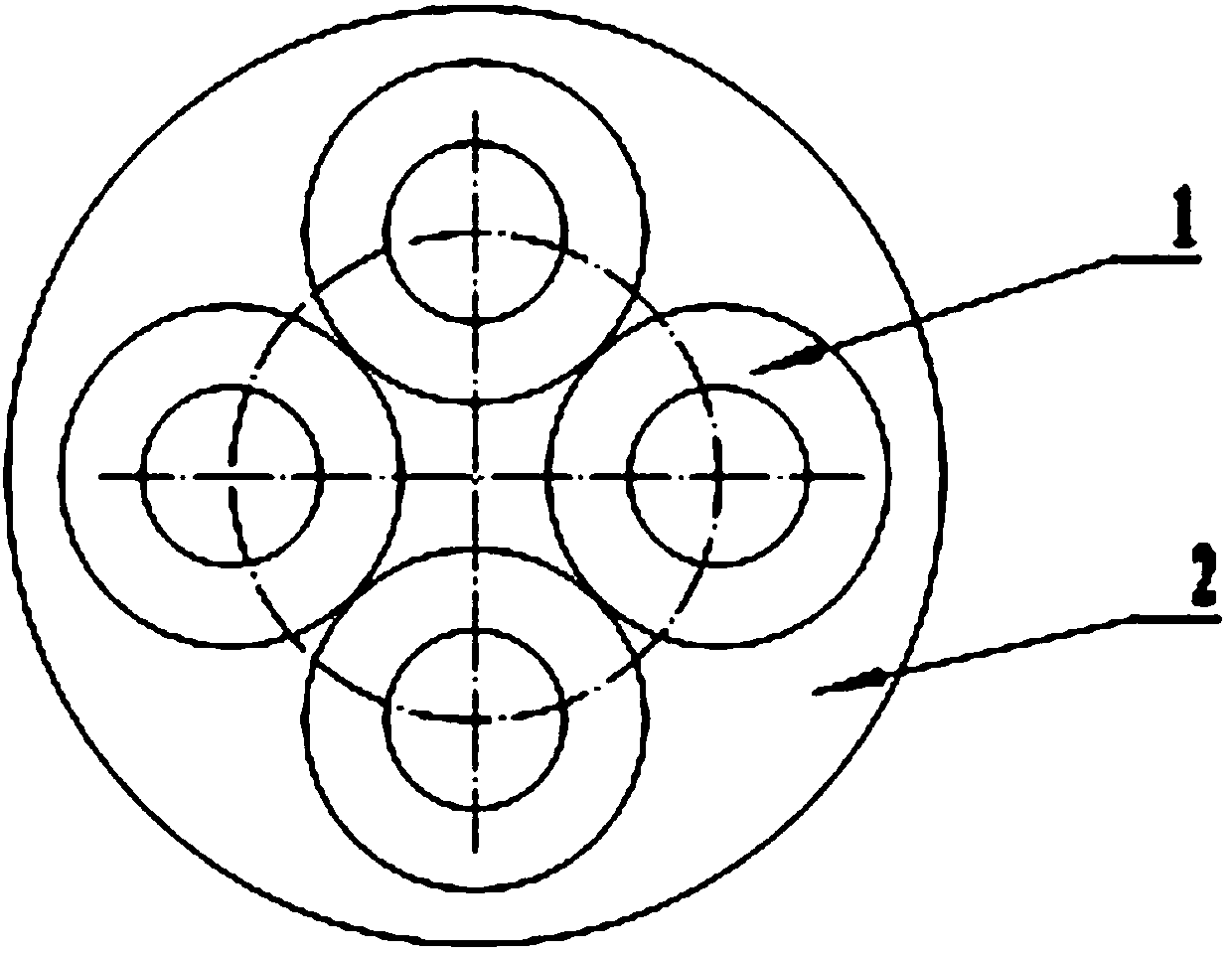

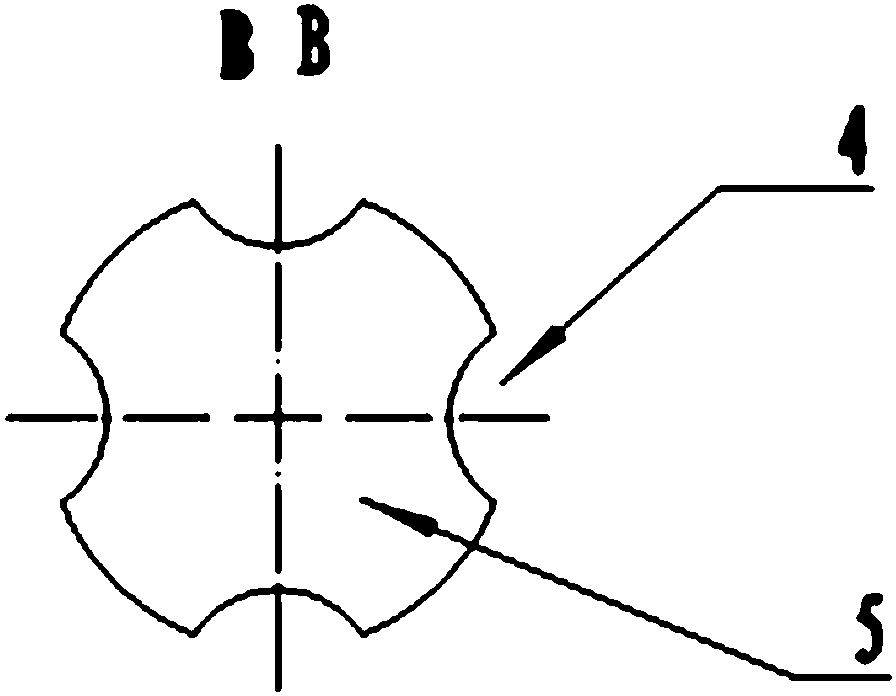

[0021] Such as figure 1 , 2 , The special drilling jig shown in 3 and 4 for quick cold extraction of scrapped nylon sleeves in concrete pillows has a disc-shaped jig body 2, four drill sleeves 1 are evenly arranged on the jig body, and one side of the jig body faces outward. There is a positioning boss 3 that matches the light hole on the upper part of the inner cavity of the nylon sleeve 8. The positioning boss 3 is extended with a guide rod 5 that is inserted into the inner cavity of the nylon sleeve 8. The outer circumference of the guide rod is provided with an arc-shaped concave hole that is concentric with the drill sleeve. Slot 4. The diameter of the guide rod matches the diameter of the inner cavity of the nylon sleeve, and the diameter 6 of the circumscribed circle of the arc groove of the guide rod is smaller than the minor diameter of the outer arc thread of the nylon sleeve. The end of the guide rod is tapered for easy insertion.

[0022] A method for quickly co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com