Alternative double-station high-efficient intelligent temperature control pressurizing stirring tank

An intelligent temperature control and double-station technology, which is applied to mixer accessories, mixers with rotating stirring devices, mixers, etc., can solve problems such as product quality differences, achieve short finished product time, save waiting time, and improve work efficiency. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

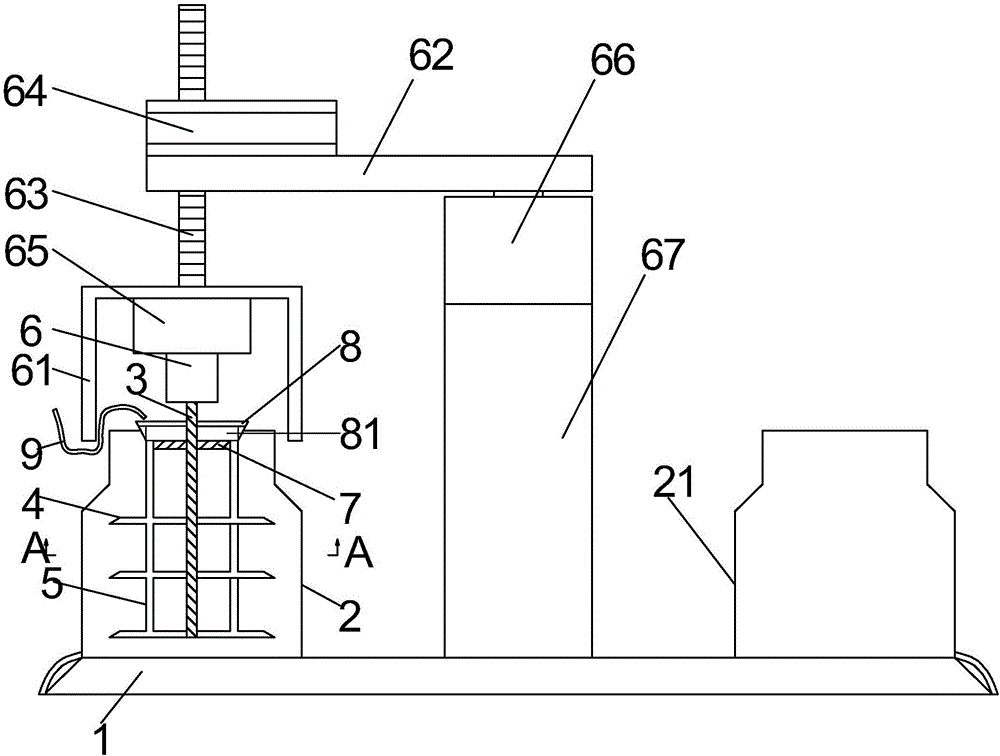

[0051] Referring to the accompanying drawings, the alternating double-station high-efficiency intelligent temperature-controlled pressurized mixing tank includes a base 1 and a stirring motor 6, and also includes:

[0052] Two tanks 2 are provided, and the bottom of any one of the tanks 2 is provided with a bottom pre-heater 22;

[0053] A protective cover 61, the inner top of the protective cover 61 is provided with a stirring motor 6, the top of the protective cover 61 is connected to a lifting mechanism, and the lifting mechanism is arranged on a cantilever 62 that can rotate horizontally;

[0054] A rotating mechanism, including a rotating motor 66 connected to one end of the cantilever 62;

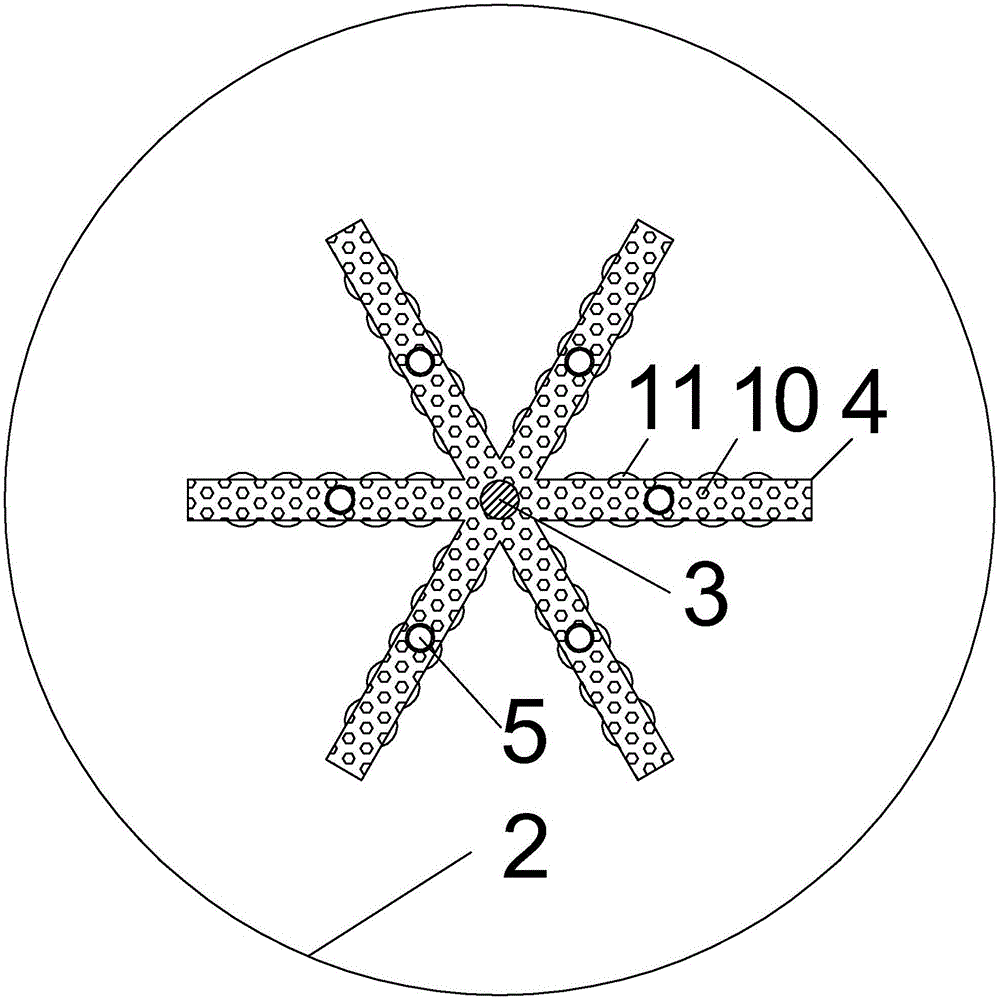

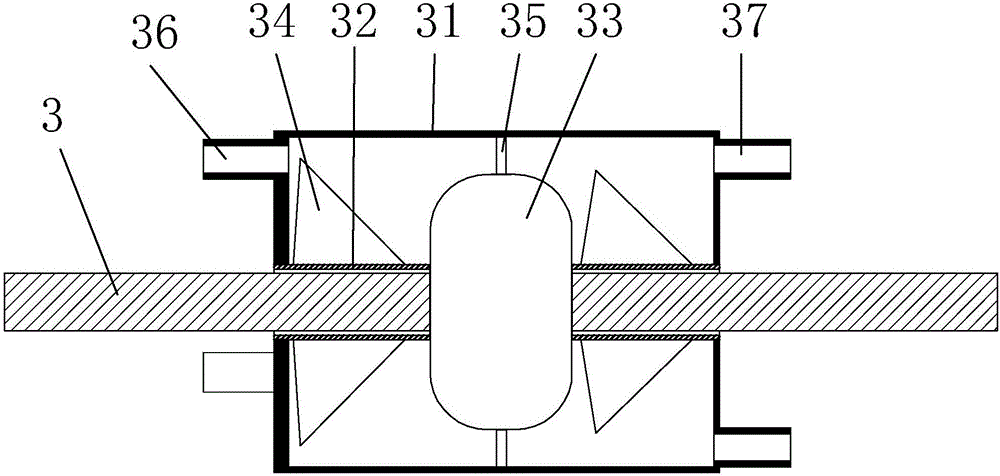

[0055] The solid shaft 3, one end of which is connected to the main shaft of the motor 6, and the other end is connected with the hollow stirring blade 4, the upper end of which is also provided with a rotating disc 7, and the top of the rotating disc 7 is provided with a liquid inlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com