Preparation method of ultrathin cavity composite microfiber material based on microfluidic technology

A microfluidic technology and microfiber technology, which is applied in the field of preparation of ultra-thin cavity composite microfiber materials, can solve problems such as difficult to achieve large-scale preparation and limit the mixing of large flow rates, and achieve novel material structure and preparation The method is simple and the effect of great application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Sodium alginate with a mass volume concentration of 1% g / ml is used as the sample fluid in advance; methyl cellulose with a mass volume concentration of 2% g / ml is used as an inert fluid; acetic acid with a volume percentage of 1.5% is prepared with a mass volume concentration of 3% g / ml chitosan solution as a modification fluid, or chitosan and methylcellulose are mixed to obtain methylcellulose solutions containing different chitosan concentrations as a modification fluid; mass volume concentration 0.5% g / mlCaCl 2 as a sheath fluid;

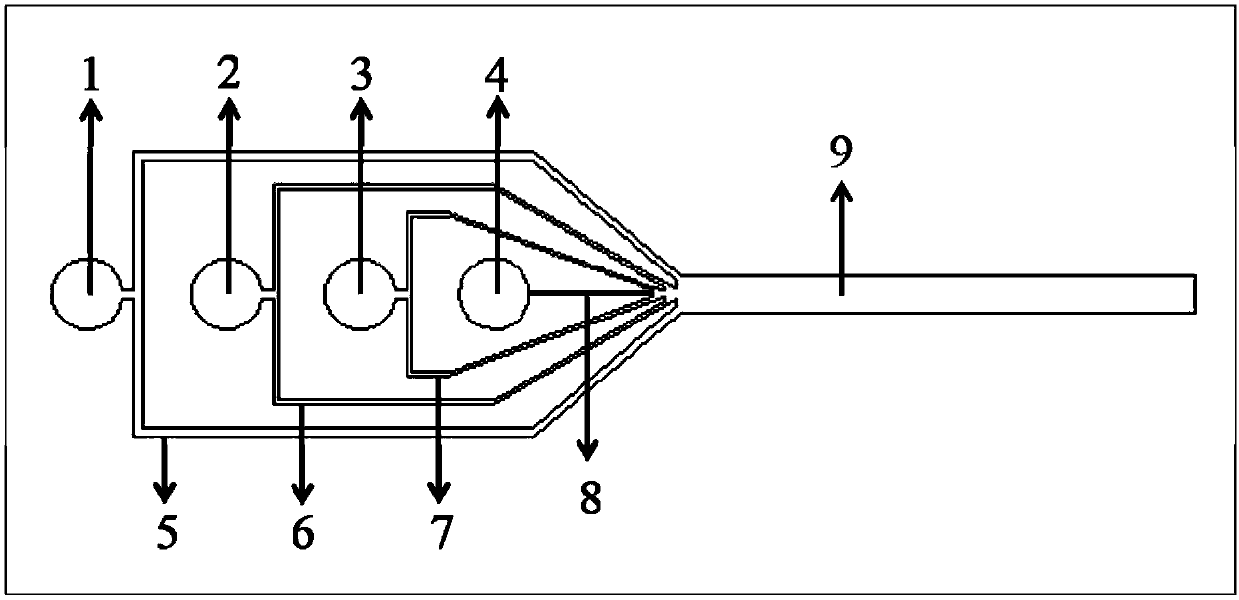

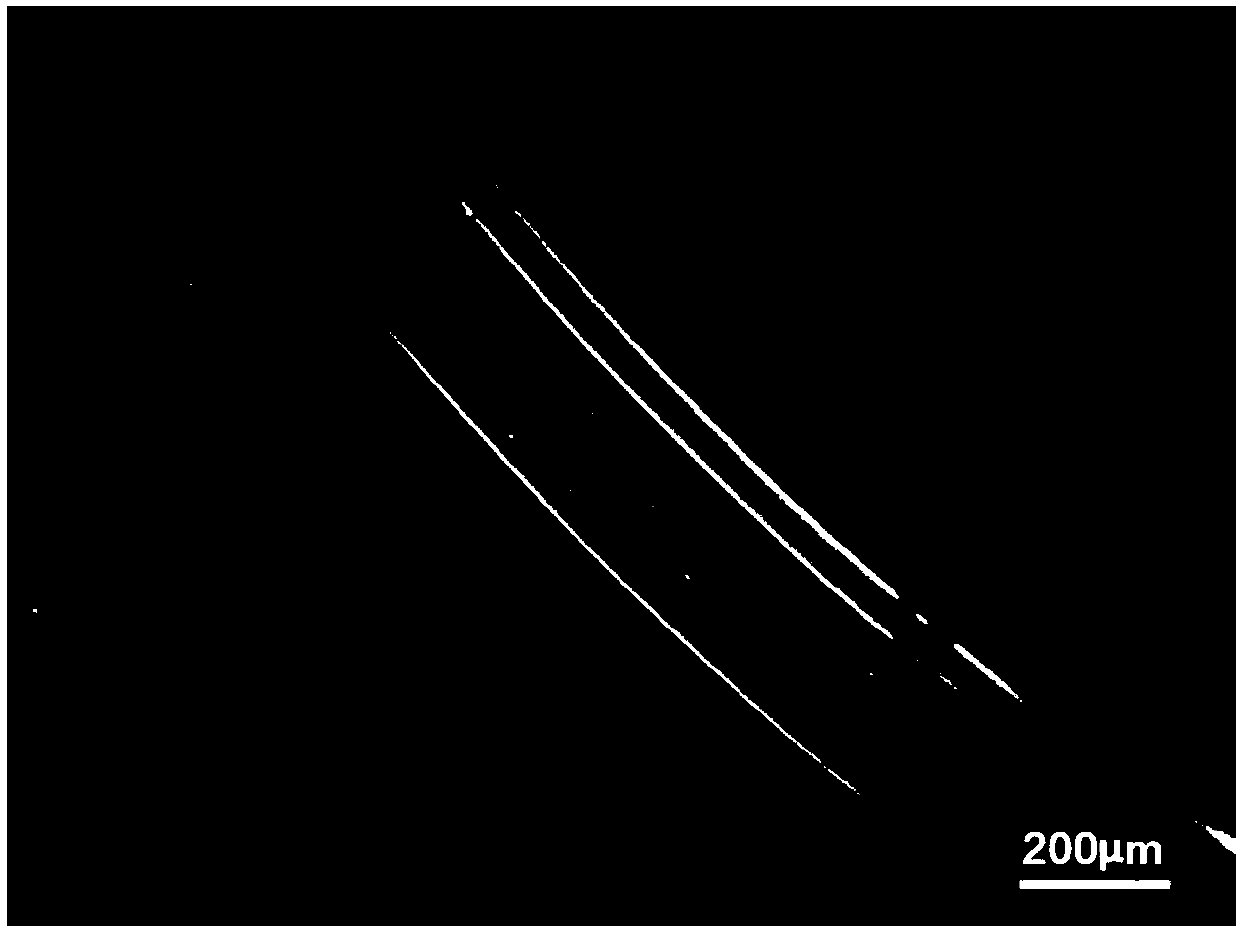

[0052] Using a microfluidic chip, using figure 1 The microfluidic chip shown, with an air pump to control the CaCl 2 The Harvard pump is used to control the fluid flow rate of the other three channels, and the inert fluid is methylcellulose, the modified fluid is chitosan or the mixture of chitosan and methylcellulose, and the sample fluid is alginic acid. Sodium and sheath fluid CaCl 2 ;The flow rates of the first three are 0.4μl / min...

Embodiment 2

[0055] Sodium alginate with a mass volume concentration of 2% g / ml is used as the sample fluid in advance; methyl cellulose with a mass volume concentration of 3% g / ml is used as an inert fluid; ml of chitosan solution as a modification fluid, or mix chitosan and methylcellulose to obtain methylcellulose solutions containing different chitosan concentrations as a modification fluid; mass volume concentration 1% g / ml CaCl 2 as a sheath fluid;

[0056] A microfluidic chip is used to control CaCl with an air pump 2 The flow rate of the fluid in the other three channels is controlled by Harvard pump, and the inert fluid containing cells, i.e. methylcellulose, the modified fluid, i.e. chitosan or the mixture of chitosan and methylcellulose, and the sample are successively introduced into the chip. Fluid sodium alginate and sheath fluid CaCl 2 ;The flow rates of the first three are 0.8μl / min, 0.2μl / min, and 10μl / min respectively; the pressure of the pneumatic pump of the sheath fl...

Embodiment 3

[0059] Sodium alginate with a mass volume concentration of 5% g / ml is used as the sample fluid in advance; methyl cellulose with a mass volume concentration of 2% g / ml is used as an inert fluid; The chitosan solution of ml is used as the modified fluid, or chitosan and methylcellulose are mixed to obtain methylcellulose solutions containing different chitosan concentrations as the modified fluid; CaCl with a mass volume concentration of 2% g / ml 2 as a sheath fluid;

[0060] A microfluidic chip is used to control CaCl with an air pump 2 The flow rate of the fluid in the other three channels is controlled by Harvard pump, and the inert fluid containing cells, i.e. methylcellulose, the modified fluid, i.e. chitosan or the mixture of chitosan and methylcellulose, and the sample are successively introduced into the chip. Fluid sodium alginate and sheath fluid CaCl 2 ;The flow rates of the first three are 1.5μl / min, 0.3μl / min, and 20μl / min respectively; the pressure of the pneumat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com