Patents

Literature

69results about How to "Accurate viscosity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

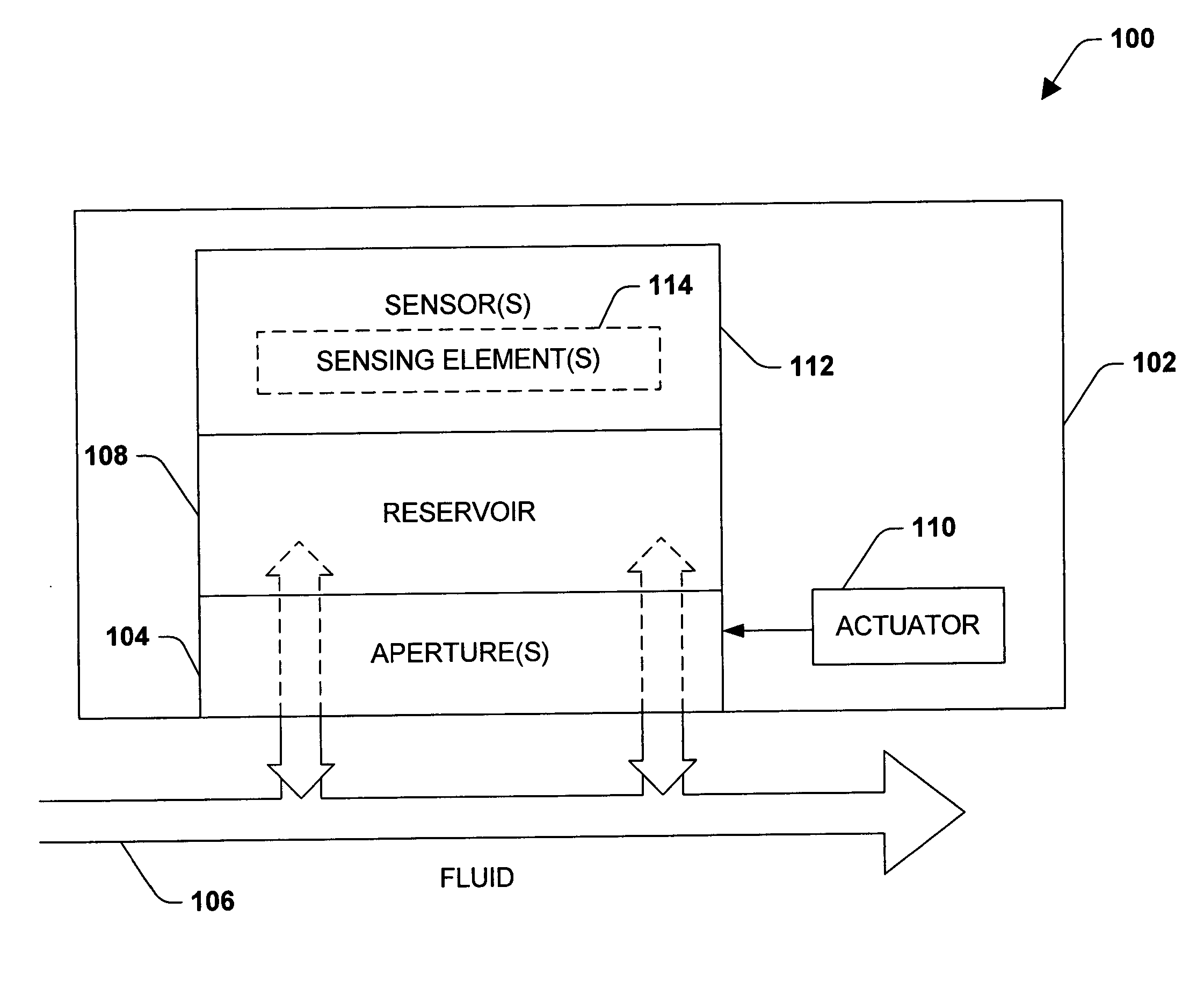

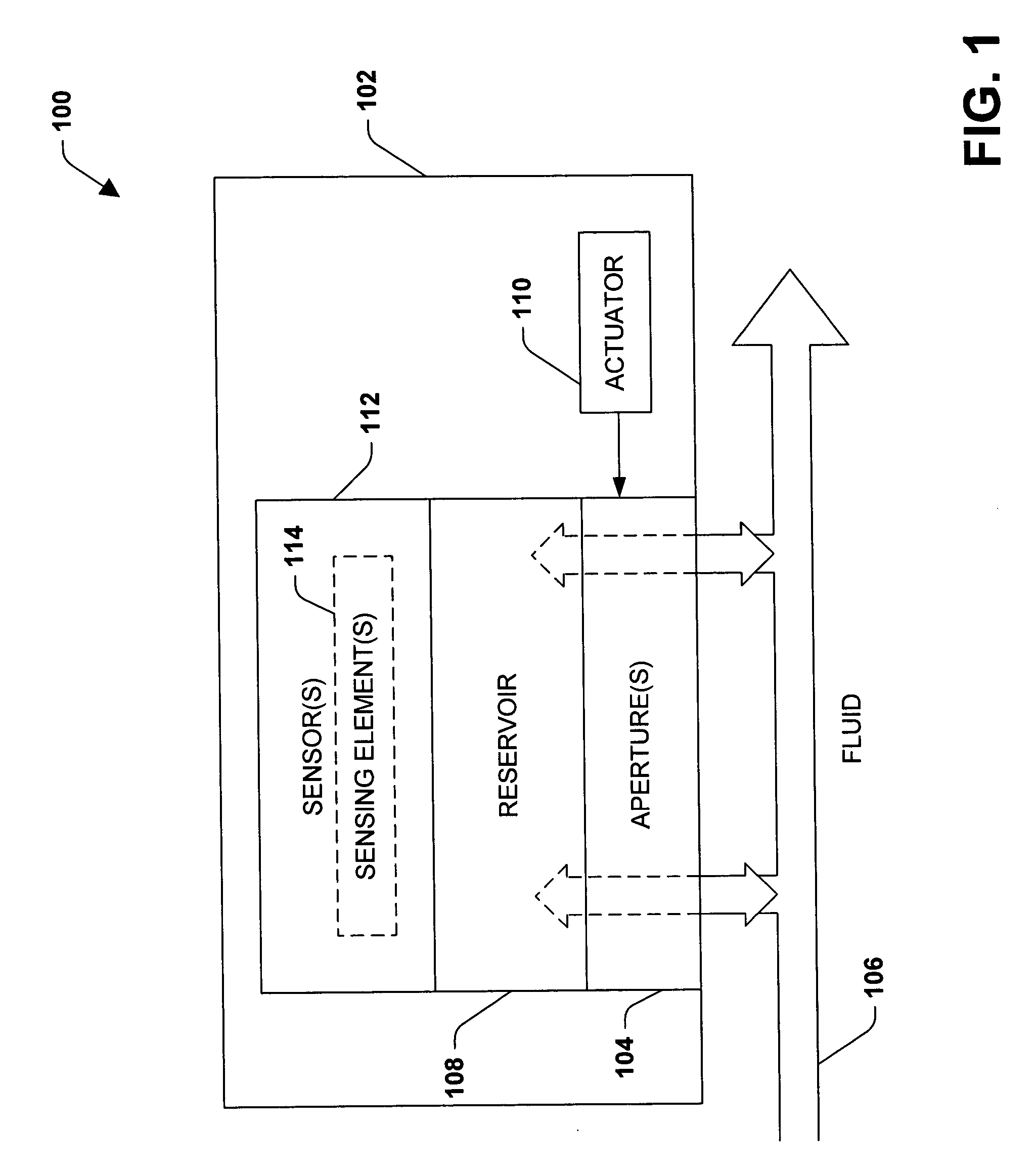

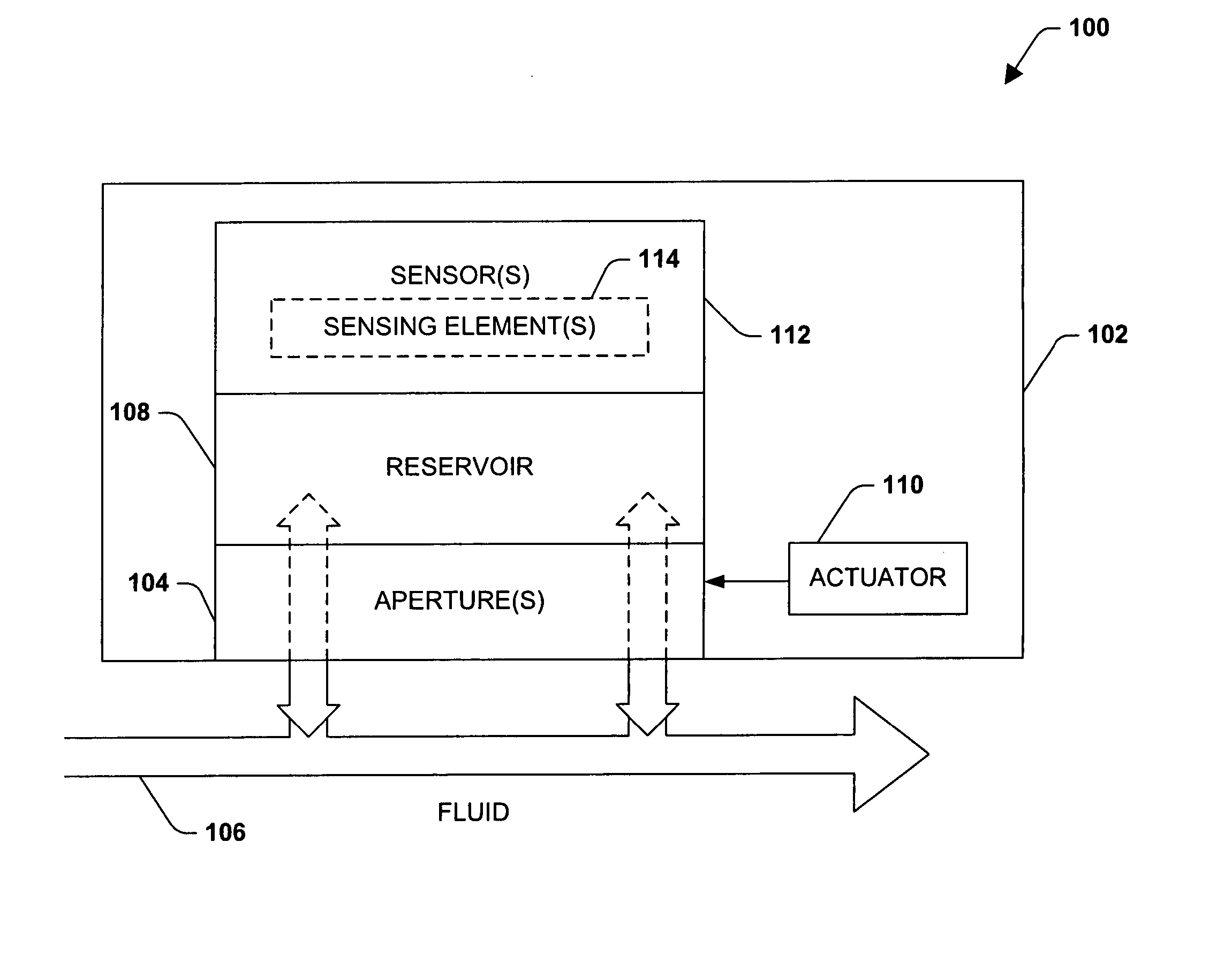

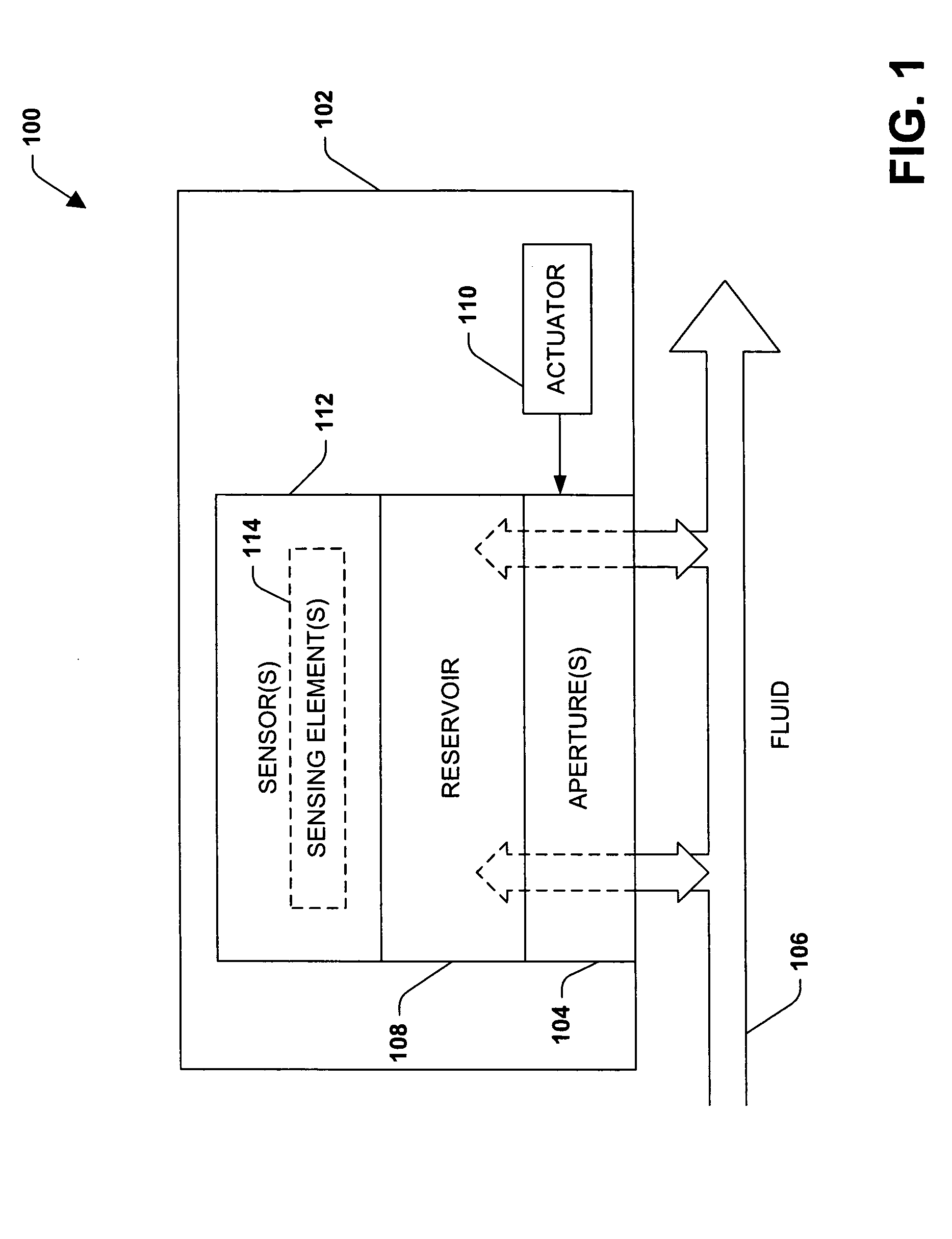

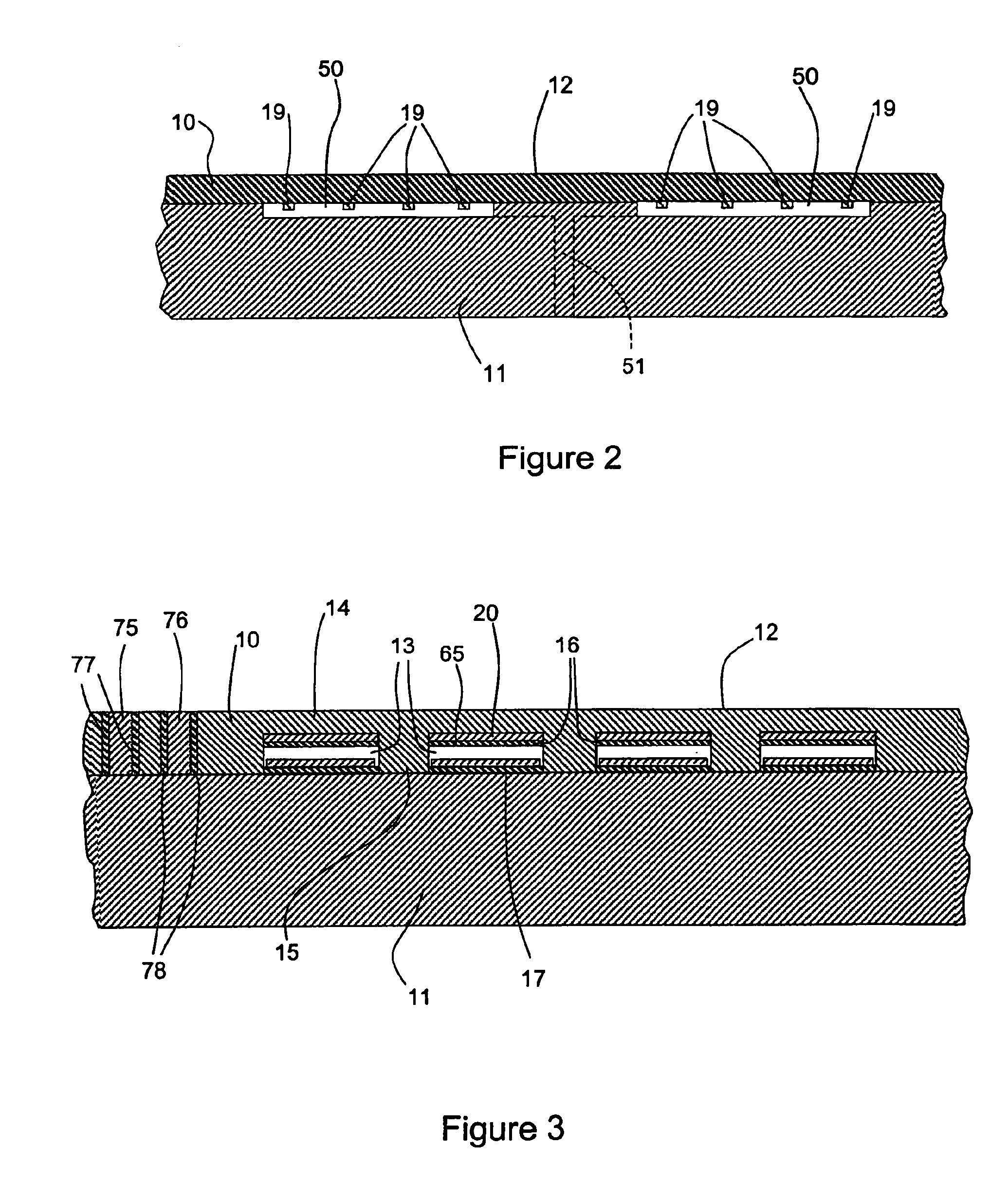

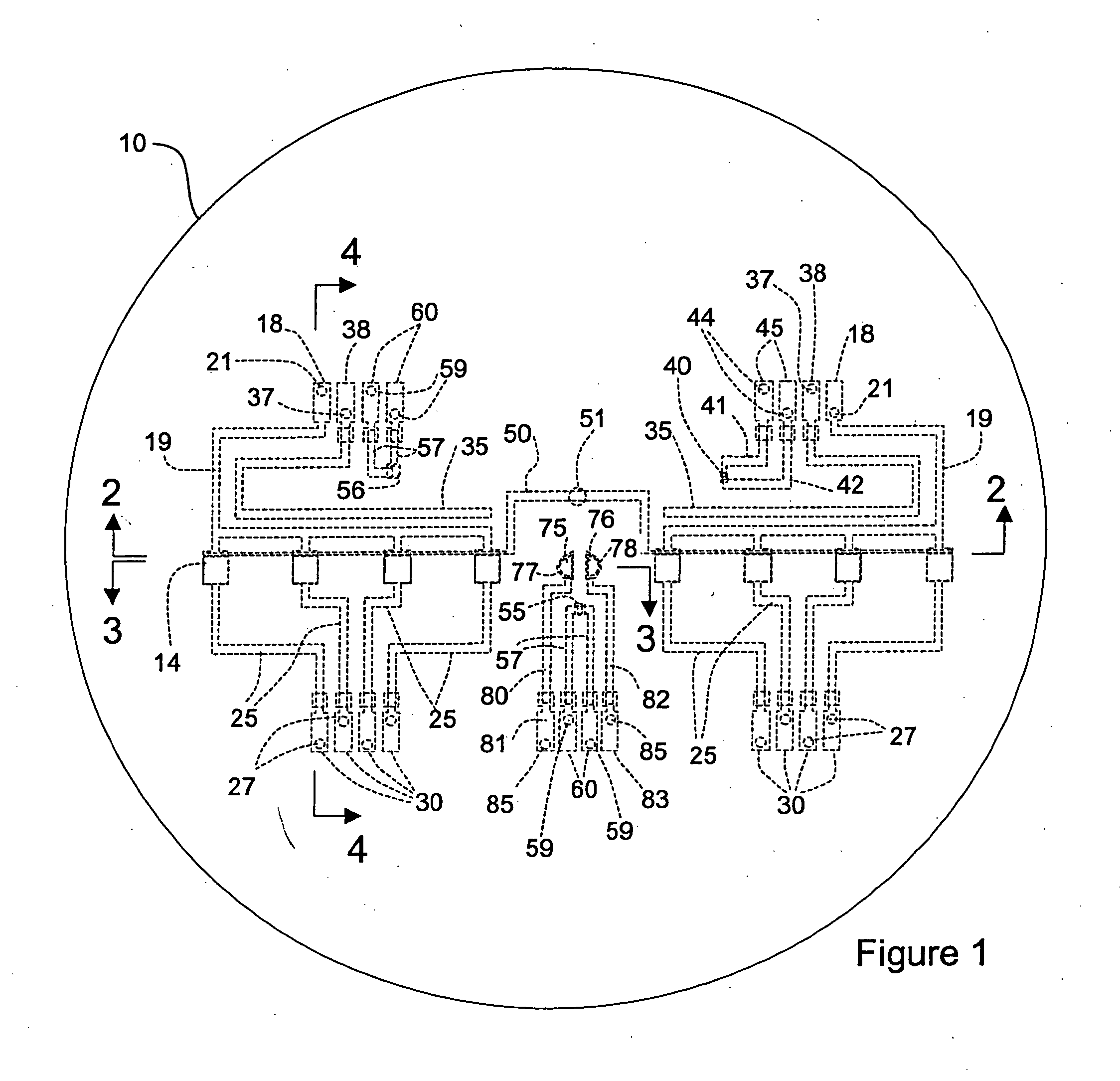

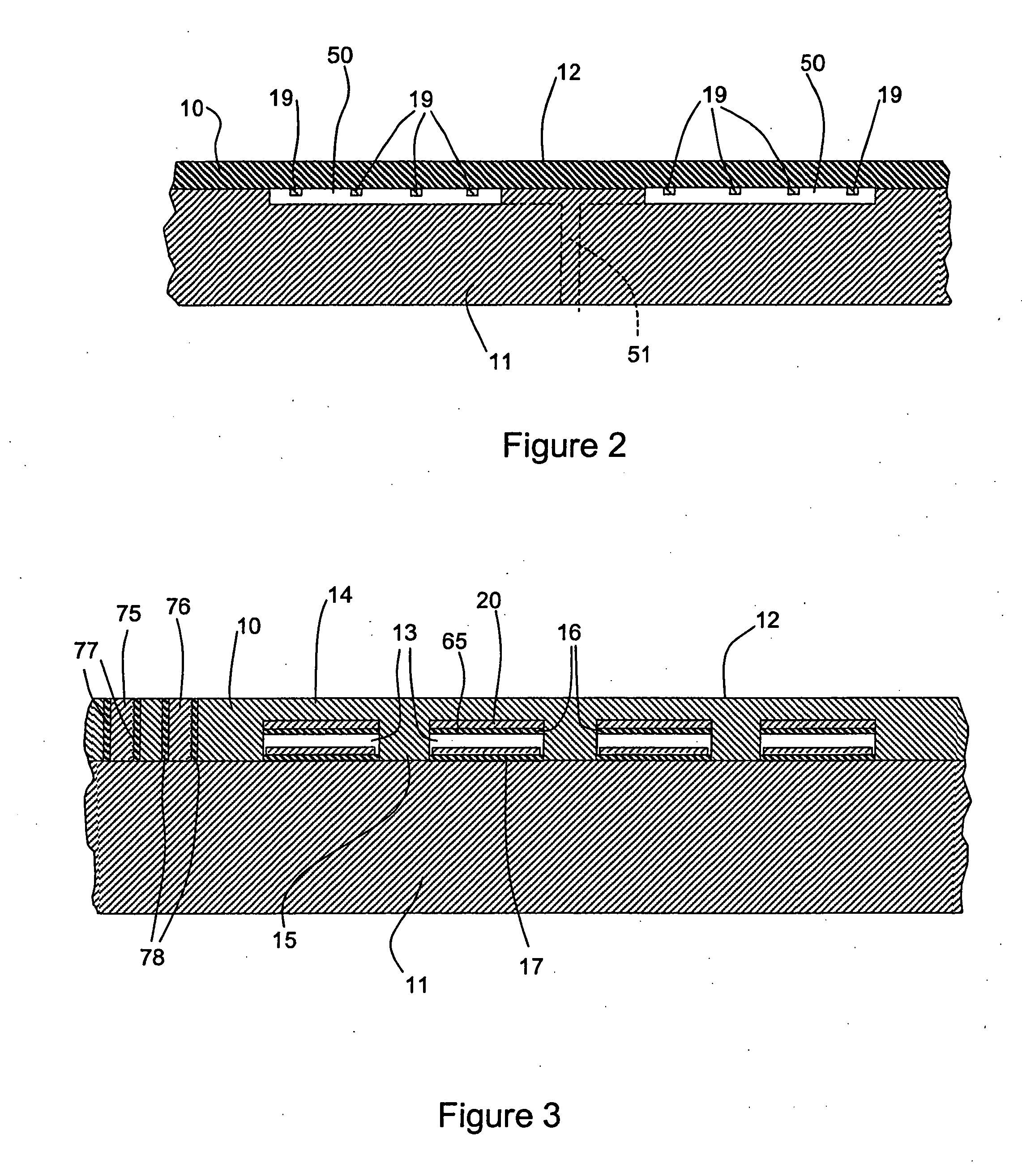

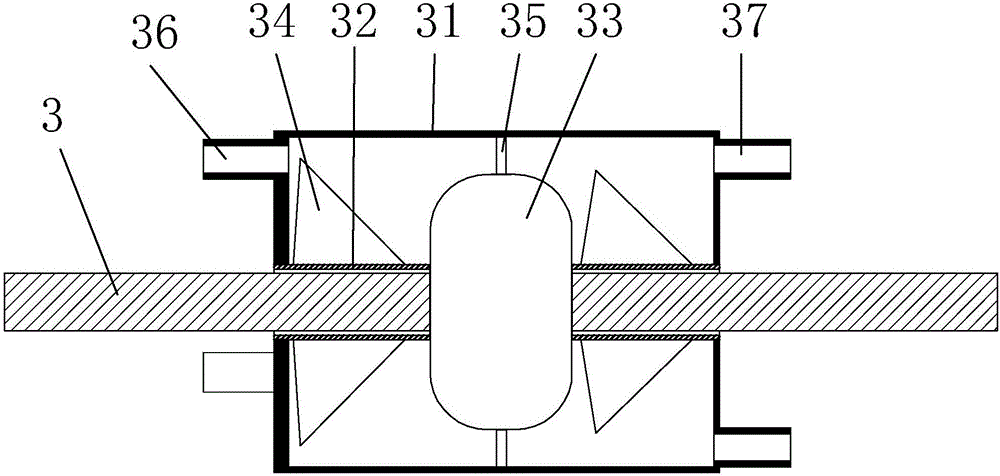

Fluid sensor fixture for dynamic fluid testing

InactiveUS20050066711A1Ease of conditionsQuickly heated and cooledFlow propertiesWithdrawing sample devicesFluid specimenEngineering

A system that facilitates measurement, analysis, and automatic maintenance of fluid comprises a fluid, and a casing that includes a plurality of apertures is immersed in the fluid. The apertures are opened to permit the fluid to enter the casing and closed to confine a sample of the fluid within the casing. A sensing element within the casing measures at least one parameter of the sample of fluid confined within the casing.

Owner:ROCKWELL AUTOMATION TECH

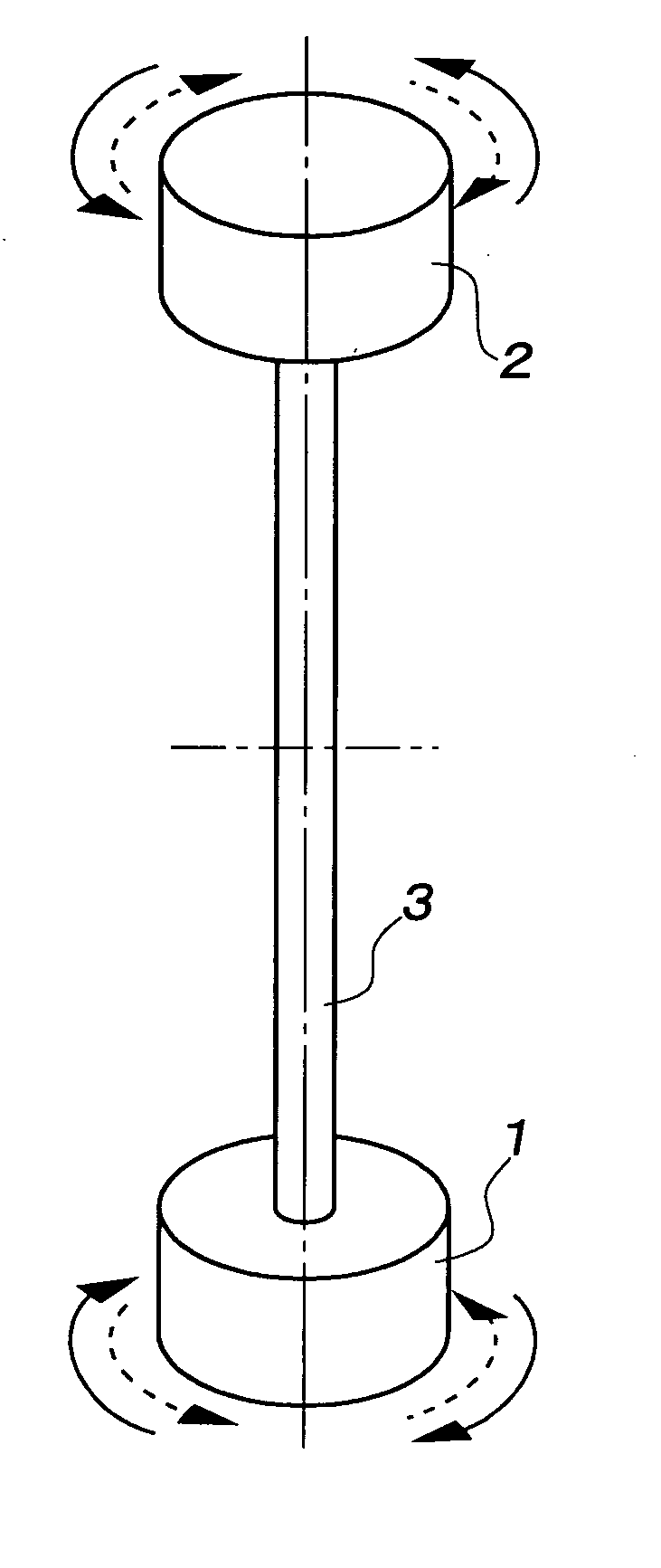

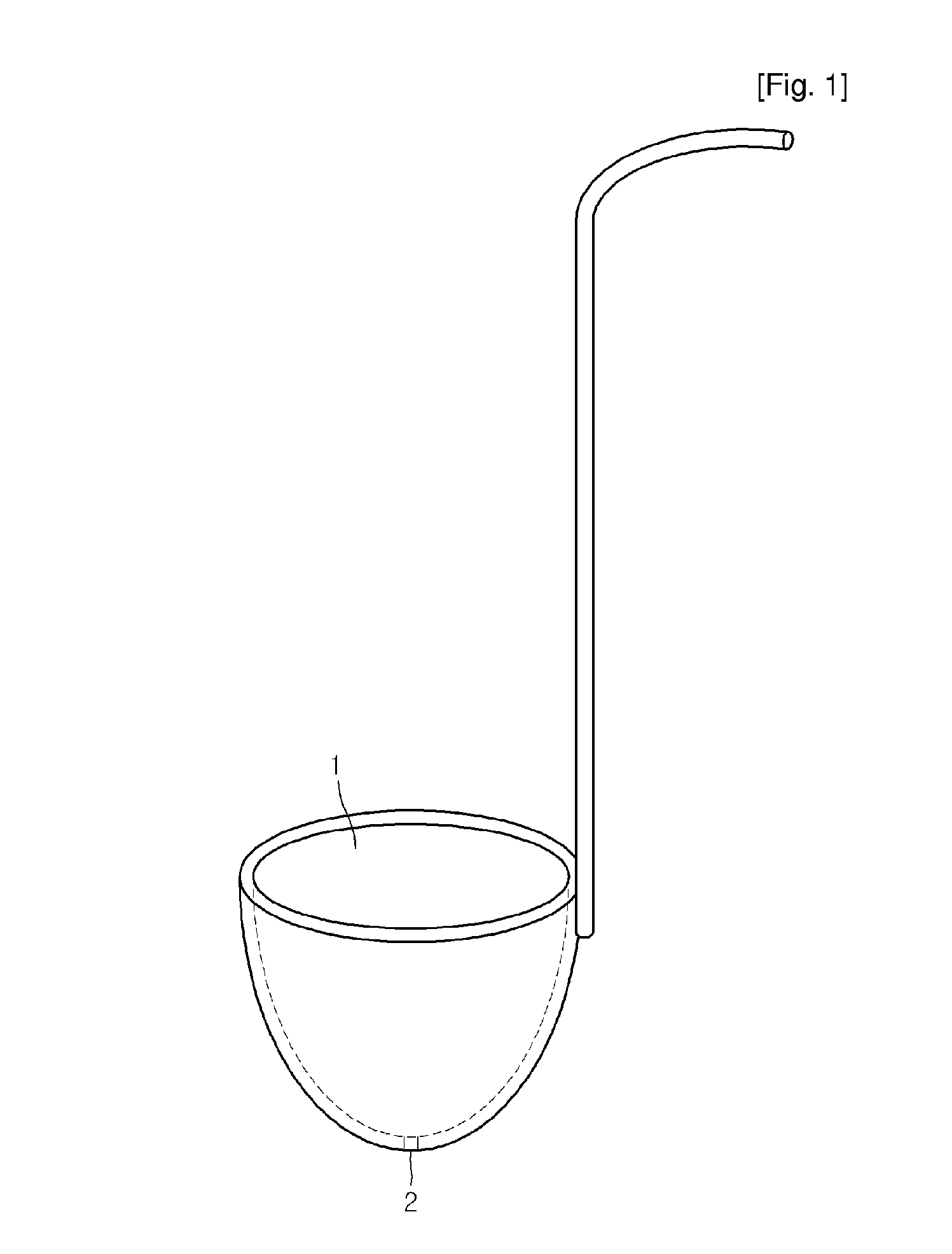

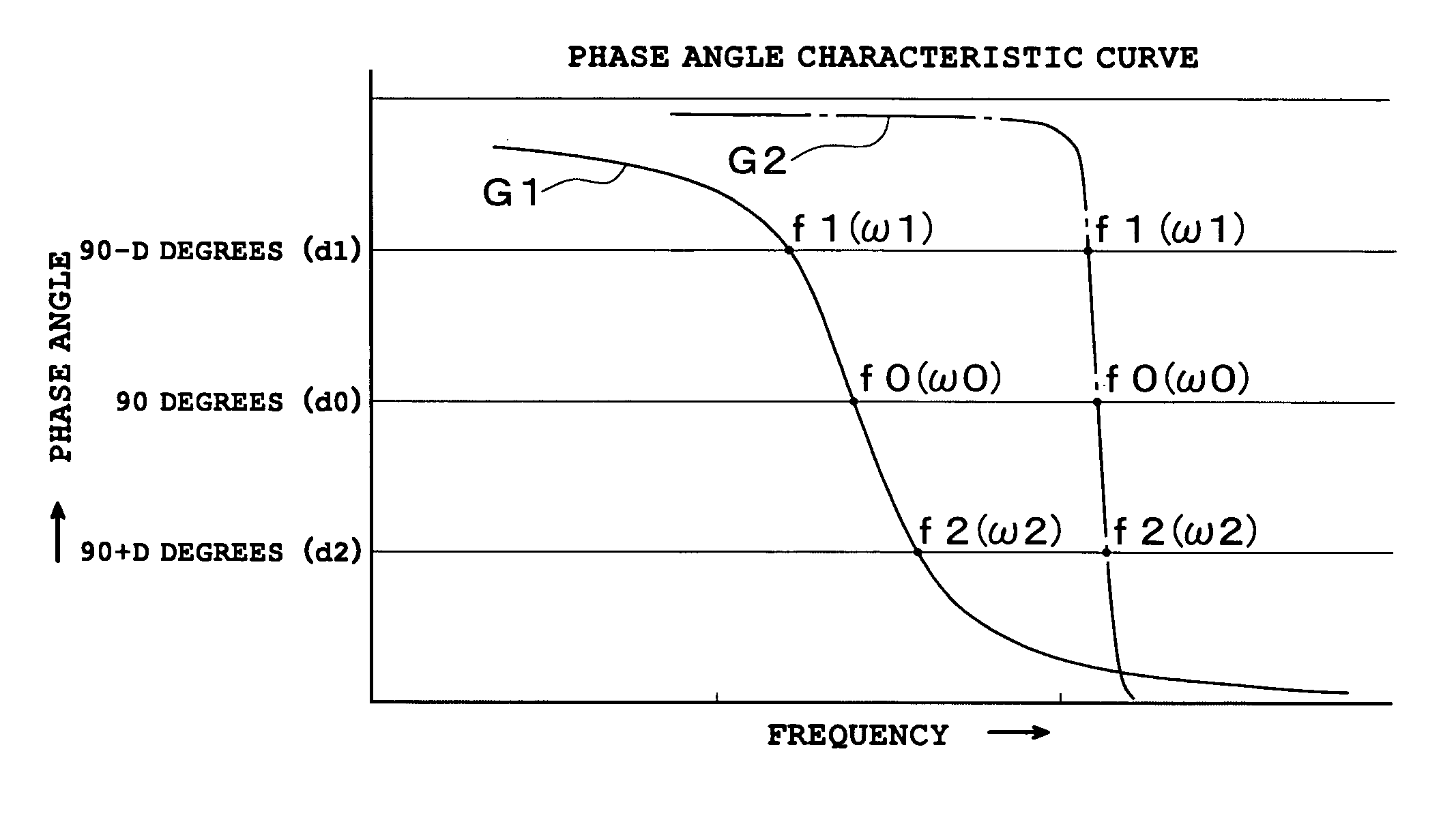

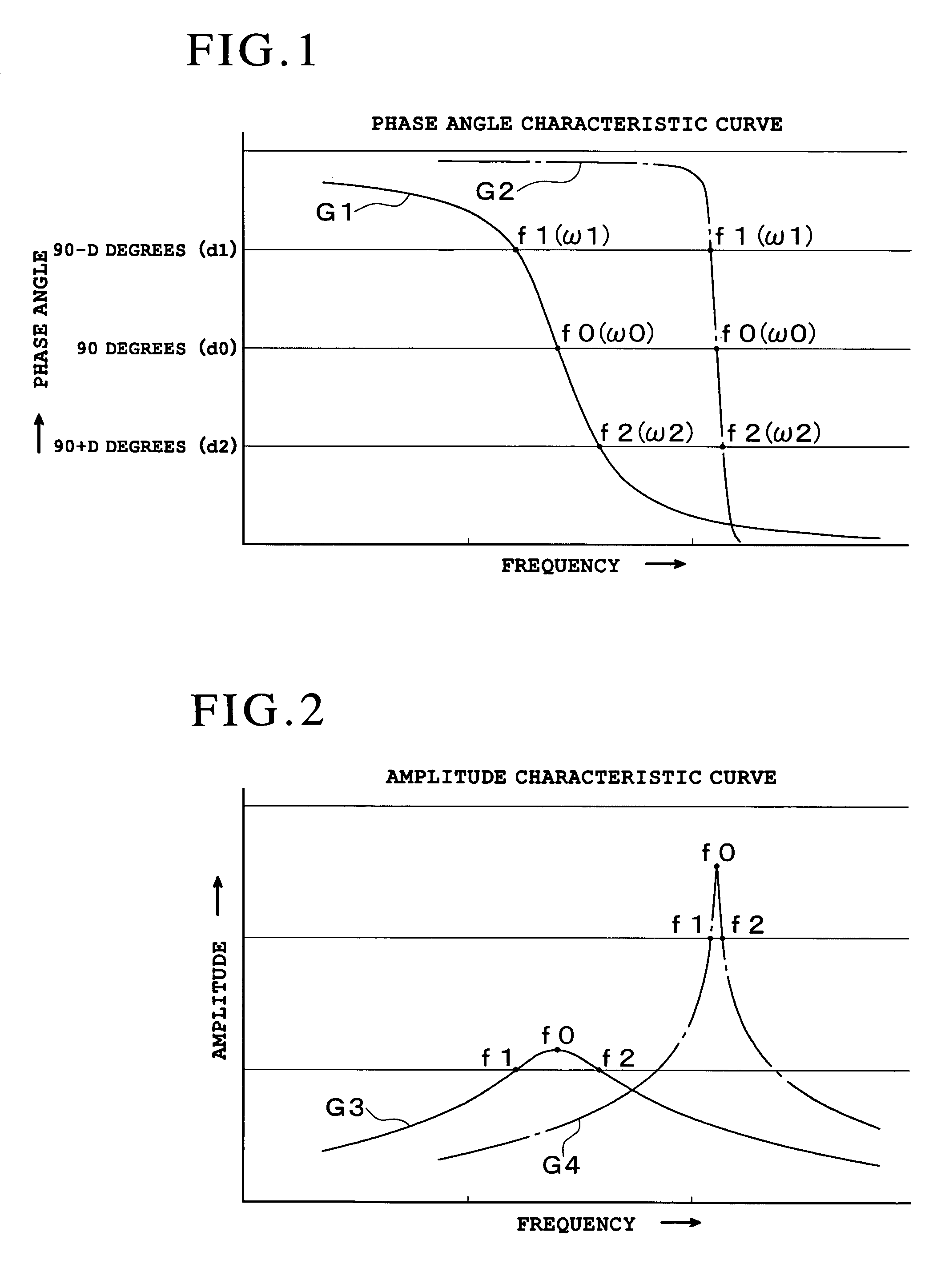

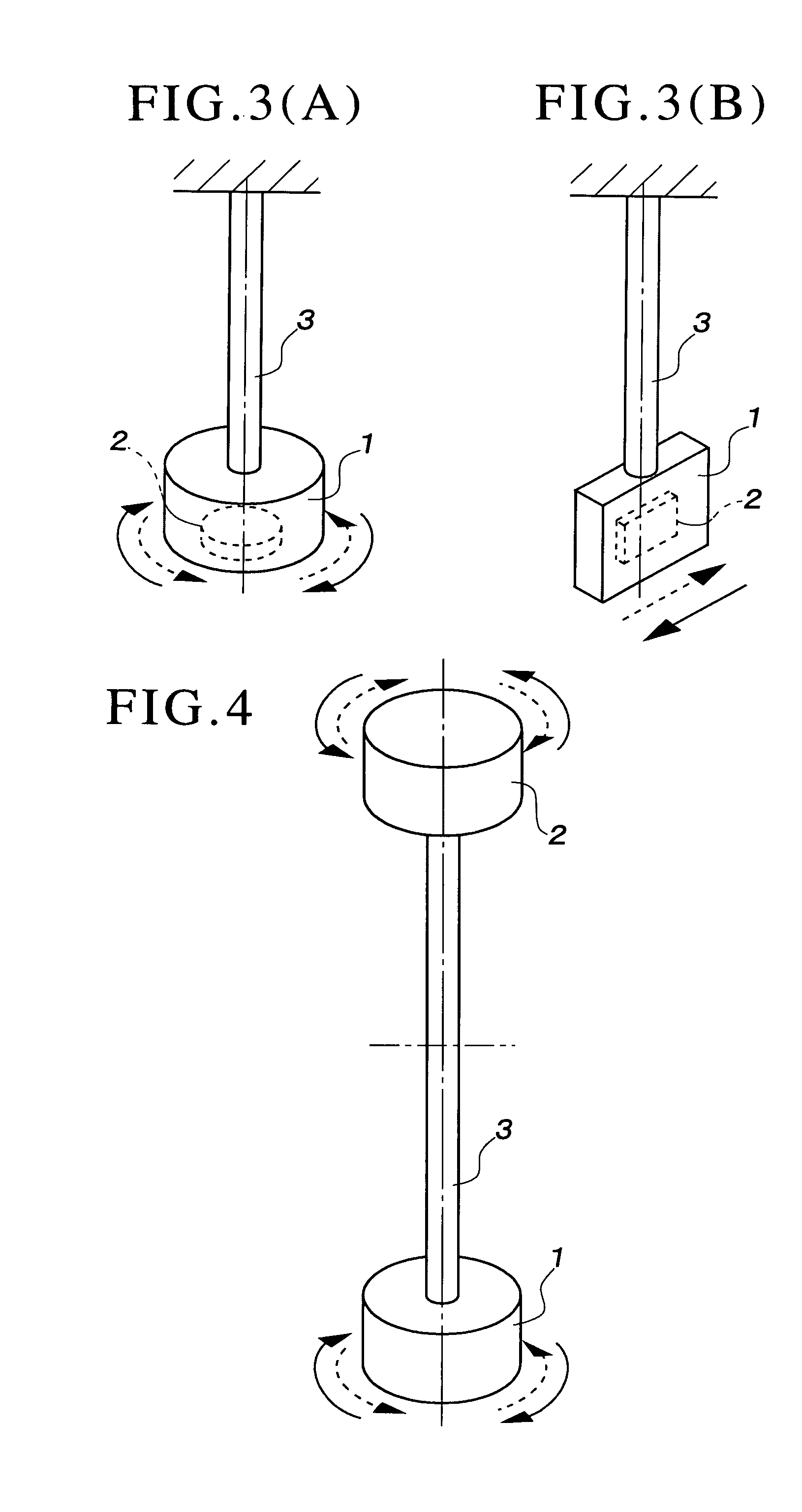

Method for measuring viscosity and/or elasticity of liquid

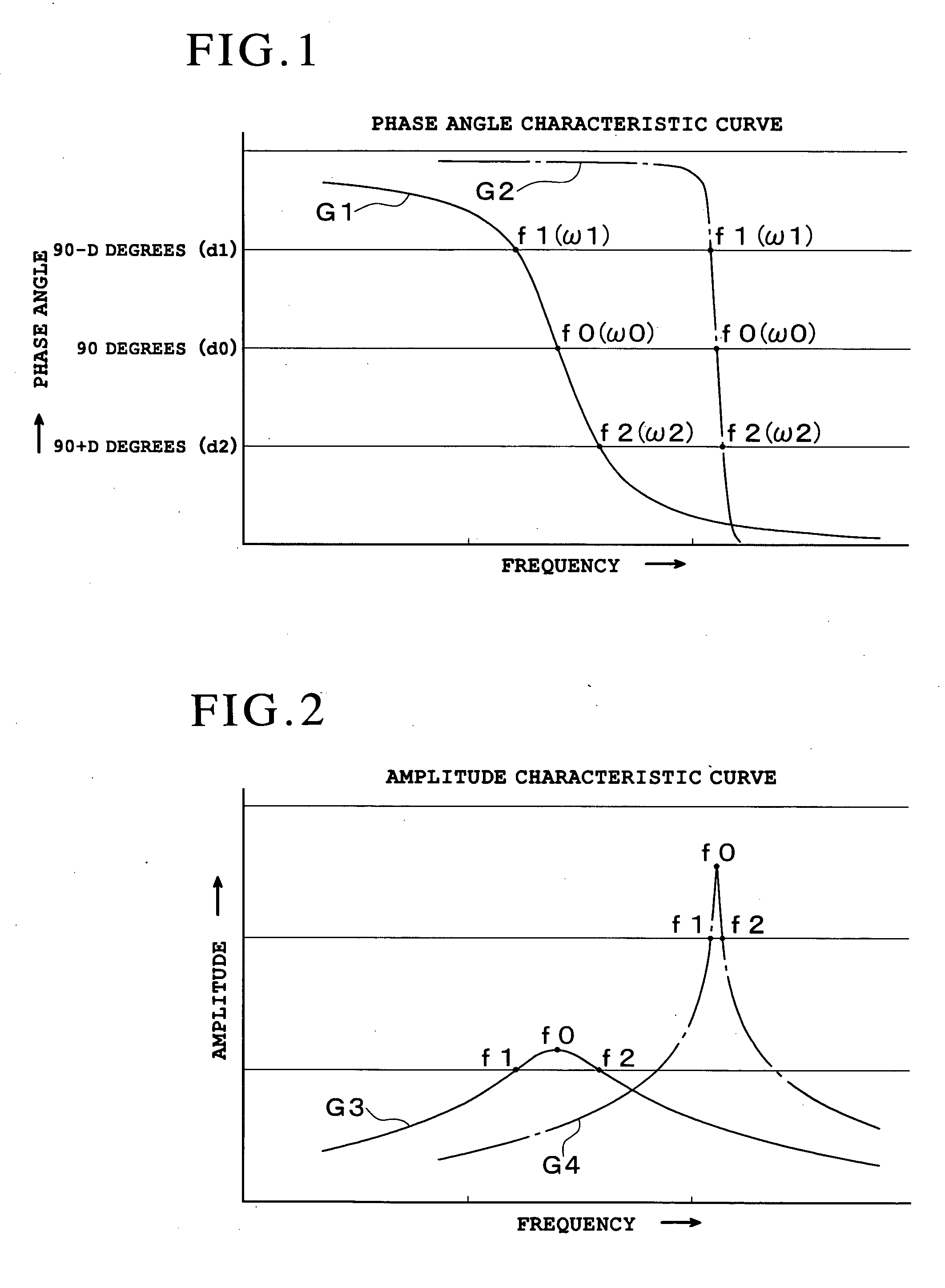

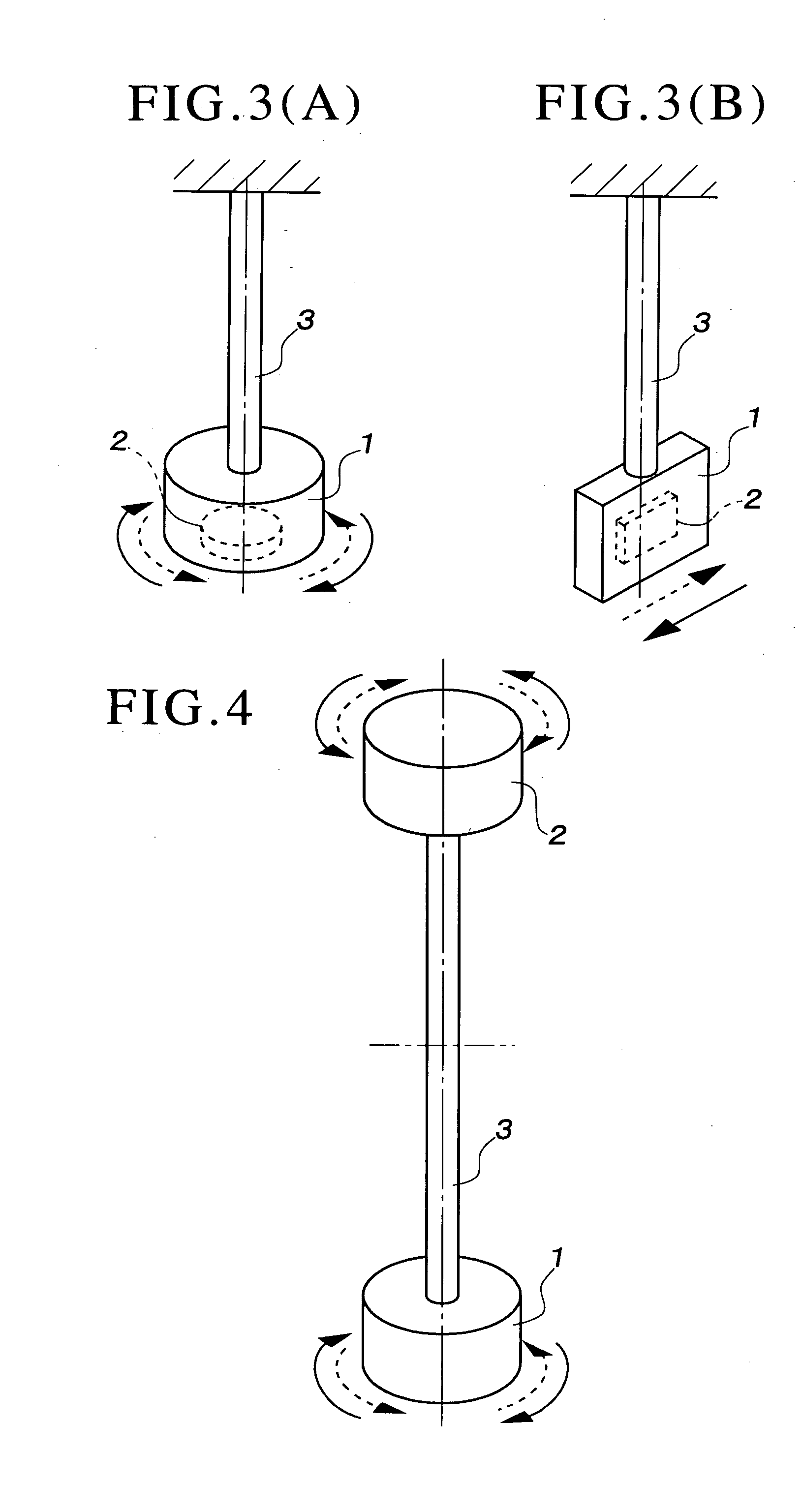

InactiveUS20100005865A1Accurate measurementHigh viscosityFlow propertiesElectrical measurementsResonanceViscosity

The present invention provides a method for measuring the viscosity and / or elasticity of a liquid by which accurate viscoelasticity measurement can be performed on a wide variety of liquids to be tested ranging from low viscosity liquids to high viscosity liquids, and viscosity and / or elasticity can be precisely determined from the viscoelasticity. This method includes: measuring three frequency values that are the resonance frequency value (f0) on the amplitude characteristic curve obtained through the vibration of the liquid tester 1 in the liquid being tested, a low frequency value lower (f1) than the resonance frequency value (f0) on the amplitude characteristic curve, and a high frequency value (f2) higher than the resonance frequency value (f0) on the amplitude characteristic curve; calculating the real part of the impedance of the liquid being tested, using the high frequency value (f2) and the low frequency value (f1); calculating the imaginary part of the impedance of the liquid being tested, using the resonance frequency value (f0); and calculating the viscosity value and / or the elasticity value of the liquid being tested from the real part and the imaginary part of the impedance.

Owner:SEKONIC CORP

Implant device

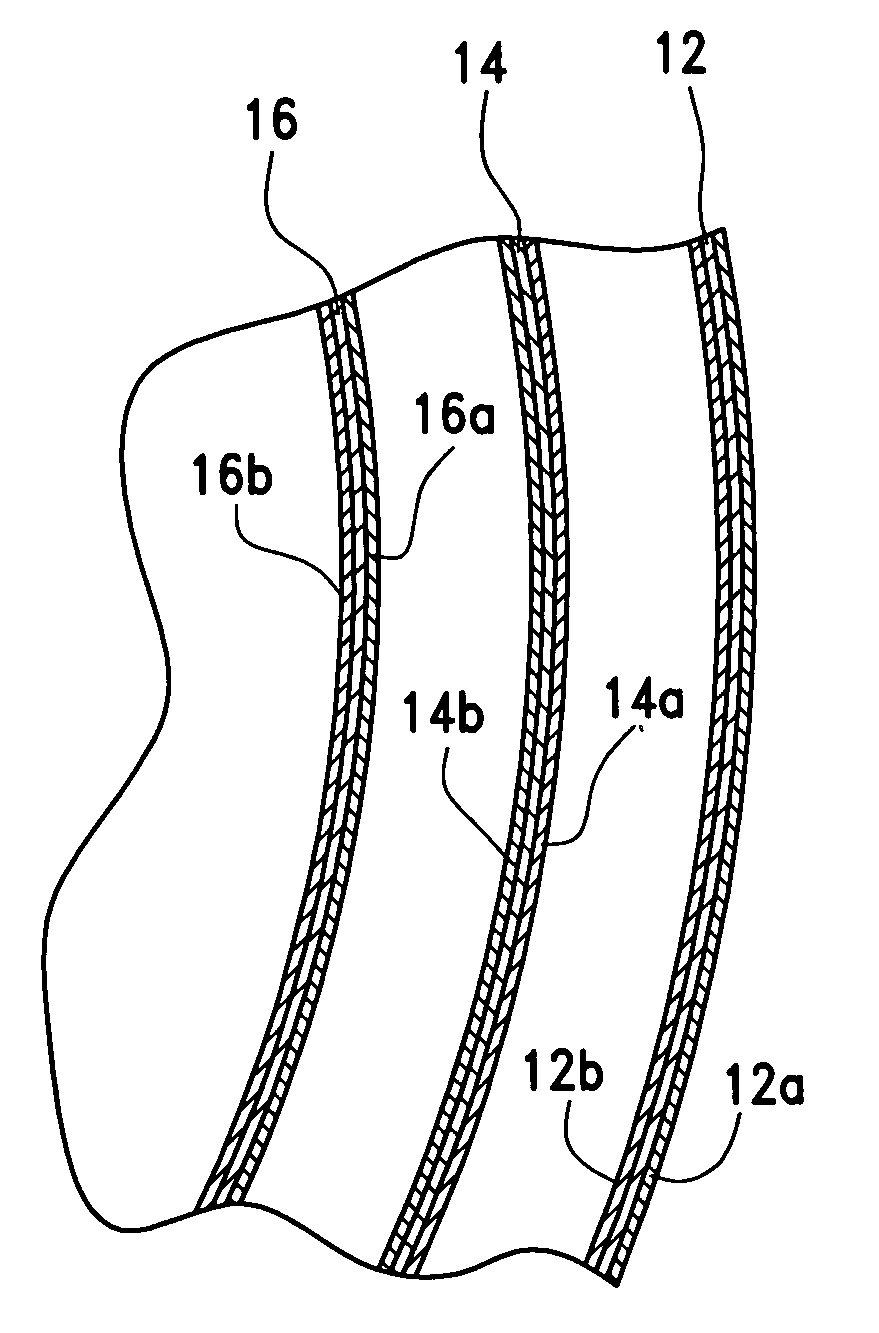

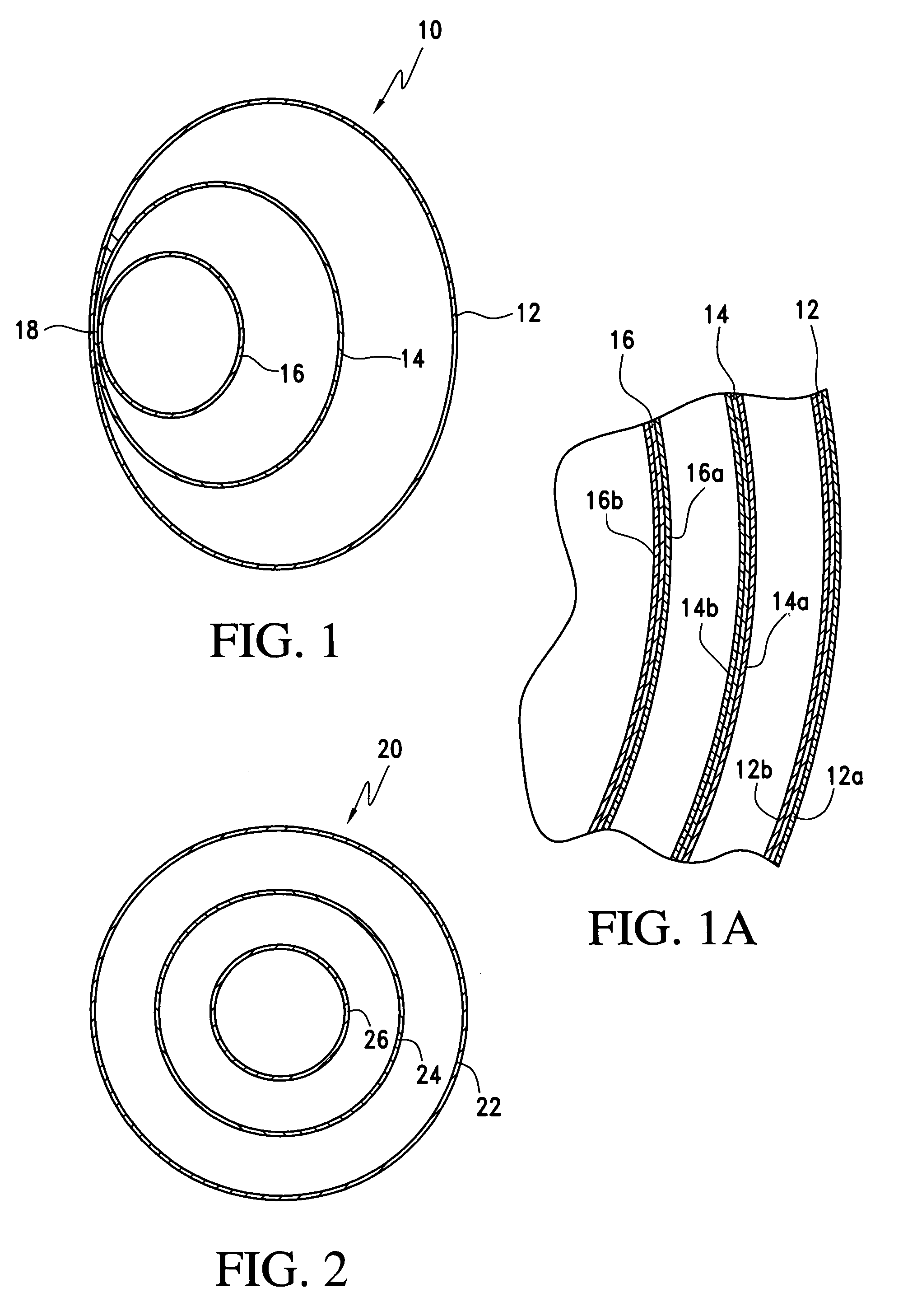

InactiveUS6932840B1Improve securityPreventing fluid gainMammary implantsJoint implantsImplanted deviceSaline solutions

A human or animal implant device including a first, inner sealed silicone sheet sac, a second, intermediate sealed silicone sheet sac completely surrounding the first, inner sac, and a third, outer sealed silicone sheet sac completely surrounding the second sac. Each sac has a coating of beeswax on inner and outer walls thereof, and the first, inner sac is filled with a substantially sterile liquid material, preferably of viscosity at least 15 cp. The second, intermediate sac and the third, outer sac are filled with aqueous saline solution.

Owner:ABSOLUTE BREAST SOLUTIONS

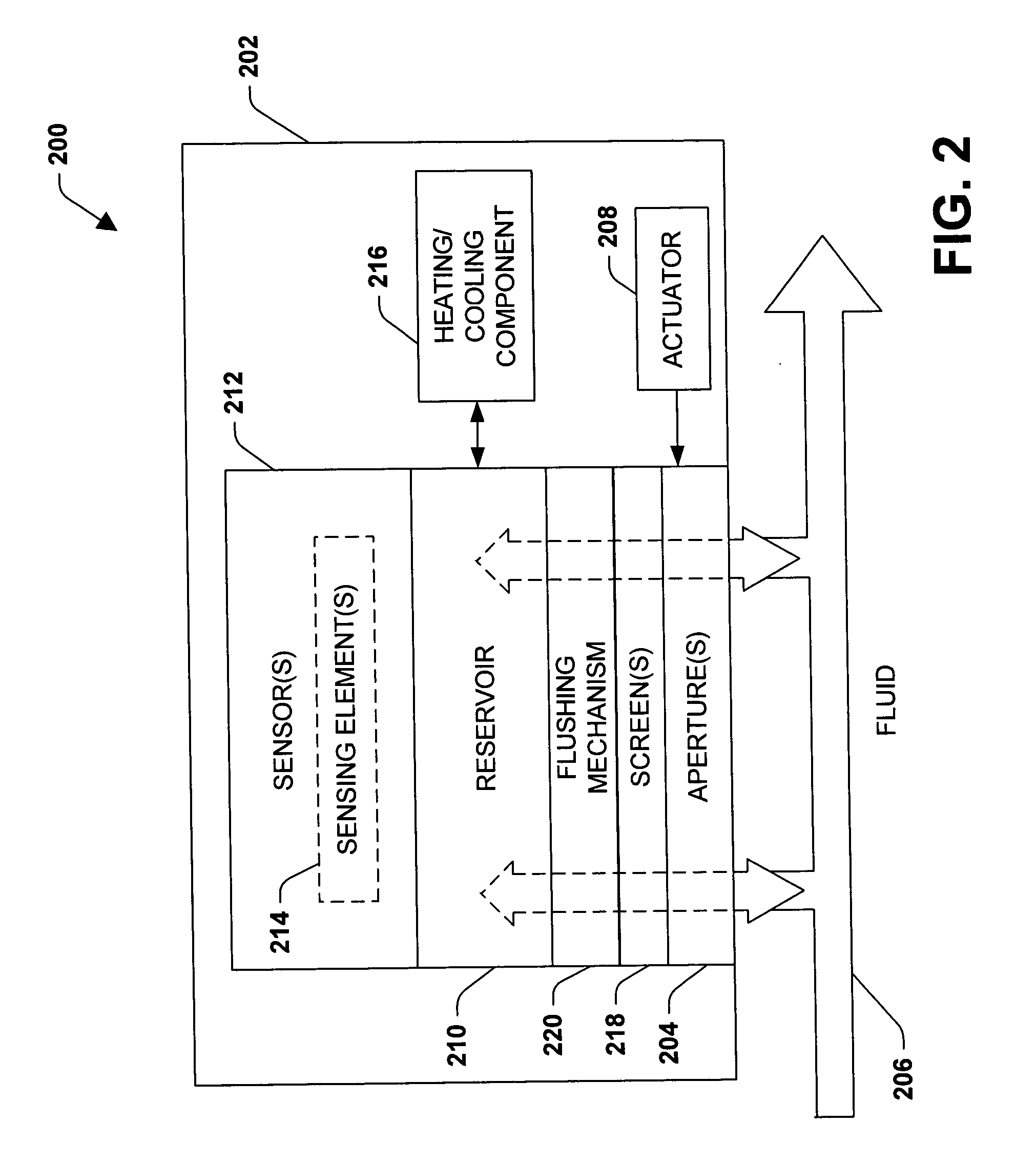

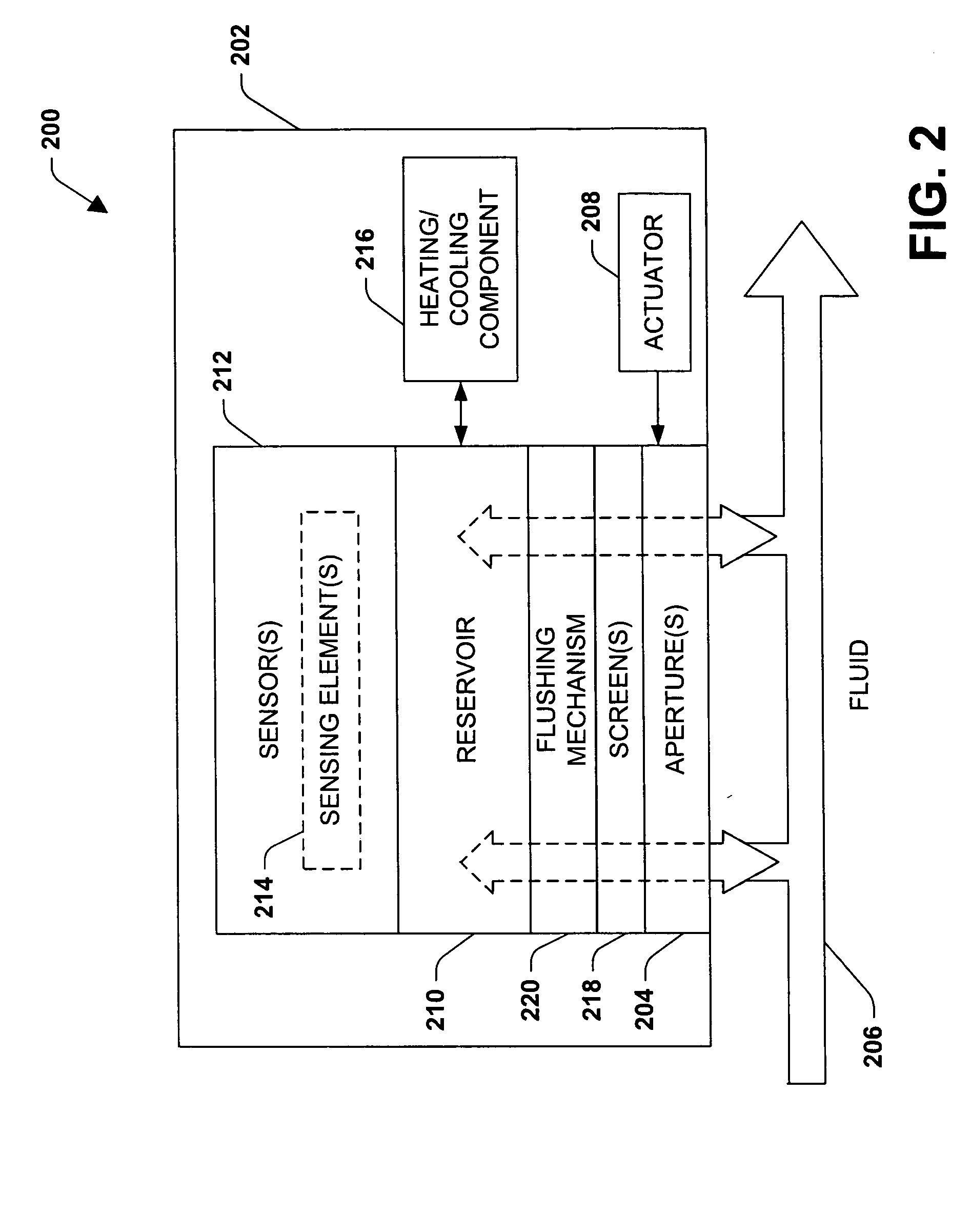

Fluid sensor fixture for dynamic fluid testing

InactiveUS20060169033A1Ease of conditionsQuickly heated and cooledSamplingFlow propertiesEngineeringFluid specimen

A system that facilitates measurement, analysis, and automatic maintenance of fluid comprises a fluid, and a casing that includes a plurality of apertures is immersed in the fluid. The apertures are opened to permit the fluid to enter the casing and closed to confine a sample of the fluid within the casing. A sensing element within the casing measures at least one parameter of the sample of fluid confined within the casing.

Owner:ROCKWELL AUTOMATION TECH

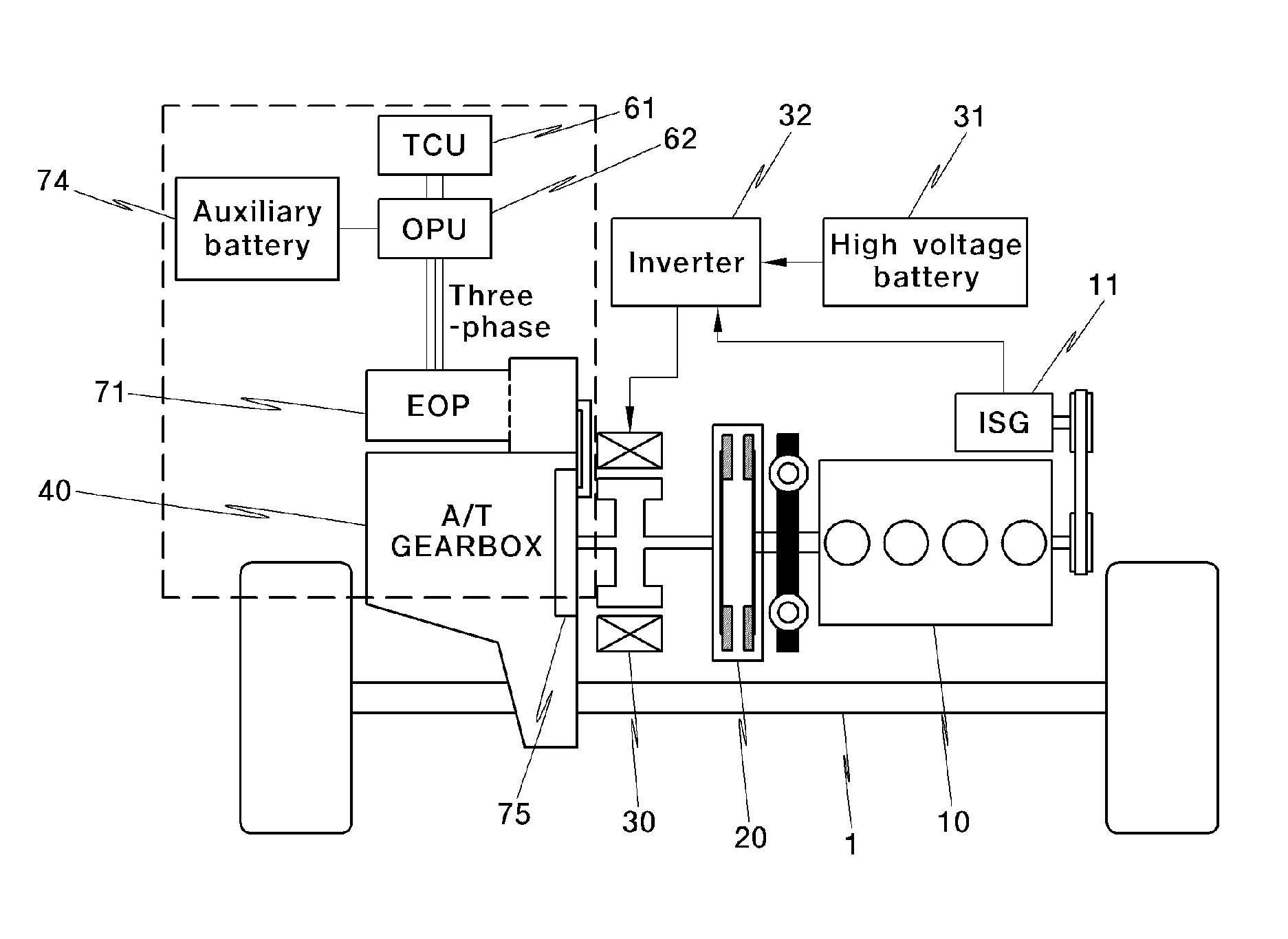

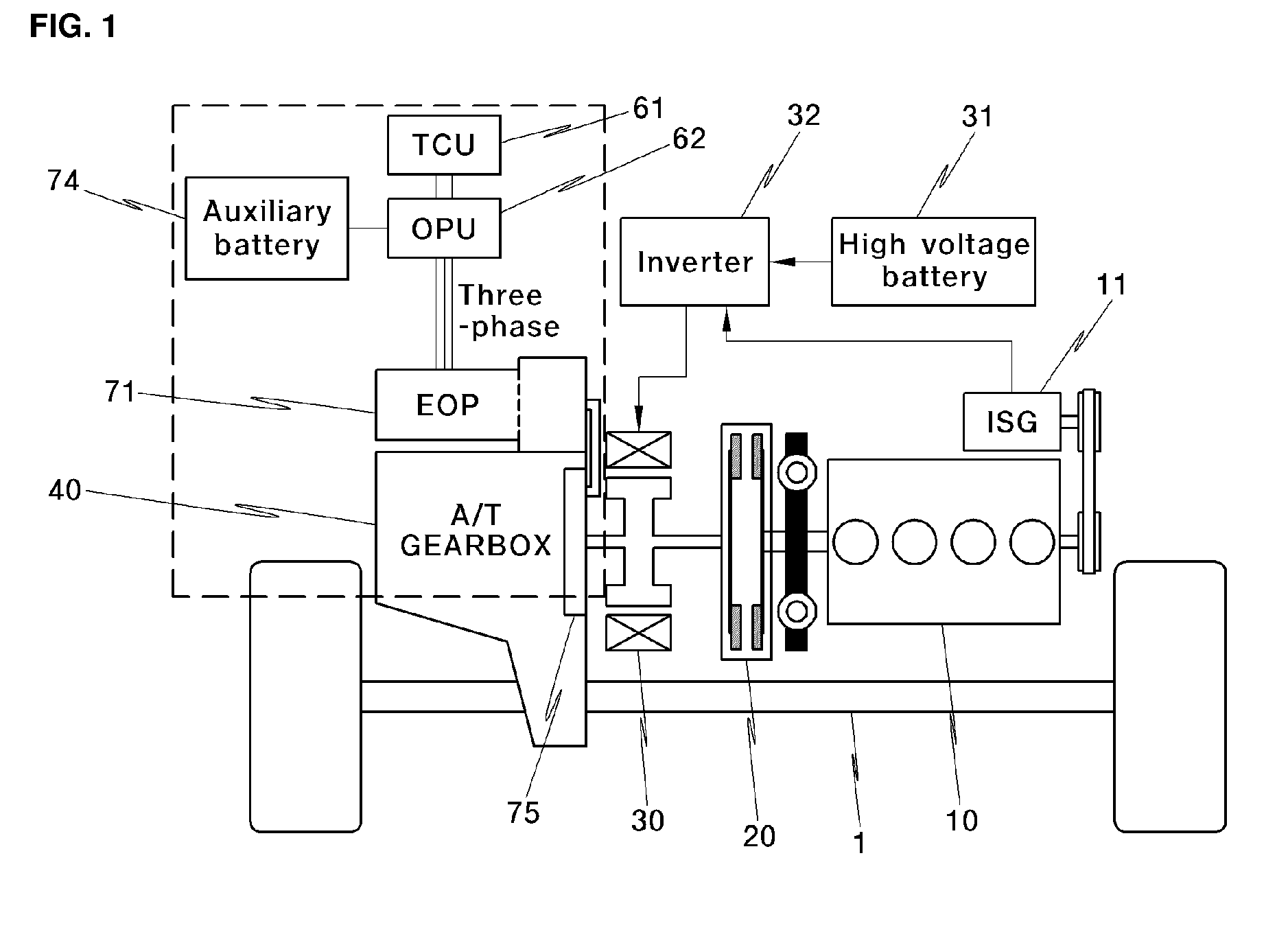

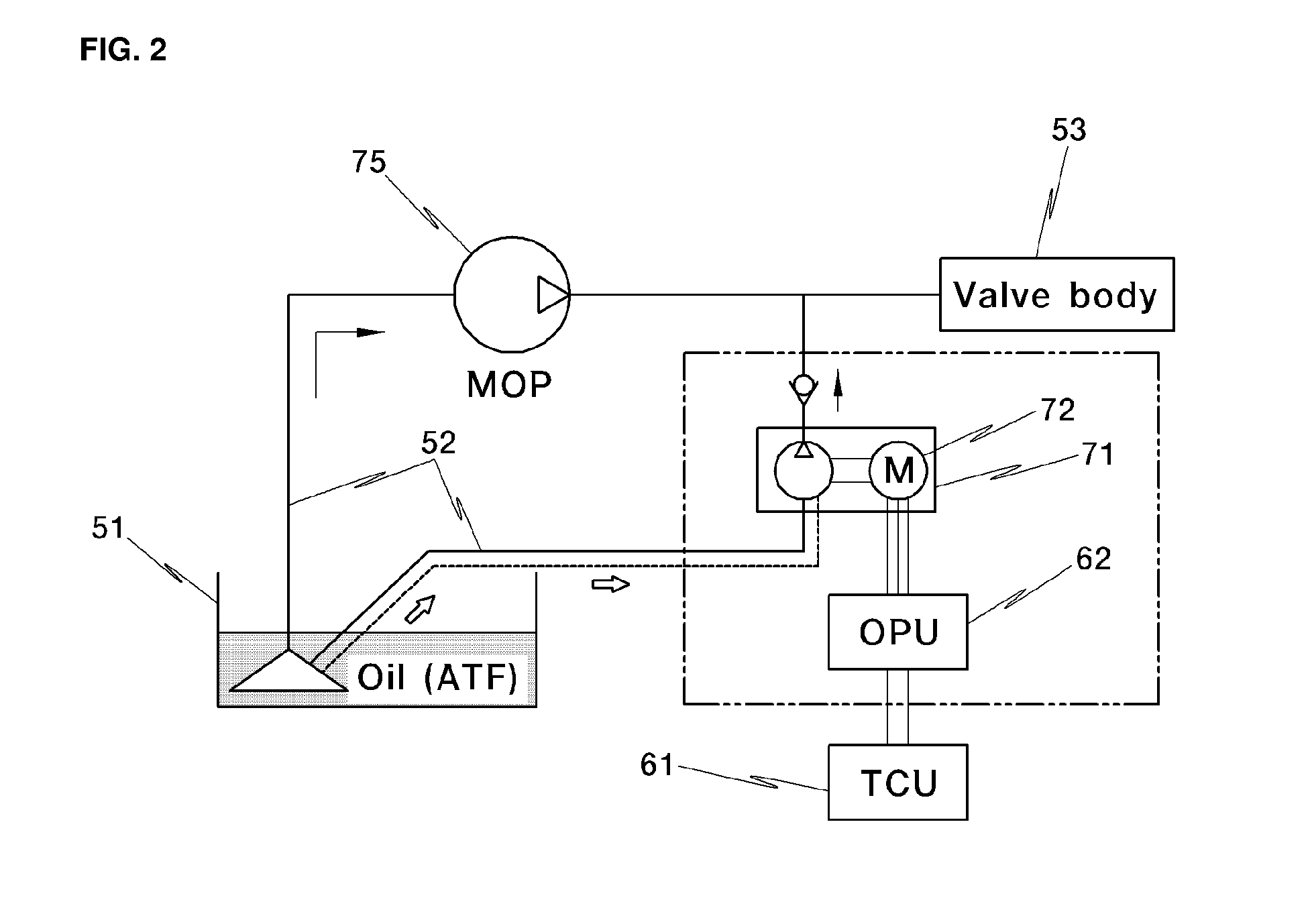

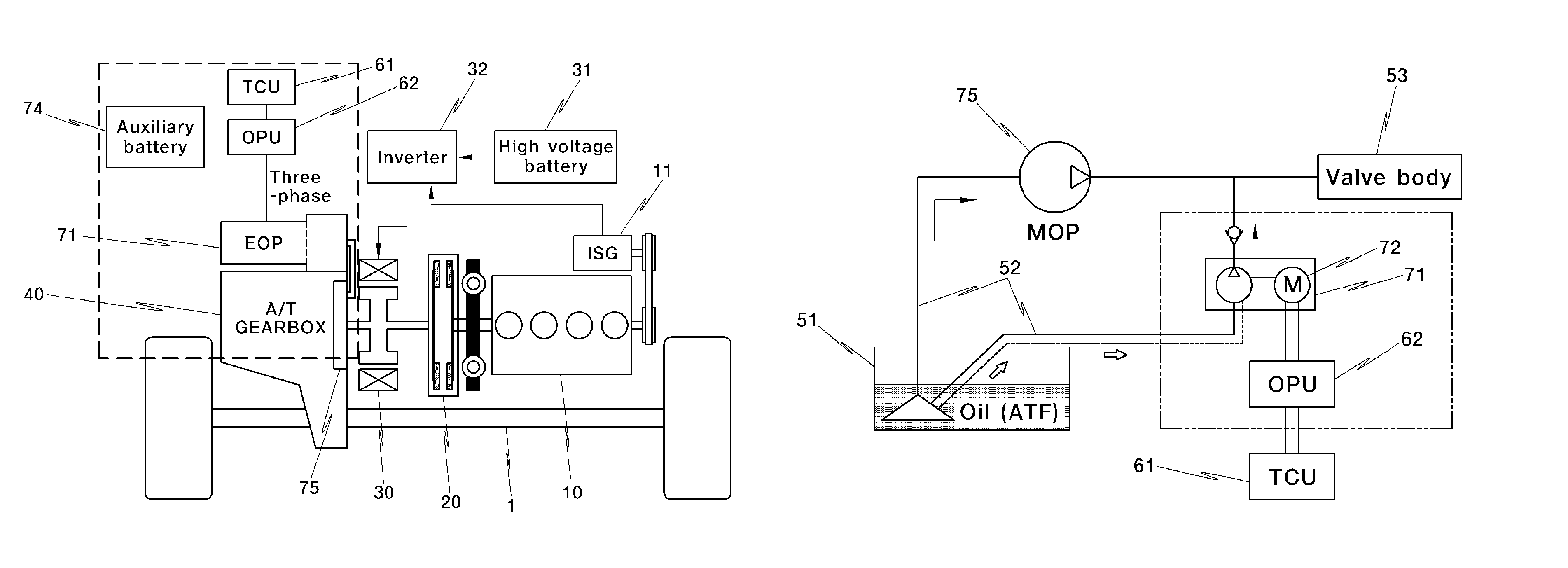

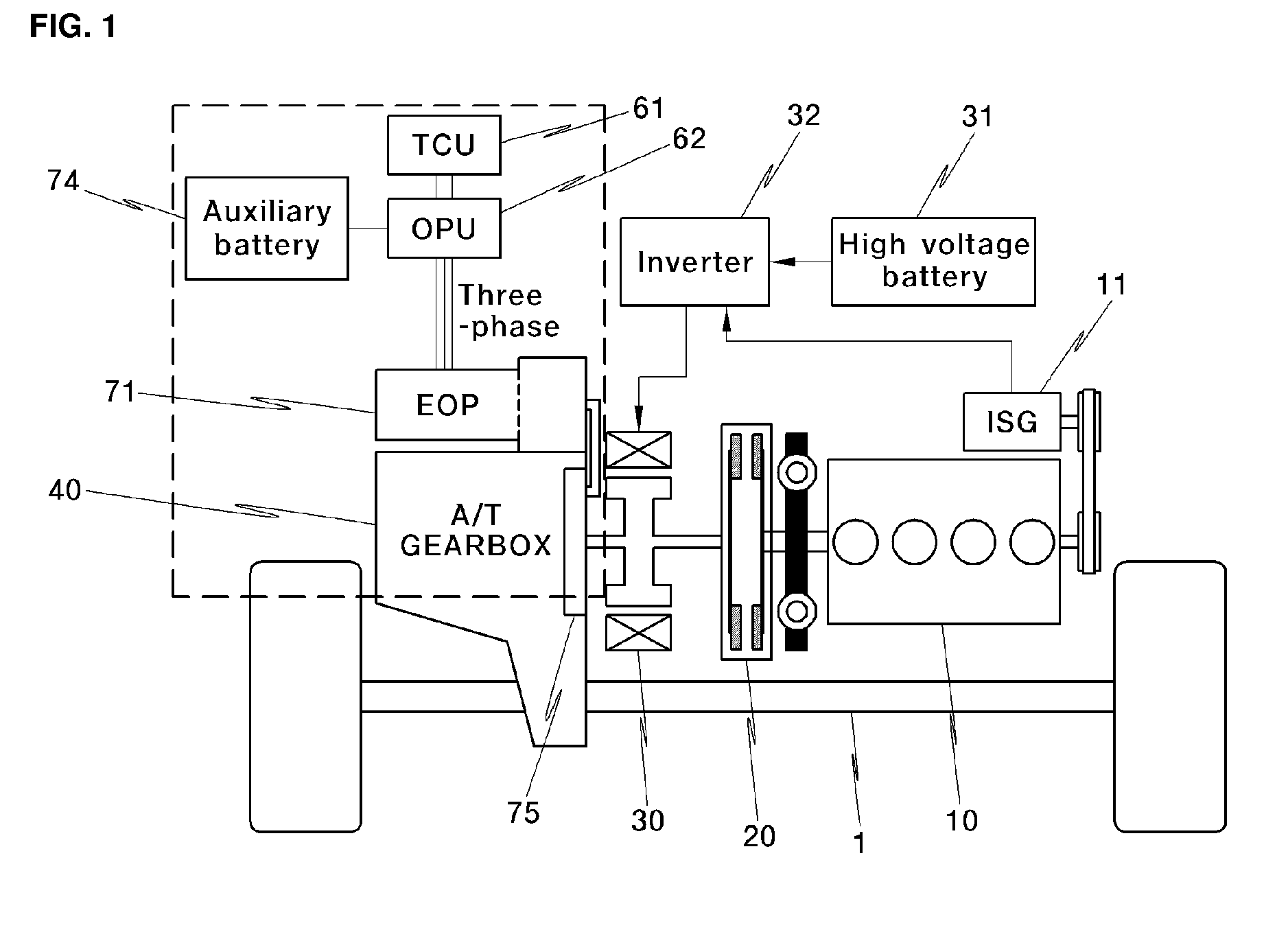

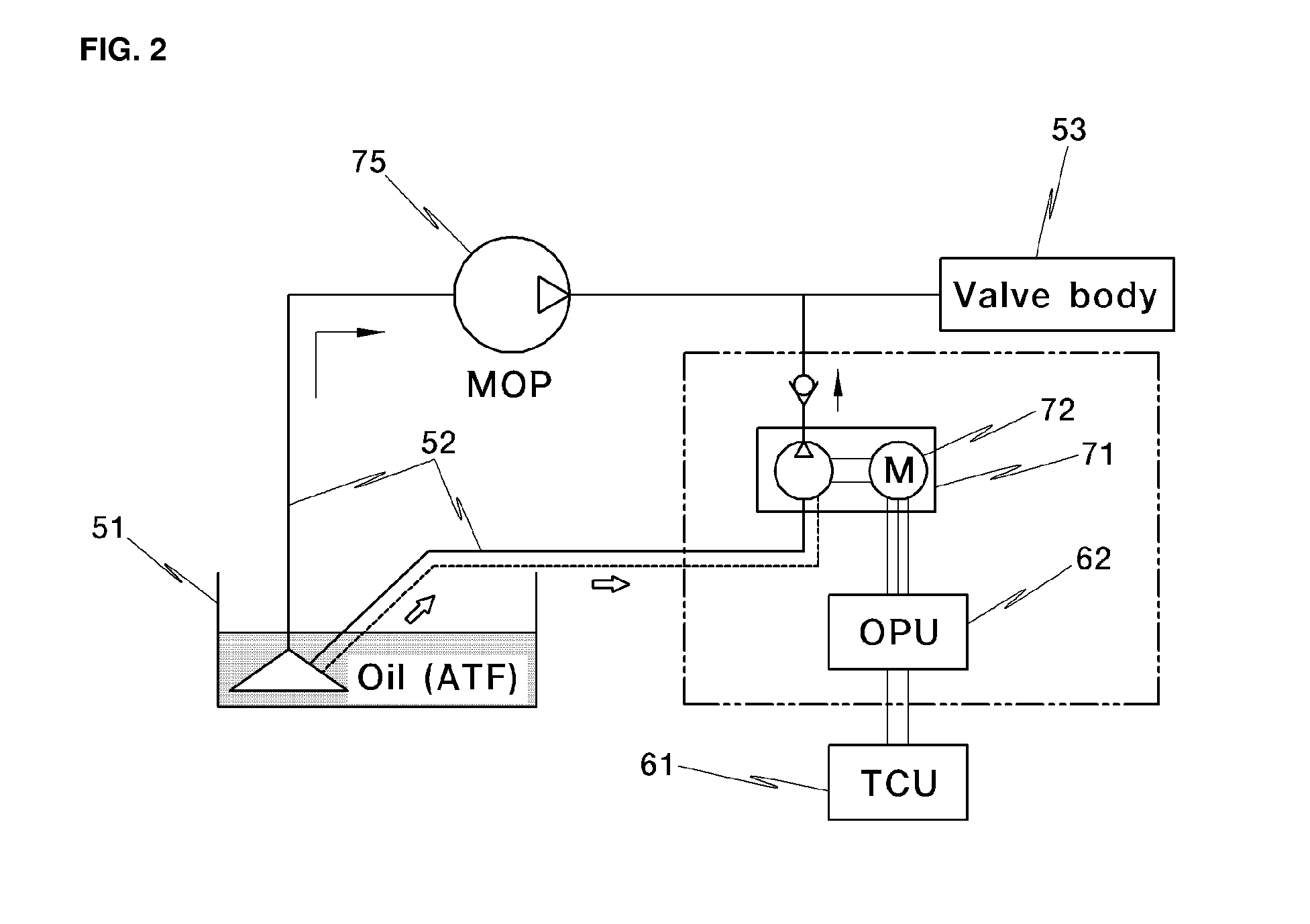

Apparatus and method for controlling operation of electric oil pump

ActiveUS20110135499A1Accurate viscosityEasy to controlGearing controlMotor parameterPower flowWorking fluid

The present invention provides an apparatus and method for controlling the operation of an electric oil pump for creating a working fluid pressure in a transmission and a clutch for a hybrid vehicle, which can accurately reflect the viscosity characteristics of oil to accurately control the operation of the pump, instead of measuring the temperature of the oil to reflect the state of the oil. In preferred embodiments, the present invention provides an apparatus for controlling the operation of an electric oil pump, the apparatus including: a current detector for detecting a current applied to a motor of an electric oil pump; a rotational speed detector for detecting a rotational speed of the motor; and a controller for calculating a load torque of the motor based on the detection values of the current detector and the rotational speed detector, calculating a target rotational speed based on the detection values, and controlling the operation of the motor based on the target rotational speed.

Owner:HYUNDAI MOTOR CO LTD +1

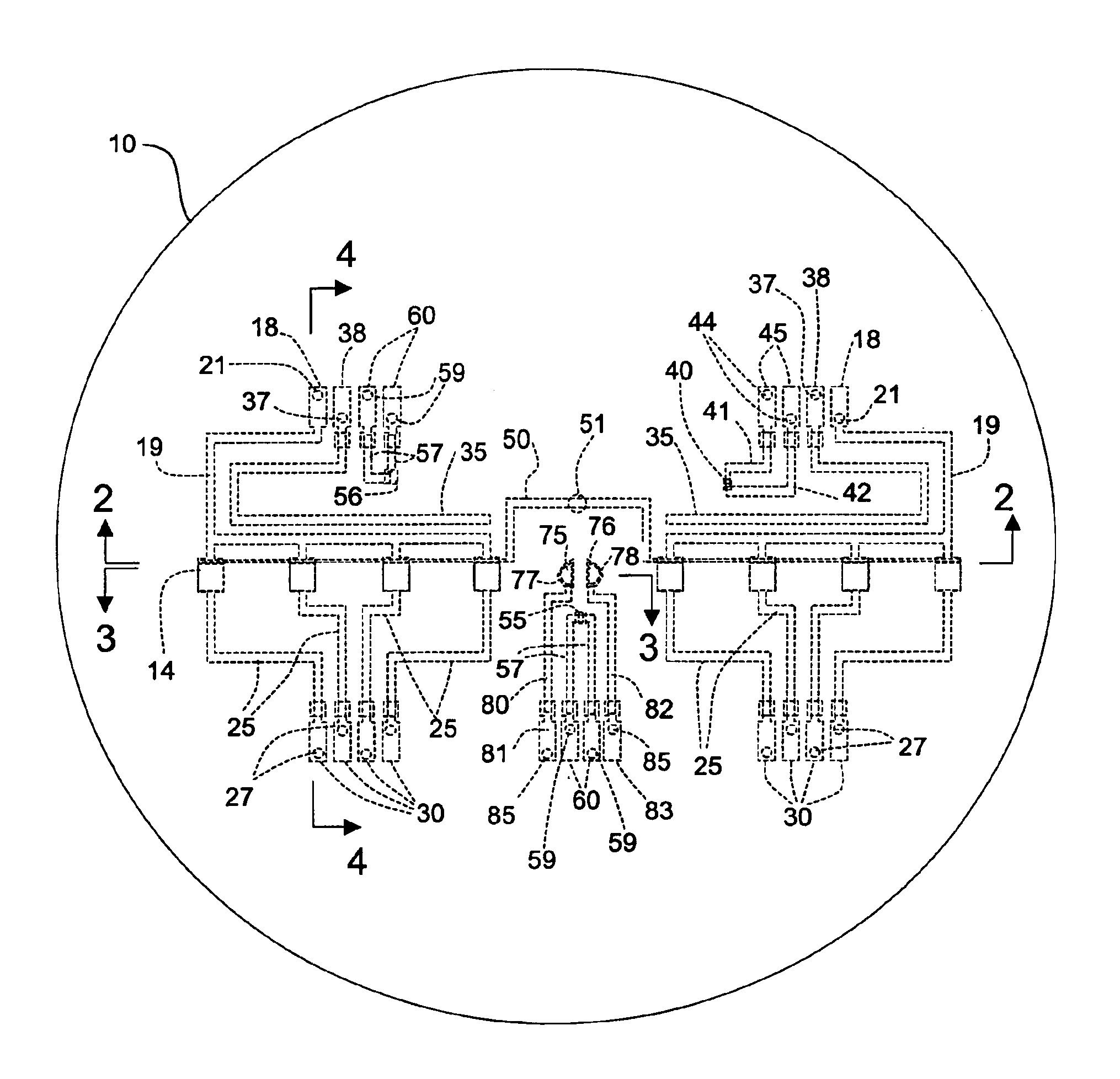

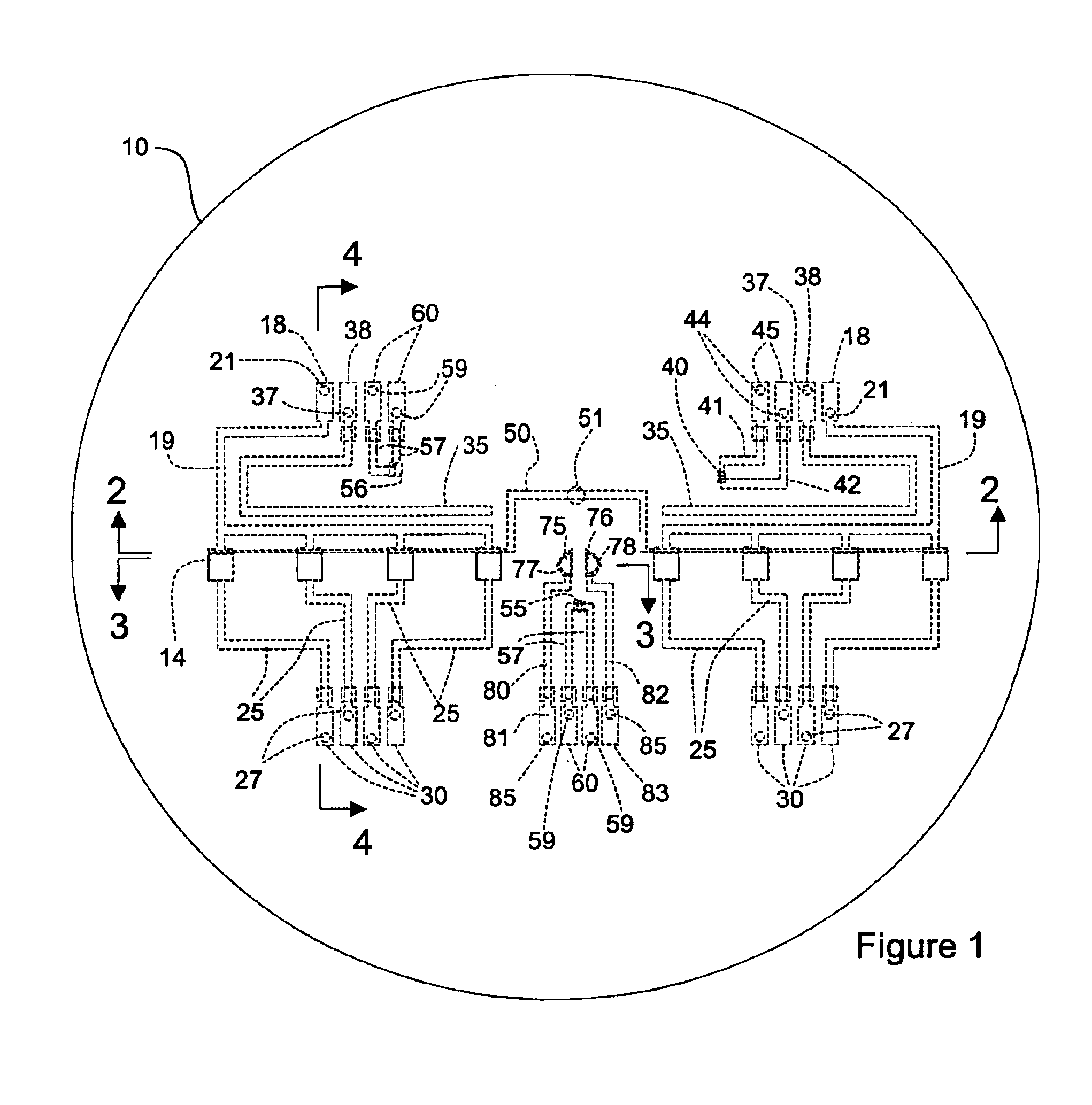

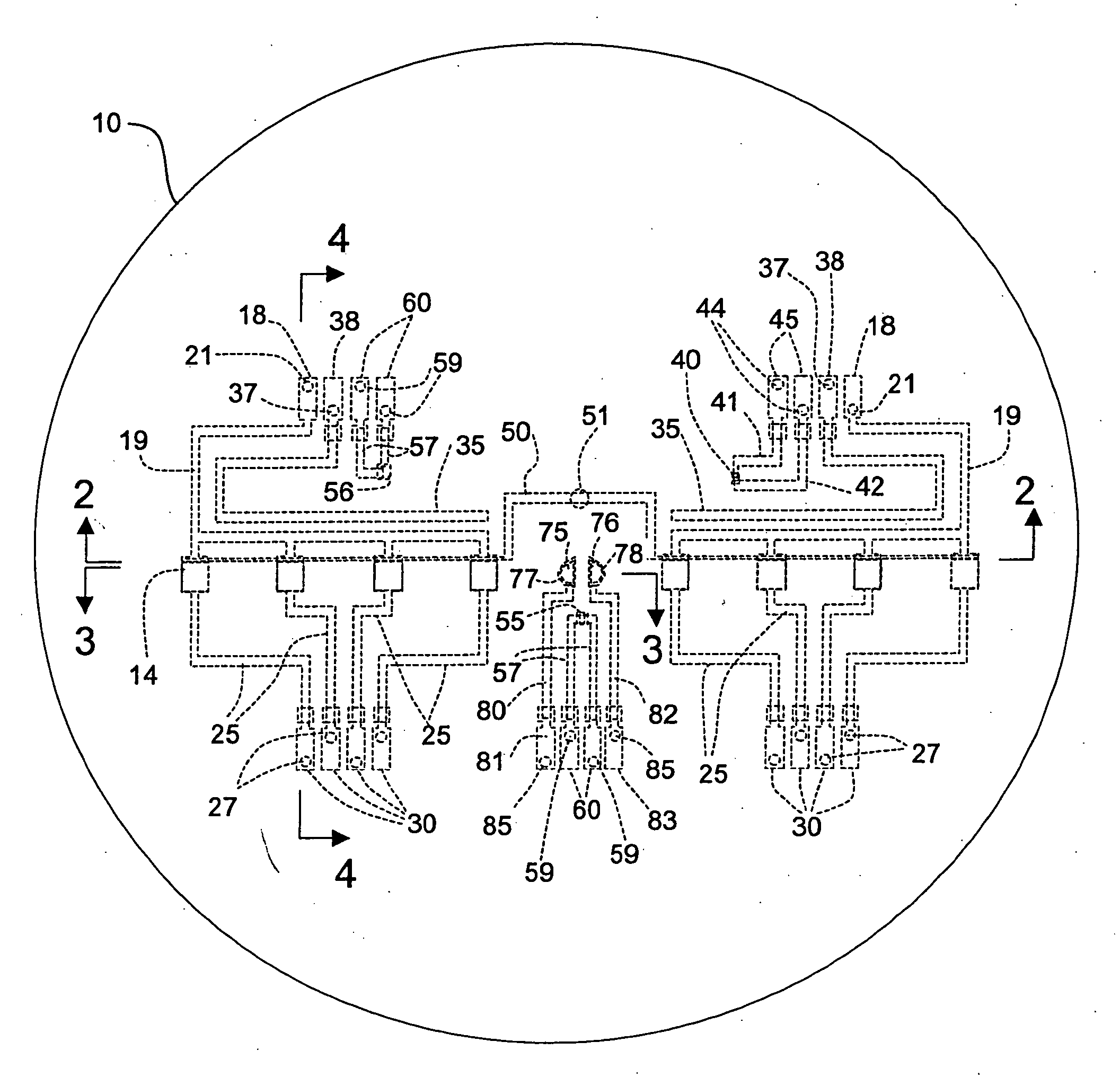

Pressure sensing device for rheometers

InactiveUS6892583B2Accurate viscosityImprove measurement accuracyMachine gearing/transmission testingFluid pressure measurement using elastically-deformable gaugesSmooth surfaceLocal pressure

An improved rheometer plate includes a smooth sensing surface with monolithically integrated miniature pressure sensors which do not interfere with the smooth surface. Pressure sensing diaphragms formed by the smooth surface deflect in response to local pressures against the surface to enable the measurement of unperturbed local pressures of materials sheared between plates. The pressure sensors are sufficiently small that measured pressures are considered to be significantly local properties compared to the size of the plate. Normal stress differences and viscosity of fluid are measured accordingly. The membrane covers a plurality of wells or recesses with pressure sensors located in the wells to measure the deflection of the membrane over the wells. Capacitive or other sensors may be used. The rheometer plate can be used as part of a slit rheometer with a slit of varying dimensions.

Owner:RHEOSENSE

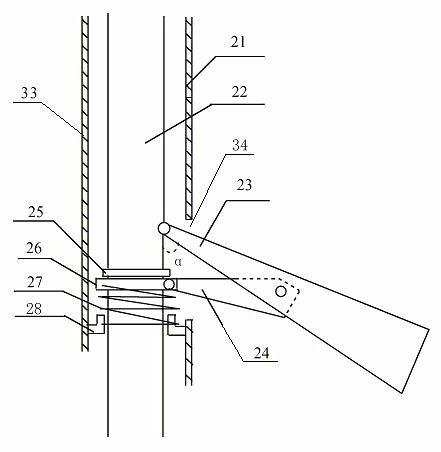

Petroleum drilling real-time monitoring system

InactiveCN102828747AViscosity is accurate in real timeAccurate viscositySurveyDisplay devicePetroleum

The invention provides a petroleum drilling real-time monitoring system which comprises a drilling liquid performance monitoring instrument, a geological logging monitoring instrument and a drilling engineering parameter monitoring instrument, wherein sensors are arranged on all the instruments; the sensors are used for transmitting a detecting signal to computer processing equipment through a wireless transmitting and receiving system, and the detecting signal is processed through the computer software and then converted into a chart to be displayed through a display in real time. With the adoption of the petroleum drilling real-time monitoring system, the shortcomings of the comprehensive logging instrument that only the geological logging and drilling engineering parameters can be monitored can be overcome; the drilling liquid performance can be monitored online in real time, so that the drilling liquid, the drilling engineering and the geological logging can be integrated and processed through a computer, and then a comprehensive system integrating the acquiring, displaying and processing of various data at a drilling site can be formed; the comprehensive system can meets the various demands of safely optimizing the drilling and comprehensively determining an oil-gas-water layer.

Owner:韩文峰

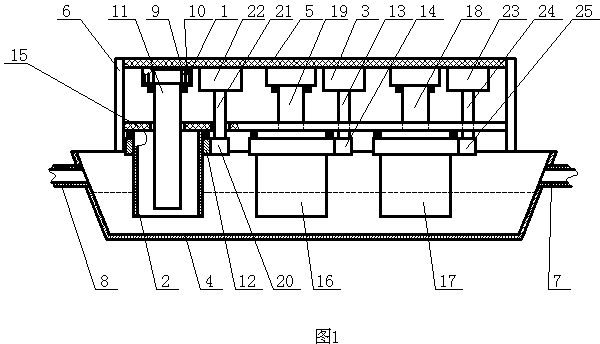

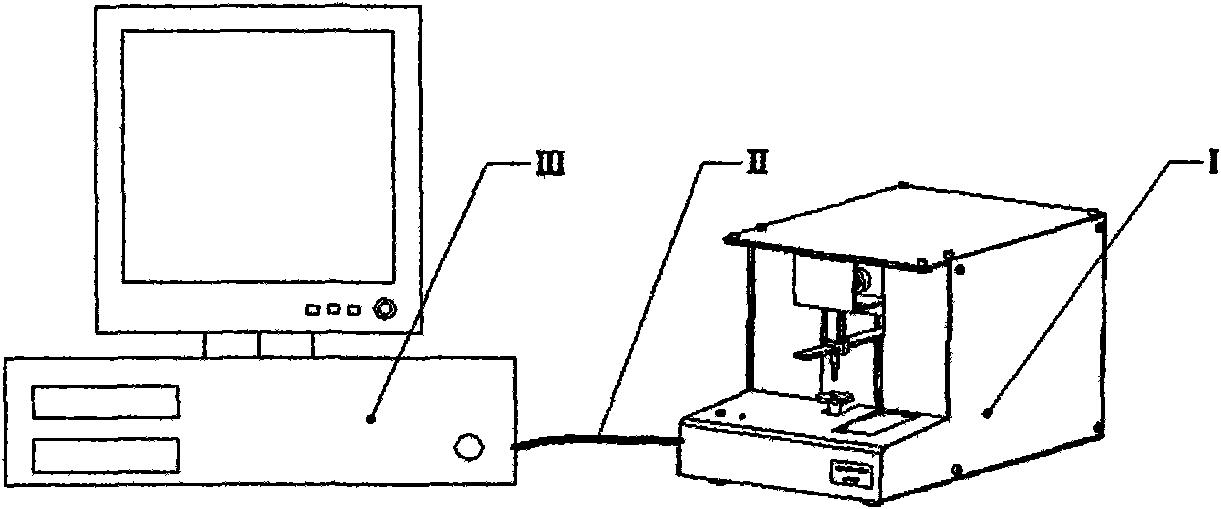

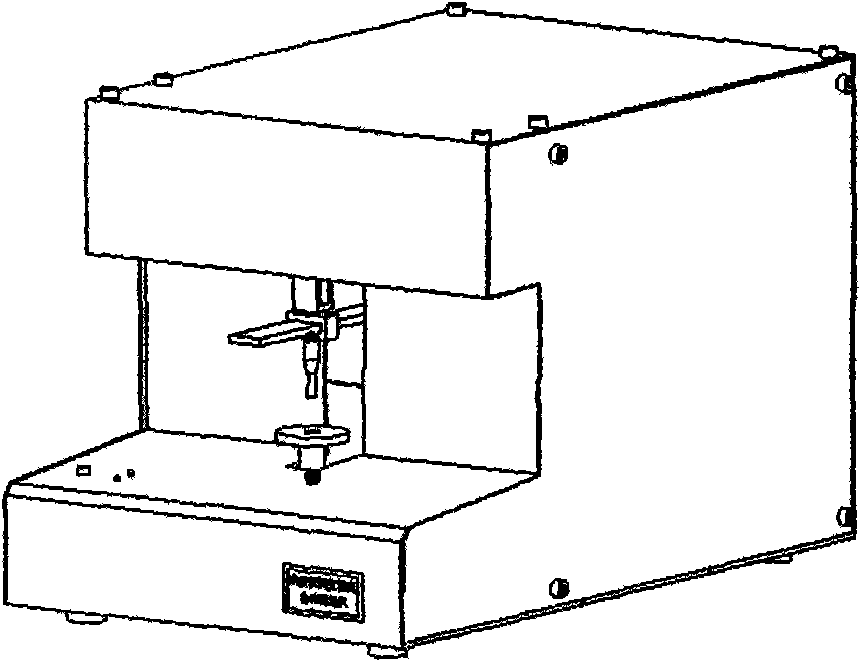

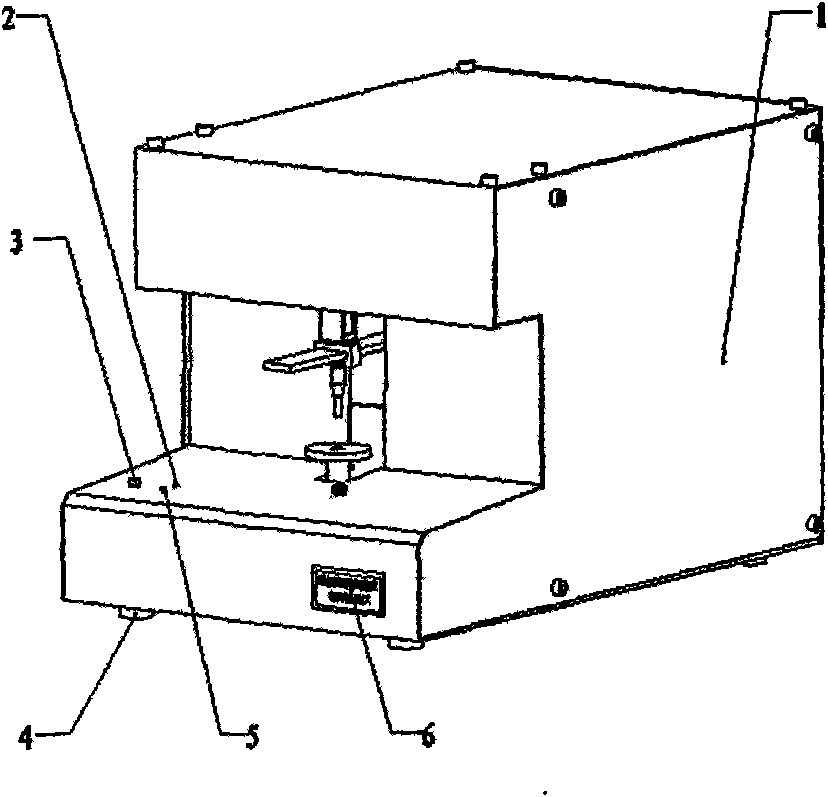

Automatic detector for textural properties of hardness and viscosity of cooked rice grains

InactiveCN101571468AAccurate hardnessReal hardnessFlow propertiesInvestigating material hardnessEngineeringHardness

The invention relates to an automatic detector aiming at textural properties of hardness and viscosity of cooked rice grains. A structure of the automatic detector comprises: a motor is connected with a shaft which is connected with a cam; a guide rod is arranged below the cam; a spring is arranged on the guide rod, and the underside of the guide rod is provided with an upper measuring arm and a lower measuring arm which are connected to a box body; the upper measuring arm is provided with an upper moveable block; a fastening screw is arranged on the upper moveable block, and the underside of the upper moveable block is connected with a pressure head; the lower measuring arm is provided with a lower moveable block which is provided with a lower fastening screw, and the above of the lower moveable block is connected with a tray which aims at the pressure head on the above; and strain gauges are arranged on the upper measuring arm and the lower measuring arm to form a differential bridge to a PC machine. The automatic detector overcomes the defects that a texture analyzer has poor accuracy and cannot represent the change relation between two parameters, namely the stress and the deformation in the process that cooked rice is stressed. The automatic detector aims at the detection of the textural properties of the cooked rice grains, accurately and truly reflects the hardness and the viscosity of the cooked rice grains and performs quantification on the hardness and the viscosity.

Owner:YANGZHOU UNIV

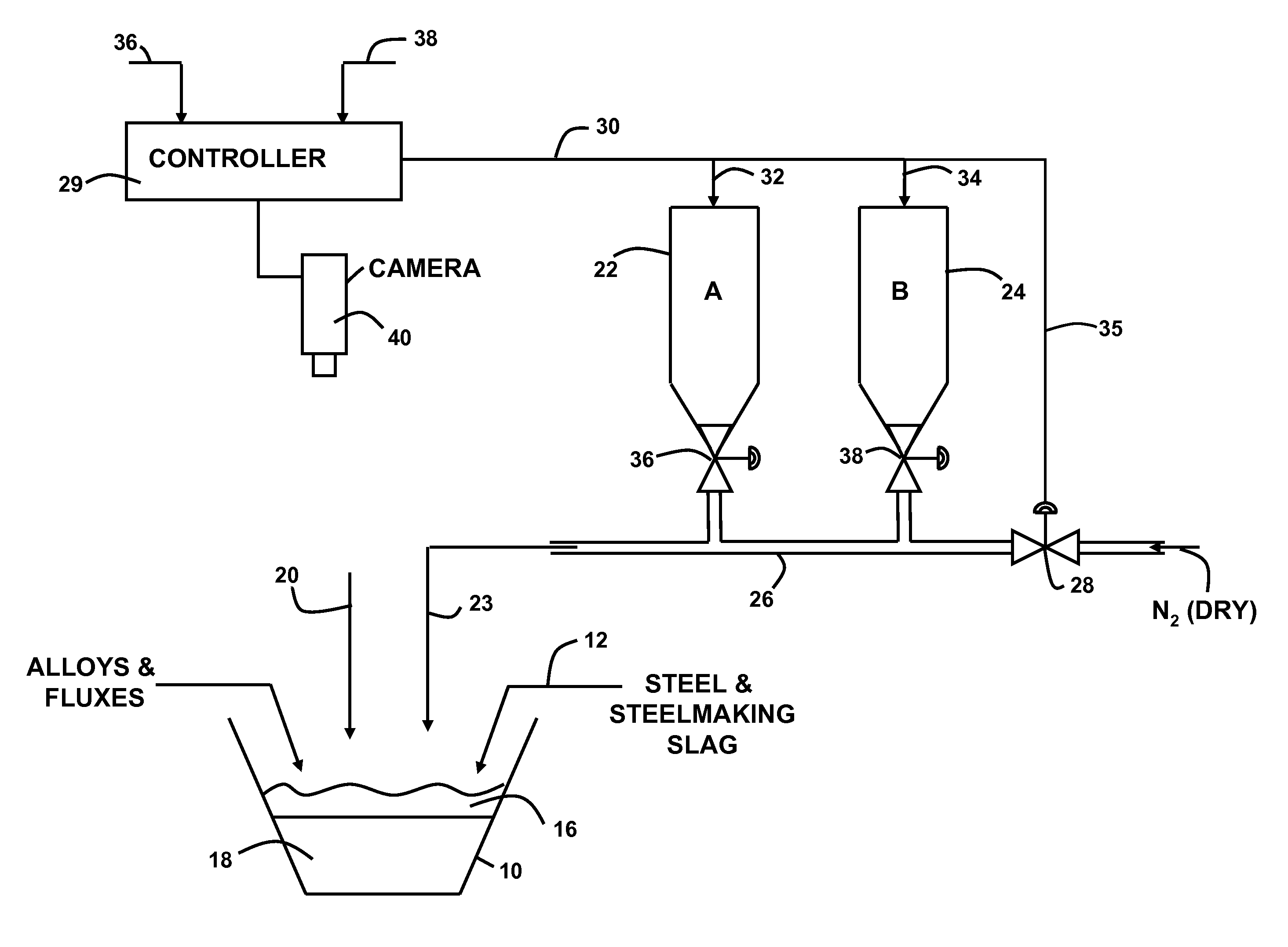

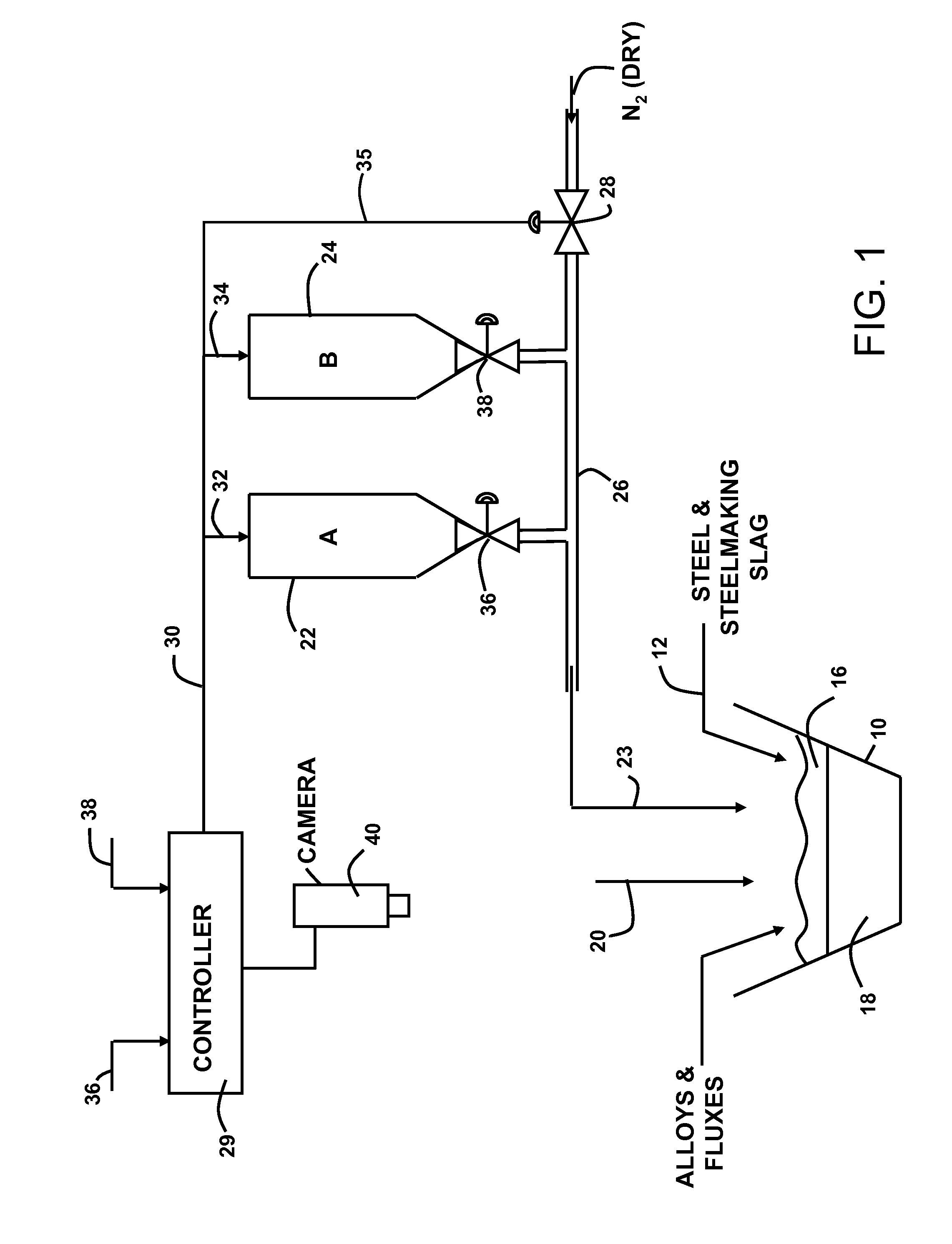

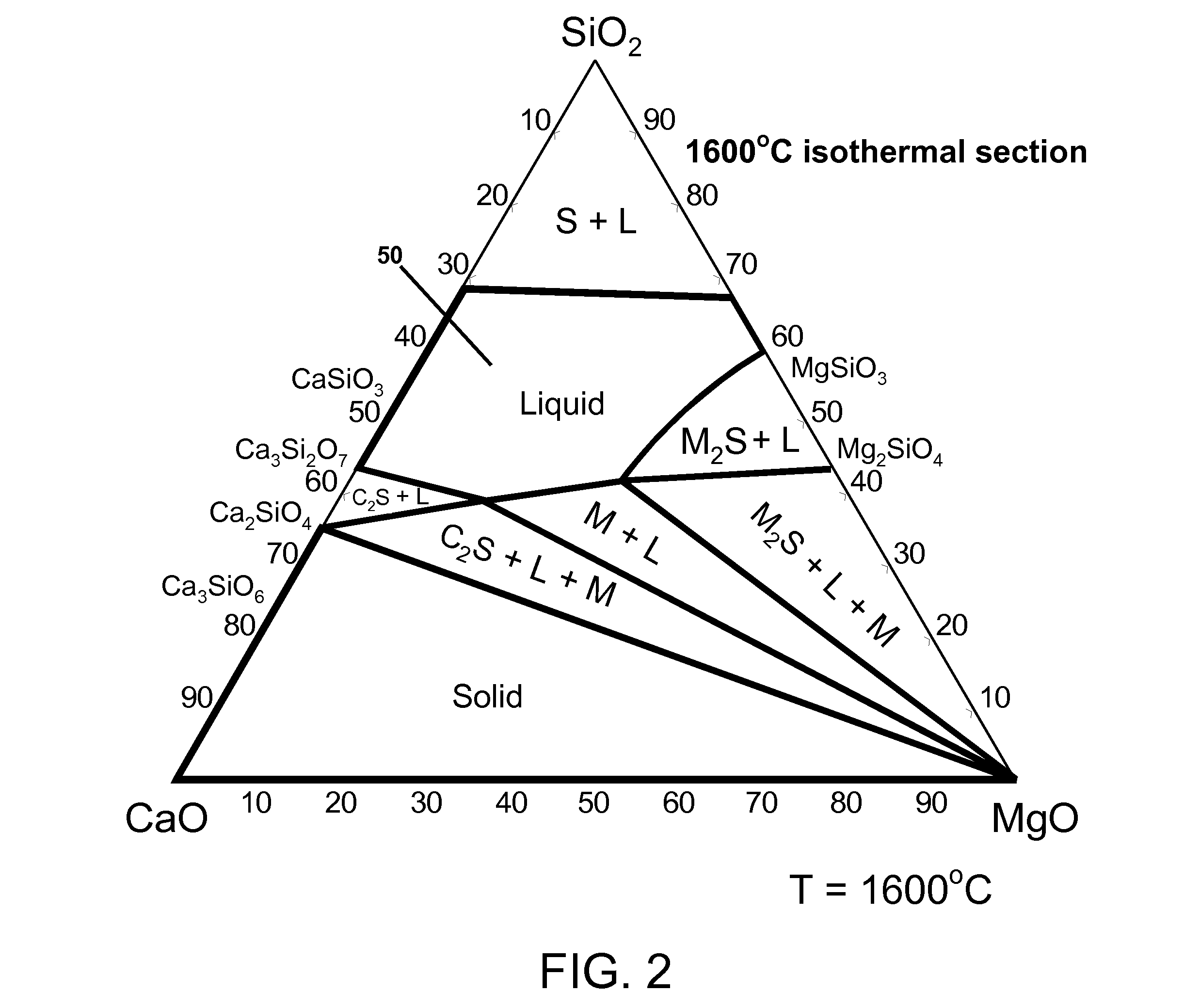

Composition for reducing the oxygen potential of slag

InactiveUS20130019715A1Easy to producePromote productionBlast furnace componentsBlast furnace detailsSteelmakingSilicon oxide

A slag composition containing steelmaking slag and from about 0.3 to about 10 weight percent of reducing agent. The steelmaking slag contains from about 20 to about 55 weight percent of calcium oxide, from about 8 to about 50 weight percent of ferrous oxide, from about 4 to about 20 weight percent of magnesium oxide, from about 8 to about 30 weight percent of silicon oxide, from 0.5 to about 10 weight per cent aluminum oxide, and from about 0.5 to about 10 weight percent of manganese oxide. The reducing agent contains from about 15 to about 70 weight percent of calcium carbide and from about 10 to about 50 weight percent silicon carbide, wherein the ratio of calcium carbide to silicon carbide is between 0.7 and 7.

Owner:NUFLUX

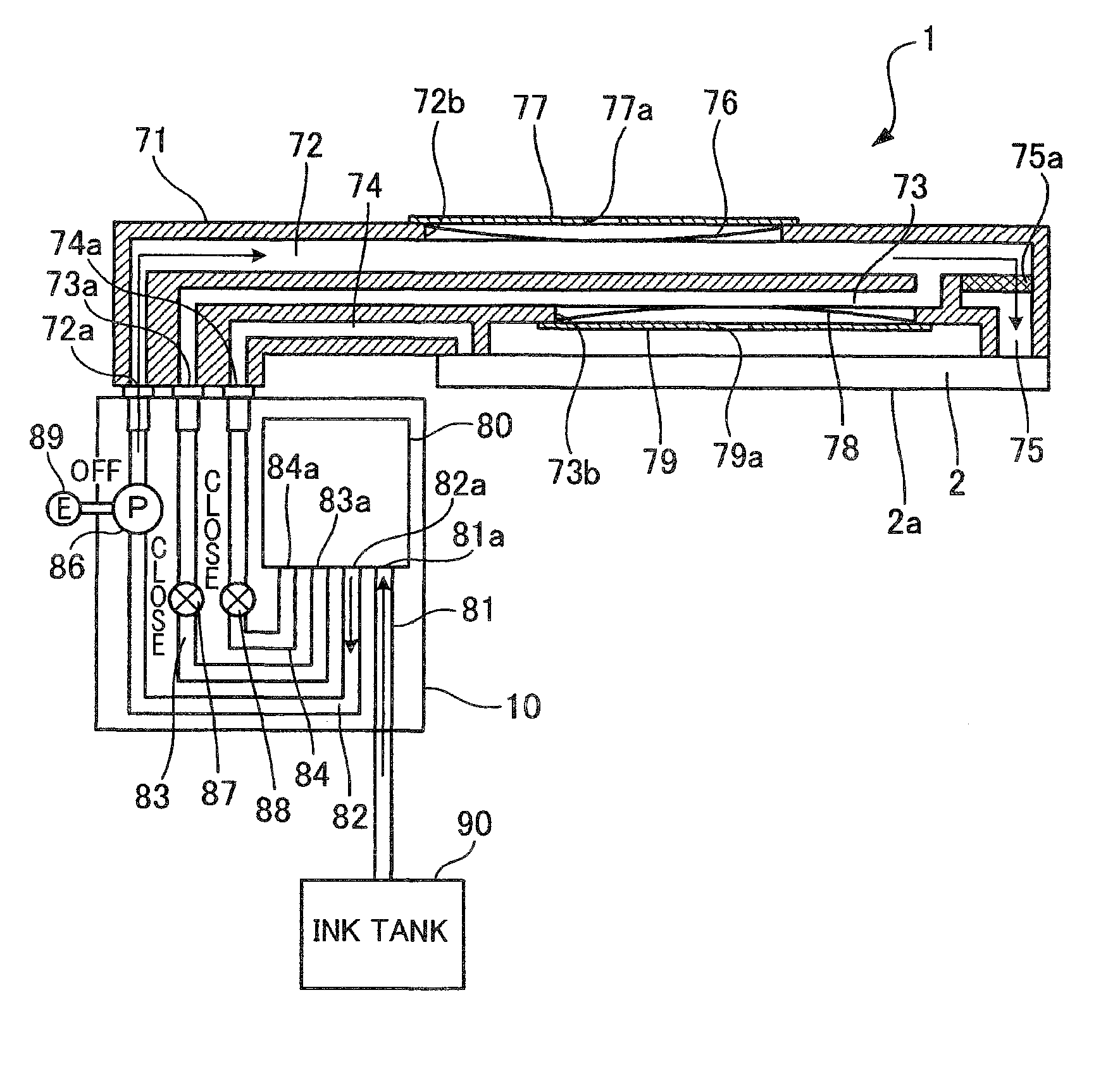

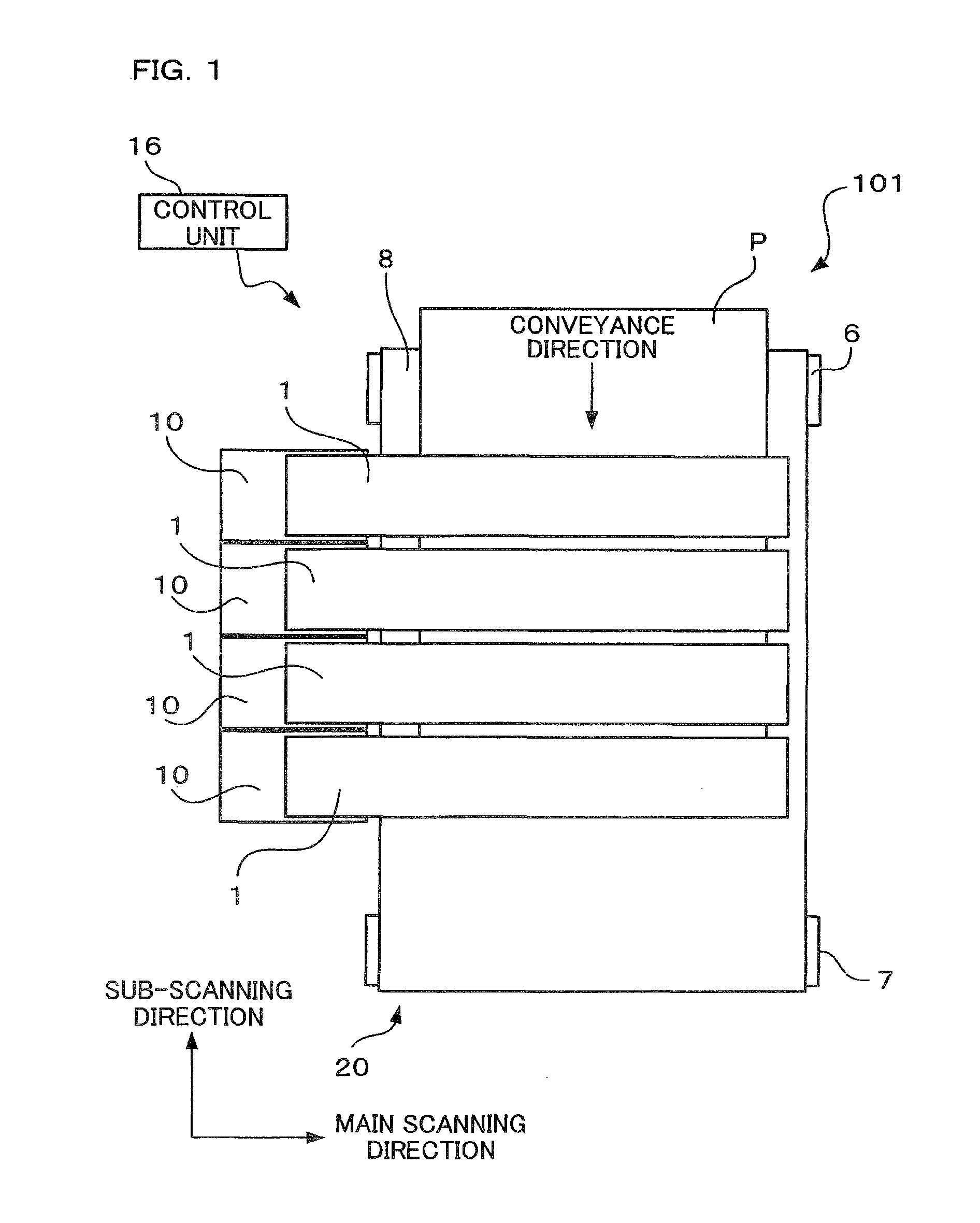

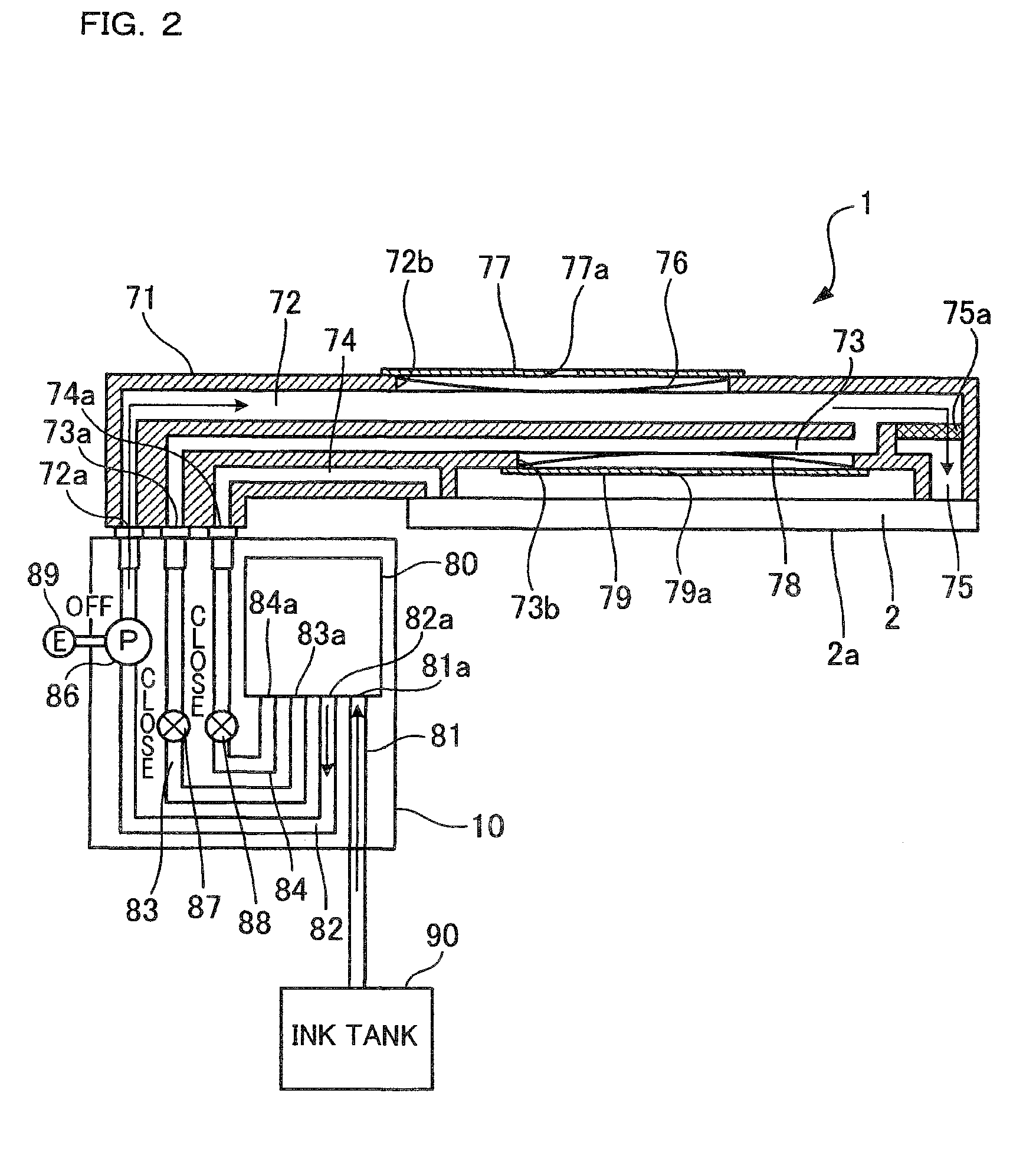

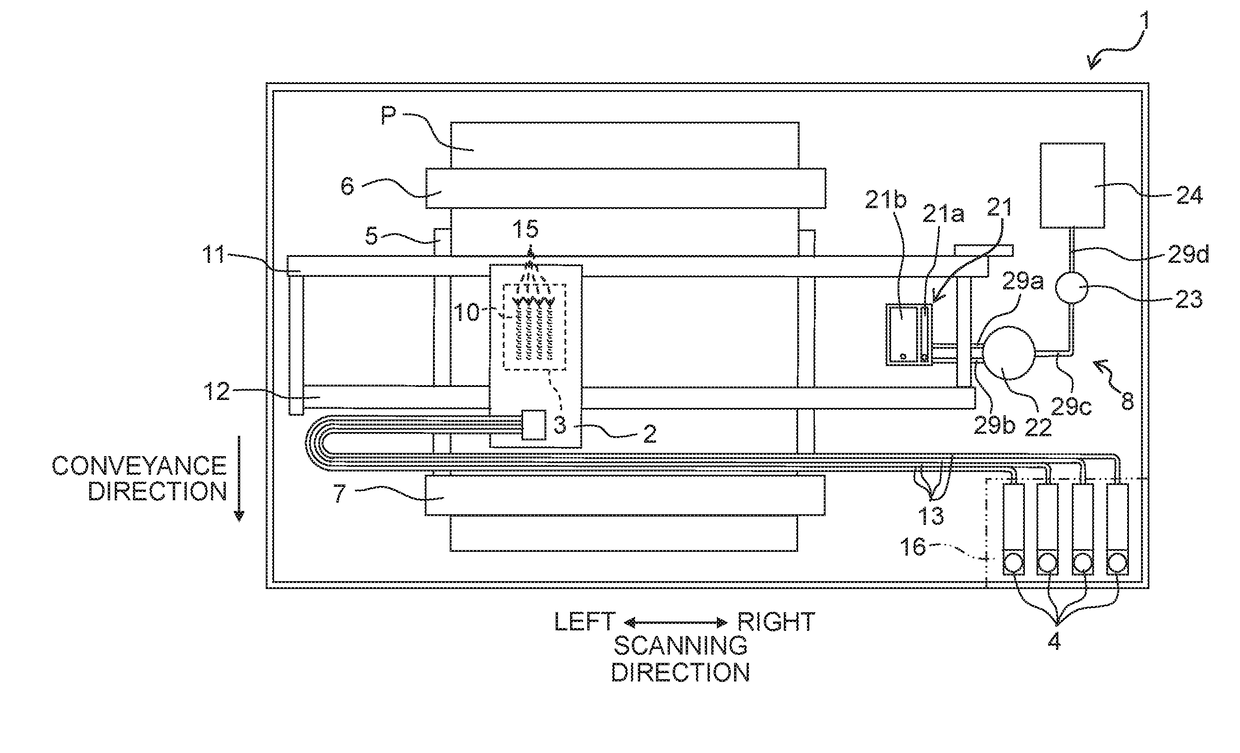

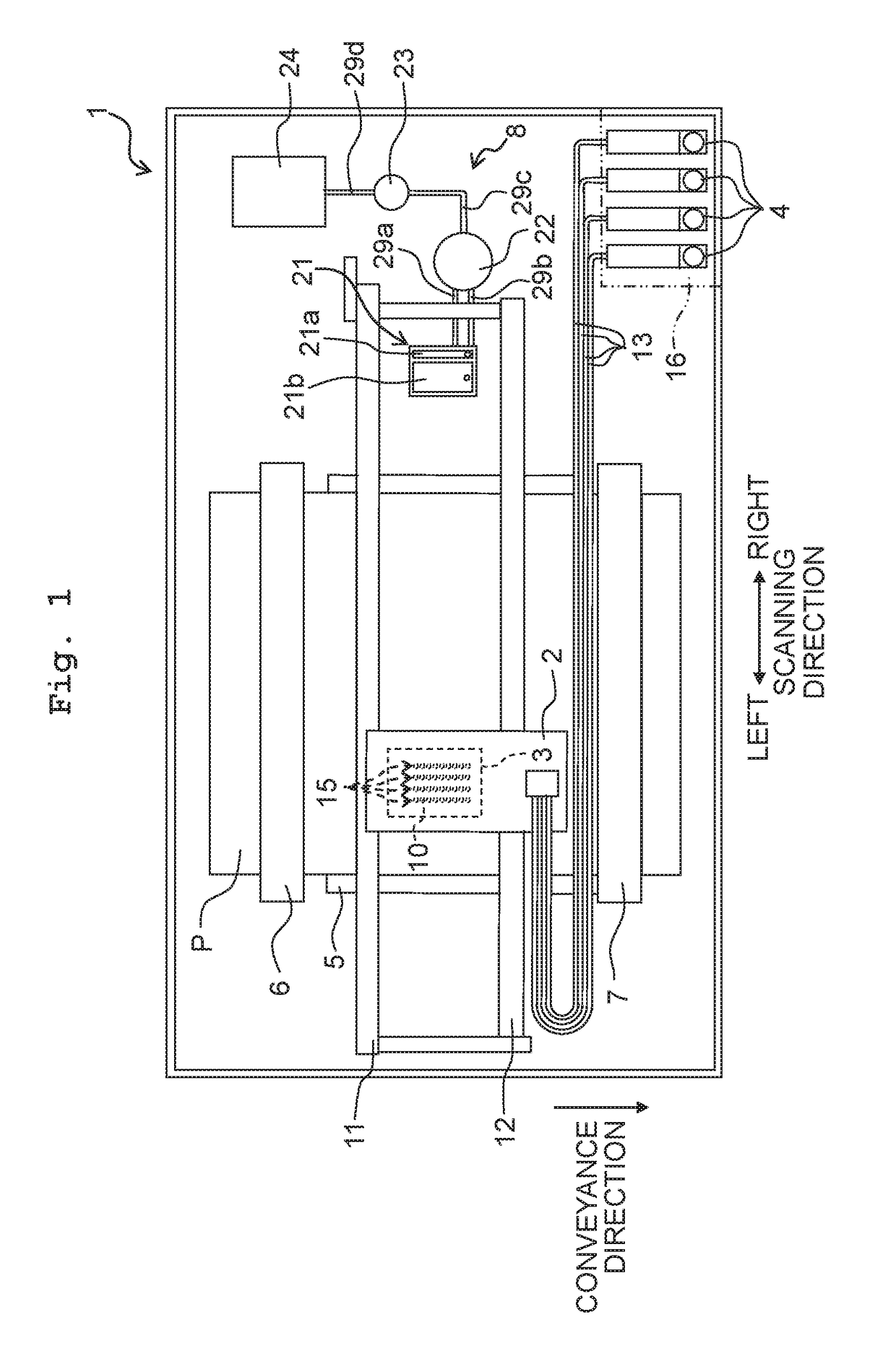

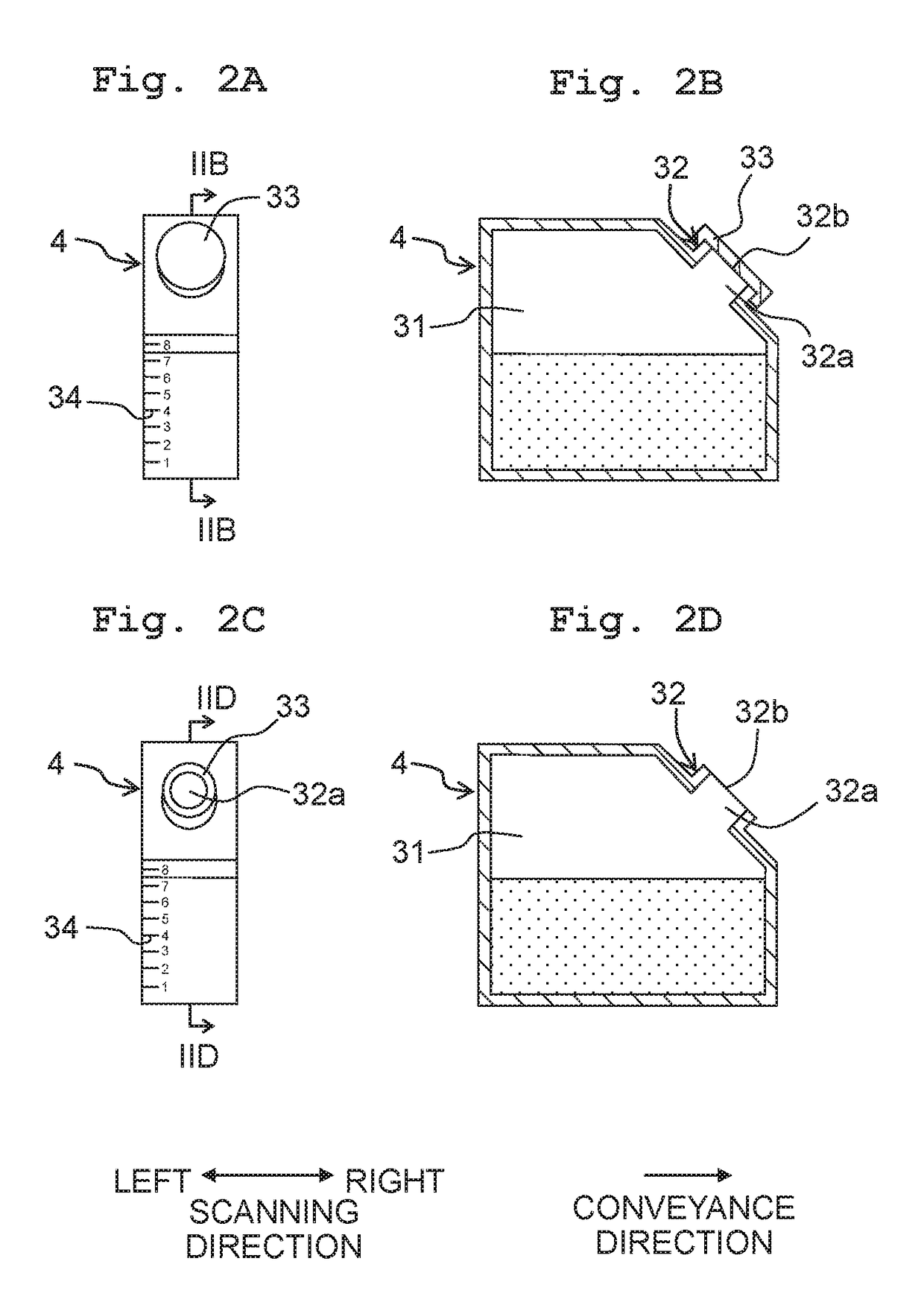

Liquid ejection apparatus

A liquid ejection apparatus includes a valve which adjusts the flow rate of a recording liquid in a return passage connecting an outflow opening with a tank, a pump which supplies the recording liquid from the tank to the internal passage via the supply passage, a detecting unit which detects an operating state of the pump, and a calculating unit which calculates the viscosity of the recording liquid. The calculating unit calculates the viscosity of the recording liquid based on the operating state of the pump detected by the detecting unit, while the recording liquid in the tank circulates so as to serially pass through the supply passage, the internal passage, and the return passage.

Owner:BROTHER KOGYO KK

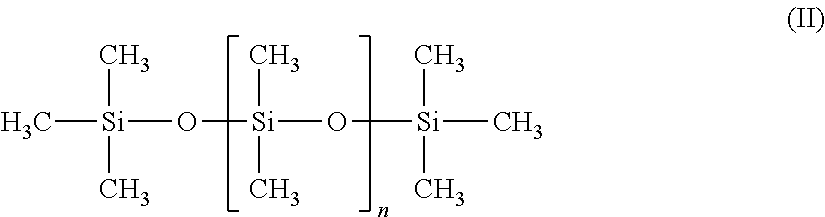

Bicomponent reactive ink for ink jet printing

ActiveUS9574096B2Good ejectabilityAccurate viscosityLiquid surface applicatorsAntifouling/underwater paintsPorous substratePolymerization catalysts

The present invention relates to (i) a reactive ink for ink jet printing comprising a two-component system, the first component comprising a polymerizable monomer, and the second component comprising a polymerization catalyst, wherein the monomer is able to form a polymeric film at low temperature within thirty minutes, preferably within ten minutes, from contacting the catalyst, (ii) a process of making an image on a non-porous substrate using such a reactive ink, and an ink jet print head including a two component ink-system.

Owner:SICPA HLDG SA

Pressure sensing device for rheometers

InactiveUS20050210964A1Eliminate surface roughnessIncrease shear rateMachine gearing/transmission testingFluid pressure measurement using elastically-deformable gaugesPressure senseLocal pressure

A rheometer for measuring flow properties of a flowable material includes a substantially smooth measuring surface having a plurality of pressure sensors at spaced locations therein to measure pressure exerted against the measuring surface at the locations of the pressure sensors, and a rotatable surface spaced a distance from the substantially smooth measuring surface to form a sample receiving space therebetween for receiving a sample of material for which flow properties are to be measured. The substantially smooth surface may include monolithically integrated miniature pressure sensors which do not interfere with the substantially smooth surface. Pressure sensing diaphragms formed by the smooth surface deflect in response to local pressures against the surface to enable the measurement of unperturbed local pressures of materials sheared between the surfaces. The pressure sensors are sufficiently small that measured pressures are considered to be significantly local properties compared to the size of the measuring surface.

Owner:BAEK SEONG-GI

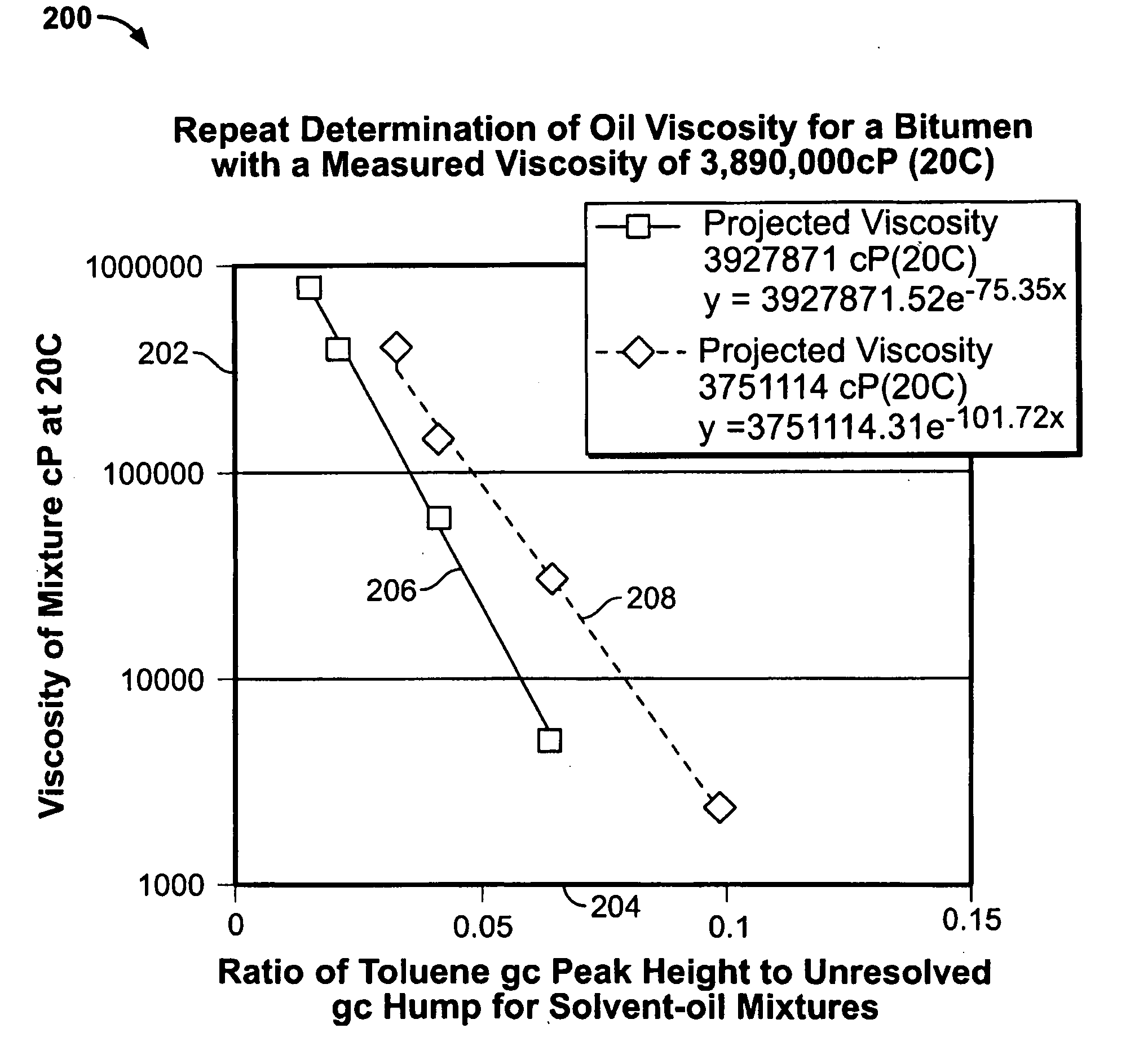

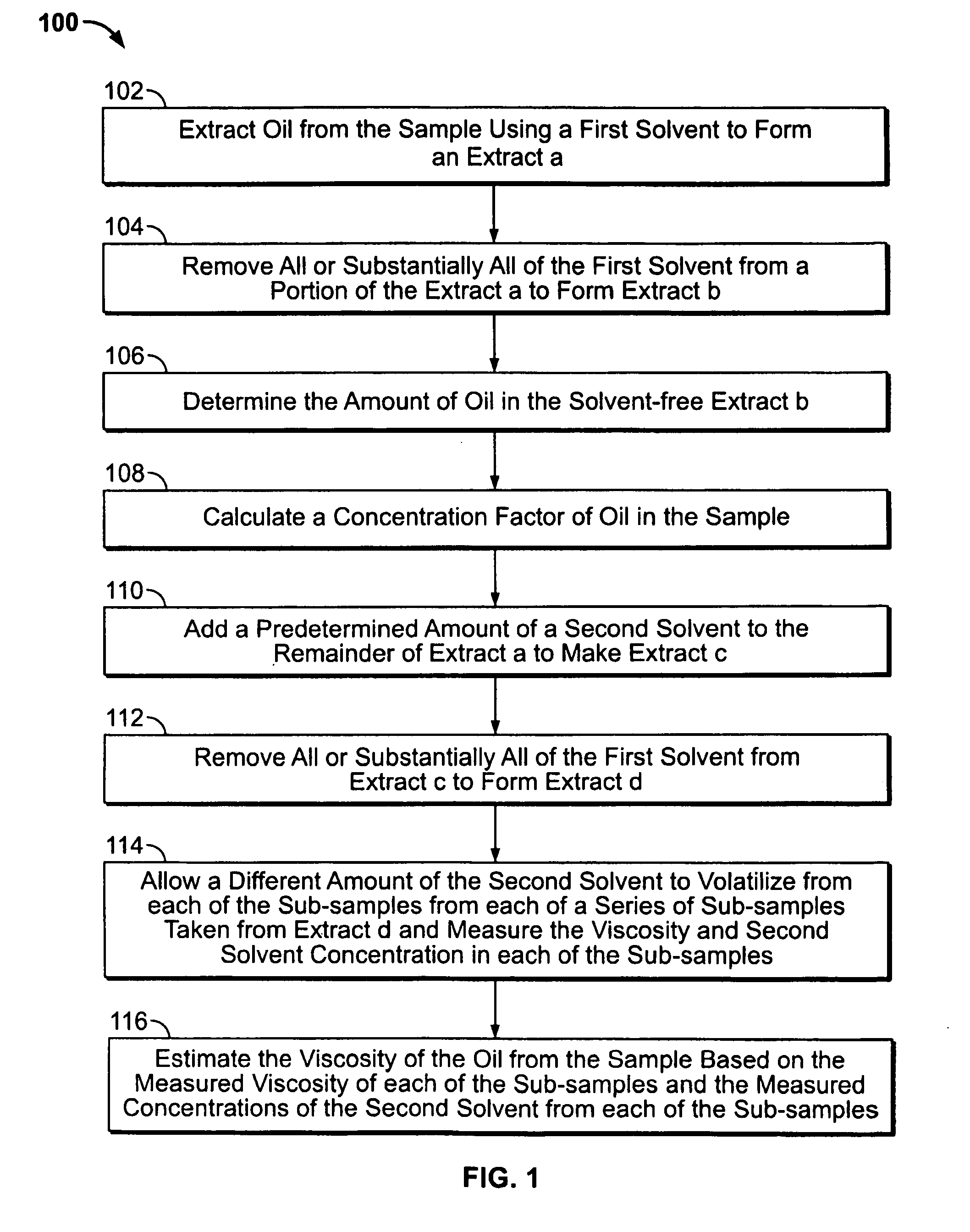

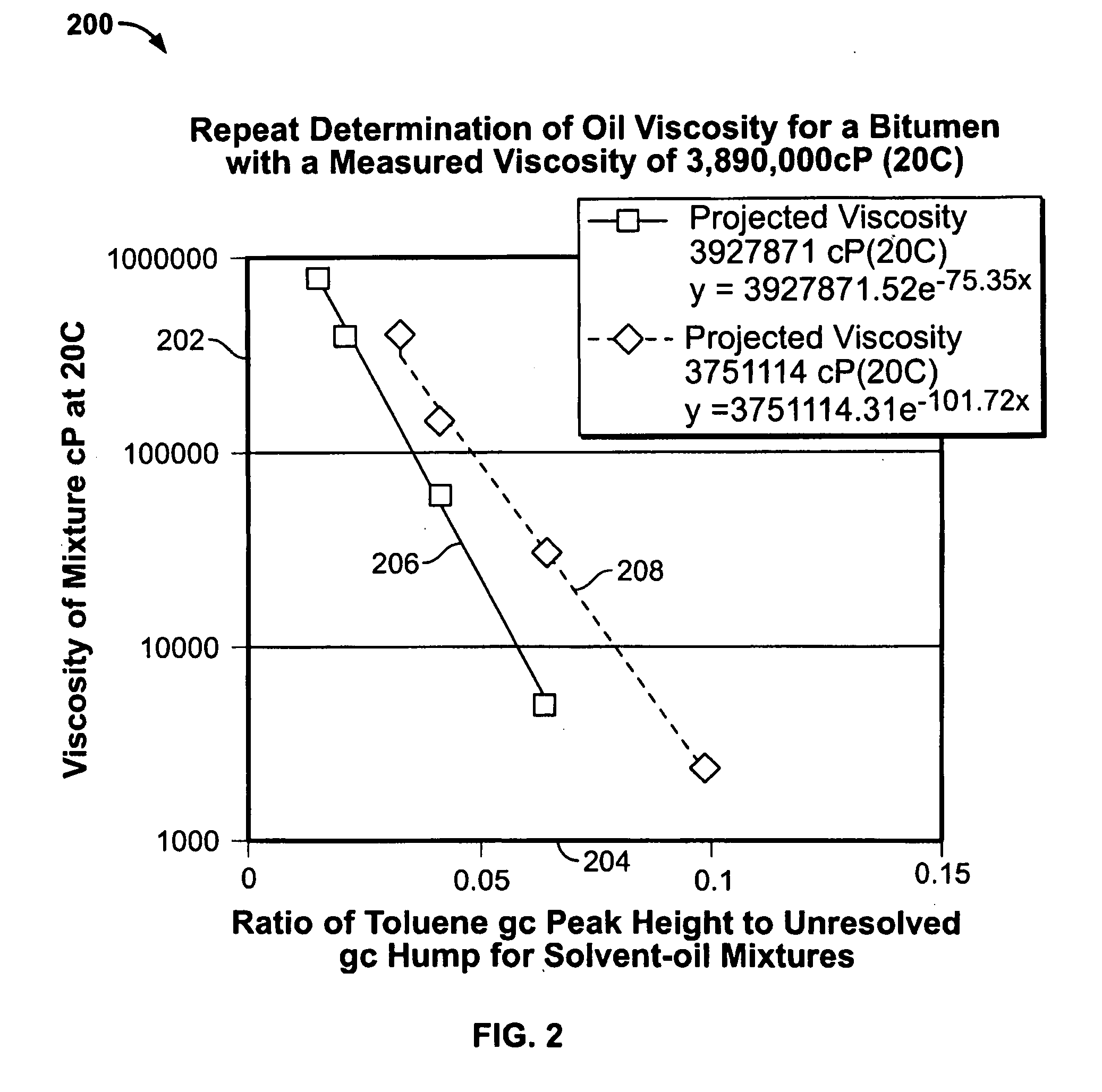

Method for measurement of crude oil and bitumen dead oil viscosity and density

ActiveUS20110056271A1Accurate determinationAccurate estimateSamplingComponent separationSolventOil viscosity

A process is described for measuring a property of oil extracted from a sample, for example, the viscosity or density. The oil is extracted from the sample using a volatile polar first solvent. A portion of the extracted oil is used to determine a concentration factor. A dry weight of the oil in the sample is calculated using the concentration factor. A second solvent less volatile than the first solvent is added to the remaining extract. The first solvent is substantially removed from the remaining extract. Different amounts of the second solvent are removed from each of a series of sub-samples taken from the remaining extract. Solvent concentrations and viscosity values and / or density values of the solvent-oil mixtures are measured for each sub-sample. Based on the measured solvent concentrations and viscosity values and / or density values, the second-solvent free viscosity and / or density of the oil in the sample is estimated.

Owner:SCHLUMBERGER TECH CORP

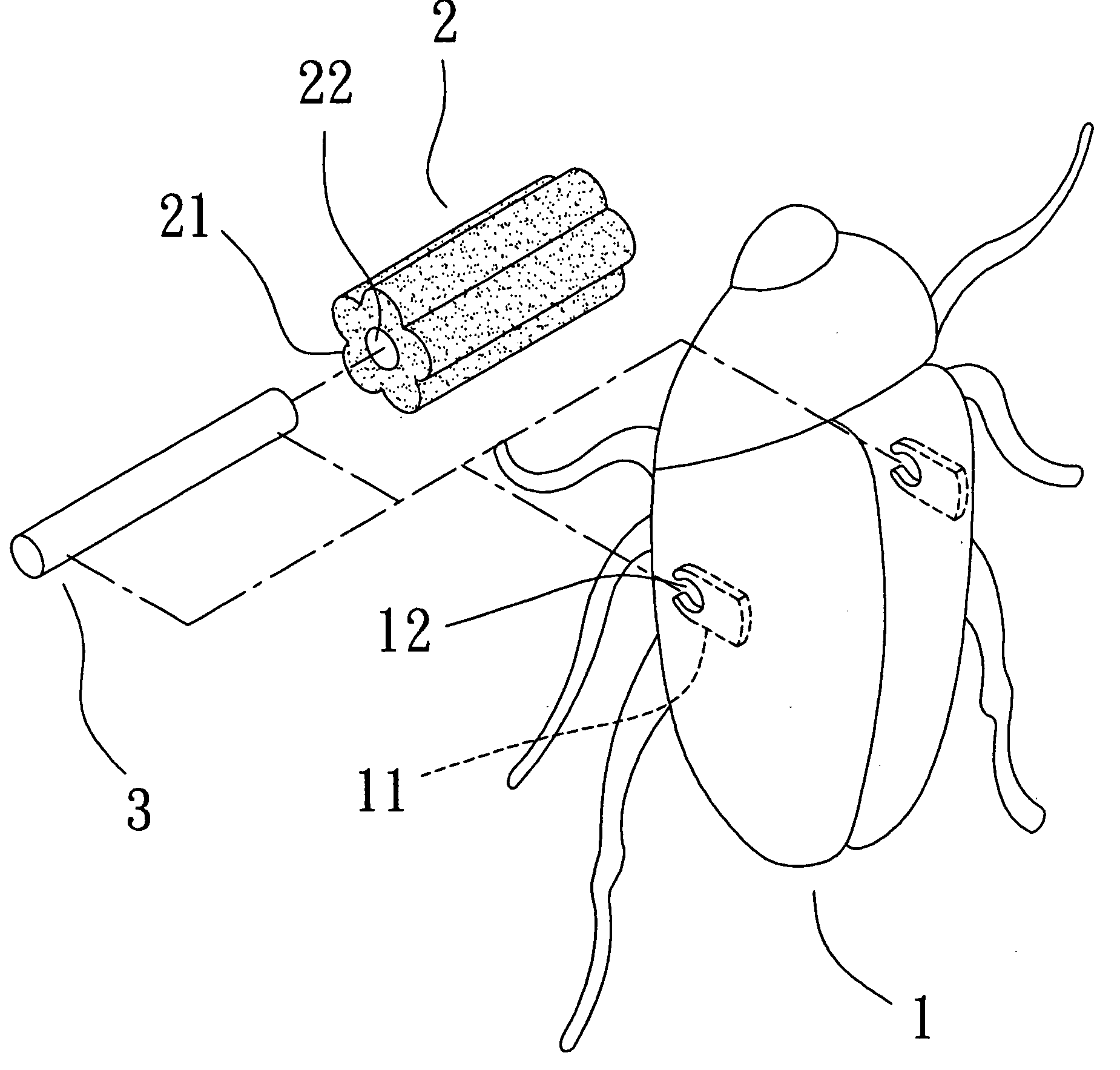

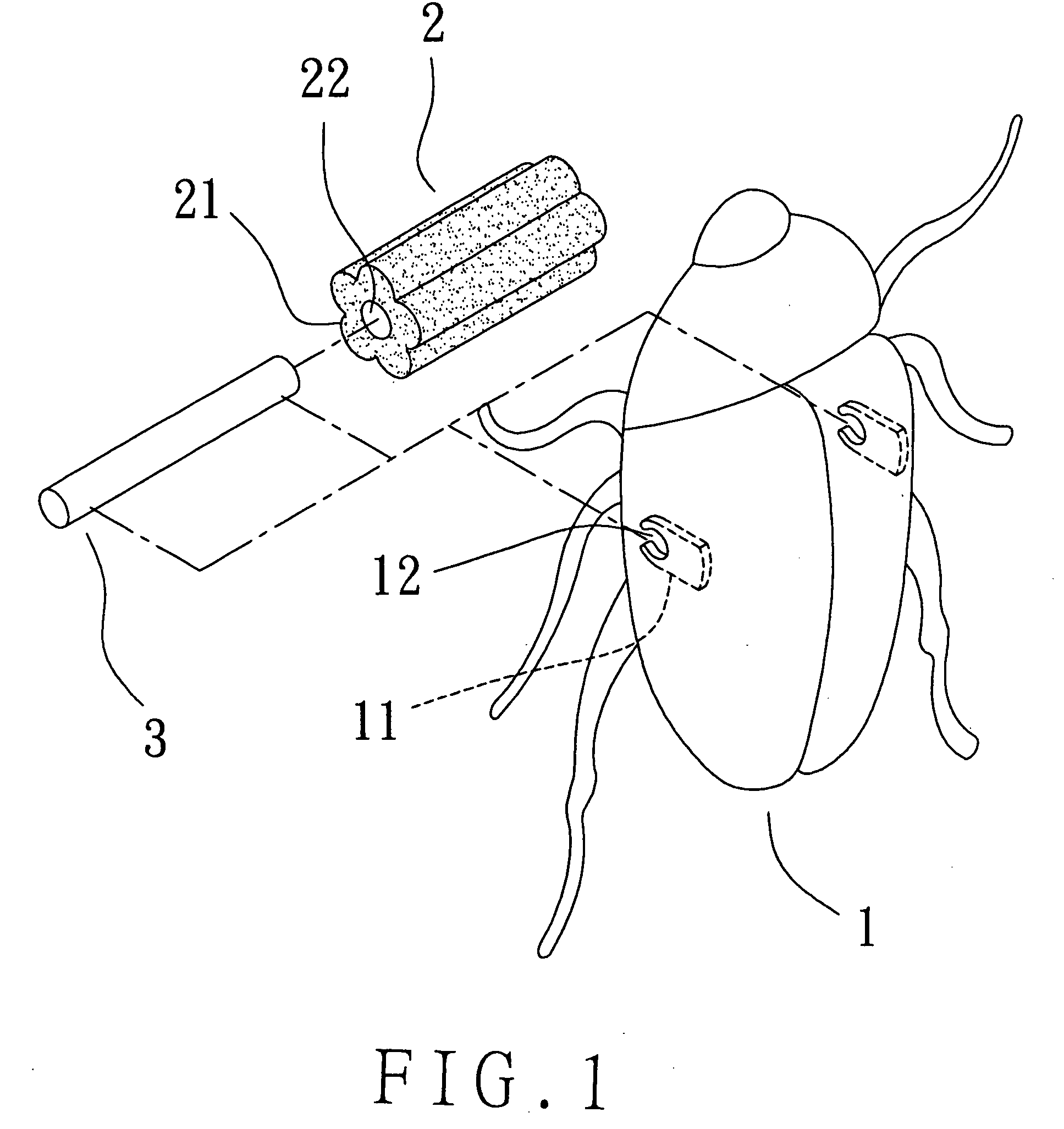

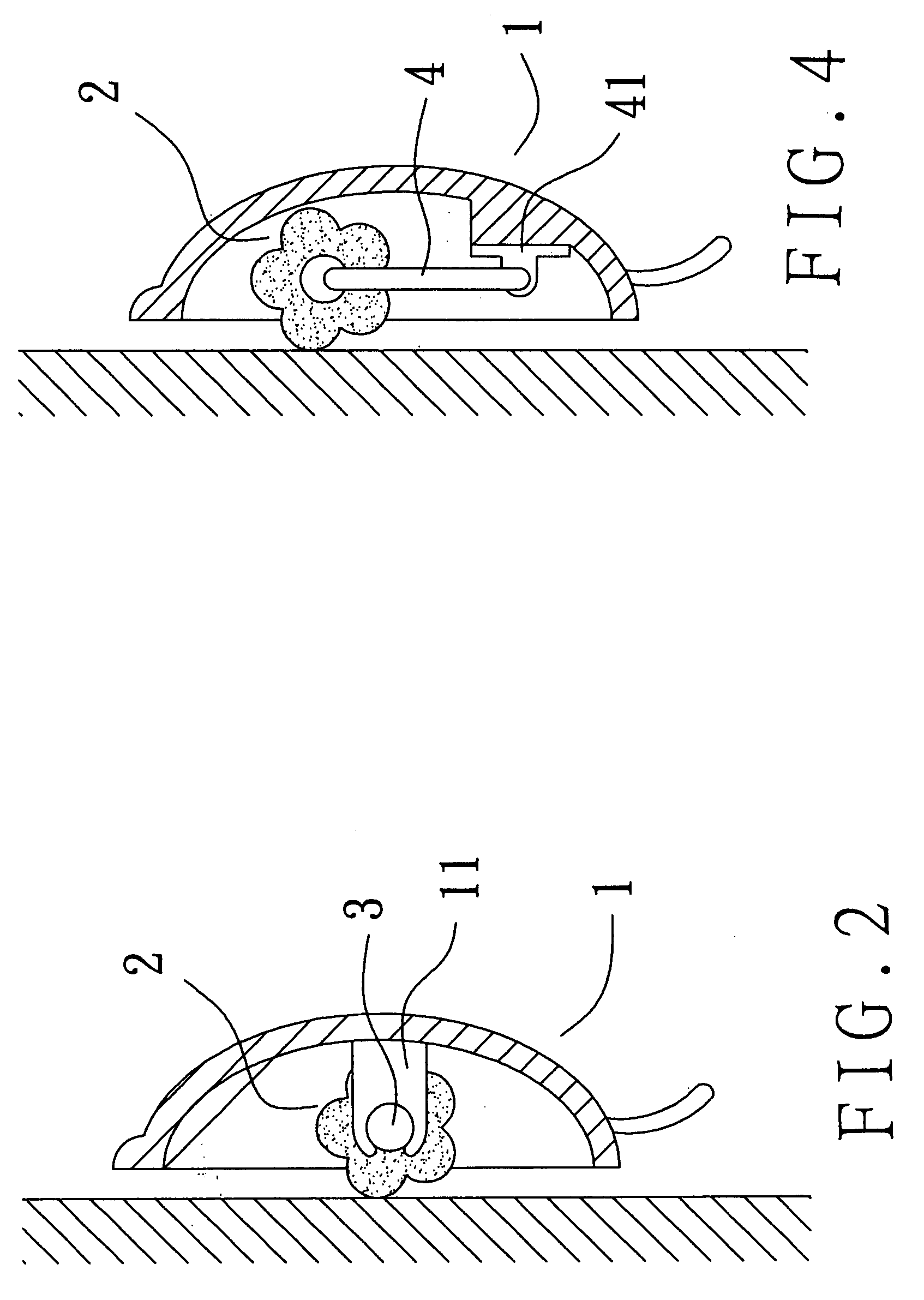

Toy

InactiveUS20050009442A1Accurate viscosityLarge lengthGavity operated toysSelf-moving toy figuresEngineeringMechanical engineering

A toy includes a body of a shape of any animal, automobile, etc. and a roller combined with the body and a shaft. The roller is made of a mixture of TPR (thermal plastic rubber) and white oil so as to give the roller some viscosity, having a plurality of lengthwise convex protrusions formed on its outer circumference, The shaft extends and fixed firmly in a center shaft hole formed in the roller, having two ends supported by two plates fixed on an inner wall of the body to let the roller roll together with the shaft. Then the toy can roll down on a slope or a vertical wall surface with slow speed caused by the roller's viscosity and the convex protrusions.

Owner:CHEN SHENG HSI +1

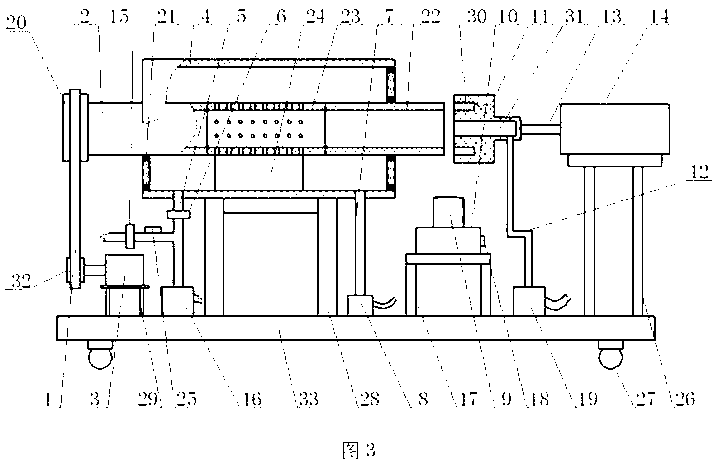

Printing ink viscosity regulating device for printing machine

InactiveCN103568584ASave human effortGuaranteed ink viscosityPrintingPrinting inkElectromagnetic valve

The invention discloses a printing ink viscosity regulating device for a printing machine. The device comprises an electric controller and an ink fountain, wherein the electric controller is connected with a viscosity detection sensor arranged on the ink fountain, the ink fountain is respectively connected with an ink storage box and a solvent box through pipelines, an electromagnetic valve is arranged on the pipeline through which the ink fountain and the solvent box are connected, and the electric controller is connected with the electromagnetic valve through a wire so as control the amount of solvent injected into the ink fountain. The device is provided with the electric controller and the viscosity detection sensor, viscosity of printing ink is automatically regulated through the electric controller, not only is manpower saved, but also accuracy of the viscosity of the printing ink can be guaranteed, it is guaranteed that patterns of presswork are clear and consistent, and a good printing effect can be achieved.

Owner:ANHUI PRINTING MECHANICAL & ELECTRICAL

Apparatus and method for controlling operation of electric oil pump

ActiveUS8371823B2Accurate viscosityEasy to controlGearing controlMotor parameterPower flowWorking fluid

The present invention provides an apparatus and method for controlling the operation of an electric oil pump for creating a working fluid pressure in a transmission and a clutch for a hybrid vehicle, which can accurately reflect the viscosity characteristics of oil to accurately control the operation of the pump, instead of measuring the temperature of the oil to reflect the state of the oil. In preferred embodiments, the present invention provides an apparatus for controlling the operation of an electric oil pump, the apparatus including: a current detector for detecting a current applied to a motor of an electric oil pump; a rotational speed detector for detecting a rotational speed of the motor; and a controller for calculating a load torque of the motor based on the detection values of the current detector and the rotational speed detector, calculating a target rotational speed based on the detection values, and controlling the operation of the motor based on the target rotational speed.

Owner:HYUNDAI MOTOR CO LTD +1

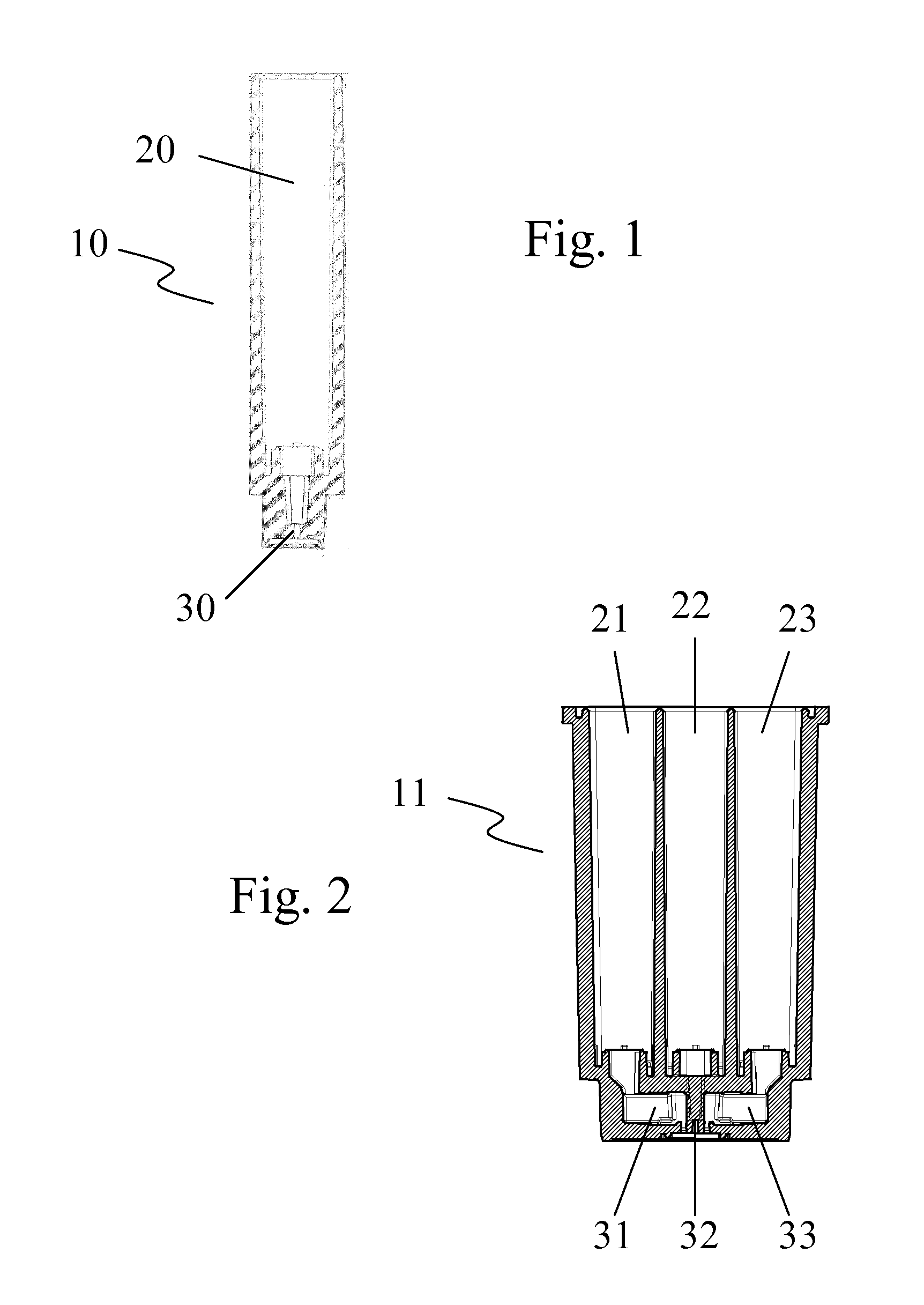

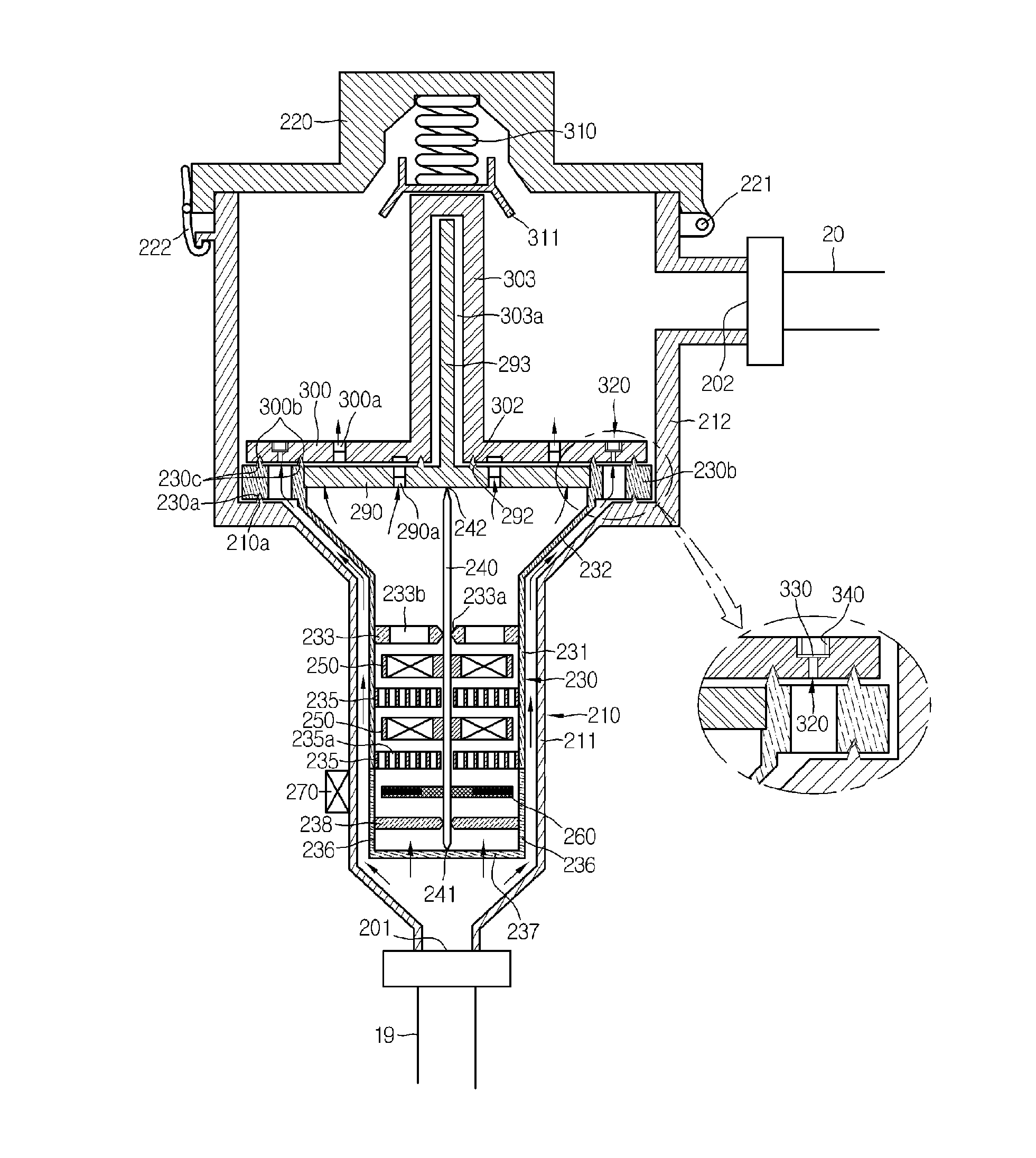

Apparatus for Regulating Viscosity of Ink

InactiveUS20080062212A1Accurate viscosityEasy to disassembleFlow propertiesOther printing apparatusEngineeringMechanical engineering

Disclosed is an apparatus for regulating viscosity of ink, which is installed on a flow path of ink in a printing device for regulation of ink viscosity. The apparatus includes a housing installed on the flow path and having an introduction hole and a discharge hole through which ink is introduced and discharged; a rotary shaft installed in the housing and to which at least one rotating fan is coupled to rotate along with flow of the ink; a sensed member having a sensed body at one end thereof and coupled to the rotary shaft to rotate together with the rotary shaft; and a sensor for sensing the sensed body.

Owner:NA JONG KAP

High-concentration polymer polyol and method for its production

If it is attempted to produce a polymer polyol at a high concentration, there will be a problem such that during polymerization of a monomer to form fine polymer particles, particles are likely to aggregate one another to form aggregates, and storage stability of the polymer polyol tends to deteriorate. A method for producing a polymer polyol is presented which comprises polymerizing at least one type of ethylenically unsaturated monomer together with a seed particle dispersion, in a polyol, wherein the seed particle dispersion is one obtained by polymerizing an ethylenically unsaturated monomer in the presence of an ethylenically unsaturated macromonomer, a solvent and a chain transfer agent, and the ethylenically unsaturated macromonomer is a reaction product of a specific polyol, an isocyanate compound and an ethylenically unsaturated monomer having a hydroxy group.

Owner:ASAHI GLASS CO LTD

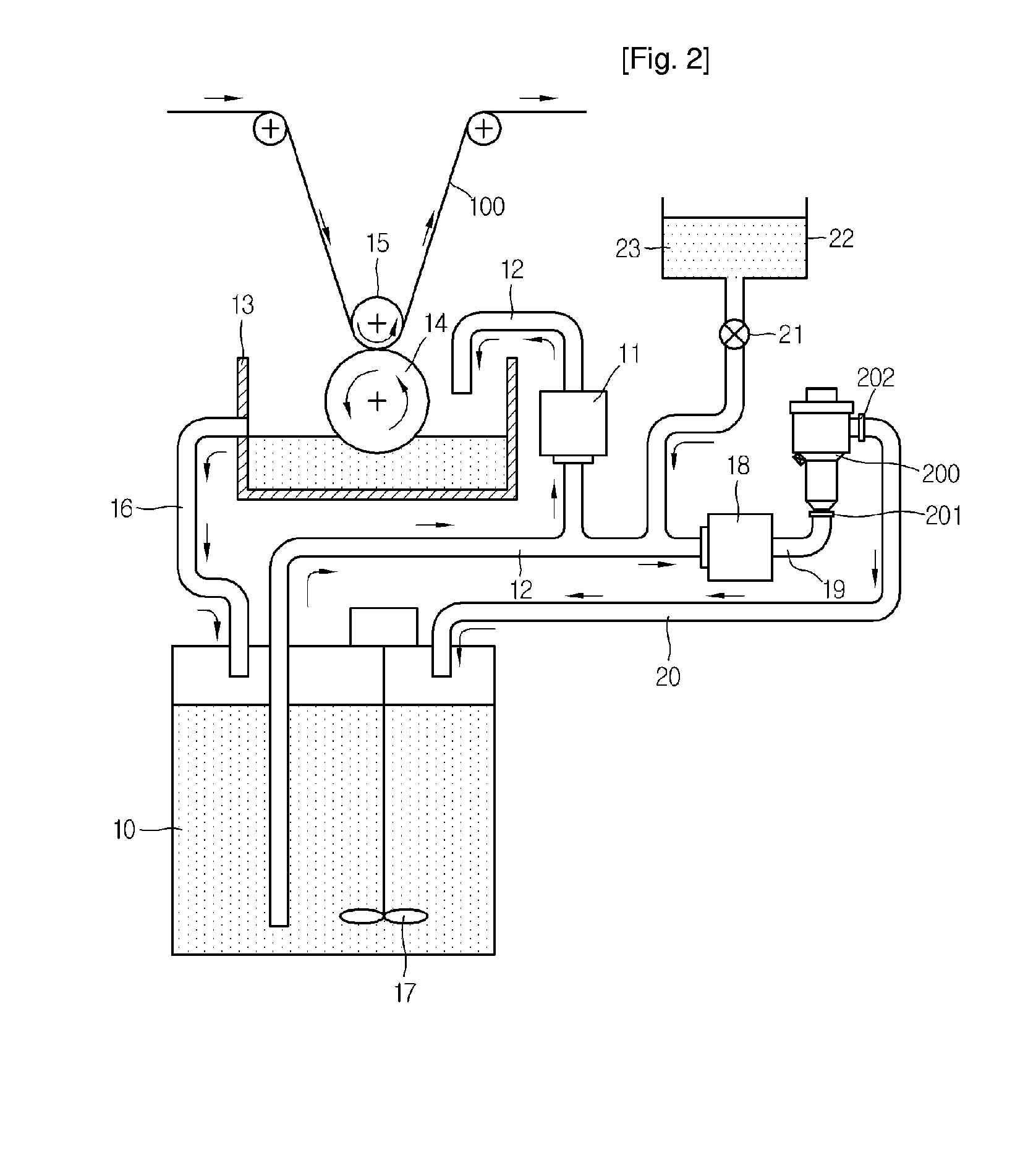

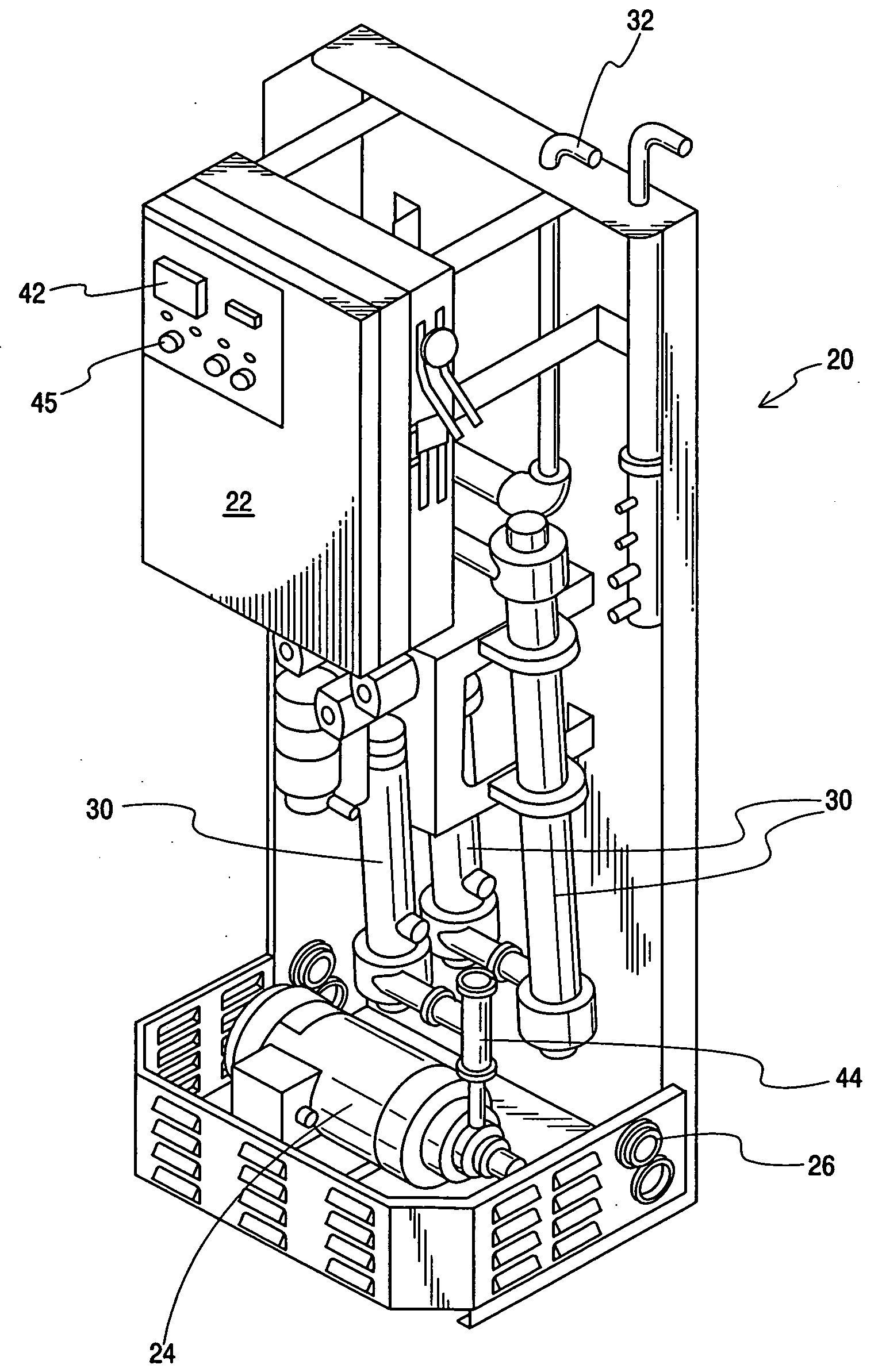

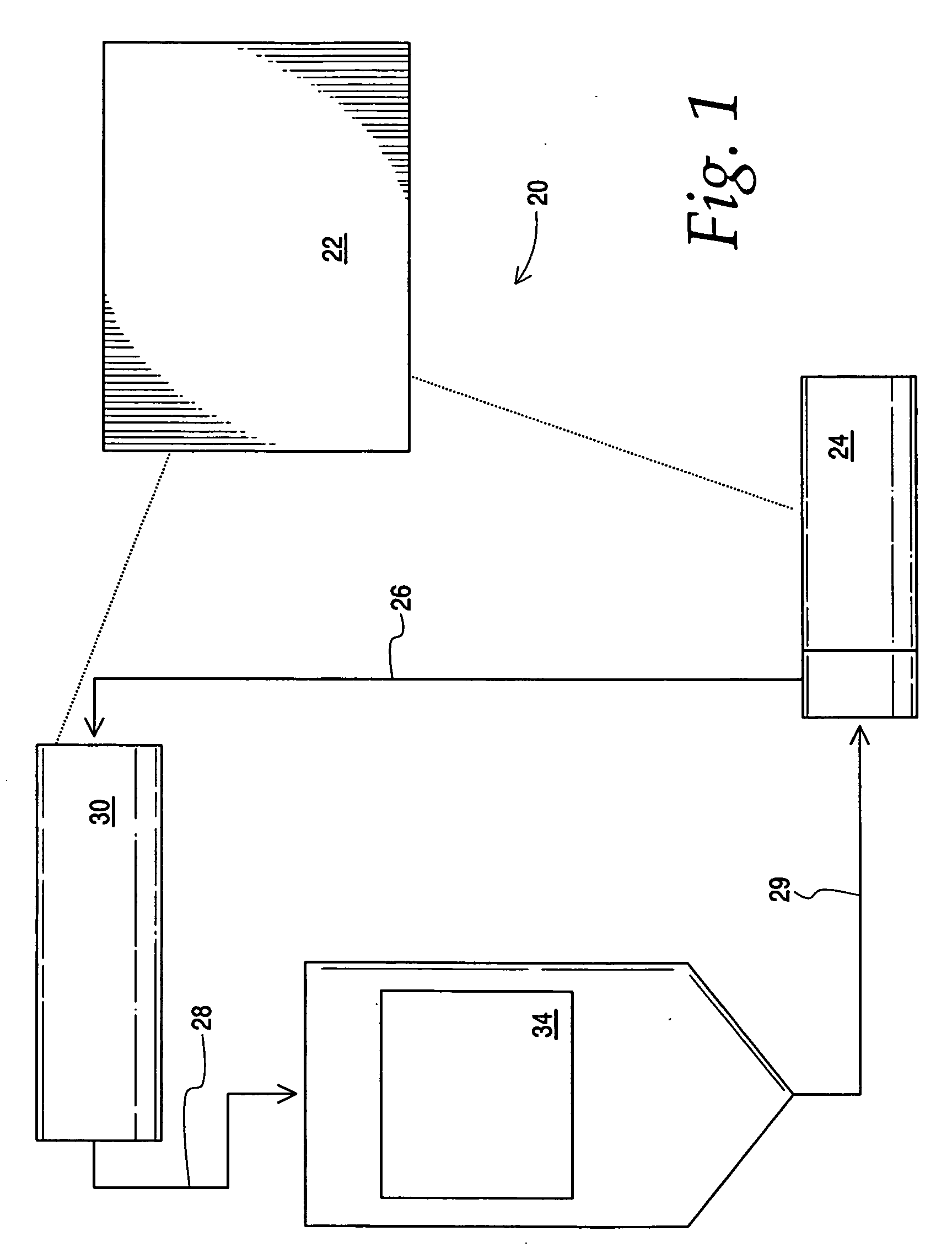

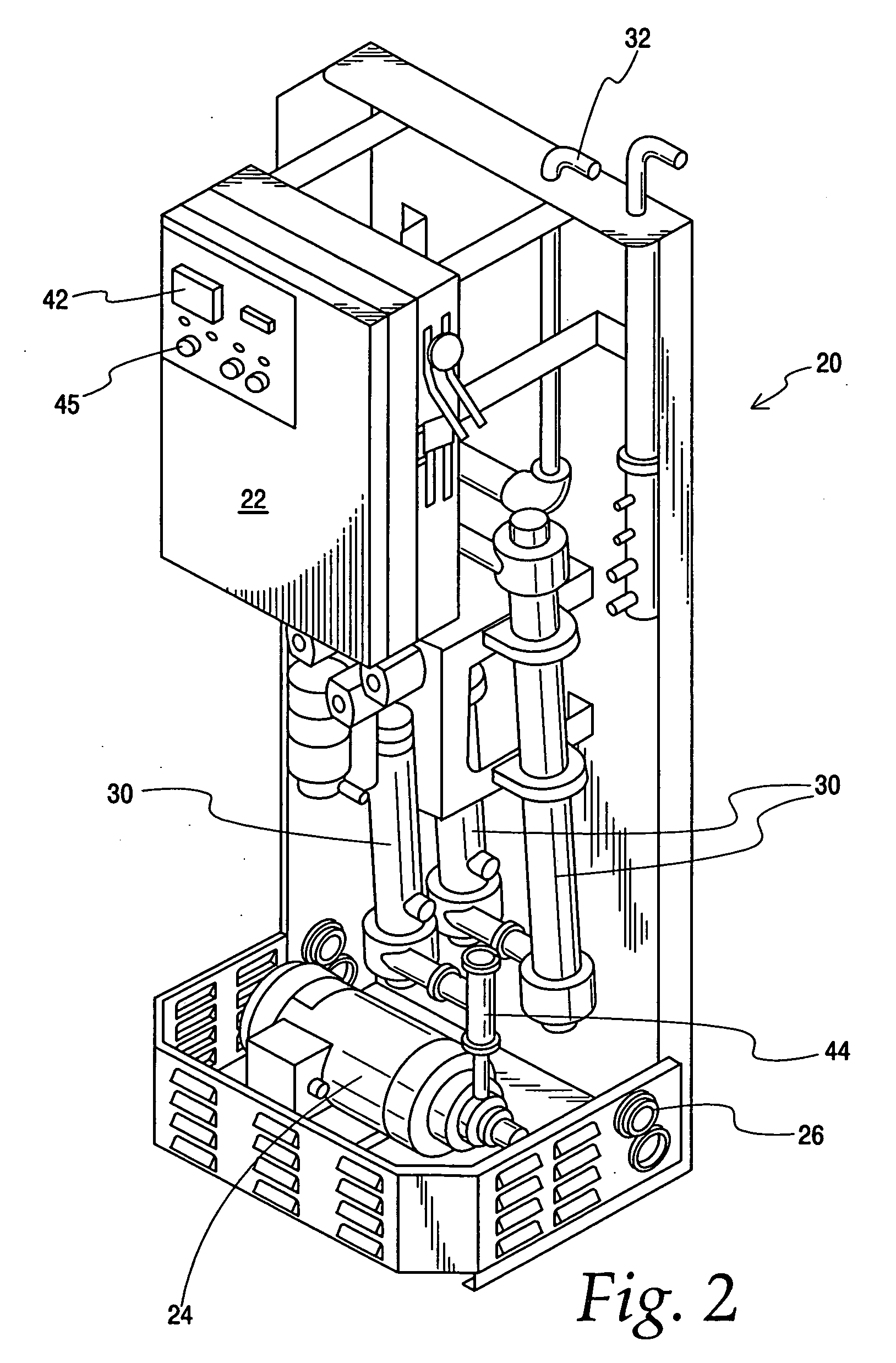

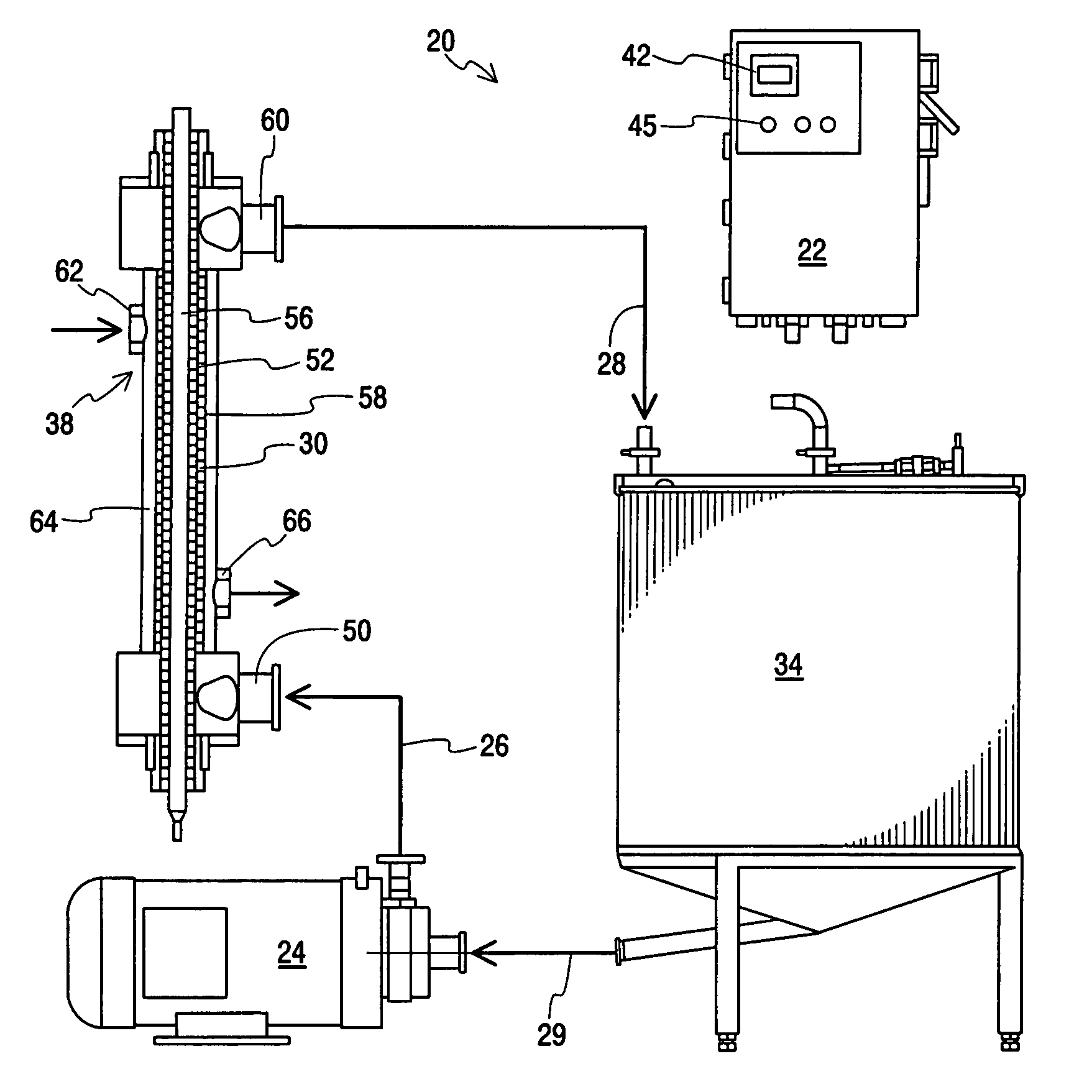

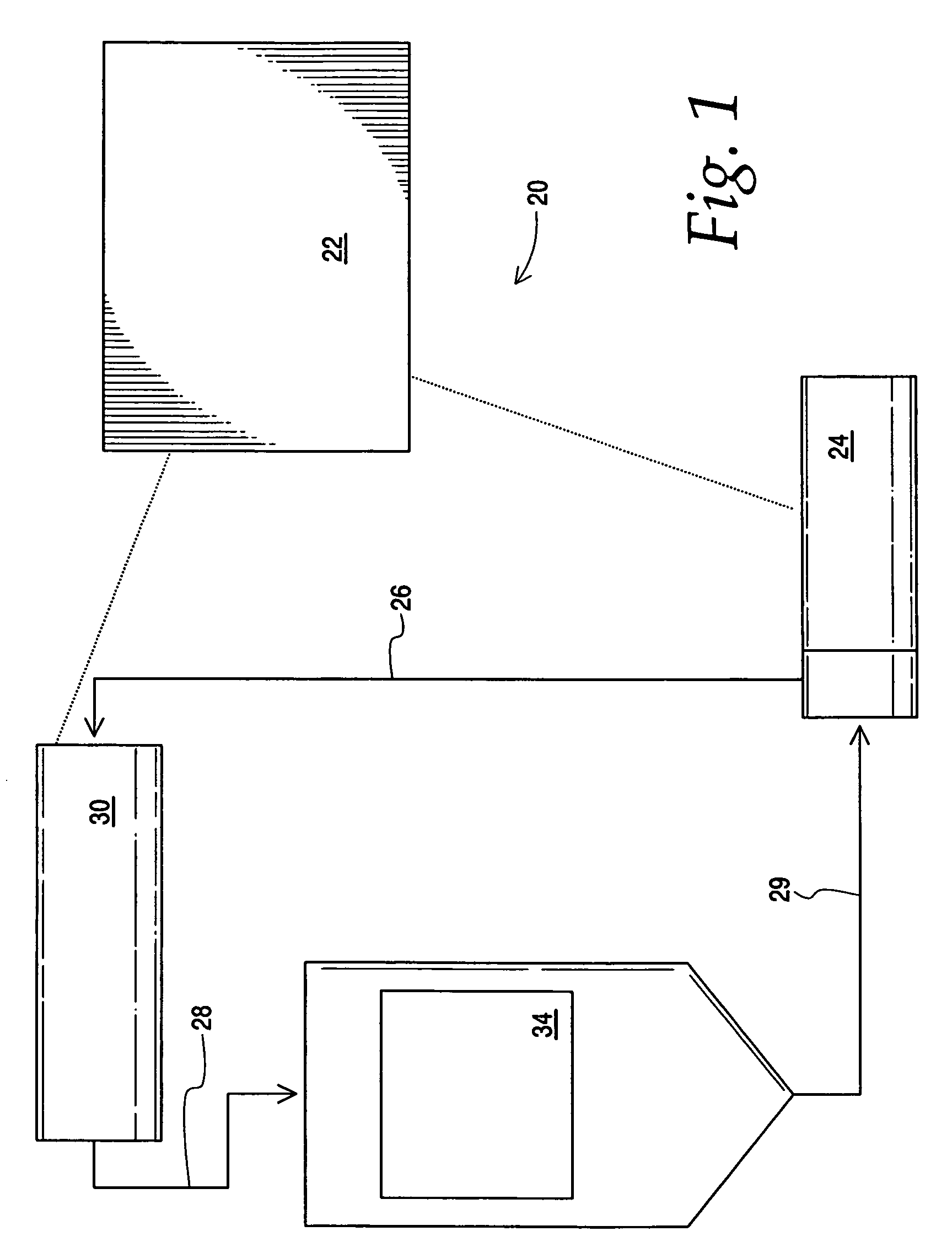

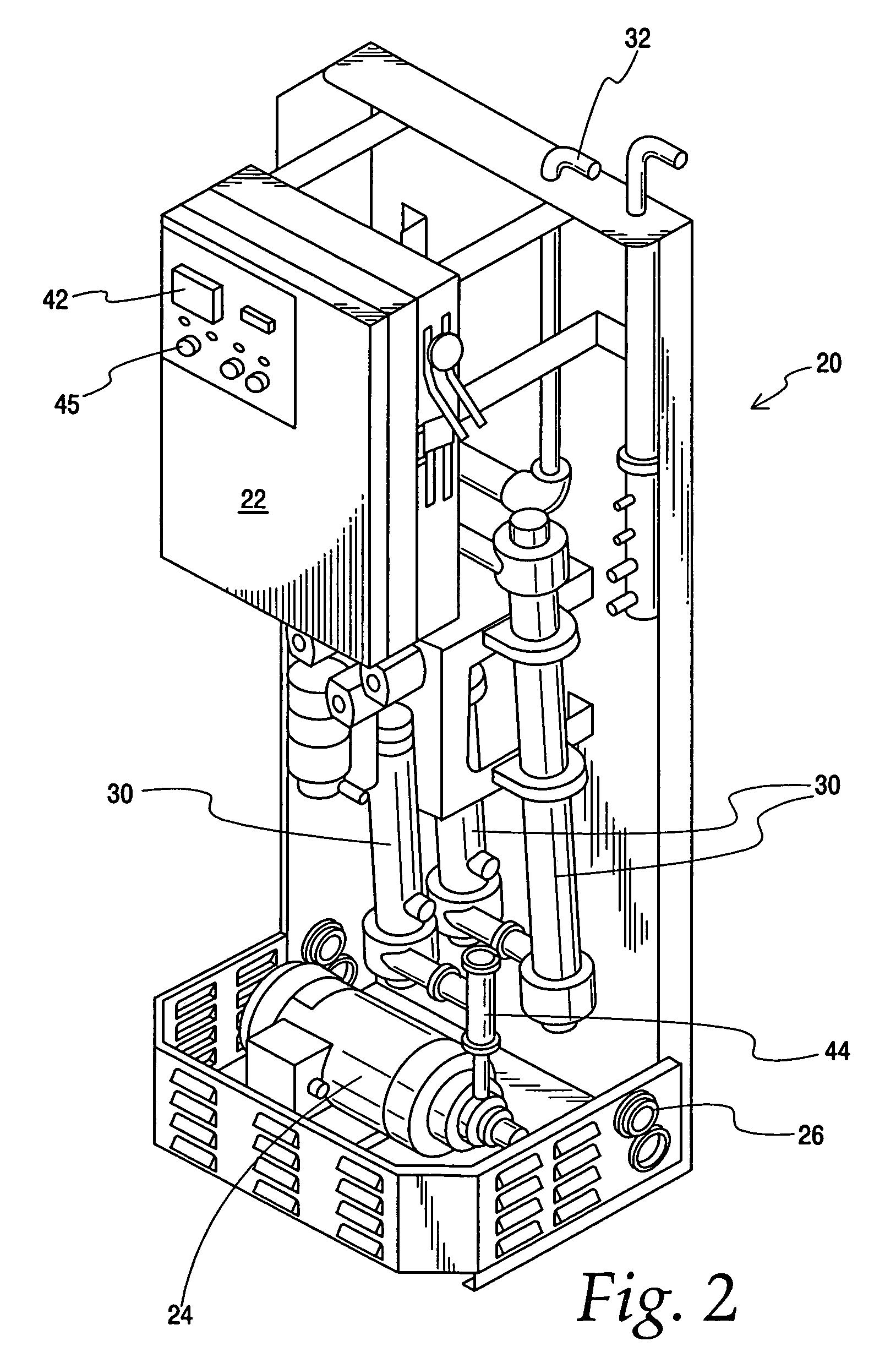

Apparatus and method for pasteurizing milk for feeding to calves

ActiveUS20100242744A1Less destructiveMinimize destructionMilk preservationFood processingUltraviolet lightsEngineering

The present invention is directed to a system and method for pasteurizing milk and colostrum for feeding to calves. The system includes a vat for storing milk or colostrum, a circulation pump and piping system, a heat exchanger for adjusting and / or maintaining milk temperature, and an ultraviolet light pasteurizing unit (“UV reactor”) that treats the milk without damaging important immunoglobulins.

Owner:GEA FARM TECH

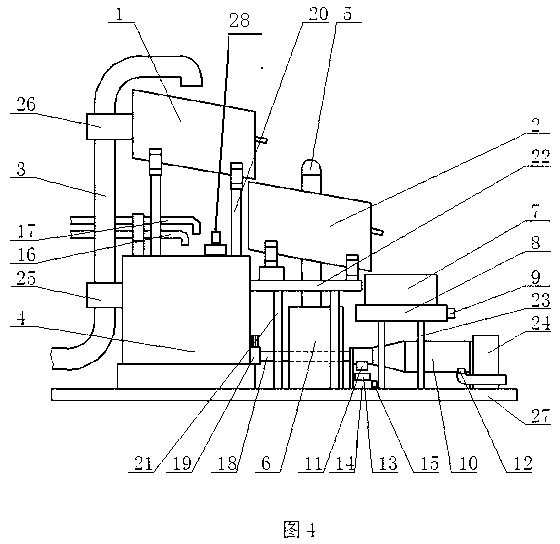

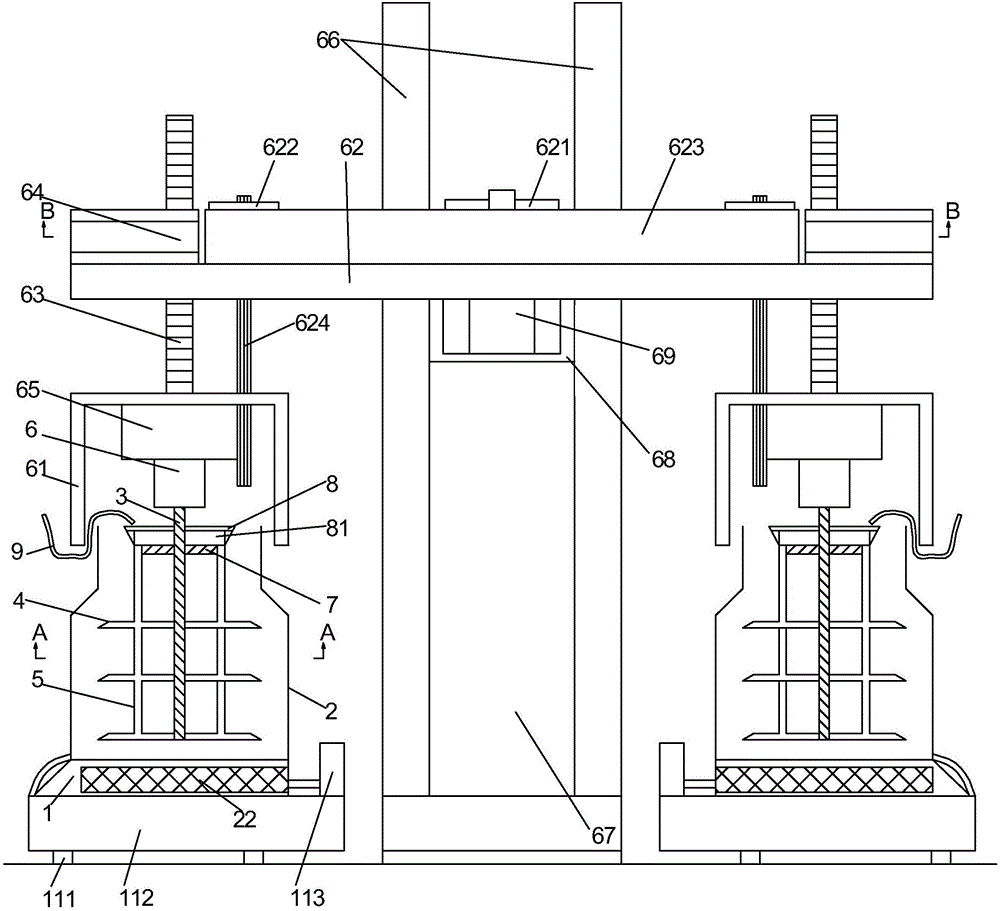

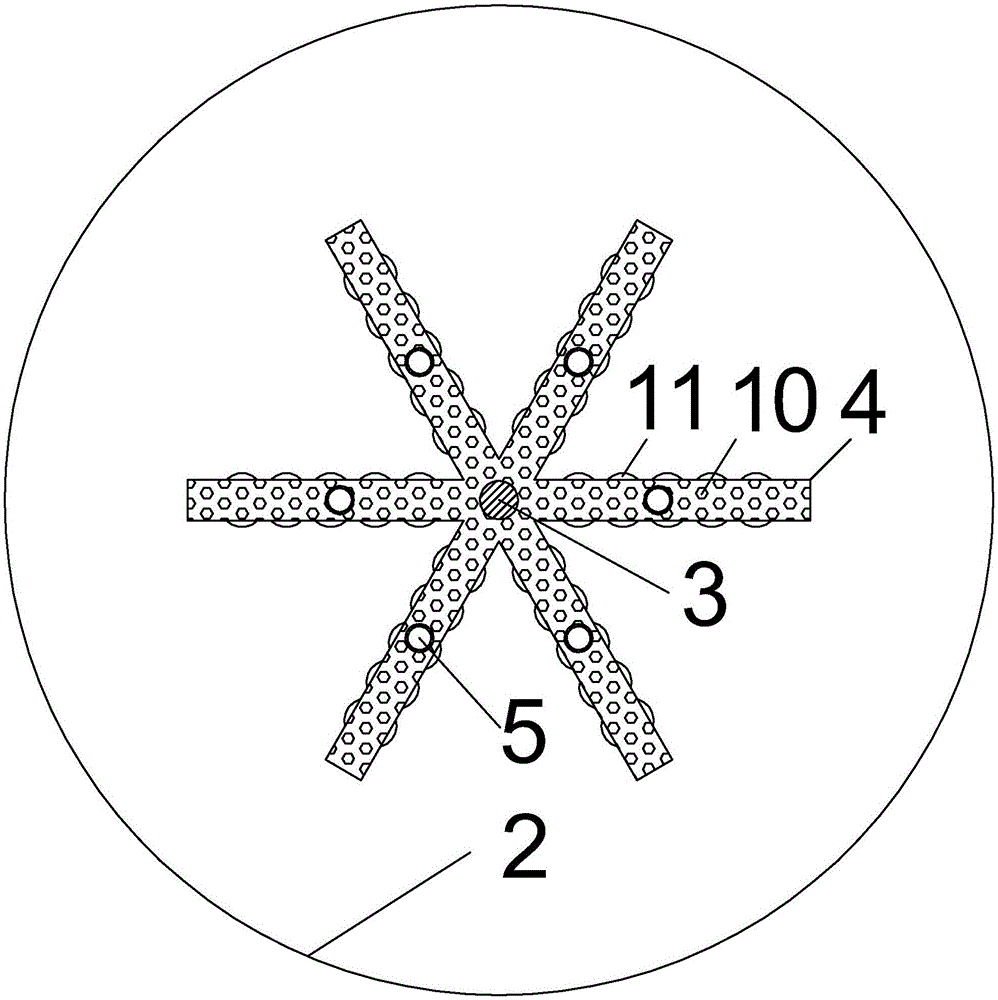

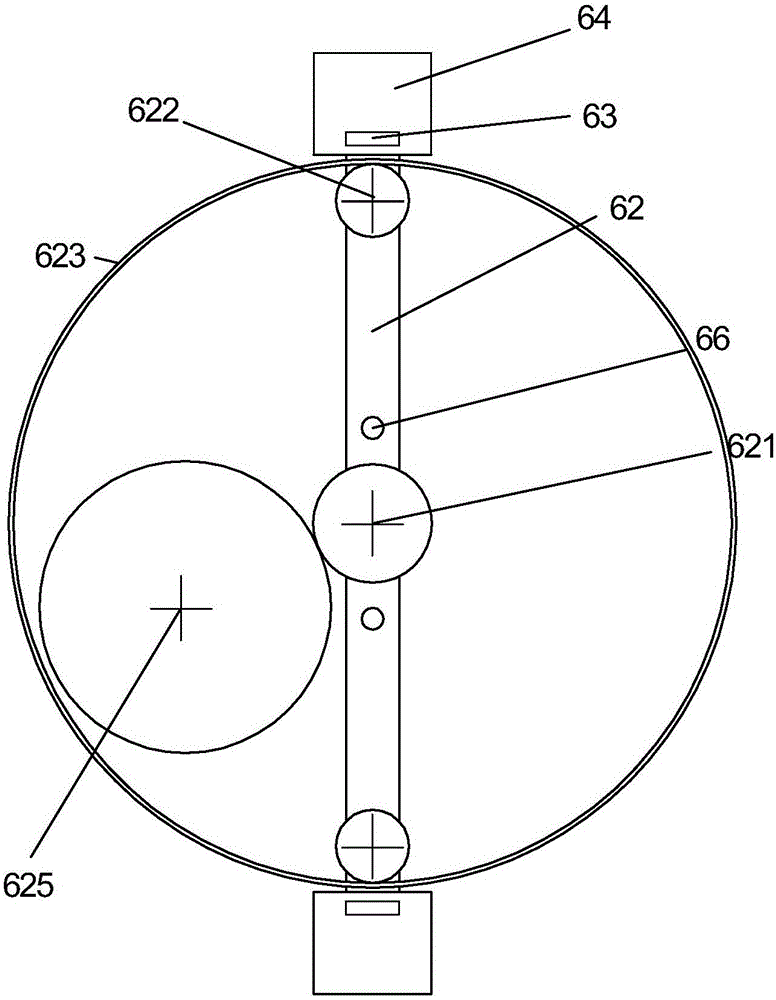

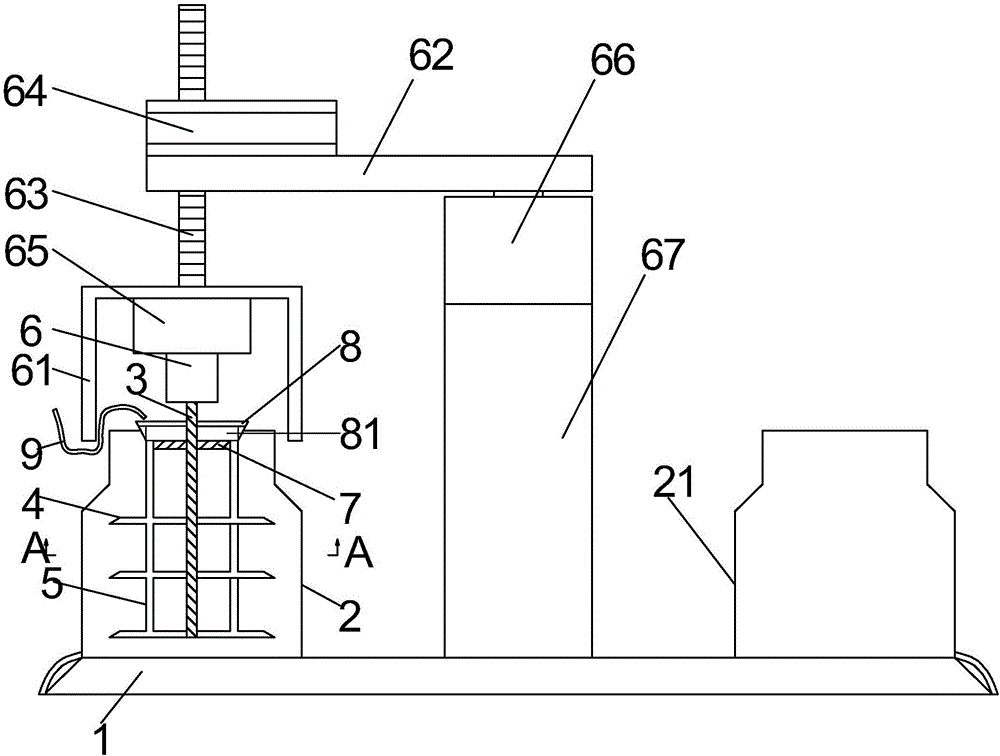

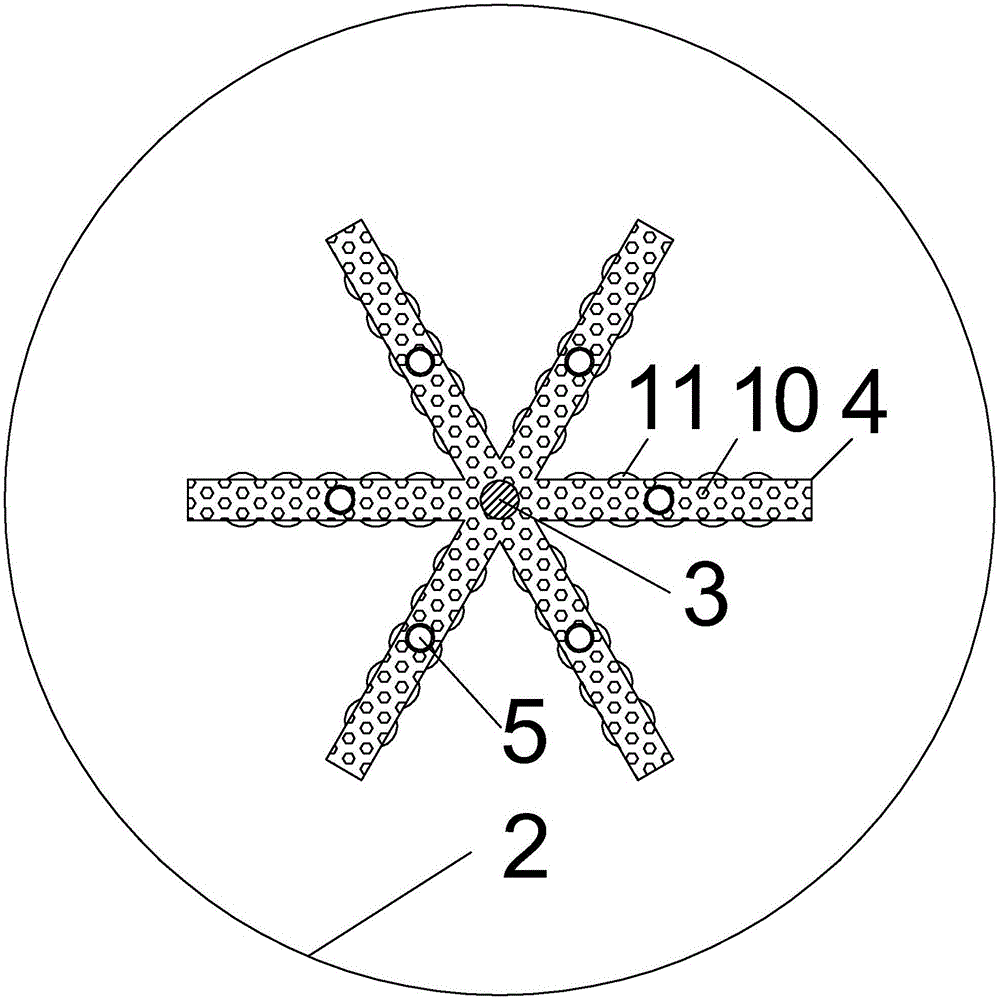

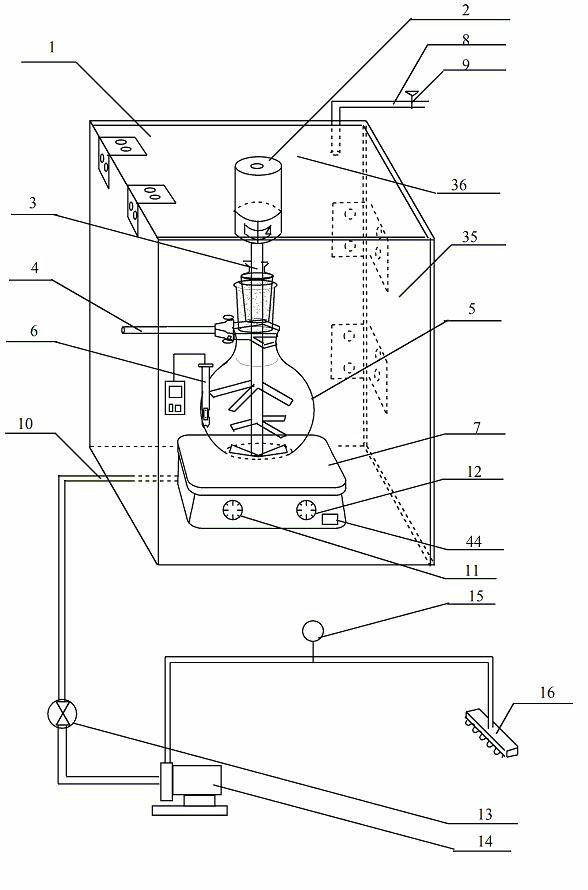

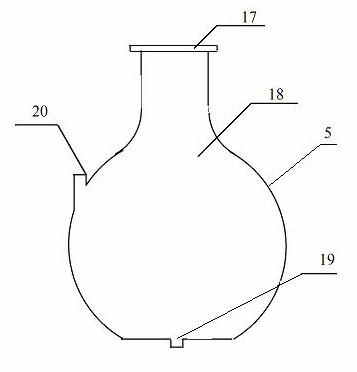

High-efficiency temperature-control pressurized ejector stirring filtering reaction system

InactiveCN106140068AImprove connection strength and stabilityAvoid damageChemical/physical/physico-chemical nozzle-type rreactorsStationary filtering element filtersGear transmissionDrive motor

The invention discloses a high-efficiency temperature-control pressurized ejector stirring filtering reaction system. The high-efficiency temperature-control pressurized ejector stirring filtering reaction system comprises a cantilever driven by an electric hydraulic jack, wherein the cantilever is provided with a guide balancing bar, two ends of the cantilever are respectively provided with a lifting mechanism and a stirring mechanism, and the bottom of the stirring mechanism is provided with a reaction tank and a filter apparatus which are matched with the stirring mechanism; and the stirring mechanism is connected with a drive motor and a drive gear which are arranged on a horizontal central axis of the cantilever, the drive gear is connected with a gear ring by virtue of a planetary gear, the gear ring is connected with a first straight gear and a straight gear transmission shaft, the transmission shaft drives a stirring assembly, and the stirring assembly comprises a hollow shaft double-head pump. By arranging hollow blades, the high-efficiency temperature-control pressurized ejector stirring filtering reaction system is uniform in dispersion, low in noise, high in efficiency, more precise in stirring process by comprehensively and intelligently controlling the stirring speed and the feeding speed, more precise in temperature and viscosity control, better in product quality, shorter in time for obtaining consistent products, capable of saving the waiting time by virtue of double-workstation processing, capable of greatly improving the working efficiency and equipment compactness and capable of saving the space occupancy rate of equipment.

Owner:ZHEJIANG ANJI TIANYANG ROLL PLASTIC EQUIP

Alternative double-station high-efficient intelligent temperature control pressurizing stirring tank

InactiveCN106268482AImprove connection strength and stabilityAvoid damageShaking/oscillating/vibrating mixersRotary stirring mixersImpellerAgricultural engineering

The invention discloses an alternative double-station high-efficient intelligent temperature control pressurizing stirring tank. The tank comprises two tank bodies, a bottom preheater, a protection cover, a stirring motor, a double-head hollow pressurizing pump, a filtering device, a rotating mechanism, a solid shaft, a hollow stirring blade and a feeding pipe, wherein the top of the protection cover is connected with a lifting mechanism; the lifting mechanism is arranged on a horizontally rotatable cantilever; the rotating mechanism comprises a rotating motor connected with one end of the cantilever; one end of the solid shaft is connected with a main shaft of the motor while the other end of the solid shaft is connected with the hollow stirring blade; a rotating plate is arranged at the upper end of the solid shaft; a liquid inlet slot is formed in the top of the rotating plate. According to the invention, the hollow impeller is arranged, so that the dispersion is uniform, the noise is low and the efficiency is high; the stirring speed and the feeding speed are comprehensively and intelligently controlled, so that the stirring process is relatively accurate; the temperature and viscosity control is relatively accurate; the product quality is relatively high; the time for acquiring the uniform products is relatively short.

Owner:ZHEJIANG ANJI TIANYANG ROLL PLASTIC EQUIP

Low free formaldehyde phenolic resins for abrasive products

InactiveUS20130232884A1Low shrinkageReduce crackingOther chemical processesAbrasion apparatusDistillationUrea-formaldehyde

The present invention provides process for the manufacture of an aqueous resin composition comprising a phenolic formaldehyde (PF) resin, which process comprises the steps of: providing a formaldehyde and phenolic compound, reacting said compounds in a condensation reaction in the presence of a catalyst, after completion of the condensation reaction to react with free formaldehyde, determining the free formaldehyde content of the resin composition, adding a pre-calculated substantially stoichiometric amount of modifying compound containing a primary amine group to reduce the amount of free formaldehyde in the resin composition to less than 0.1 wt % (relative to the total weight of the aqueous resin composition), and optionally distillation of the reaction product.

Owner:PREFERE RESINS HLDG

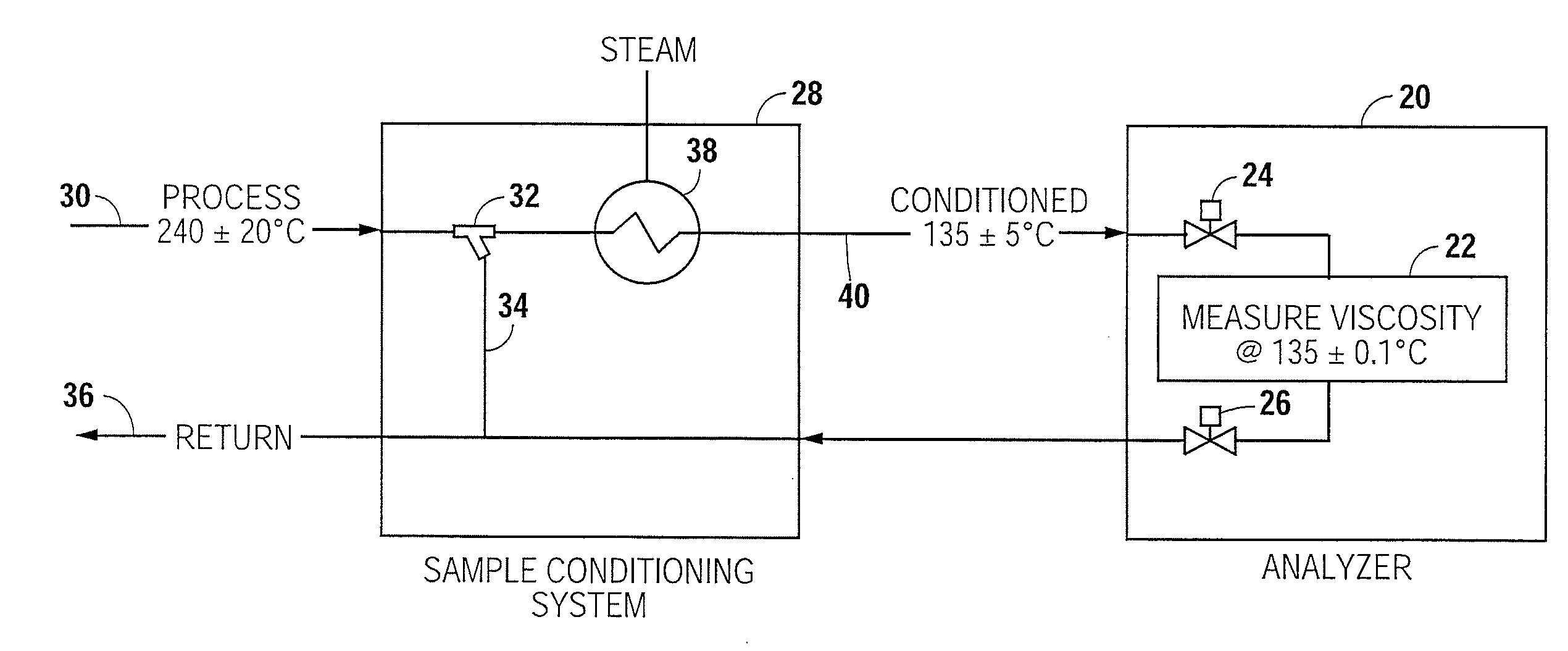

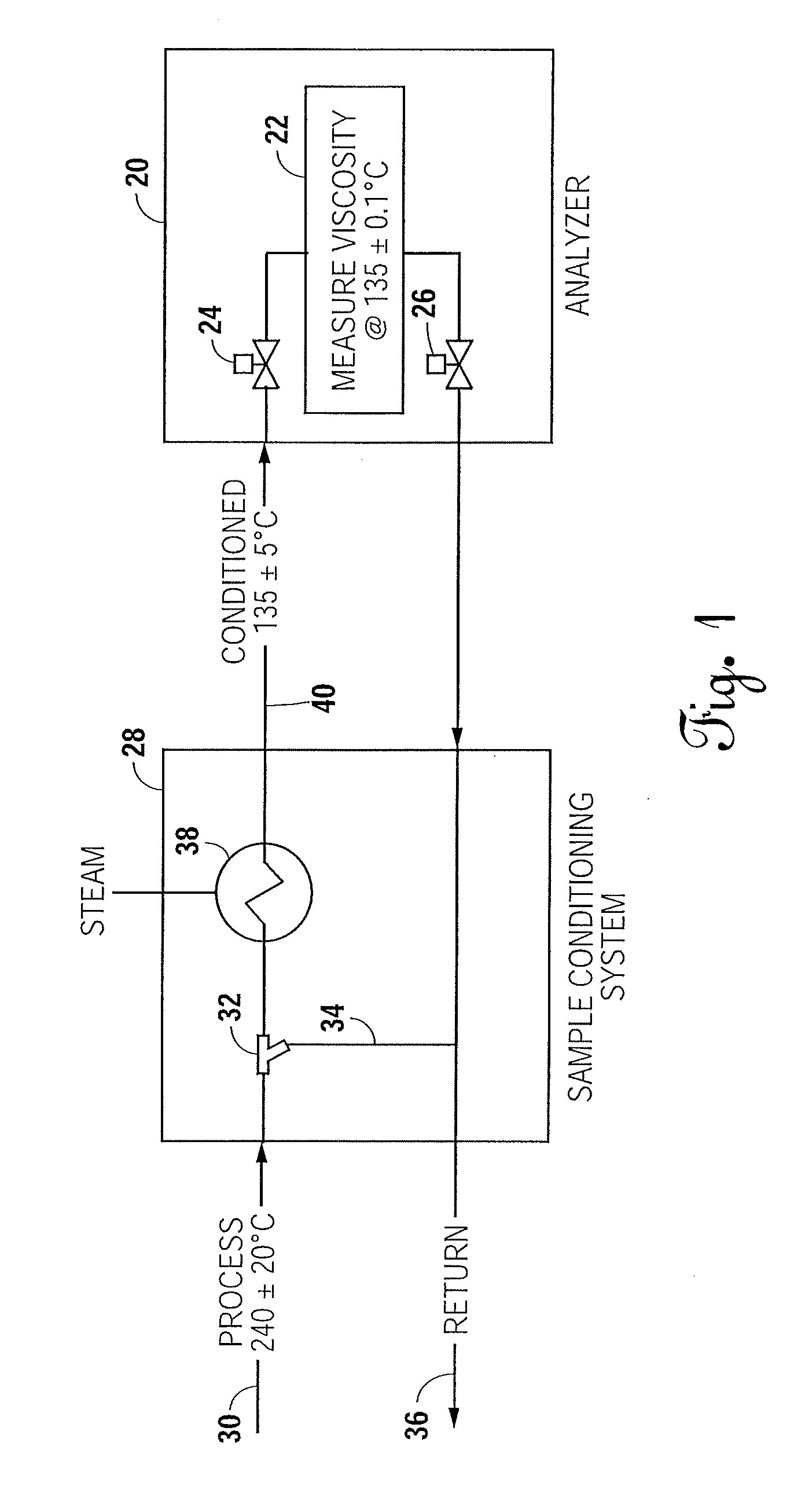

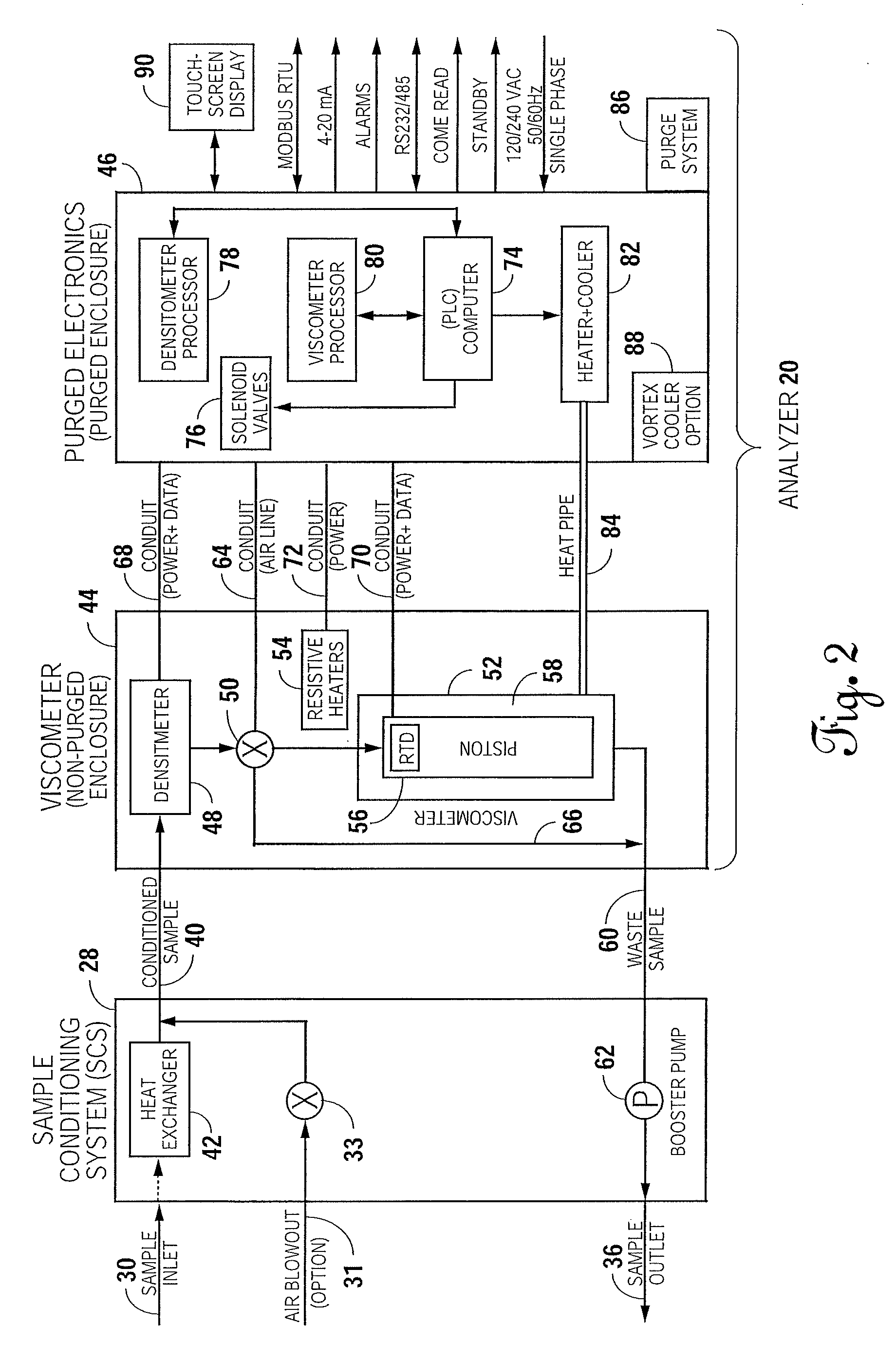

Method and apparatus for measuring characteristics of a heated fluid in a hostile environment

InactiveUS20160313292A1Accurate viscosityAccurate measurementPreparing sample for investigationSpecific gravity using flow propertiesElectrical controlEngineering

In the production of petroleum-based products in a refinery, viscosity and density are accurately and repeatedly measured at an elevated temperature, sometimes in a hostile environment. A densitometer and viscometer are located in a non-purged enclosure, but the electrical controls that could cause a spark to ignite fumes are located in a purged enclosure with connections there between. A heat pipe extending from the purged enclosure to the non-purged enclosure accurately controls the temperature of a sample during testing. For difficult to handle petroleum-based products such as asphalt, a sample conditioning system prepares the sample prior to testing.

Owner:PETROLEUM ANALYZER COMPANY

Apparatus for pasteurizing milk for feeding to calves

ActiveUS8127667B2Less destructiveMinimize destructionMilk preservationFood processingUltraviolet lightsEngineering

The present invention is directed to a system and method for pasteurizing milk and colostrum for feeding to calves. The system includes a vat for storing milk or colostrum, a circulation pump and piping system, a heat exchanger for adjusting and / or maintaining milk temperature, and an ultraviolet light pasteurizing unit (“UV reactor”) that treats the milk without damaging important immunoglobulins.

Owner:GEA FARM TECH

Liquid discharging apparatus

There is provided a liquid discharging apparatus including a liquid discharge head, a tank, and a controller configured to perform: estimating an amount of liquid remained in the tank; estimating a viscosity of the remained liquid; estimating an amount of the refilled liquid; estimating a viscosity of the refilled liquid; and estimating a viscosity of a mixed liquid of the remained liquid and the refilled liquid at a point of time of finishing a refill of the tank with the liquid, based on the estimated amount of the remained liquid, the estimated viscosity of the remained liquid, the estimated amount of the refilled liquid, and the estimated viscosity of the refilled liquid.

Owner:BROTHER KOGYO KK

Device for quickly mixing, automatically delivering and filling slurry

InactiveCN102580597AAccurate locationAdd evenlyRotary stirring mixersMixer accessoriesTemperature controlSlurry pipeline

The invention discloses a device for quickly mixing, automatically delivering and filling slurry, wherein the bottom of a slurry stirring container of a slurry stirring device is positioned in an accommodating groove of the upper end surface of a delivery and temperature control platform, a stirrer is positioned in the slurry stirring container, and a stirring shaft of the stirrer is installed on an output shaft of a liftable motor; 2-5 layers of stirring wings are rotatably and fixedly installed on the stirring shaft of the stirrer, each layer of stirring wing comprises 2-5 wing type blades, the wing type blades of the adjacent layers are installed on an inner shaft of the stirring shaft in a staggering way, when the device works, the wing type blades of the lowermost layer are upswept, and the wing type blades of the other layers are downwarped; and an outlet of a slurry delivery pipeline of the delivery and temperature control platform is connected with a slurry automatic delivery and filling device through the slurry pipeline. The device is used to stir and delivery the slurry, the slurry can be more uniformly stirred, no dead angle is generated, the accuracy degree of a slurry filling position is high, the filling amount is more uniform, and the device is convenient for specific industrial use.

Owner:河北兆能新能源科技有限公司

Dairy product and method for producing the same

ActiveUS20100003395A1Proper flavorAccurate viscosityMilk preparationMilk preservationAdditive ingredientWhole milk

The present invention provides a dairy product which endures cryopreservation for a long period, and also has viscosity suited for use in a dispenser for beverage. An emulsified composition containing a milk fat content, a milk protein content, a disaccharide alcohol and an emulsifier in a certain ratio is prepared. A ratio of each component of the emulsified composition can be obtained by accurately adjusting the amounts of raw materials such as milk, whole milk powders, butter, cheese, cream, condensed milk, butter oil, butter milk and butter milk powders serving as a milk fat source and a milk protein source; a disaccharide alcohol; an emulsifier; and moisture.

Owner:UCC UESHIMA COFFEE CO LTD

Method for measuring viscosity and/or elasticity of liquid

InactiveUS8215156B2Accurate measurementAccurately determineFlow propertiesElectrical measurementsLiquid viscosityTester device

Viscosity and elasticity of a liquid are measured by immersing and vibrating a liquid tester in the liquid to be tested and measuring three frequency values that are a resonance frequency value on an amplitude characteristic curve obtained through vibration of the liquid tester in the liquid being tested, a low frequency value lower than the resonance frequency value on the amplitude characteristic curve at a phase angle smaller than a phase angle of 90 degrees at a resonance point on a phase angle characteristic curve obtained through the vibration in the liquid being tested, and a high frequency value higher than the resonance frequency value on the amplitude characteristic curve at a phase angle larger than the phase angle at the resonance point on the phase angle characteristic curve.

Owner:SEKONIC CORP

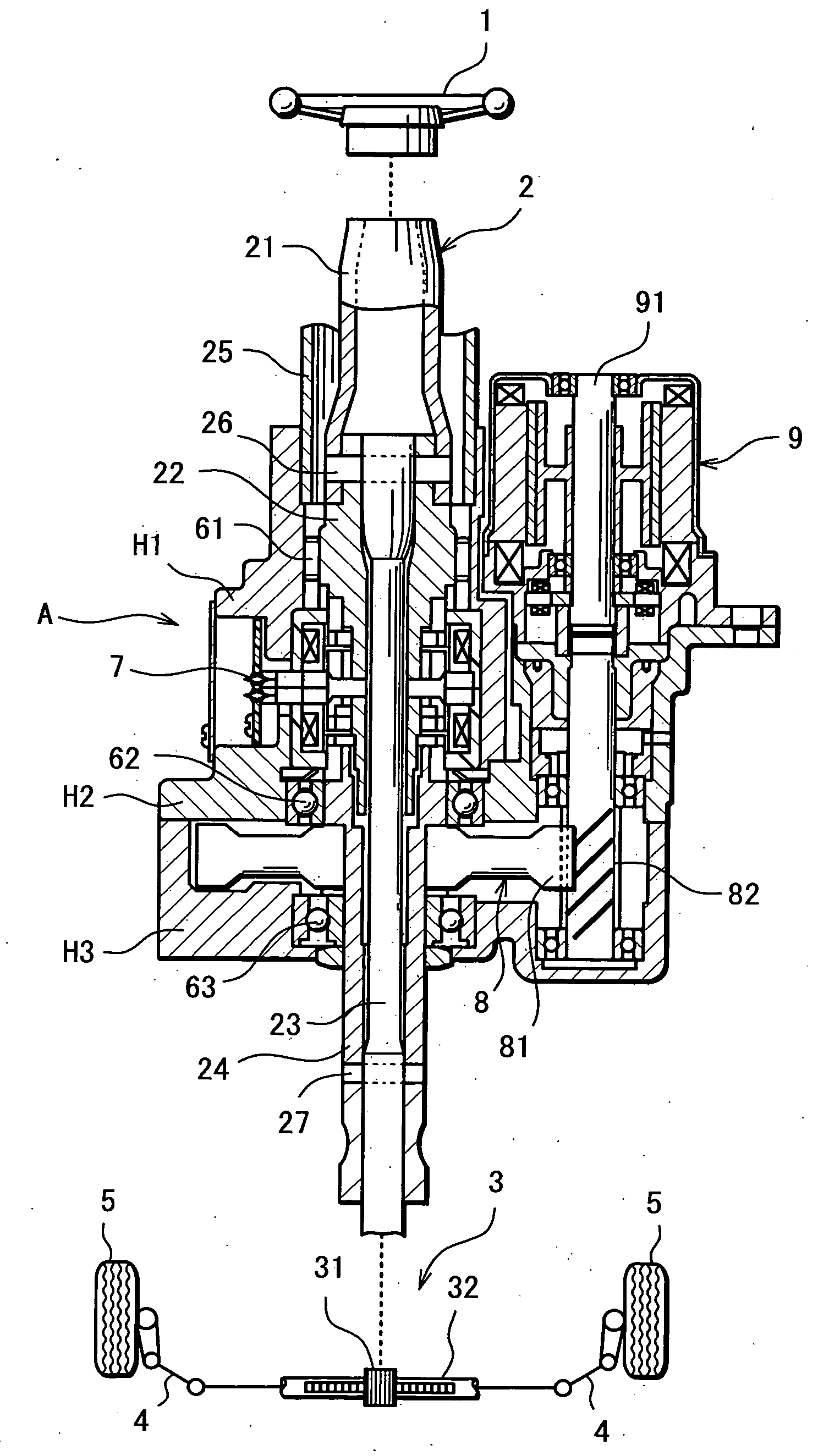

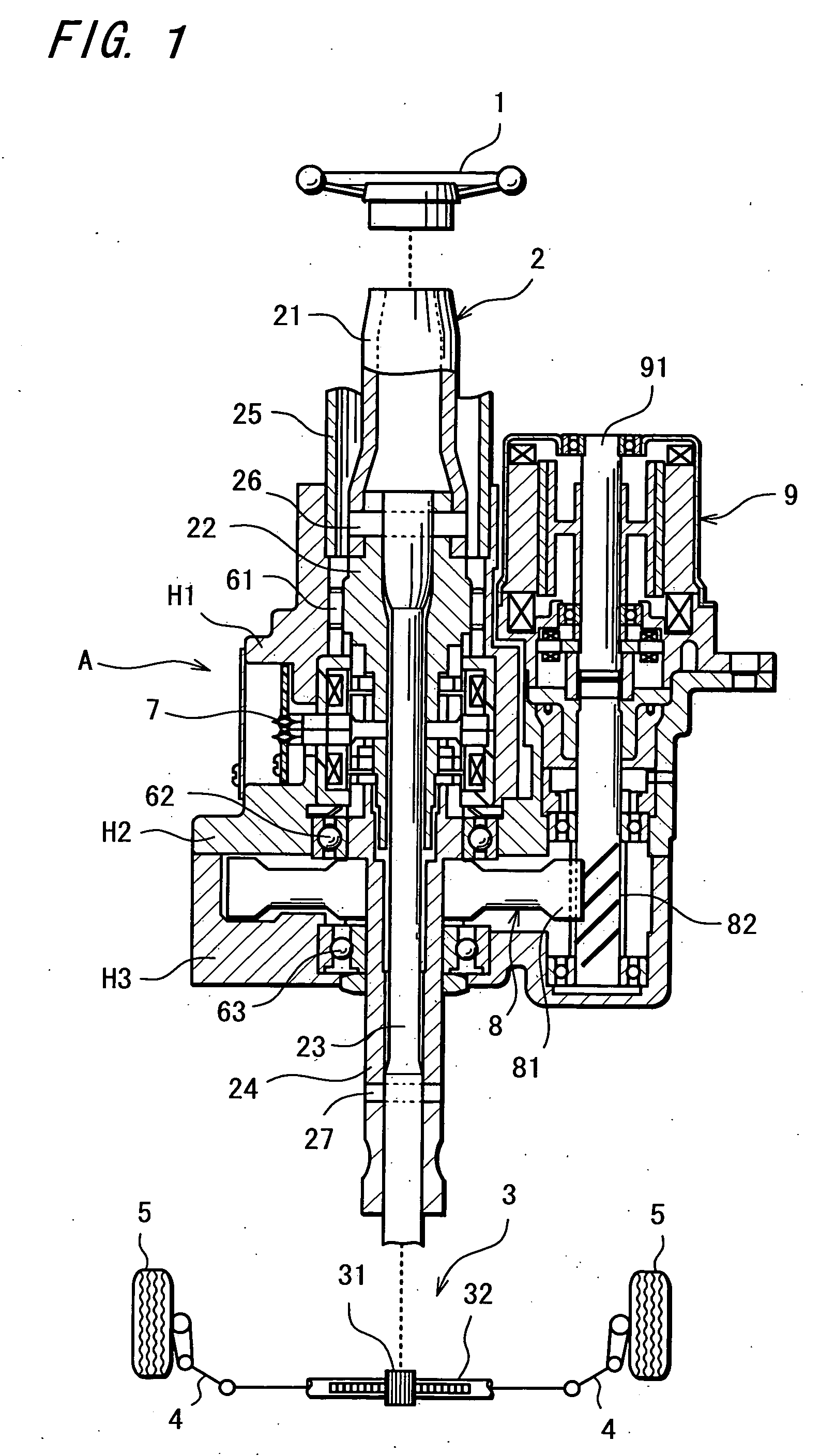

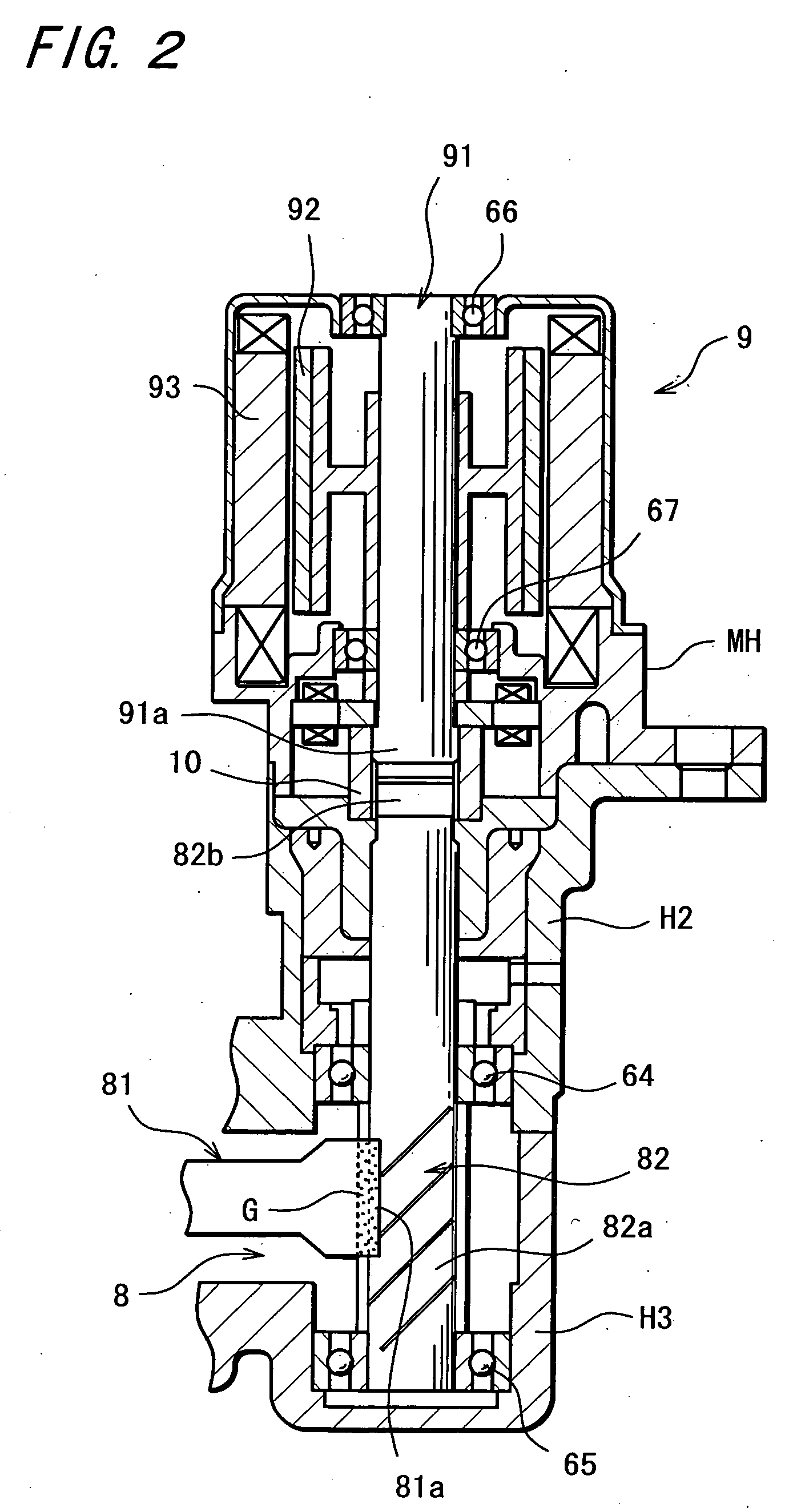

Electric motor power steering system

InactiveUS20070068725A1Accurate viscosityReduce vibrationRotating vibration suppressionNon-rotating vibration suppressionElectric power steeringViscosity

In an electric power steering system providing steering assist by applying a power of an electric motor to a steering mechanism via a reduction mechanism, the steering mechanism extending from a steering member to dirigible wheels, a grease (viscous material) is applied to a meshing engagement portion between teeth portions disposed on a motor-power transmission path extending from the electric motor to the steering mechanism via the reduction mechanism, the grease having a viscosity constant C satisfying 0.8 Jωp≦C where J denotes the inertia of the electric motor, and cop denotes the resonant angular frequency of the steering mechanism including the electric motor and the reduction mechanism. This provides for the prevention of the occurrence of rattling noises caused by a vibration system including the reduction mechanism and the electric motor and the degradation of the steering feeling.

Owner:JTEKT CORP

Curable unsaturated resin composition

The present invention provides a curable unsaturated resin composition, which has less odor characteristics and high safety and is also superior in thin film coating characteristics in a coating film. The curable unsaturated resin composition contains a polymerizable unsaturated resin (A) having two or more polymerizable unsaturated double bonds in a molecule, a hydroxyalkyl (meth)acrylate (B), and an unsaturated compound (C) having one or more cyclohexene rings and two or more allyl ether groups in a molecule, which is liquid at normal temperature.

Owner:DAINIPPON INK & CHEM INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com