High-efficiency temperature-control pressurized ejector stirring filtering reaction system

A reaction system, stirring reaction technology, applied in filtration separation, chemical/physical/physical-chemical nozzle reactors, fixed filter element filters, etc., can solve the problem of poor dispersion of open reaction tanks, uneven local mixing, change Stirring speed and other issues can save space and equipment occupancy, improve equipment compactness, and reduce stirring noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

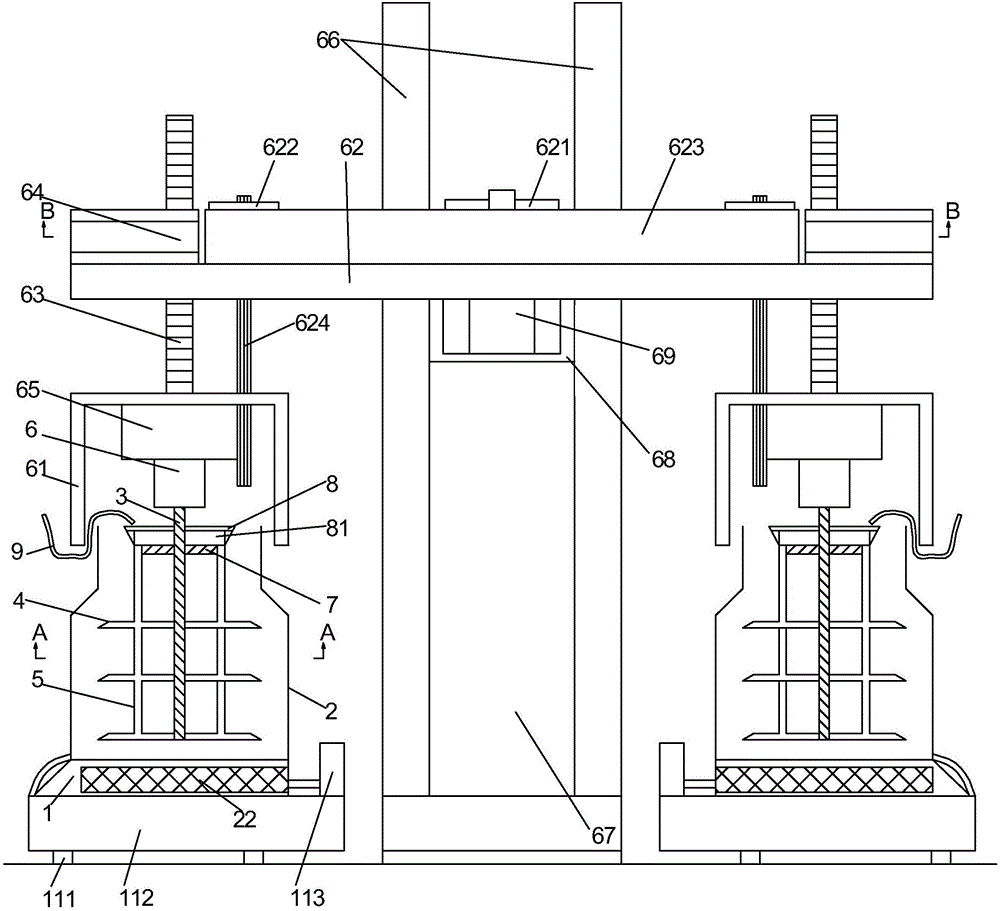

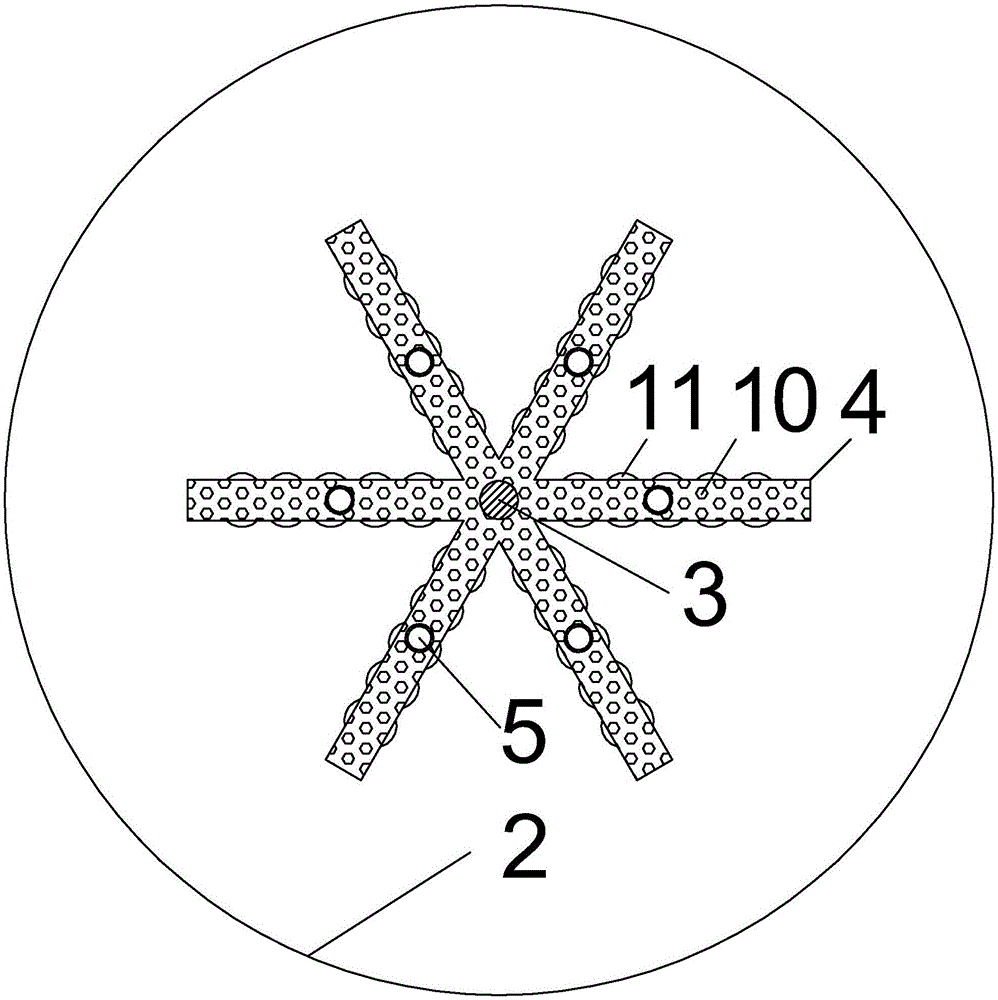

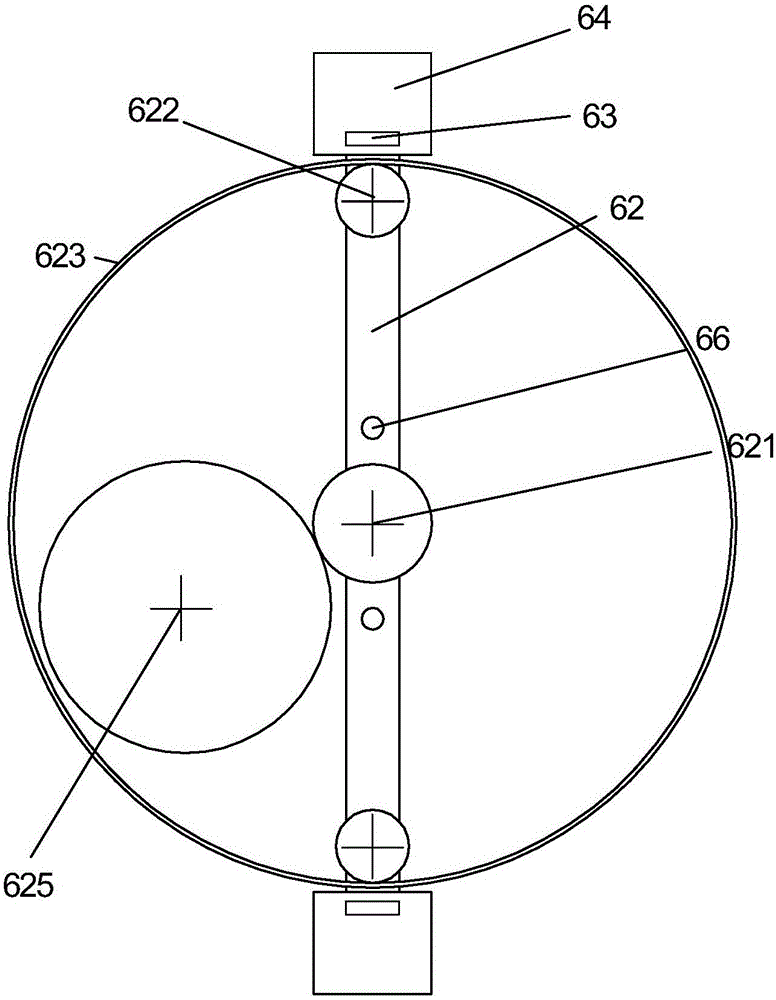

[0052] With reference to the accompanying drawings,

[0053]High-efficiency temperature-controlled pressurized jet stirring and filtering reaction system, high-efficiency temperature-controlled pressurized jet stirring and filtering reaction system, the above-mentioned system includes a circular track 111 and a rail car 112 for conveying the stirring reaction tank, and the above-mentioned rail car 112 is also equipped with an electric pusher Pull rod 113 and chute (the chute is for the slide rail at the bottom of the reaction tank to pass through, and the slide rail matches the ground chute 114 on the workshop floor to replace the reaction tank); there is a stirring device inside the above track, Above-mentioned stirring device comprises the horizontal cantilever 62 that is driven to move up and down by electro-hydraulic jack 67, and described cantilever 62 is provided with 2 guiding balance bars 66 that are respectively arranged on the left side and the right side of jack 67, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com