Mascara Remover

A technology of remover and mascara, applied in the field of mascara remover, can solve the problems of low stability, dry eyelid skin, dark circles around the eyes, etc., and achieves the effects of excellent storage stability and good feeling of use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

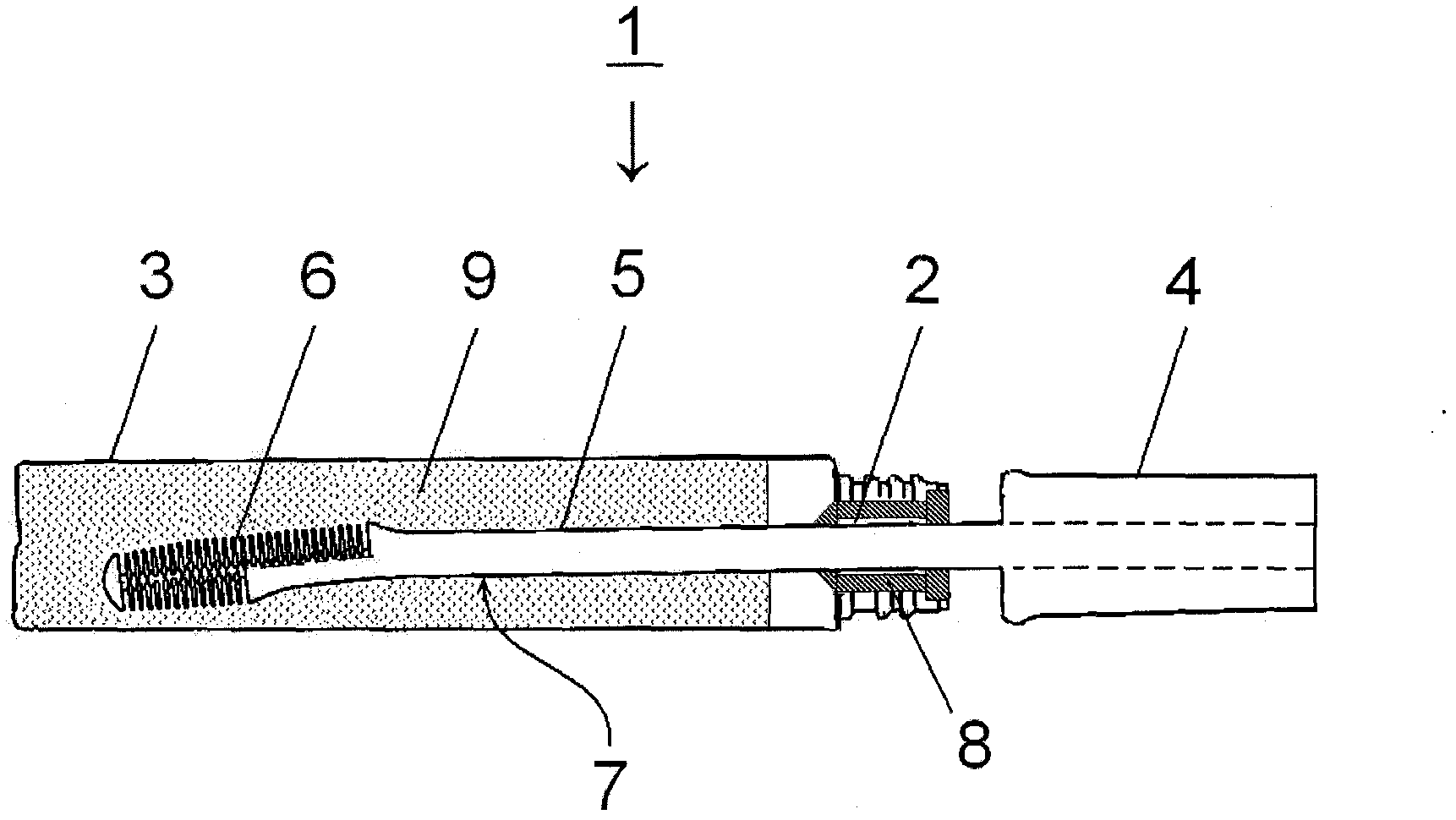

Image

Examples

Embodiment 1~4

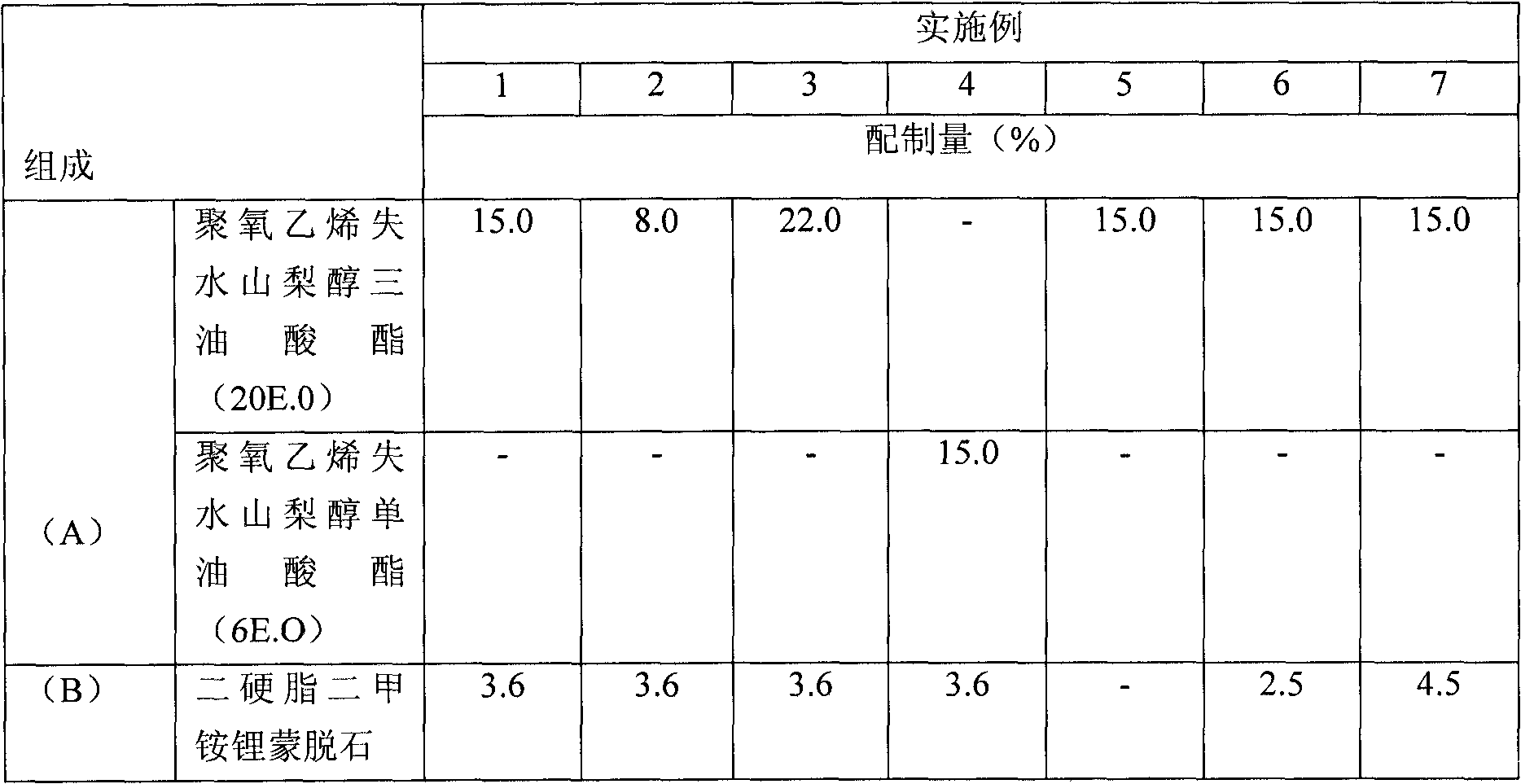

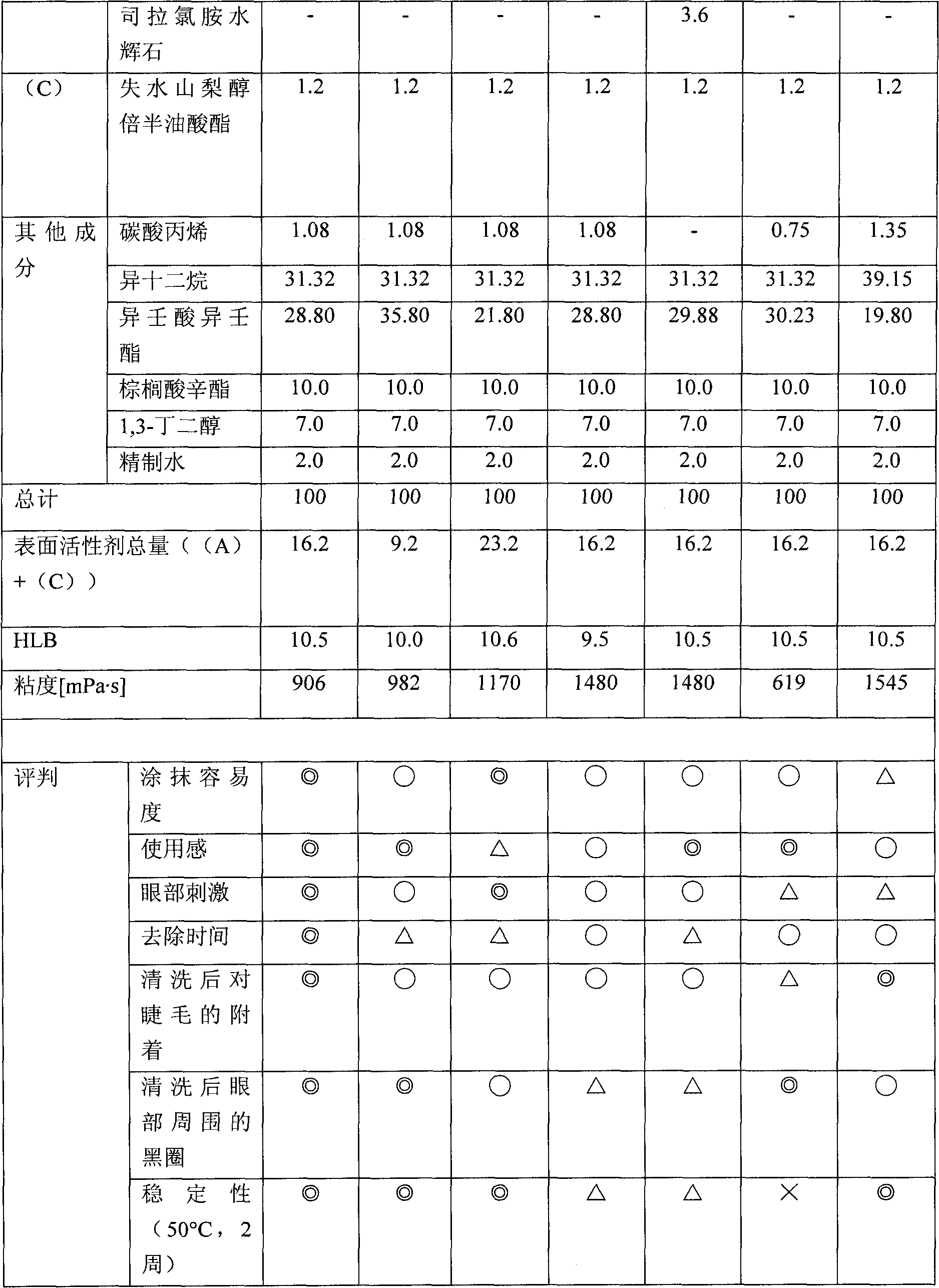

[0089] (Examples 1-4, 6-9, 11 and 12)

[0090] The mascara removers of Examples 1 to 4, 6 to 9, 11 and 12 were prepared by the following method according to the composition and preparation amount of the following Tables 1 to 2.

[0091] (B) Component, (C) Component, isononyl isononanoate, and if necessary, isododecane were stirred at 3000 rpm for 3 minutes using a disperser mixer (manufactured by T.K Robotmix Primix). Next, octyl palmitate (Ethylhexyl Palmitate) was added and stirred for 5 minutes using a magnetic mixer (MG600H, manufactured by Yamato). Then, (A) component was added, and it stirred for 5 minutes using the magnetic mixer (MG600H, the Yamato company make). Then add 1,3-butanediol (1,3-Butylene Glycol) and purified water, use a magnetic mixer (MG600H, produced by Yamato Corporation) to stir for 5 minutes, and prepare Examples 1-4, 6-9, 11 and 12 mascara remover.

Embodiment 5

[0093] In Examples 1 to 4, 6 to 9, 11 and 12, except that the stirring conditions of (B) component, (C) component and isononyl isononanoate were changed from 3000 rpm for 3 minutes to 1000 rpm for 60 minutes , The mascara remover of Example 5 was prepared in the same manner as in Examples 1-4, 6-9, 11 and 12.

Embodiment 10

[0095] According to the composition and preparation amount in Table 2 below, the (B) component, (C) component, isononyl isononanoate and 1% purified water were stirred at 3000 rpm for 3 minutes using a dispersing mixer (manufactured by T.K robotmix primix). Next, octyl palmitate was added and stirred for 5 minutes using a magnetic mixer (MG600H, manufactured by Yamato). Then, (A) component was added, and it stirred for 5 minutes using the magnetic mixer (MG600H, the Yamato company make). Then add 1,3-butanediol and 1% purified water, and stir for 5 minutes using a magnetic mixer (MG600H, produced by Yamato Co., Ltd.) to prepare the mascara remover of Example 10.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com