Homogeneous gas-liquid mixed dielectric viscosity measuring device and method

A gas-liquid mixing and mixed medium technology, applied in the direction of measuring devices, flow characteristics, instruments, etc., can solve problems such as inapplicability and no protection measures, and achieve the effects of improving test accuracy, improving measurement accuracy, and improving real-time performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

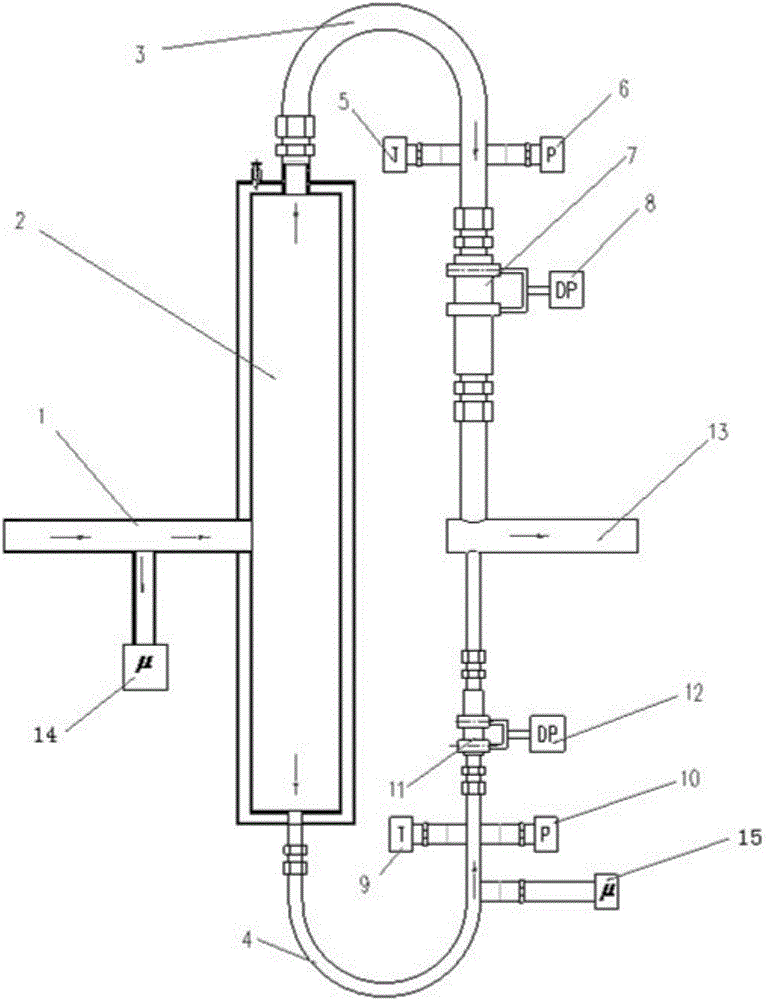

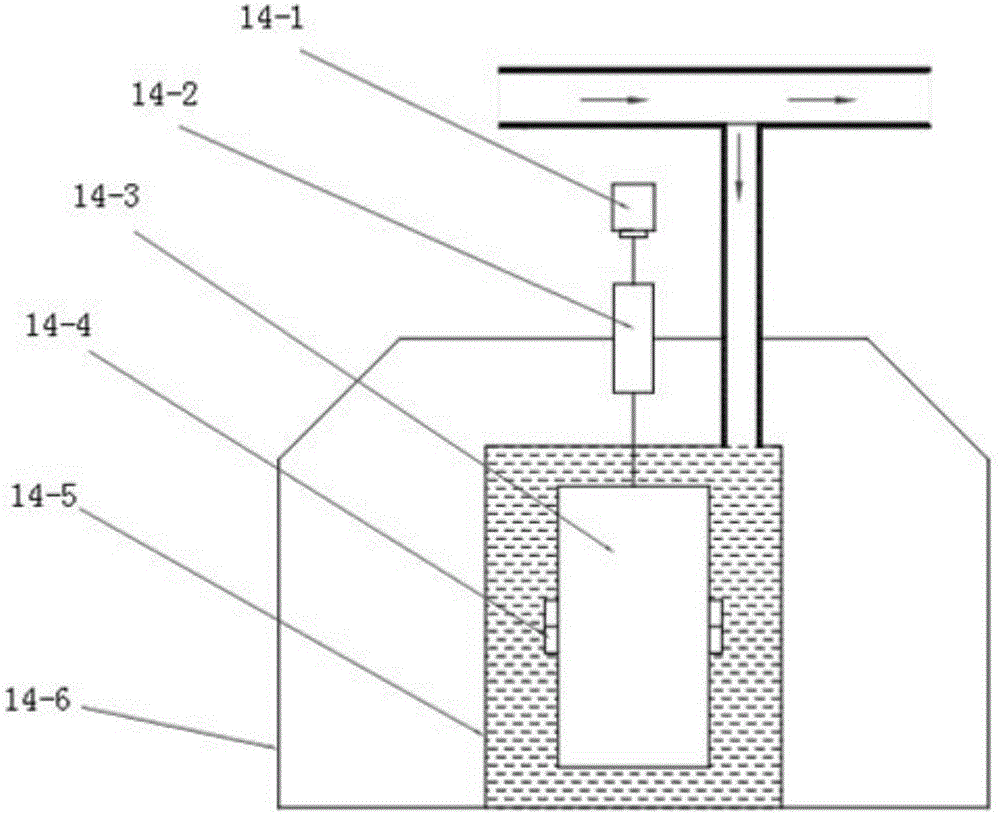

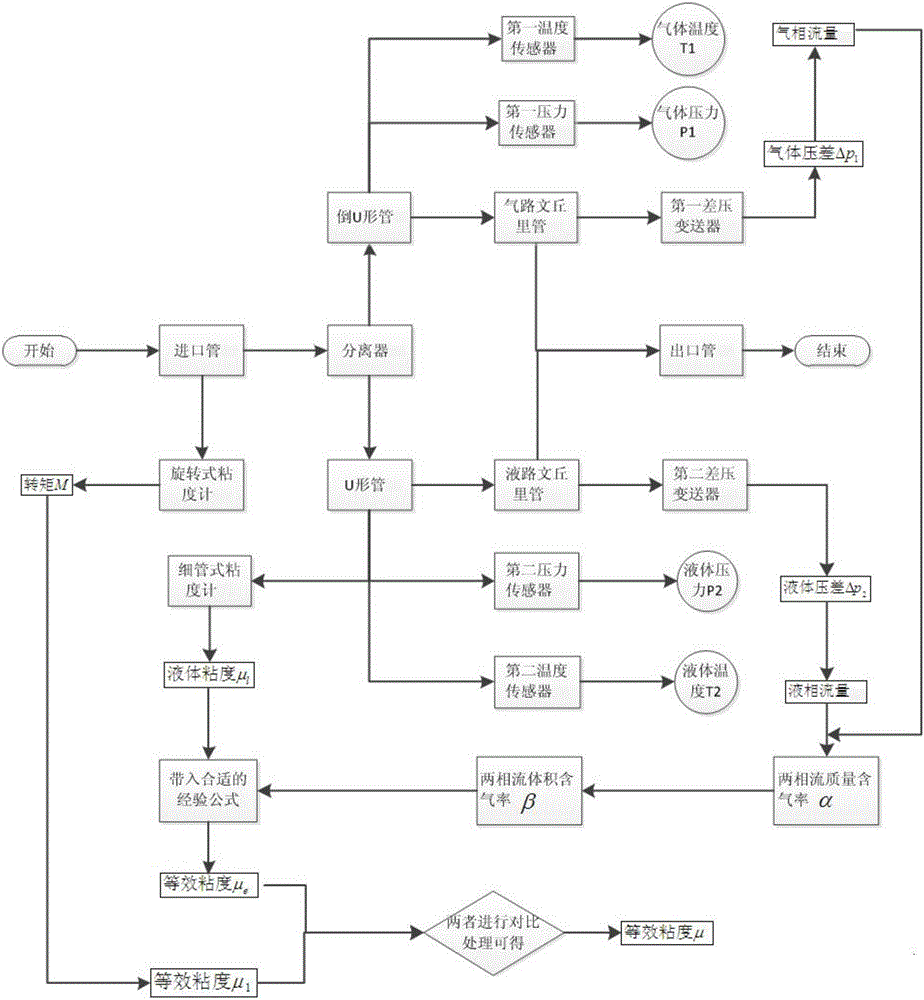

[0030] See attached figure 1 and attached image 3 , the present invention provides a homogenous mixed medium viscosity measuring device and method, the device includes an inlet pipe 1, a separator 2, a U-shaped pipe 4, an inverted U-shaped pipe 3, a first temperature sensor 5, a second temperature sensor 9 , the first pressure sensor 6, the second pressure sensor 10, the gas path venturi tube 7, the liquid path venturi tube 11, the first differential pressure transmitter 8, the second differential pressure transmitter 12, the rotary viscometer 14 , a narrow tube viscometer 15 and an outlet pipe 13, the inlet of the inlet pipe 1 is connected to the outlet port of the tested homogeneous gas-liquid two-phase flow mixed fluid, the outlet of the inlet pipe 1 is connected to the separator 2, and the gas-liquid two-phase The flow is separated, and the inlet pipe 1 also has a rotary viscometer 14 for measuring the viscosity of the homogeneous gas-liquid two-phase flow mixed fluid; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com