Patents

Literature

32results about How to "Improve automated processing efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

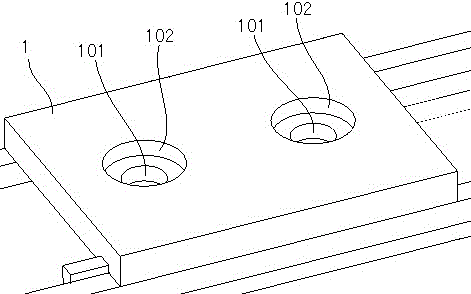

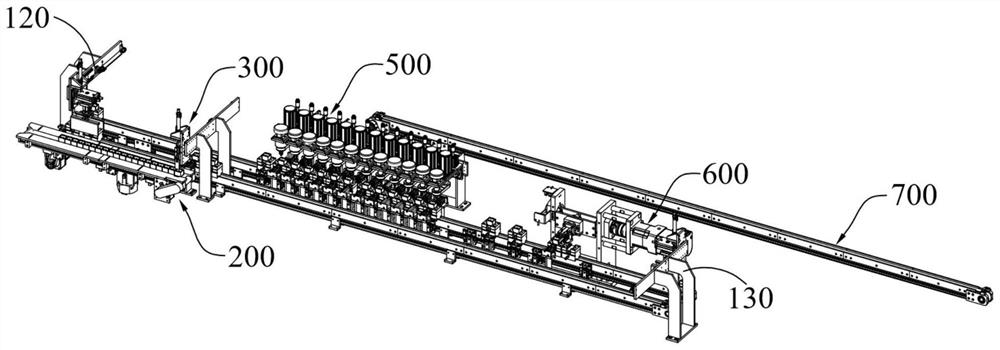

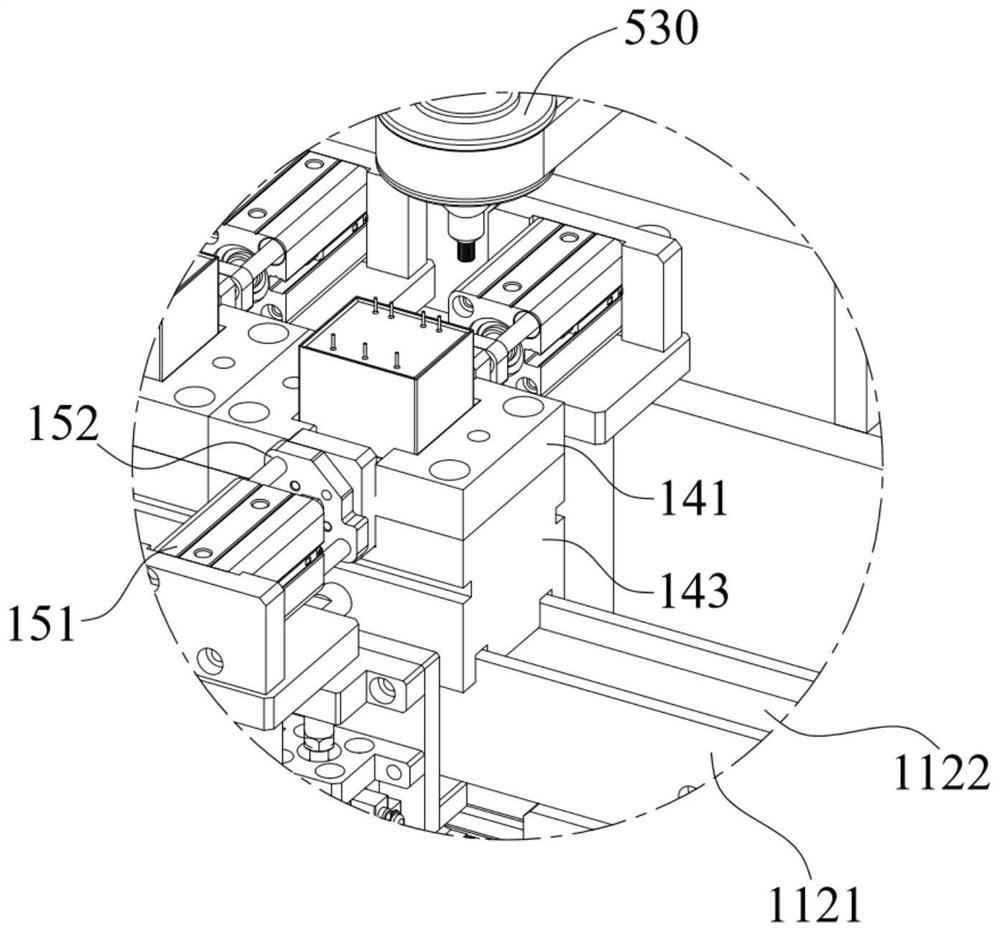

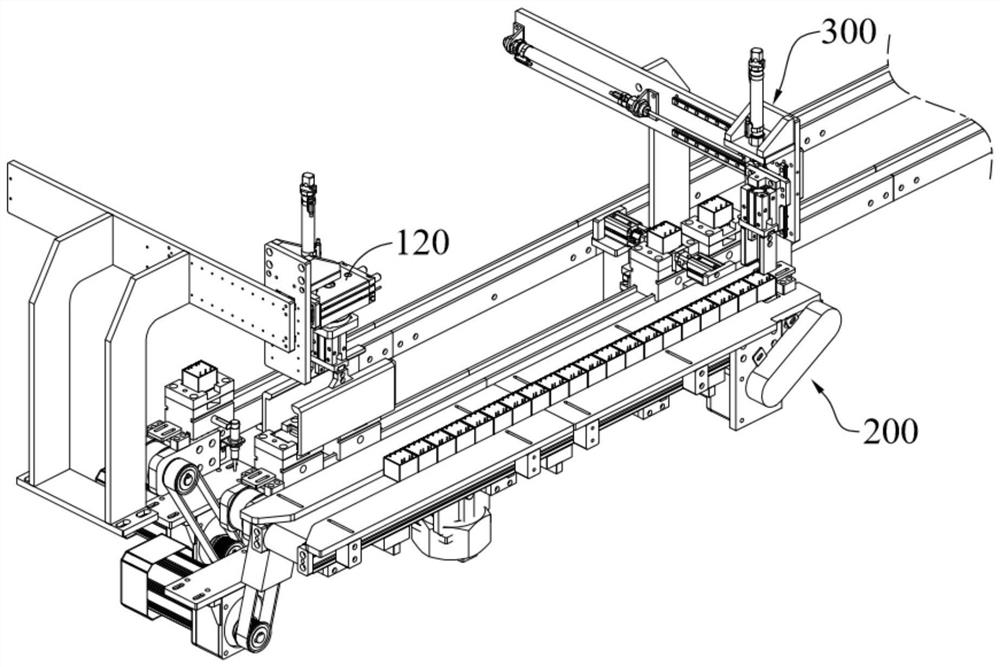

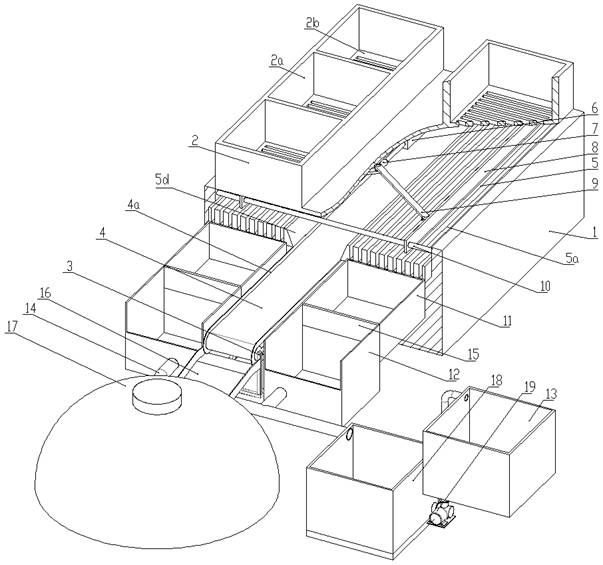

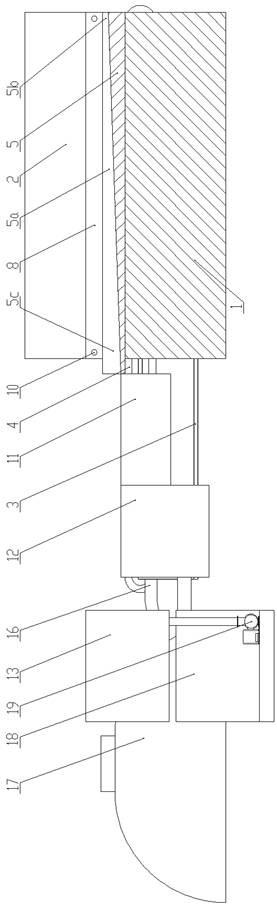

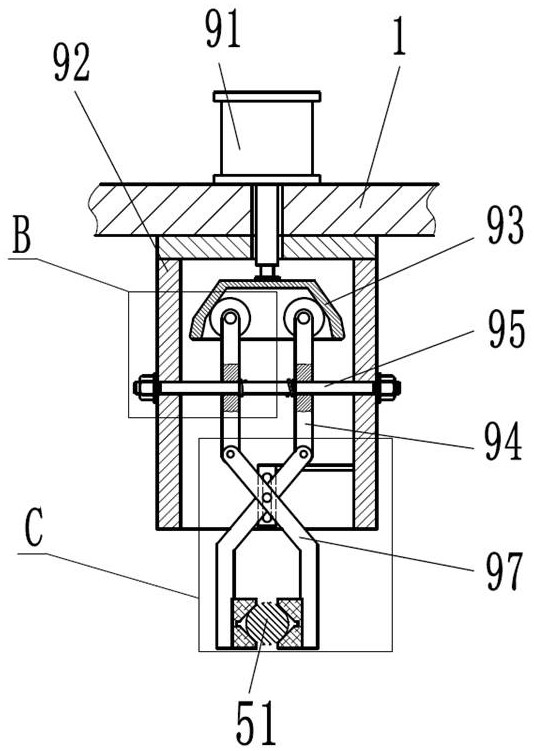

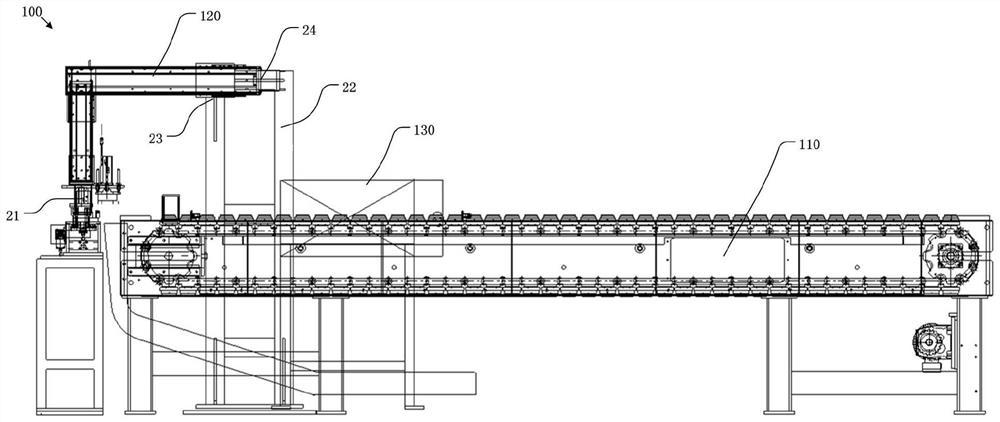

Automatic magnetizing and demagnetizing equipment of magnetic workpieces

PendingCN111128512AImprove automated processing efficiencyImprove versatilityMagnetic bodiesDemagnetizing deviceEngineering

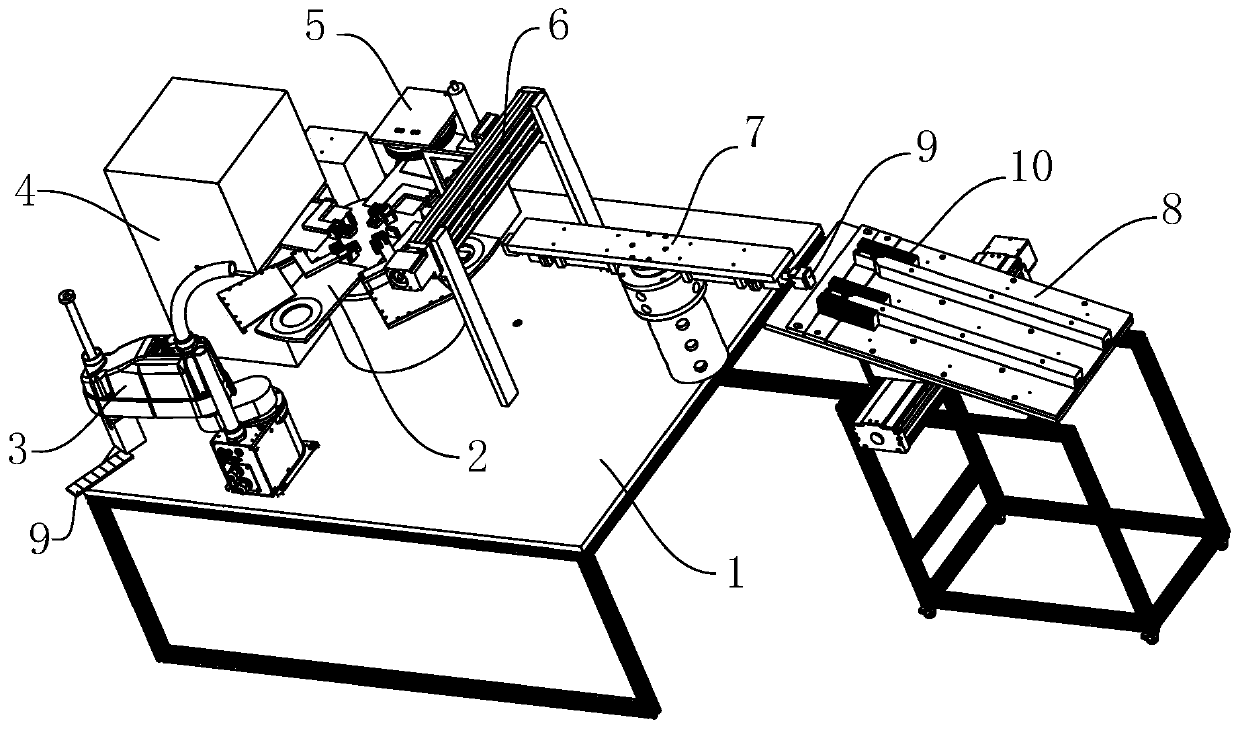

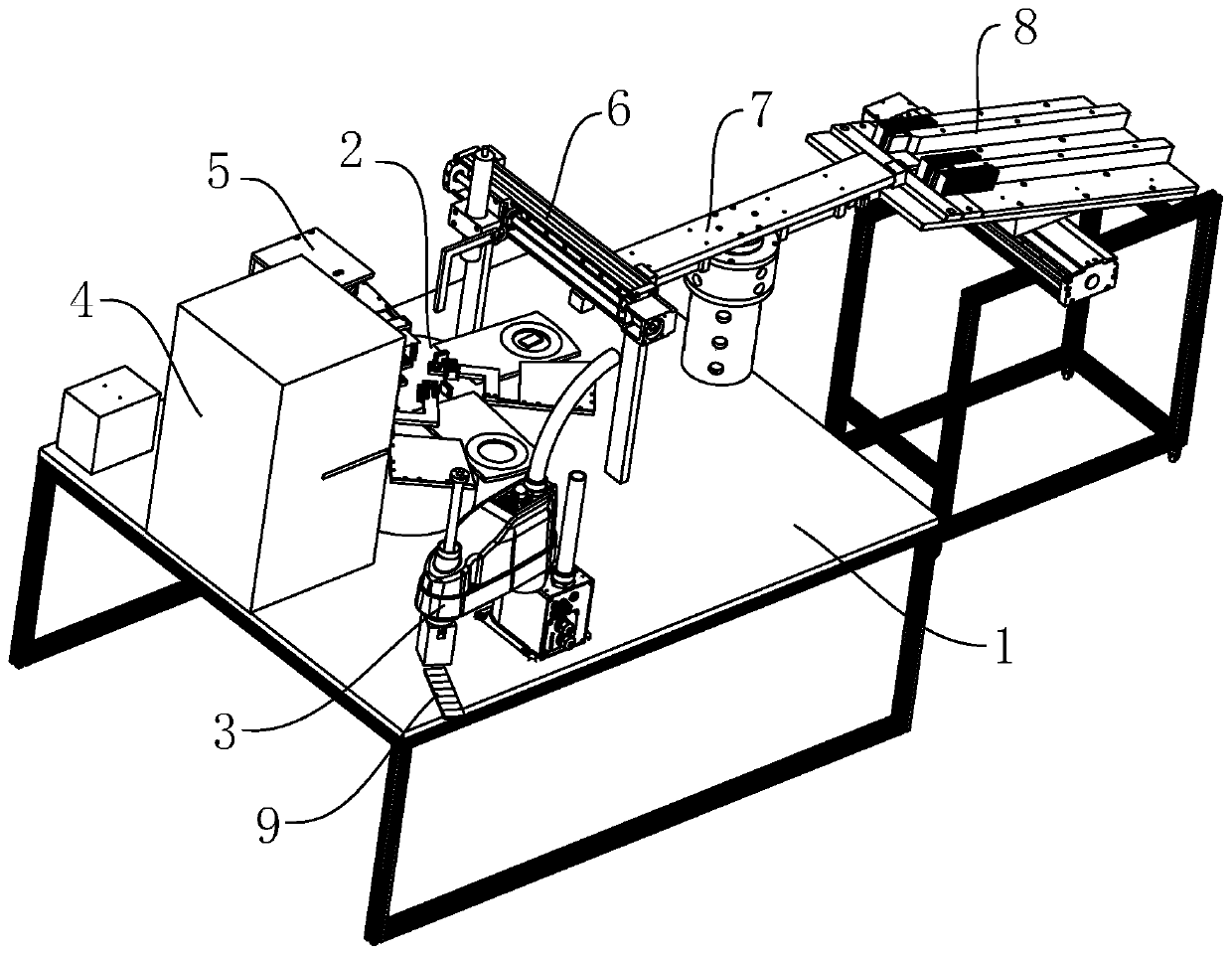

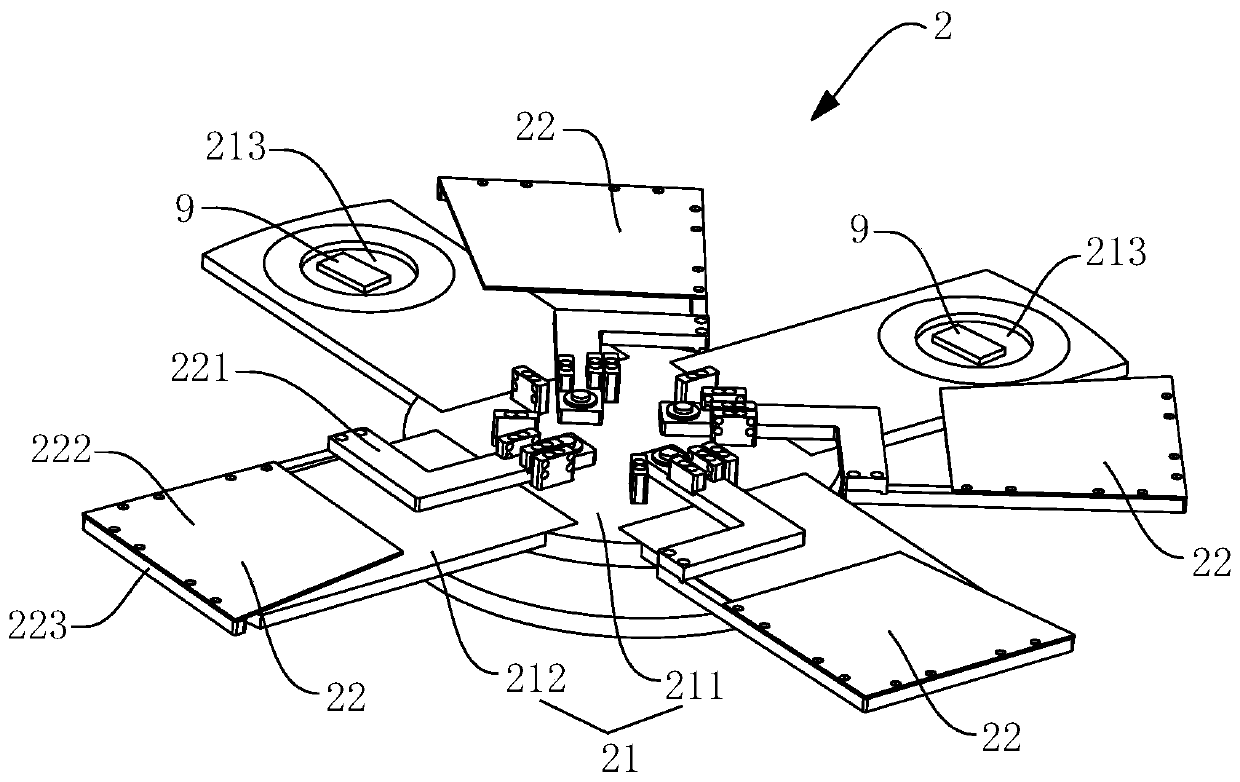

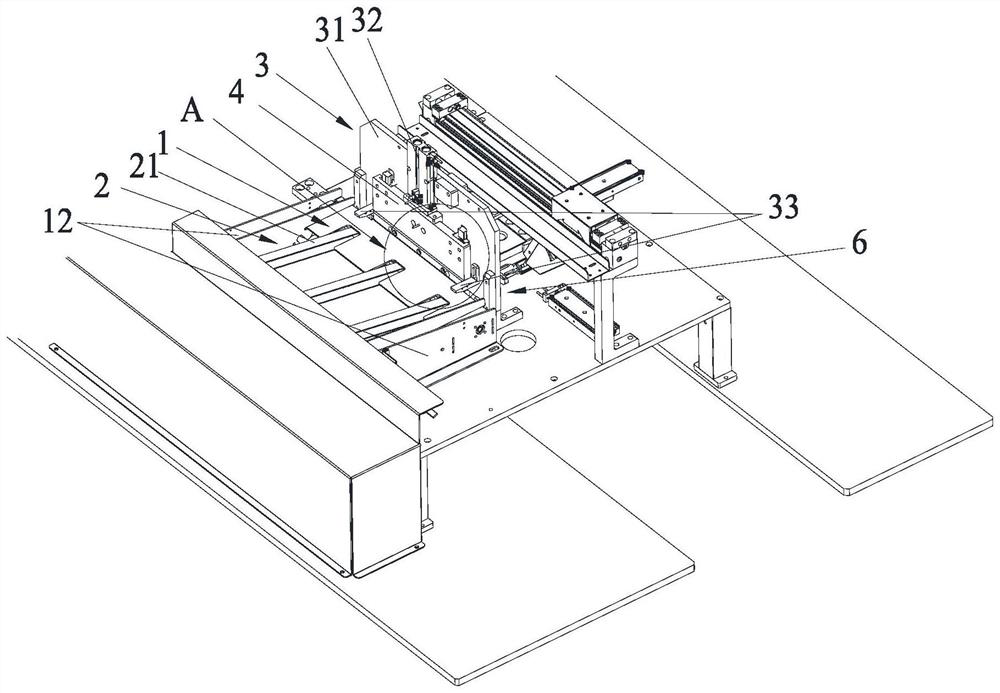

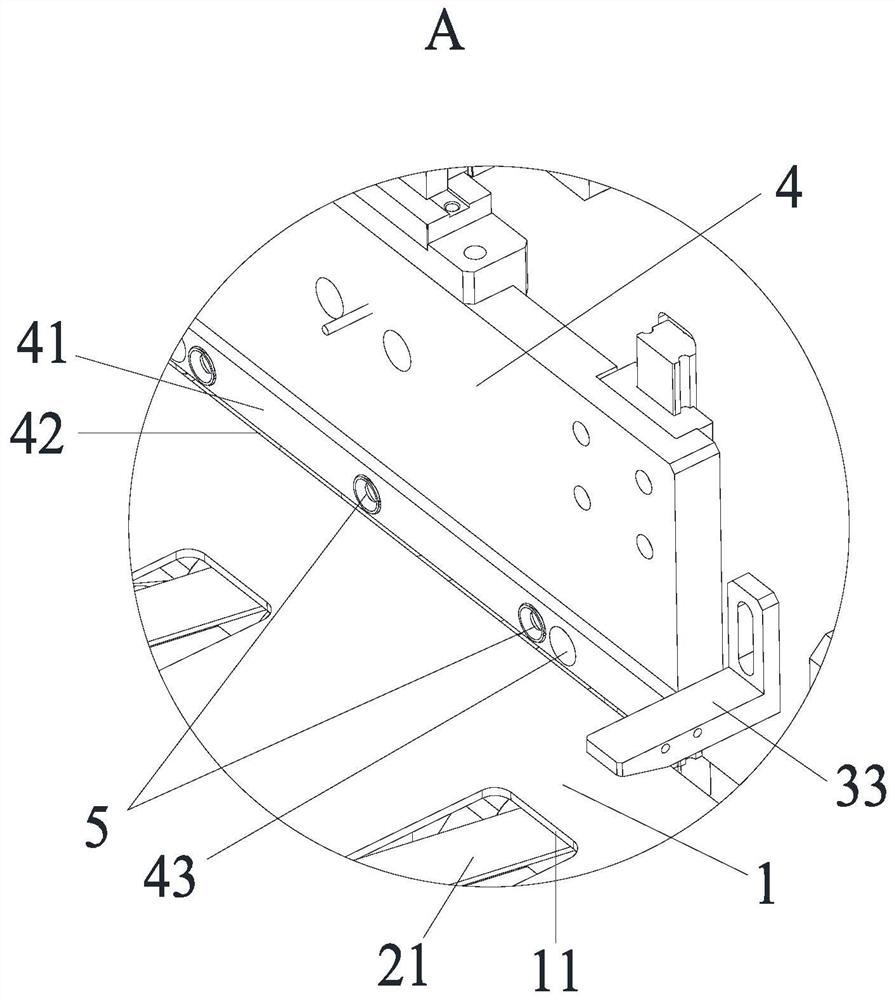

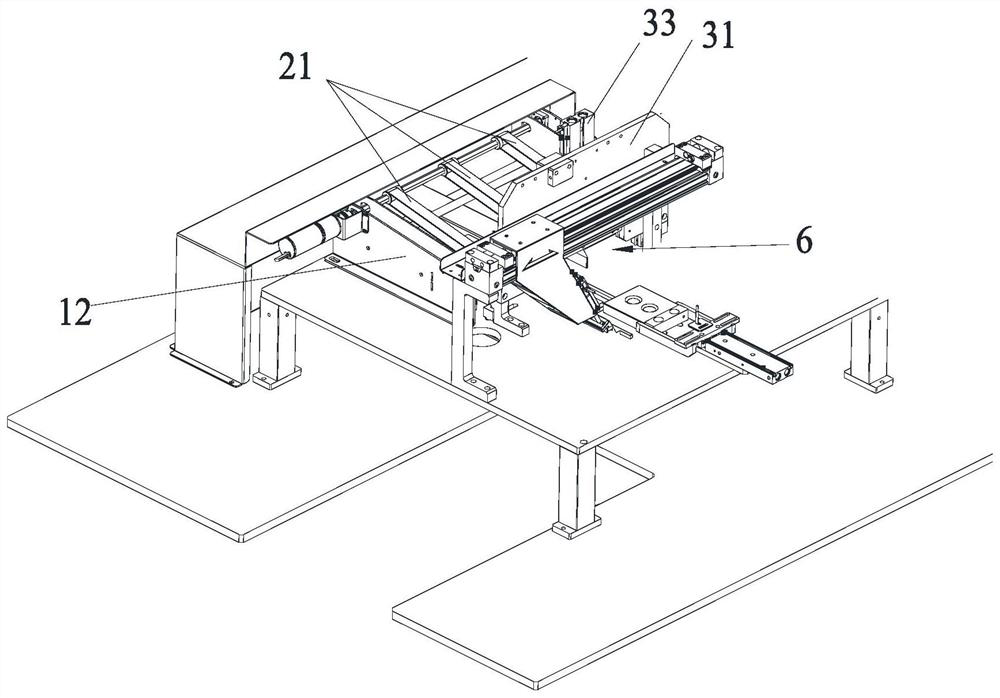

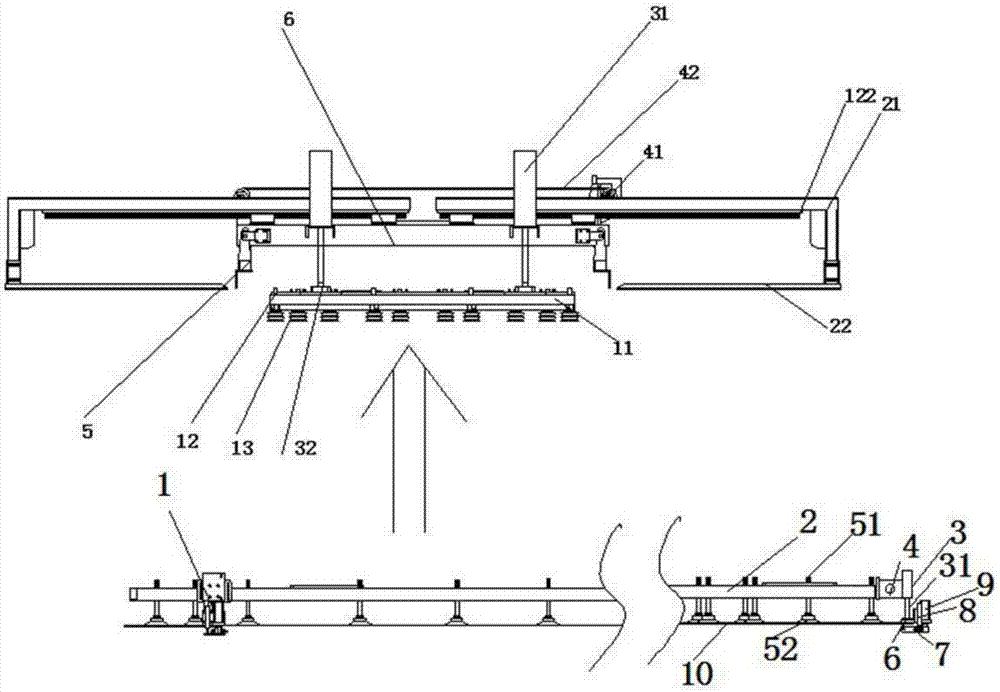

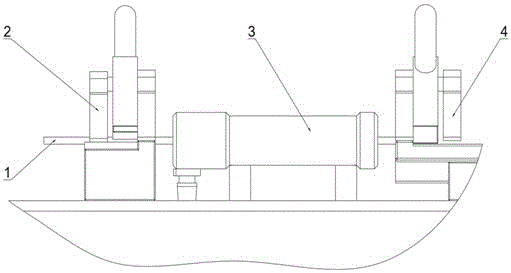

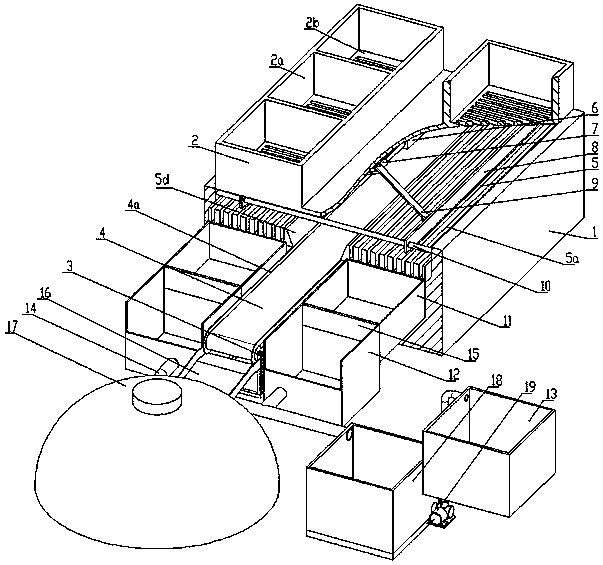

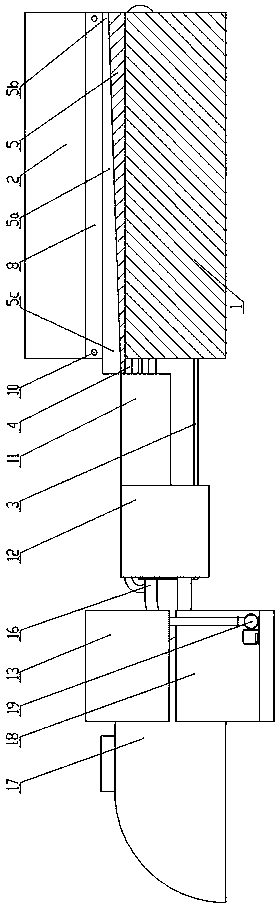

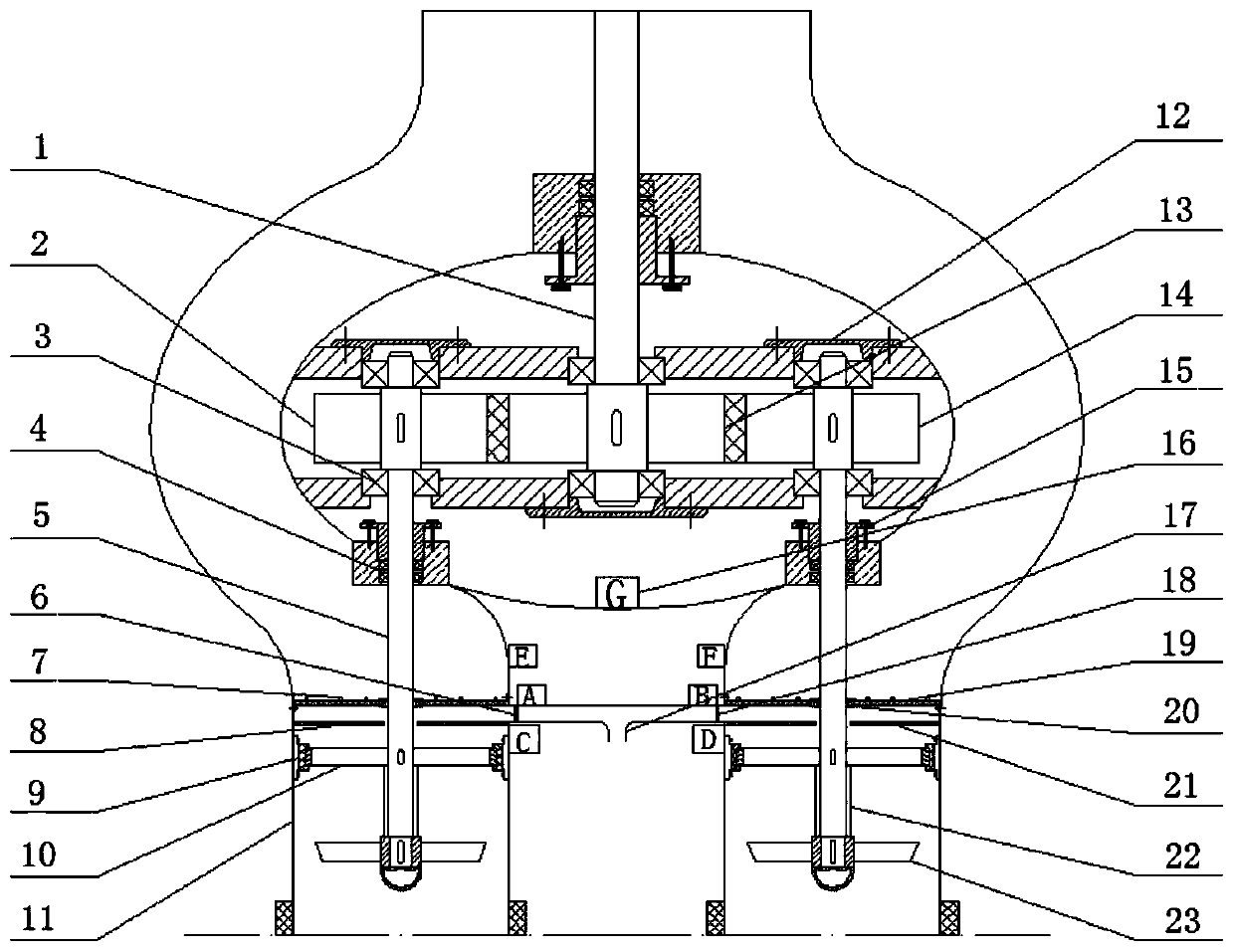

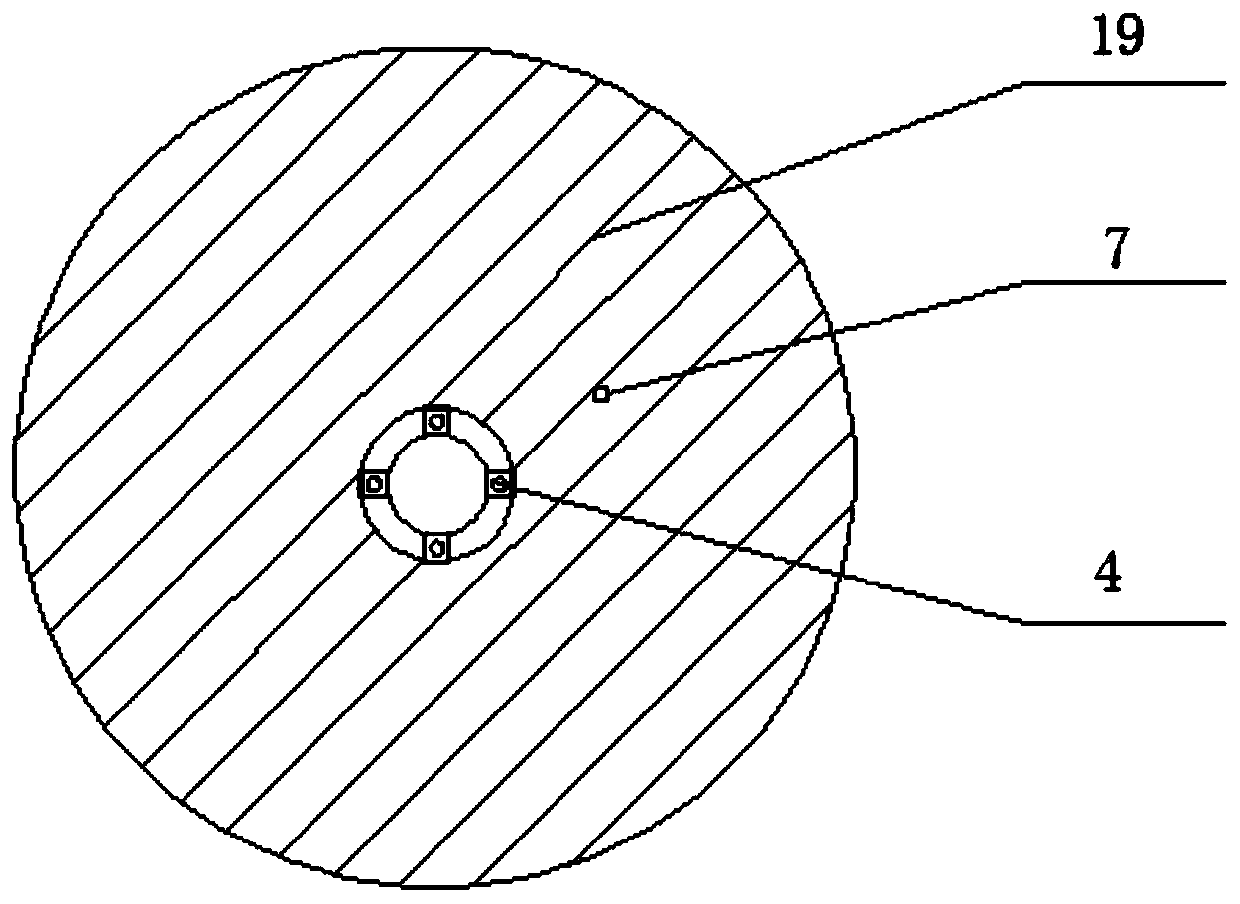

The invention discloses automatic magnetizing and demagnetizing equipment of magnetic workpieces. The equipment comprises a workpiece conveying device, a magnetizing and demagnetizing device and a workpiece processing device , wherein the workpiece conveying device is provided with a feeding station, a magnetizing and demagnetizing station and a discharging station along a conveying direction, andthe workpiece conveying device is also provided with a processing station positioned at an upstream position or a downstream position of the magnetizing and demagnetizing station; the magnetizing anddemagnetizing device is arranged at the magnetizing and demagnetizing station and includes a first permanent magnet and a second permanent magnet, and a workpiece placing space is formed between thefirst permanent magnet and the second permanent magnet; the workpiece processing device is arranged at the processing station; the workpiece conveying device bears a workpiece at the feeding station,and when a workpiece is conveyed to the magnetizing and demagnetizing station through the workpiece conveying device and enters the workpiece placing space, the workpiece is magnetized or demagnetized; and when the workpiece is conveyed to the processing station, the workpiece processing device processes the workpiece, and at the discharging station, the workpiece leaves the workpiece conveying device. According to the automatic magnetizing and demagnetizing equipment of the magnetic workpieces, the magnetic workpiece magnetizing and demagnetizing efficiency and the automatic processing efficiency of other procedures are greatly improved, and universality and accuracy are good.

Owner:茵诺麦格(杭州)自动化设备有限公司

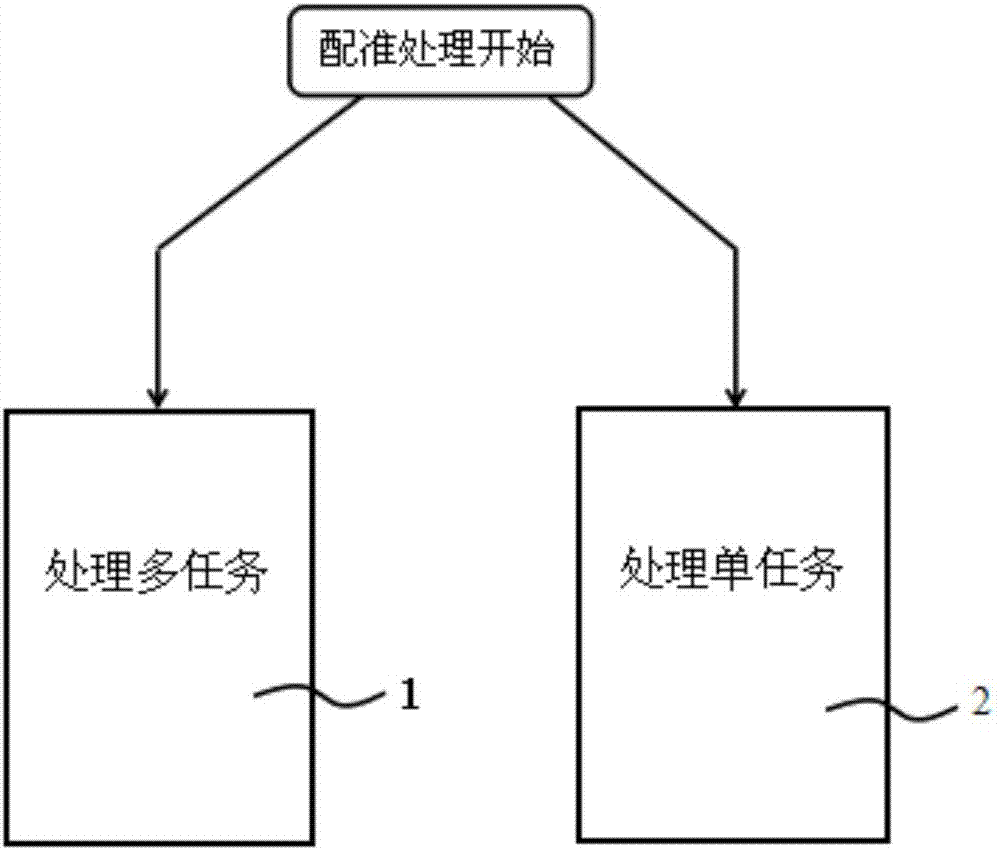

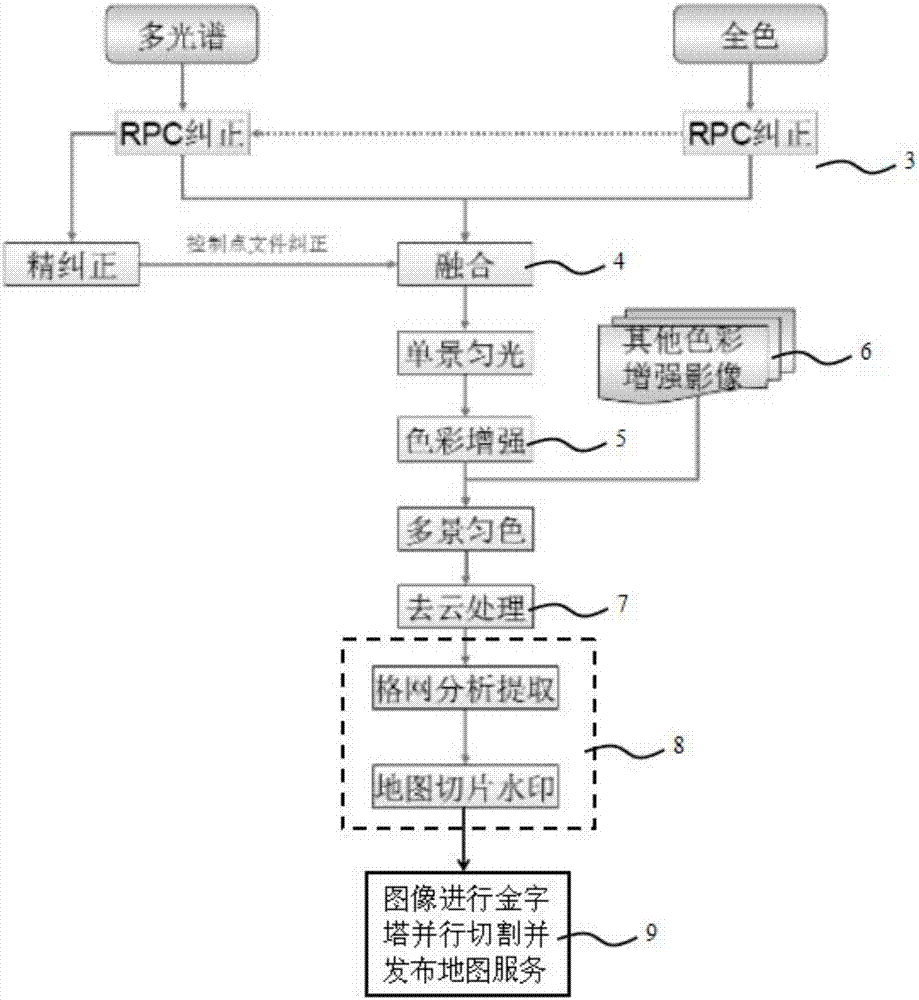

Remote sensing image automatic processing method based on parallel calculation and distributed storage

InactiveCN106971371AStorage supportEfficient storageImage enhancementImage analysisSatellite image processingTherapeutic effect

The invention belongs to the technical field of satellite image processing, and particularly relates to a remote sensing image automatic processing method based on parallel calculation and distributed storage. The method comprises a multi-task processing step and a single-task processing step. Thus, the beneficial effects of the method are that problems of low automation degree, low efficiency, limited capacity caused by single-point machines, low data safety and troublous data retrieval are solved; storage of big files is supported; small files can be highly efficiently stored; it is convenient for users to quickly and seamlessly browse images; and under the premise of ensuring processing effects, efficiency of automation processing of images is improved.

Owner:梅非

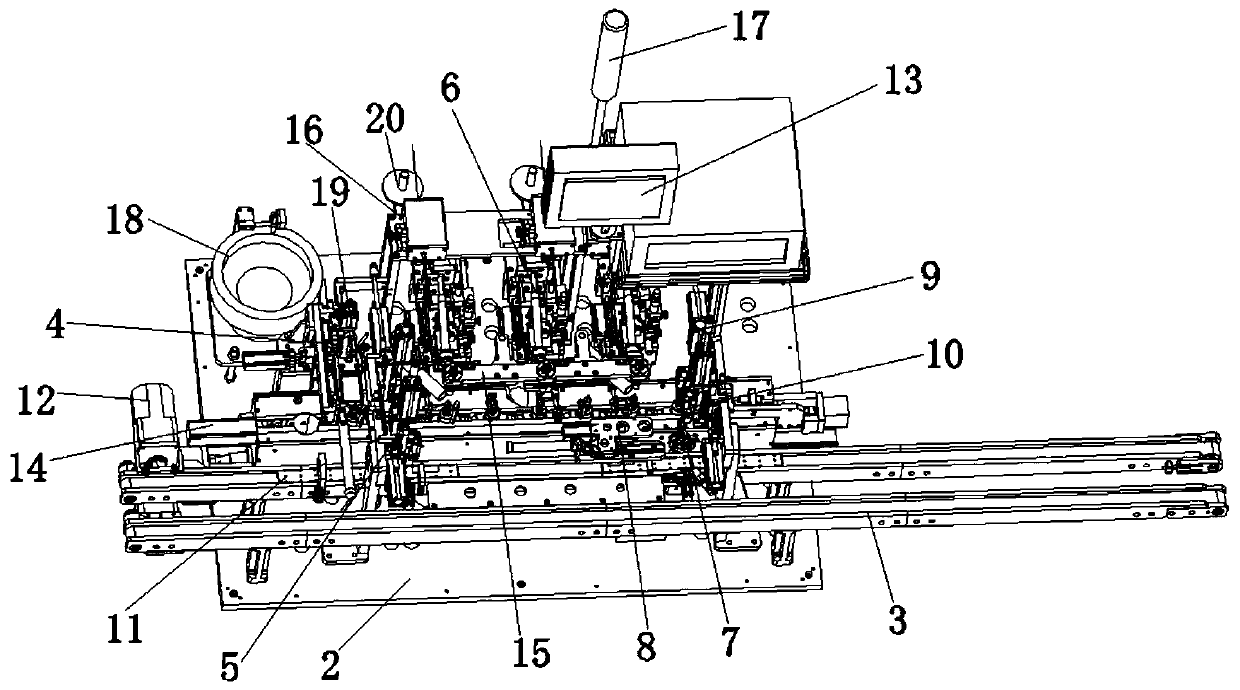

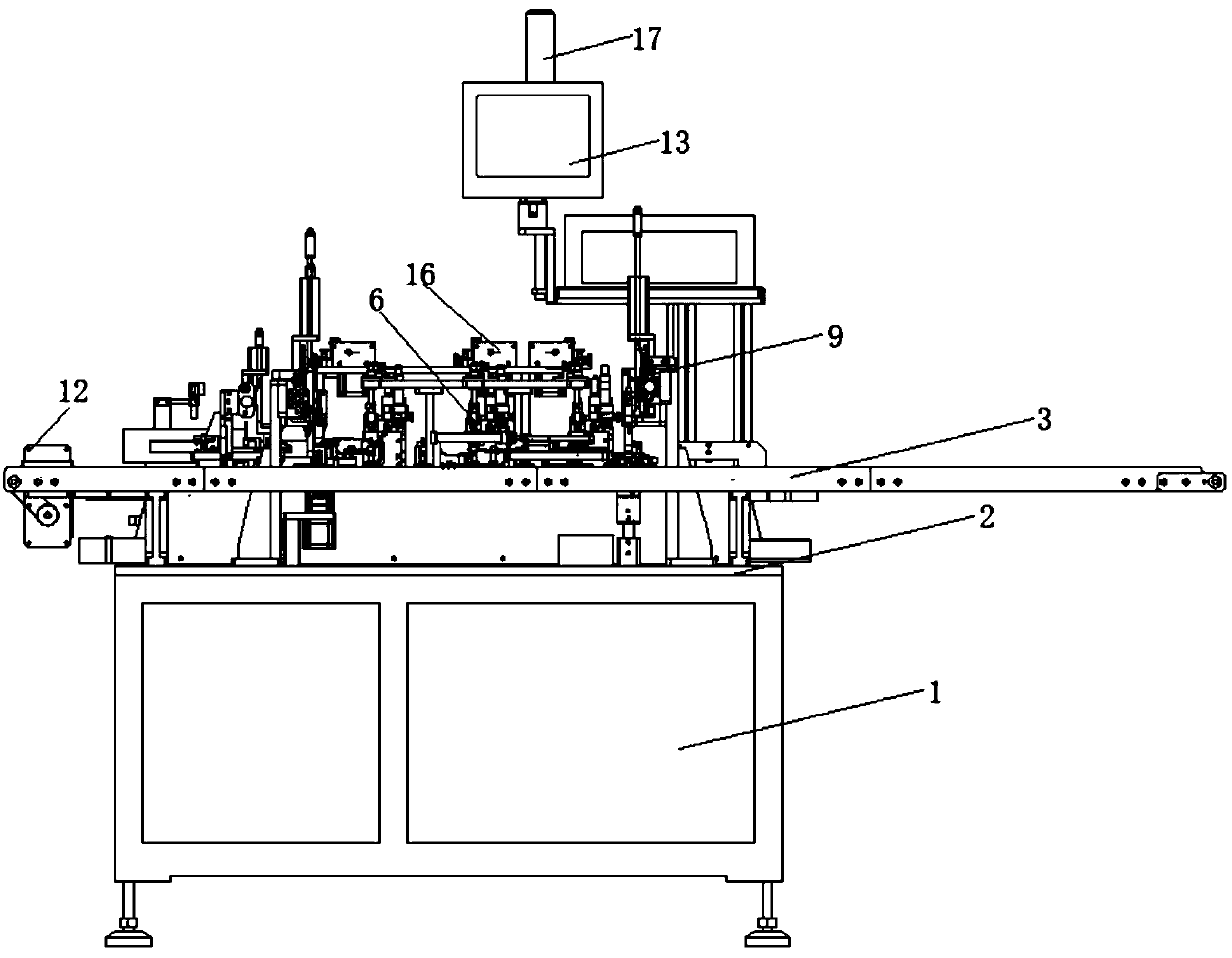

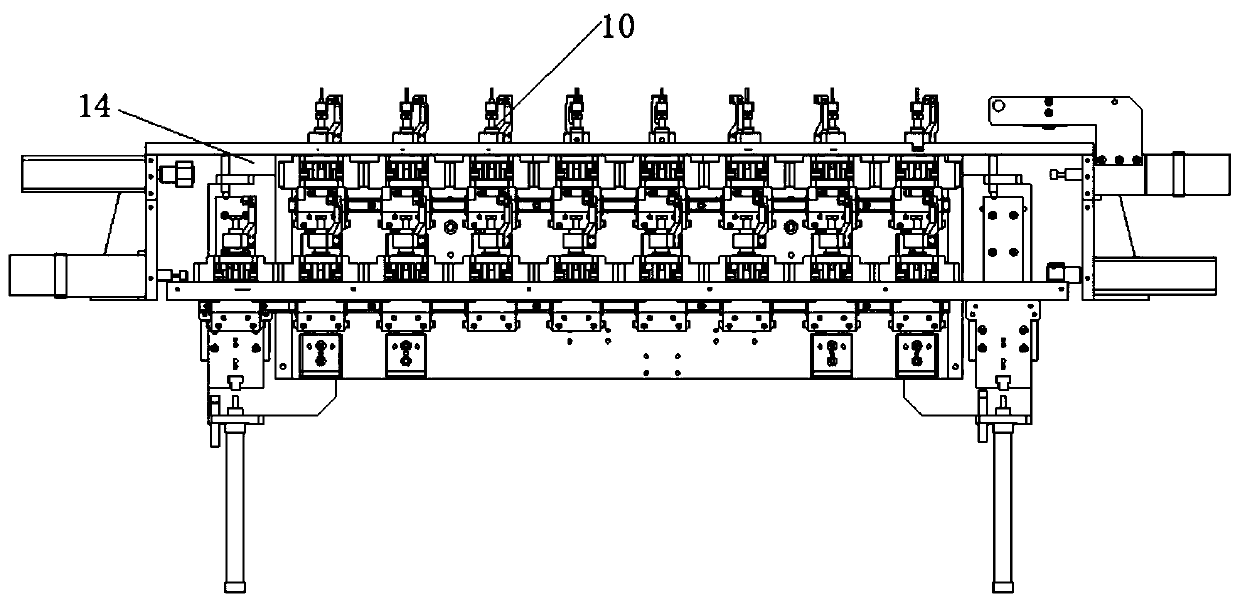

Full-automatic welding pressure-sensitive machine

PendingCN109702283ARealize automated productionLabor savingMetal working apparatusSoldering auxillary devicesPressure sensitiveWelding

The invention discloses a full-automatic welding pressure-sensitive machine. The machine comprises a case, a worktable arranged on the case, a linear transfer plate conveying guide rail arranged on the worktable, an upper pressure-sensitive mechanism for mounting of a piezoresistor, an upper rotor mechanism for mounting of a motor rotor, a welding mechanism, a detecting mechanism, a non-performingproduct discharge mechanism and a discharging mechanism used for finished product discharging; the upper pressure-sensitive mechanism, the upper rotor mechanism, the welding mechanism, the detectingmechanism, the non-performing product discharge mechanism and the discharging mechanism are sequentially arranged along the linear transfer plate conveying guide rail from the feeding end of the linear transfer plate conveying guide rail. The upper pressure-sensitive mechanism, the upper rotor mechanism, the welding mechanism, the detecting mechanism, the non-performing product discharge mechanismand the discharging mechanism are in control connection through a control mechanism; the worktable is provided with a mold core carrying rail capable of circularly moving, and multiple mold core carrying mechanisms are arranged on the mold core carrying rail. The machine is controlled by the control mechanism, the mechanisms are sequentially arranged along the linear transfer plate conveying guide rail, the number of machining procedures is small, production cost is saved, machining efficiency is high, the machining precision is stable, and the product yield is high.

Owner:东莞市点亮自动化设备有限公司

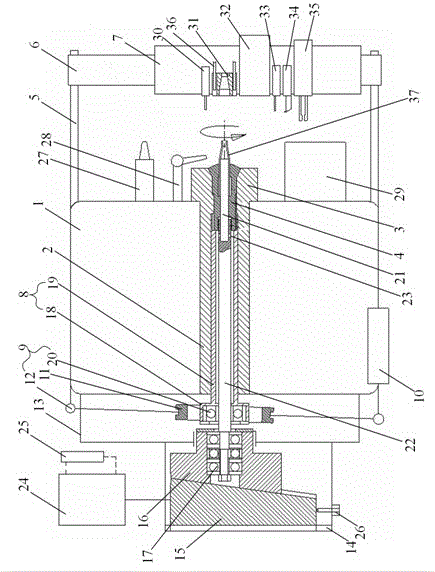

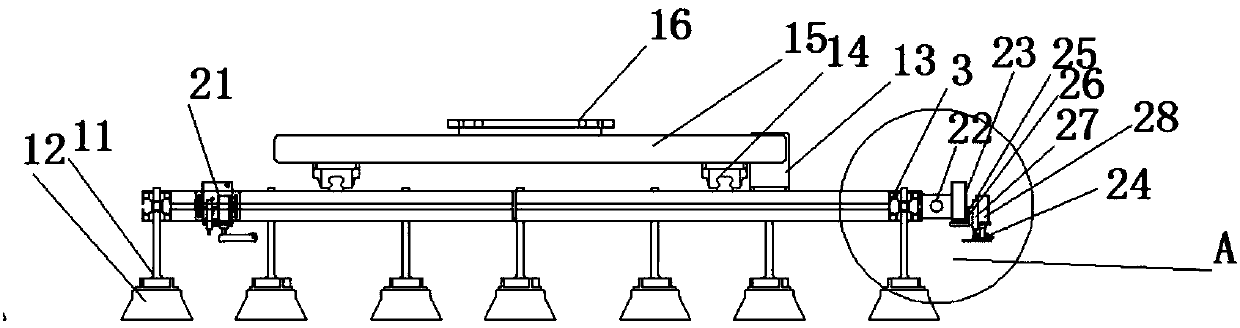

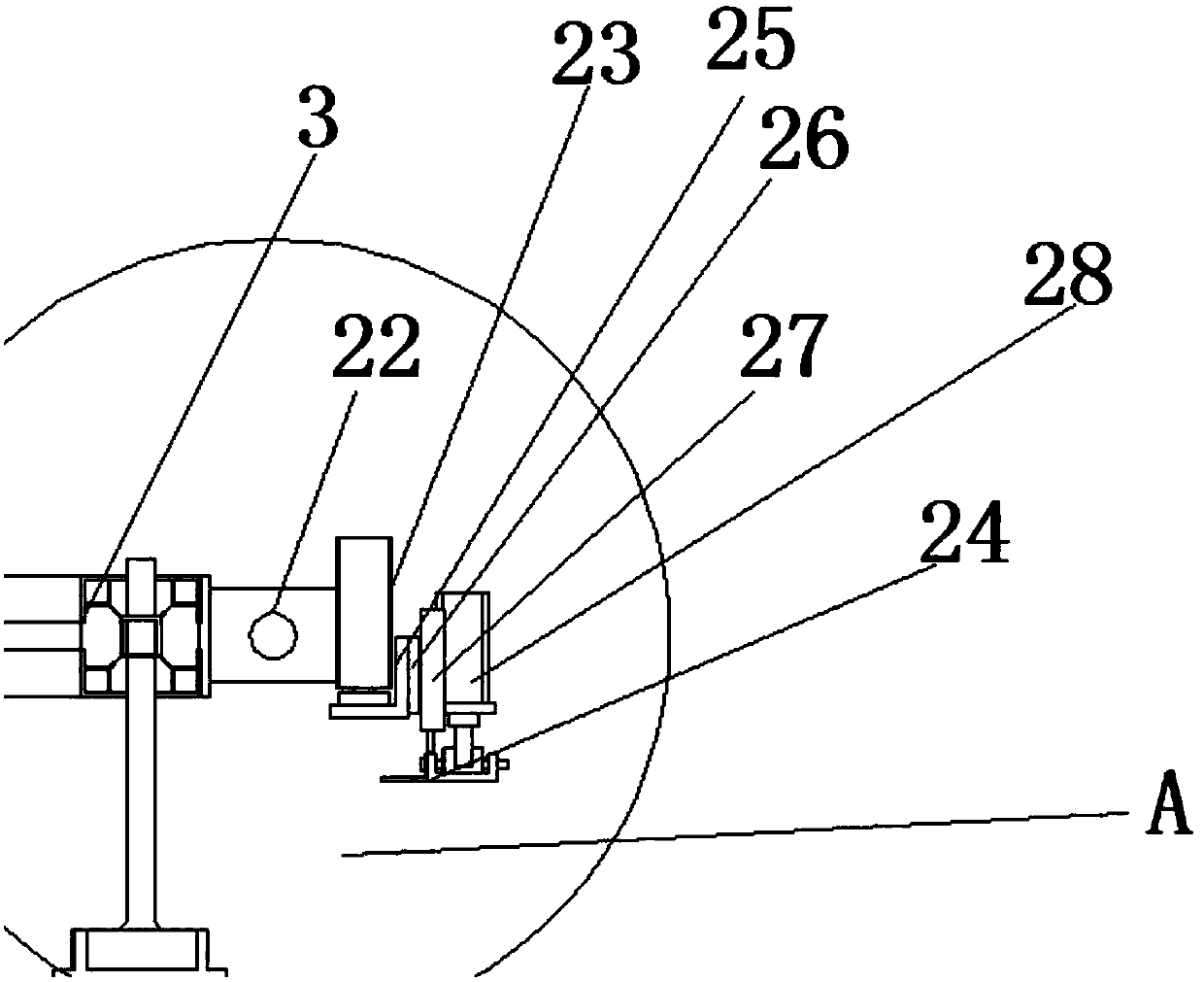

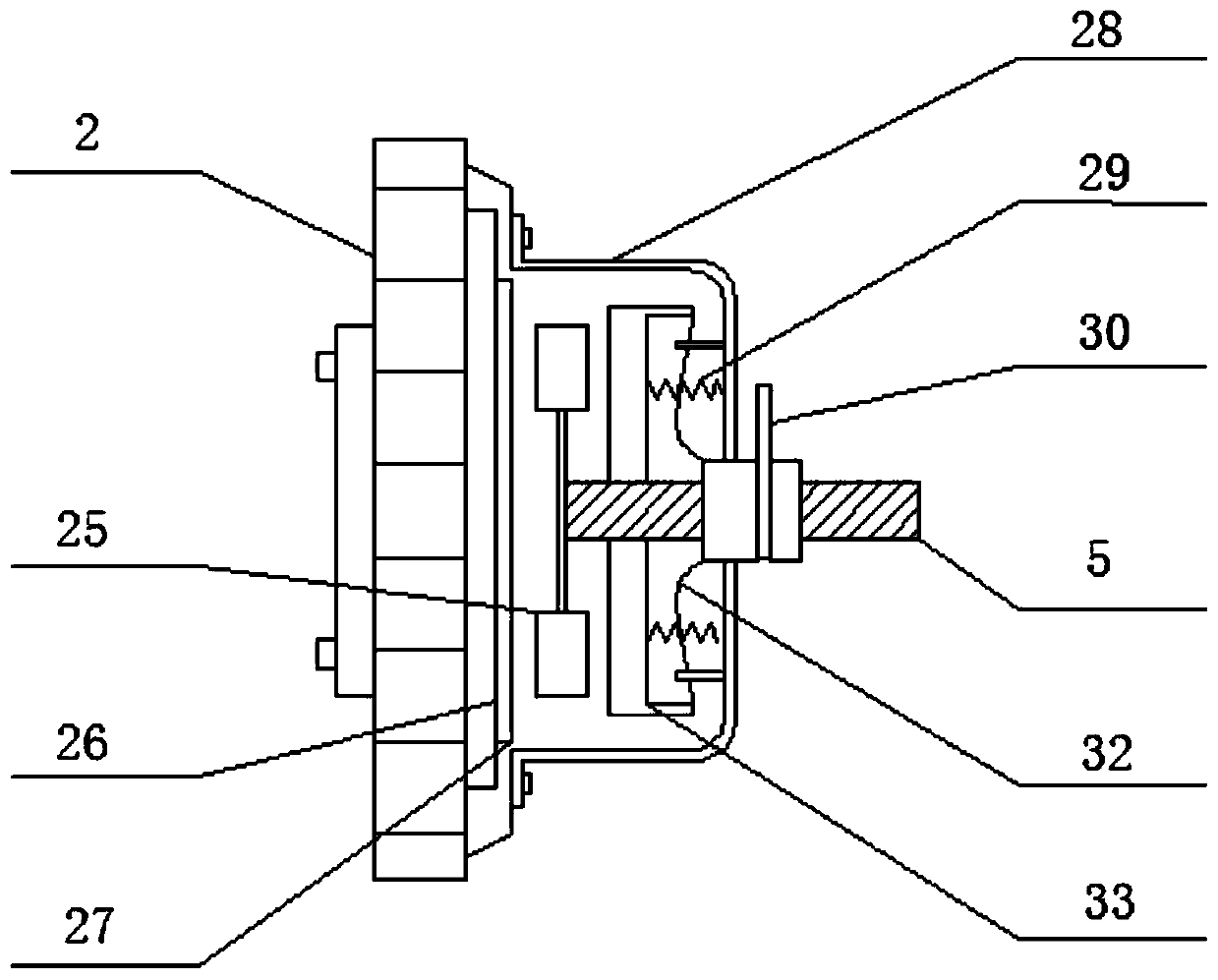

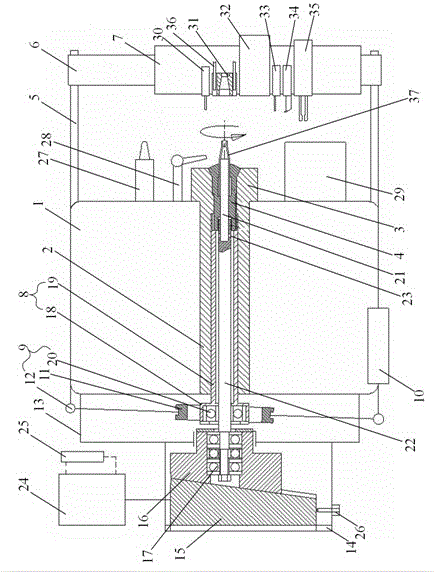

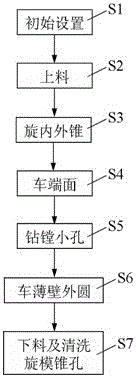

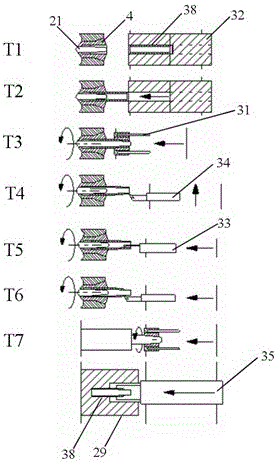

Automatic processing equipment for small-diameter copper pipe with inner and outer cones and thin-wall cylinder

ActiveCN104440112AQuality improvementSimple structureOther manufacturing equipments/toolsDrive motorEngineering

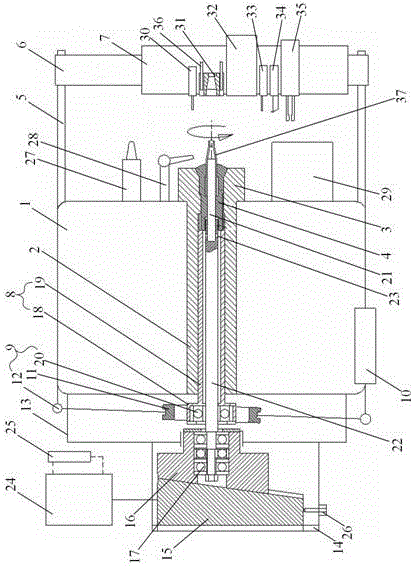

The invention discloses automatic processing equipment for a small-diameter copper pipe with inner and outer cones and a thin-wall cylinder. The automatic processing equipment comprises matched equipment, a pipe inner cone spinning executing mechanism, an integral cone spinning die for spinning a pipe outer cone, a die washing swivel head and a pipe loading and unloading device, wherein the matched equipment comprise a spindle box, a transverse guide rail, a longitudinal guide rail, a sliding carriage and a servo motor; the pipe inner cone spinning executing mechanism comprises a tapered spindle assembly and a driving motor thereof, and the tapered spindle assembly is arranged on a fixed slider in an oblique slider assembly; the integral cone spinning die for spinning the pipe outer cone is arranged on a water-cooling base; the die washing swivel head is connected with a stepper motor shaft; the pipe loading and unloading device comprises a loading mechanism and an unloading mechanism; an inner cone washing swivel head of the integral cone spinning die, an oil nozzle and a pipe collecting box are mounted on the spindle box body of the equipment. The automatic processing equipment is reasonable and simple in structure and convenient to operate, spins the inner and outer cones at high quality, improves the wall thickness evenness by the methods of drilling, precise boring and non-spindle thin-wall cylinder finish turning, is high in automatic processing efficiency and is low in cost.

Owner:CHINA NUCLEAR TIANJIN TECH DEV

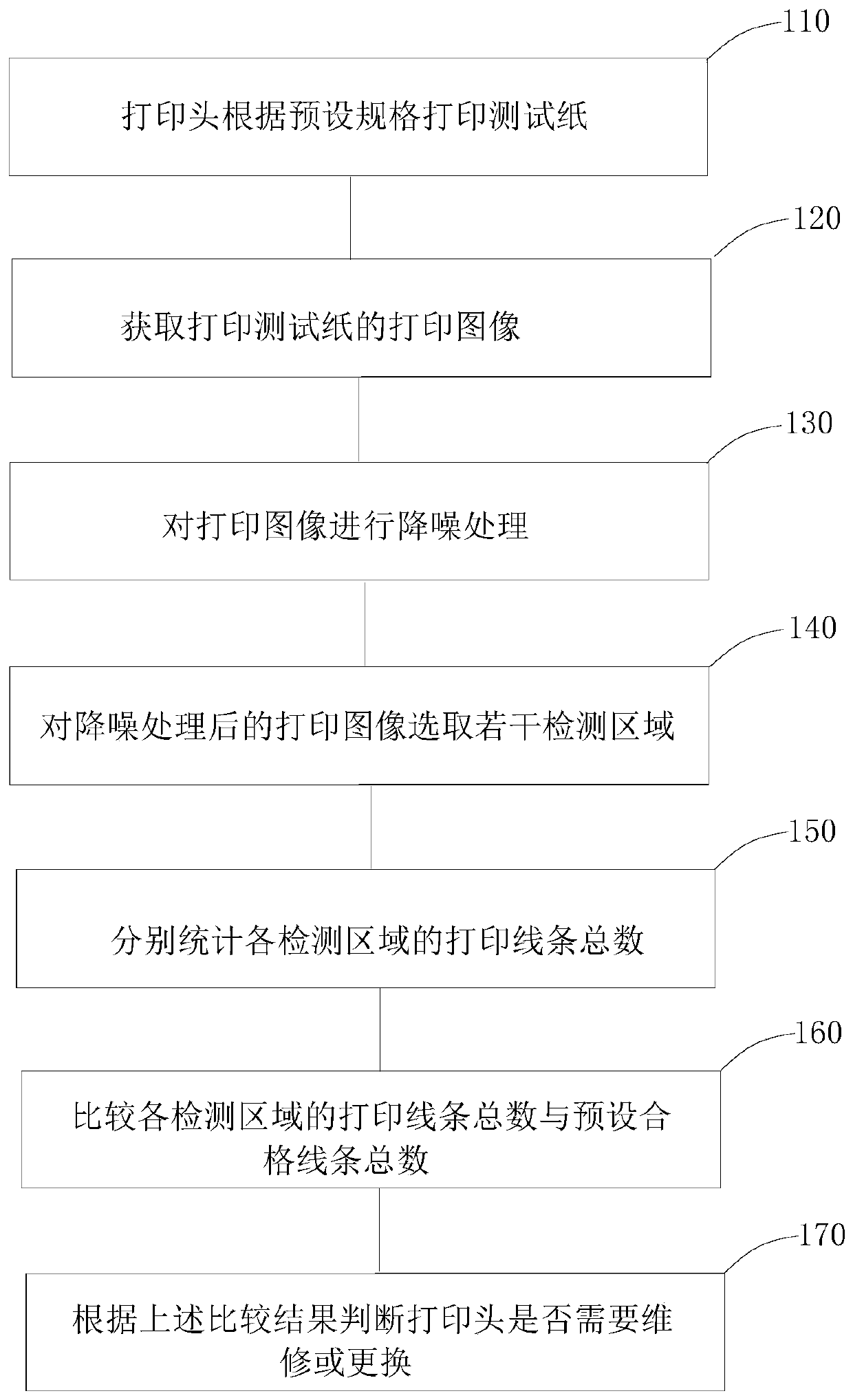

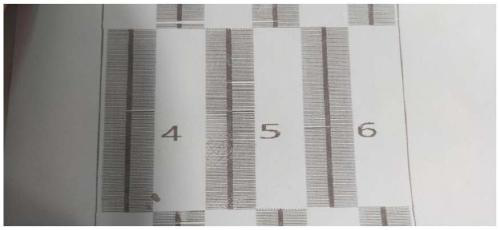

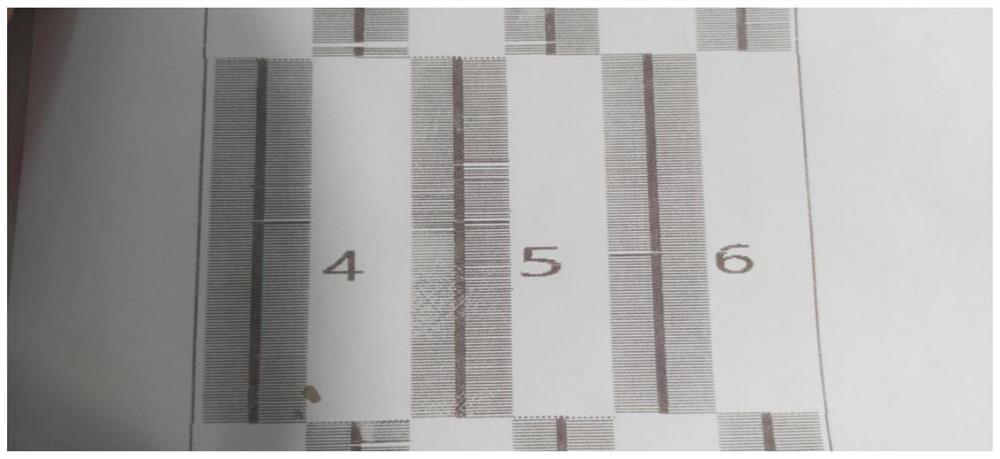

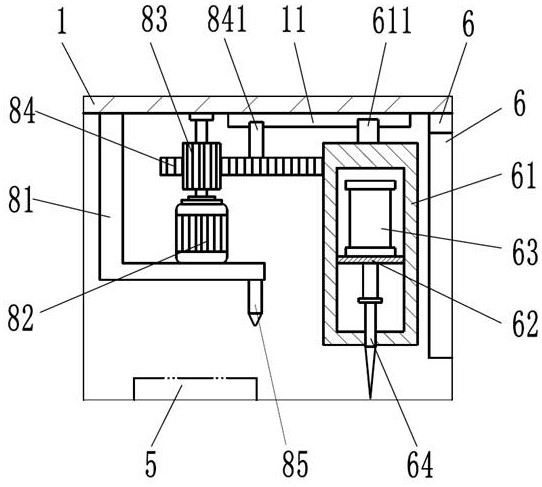

Printing head state detection method, printing head detection system and three-dimensional printer

ActiveCN111421957AImprove automated processing efficiencyEasy to compareMaterial analysis by optical meansStructural/machines measurementComputer printingProcess engineering

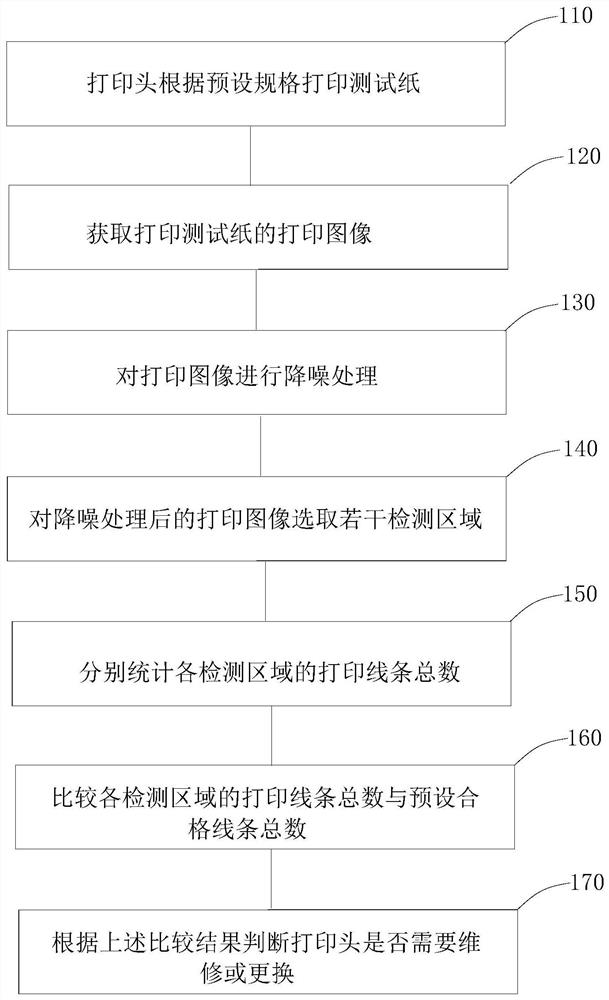

The invention relates to a printing head state detection method, a printing head detection system and a three-dimensional printer. The three-dimensional printer comprises the printing head detection system. The printing head state detection method comprises the following steps that the printing head prints test paper according to preset specification; a print image of the printed test paper is acquired; noise reduction processing is carried out on the print image; a plurality of detection areas are selected from the print image subjected to noise reduction processing; the total number of printlines of the detection areas is counted; the total number of the print lines of each detection area is compared with the total number of preset qualified lines; and whether the printing head needs tobe maintained or replaced is judged according to the comparison result. According to the printing head state detection method, the printing head detection system and the three-dimensional printer, the automatic detection can be achieved, and therefore the printing head state detection efficiency can be improved.

Owner:NINGXIA KOCEL MOLD

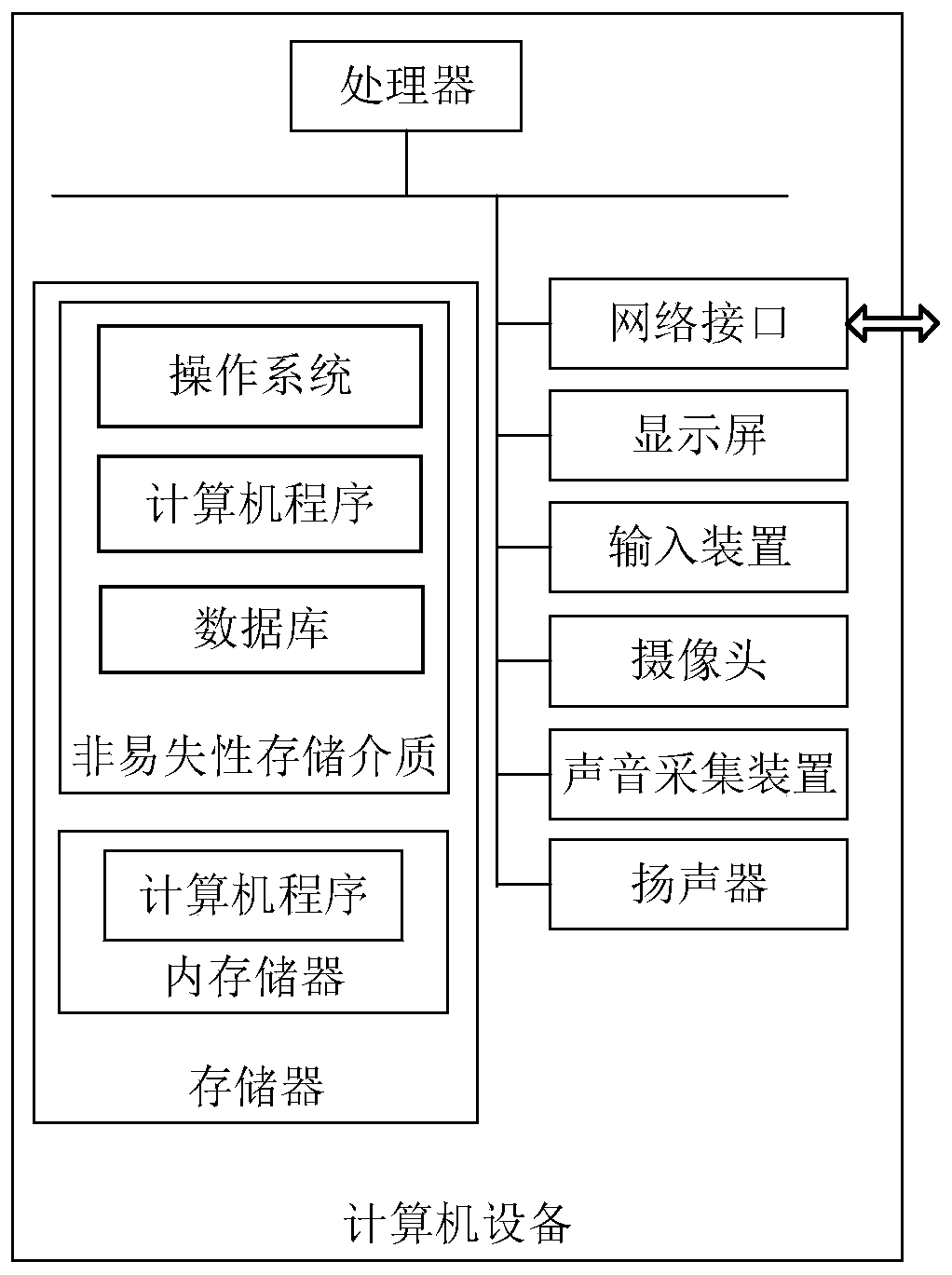

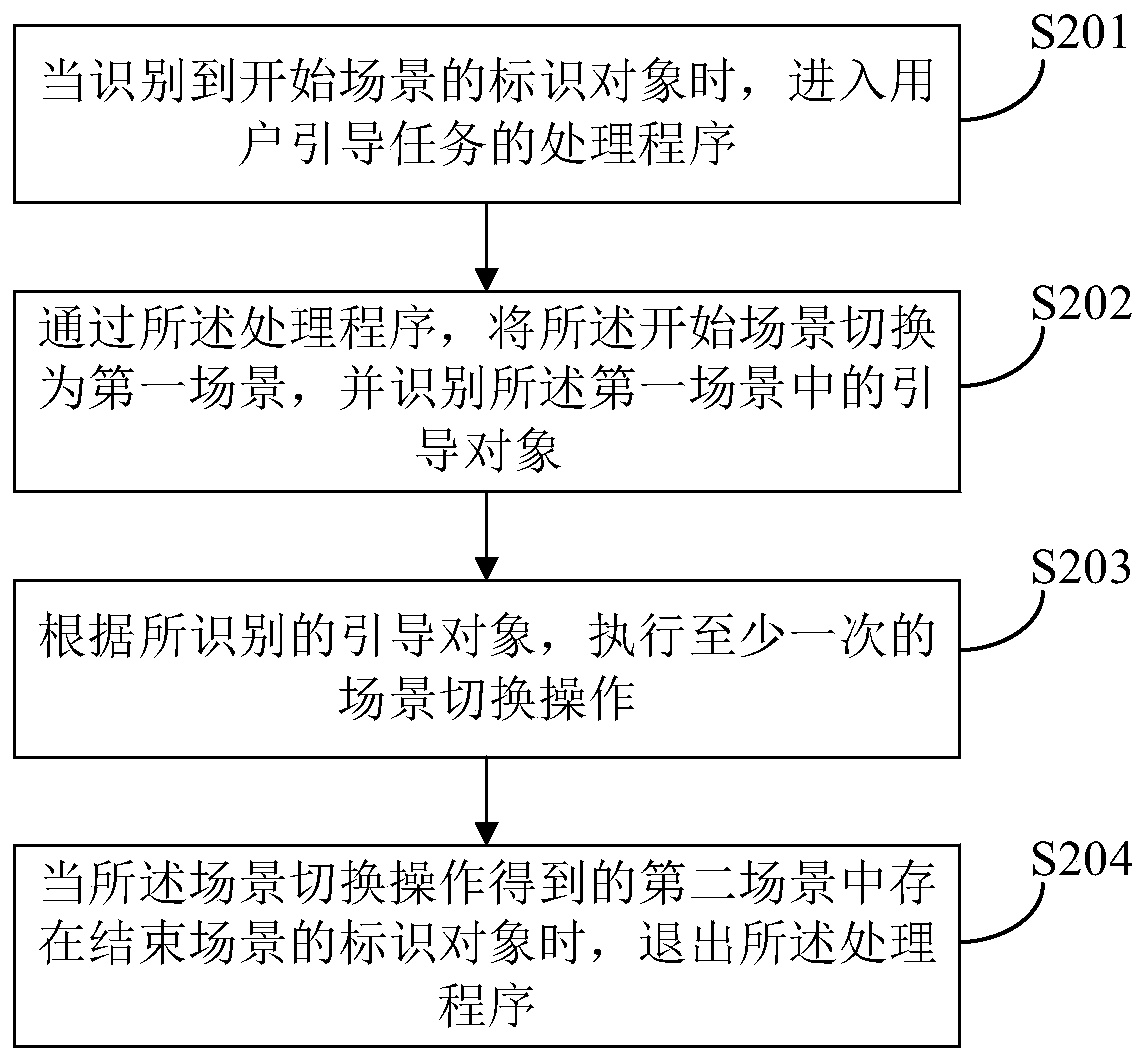

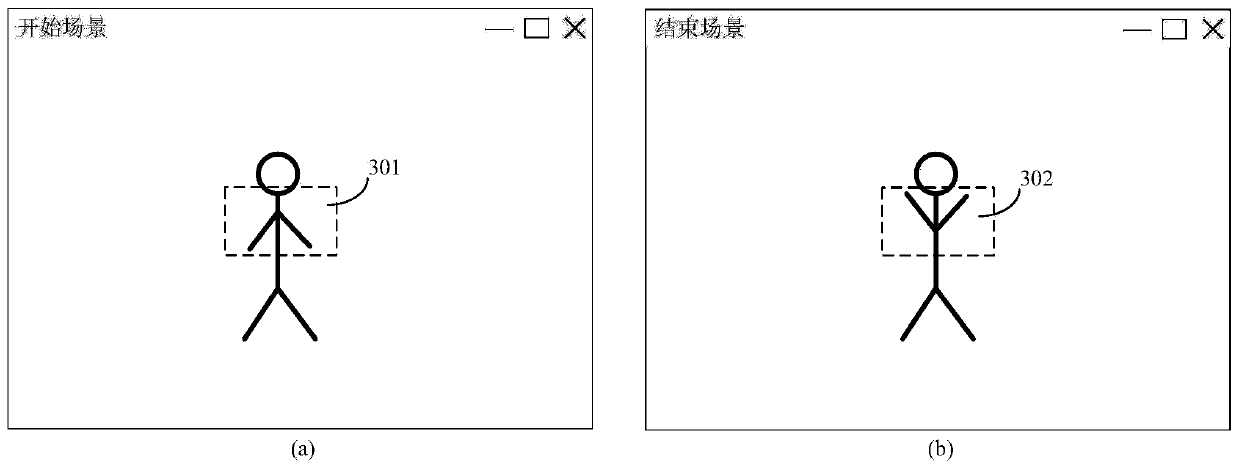

User guide task processing method and device, computer equipment and storage medium

PendingCN110597593AImprove automated processing efficiencyExecution for user interfacesInformation processingComputer science

The invention relates to a user guide task processing method and device, computer equipment and a storage medium, and belongs to the technical field of information processing. The method comprises thesteps of when an identification object of a starting scene is identified, entering a processing program of a user guiding task; switching the starting scene to a first scene through the processing program, and identifying a guide object in the first scene; executing at least one scene switching operation according to the identified guide object; and when the identification object of the ending scene exists in the second scene obtained by the scene switching operation, exiting the processing program. According to the technical scheme, the problem that the automatic processing efficiency of user tasks is low is solved. The user guiding task can be automatically completed without marking all scenes in the user guiding task one by one, and the automatic processing efficiency of the user taskcan be effectively improved.

Owner:TENCENT TECH (SHENZHEN) CO LTD

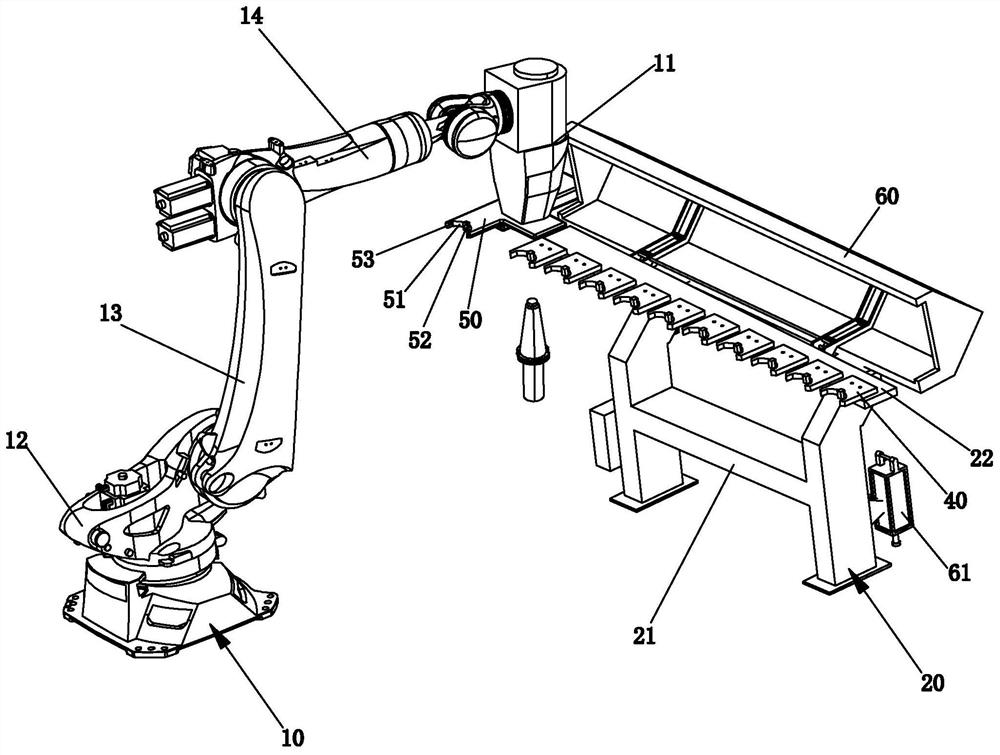

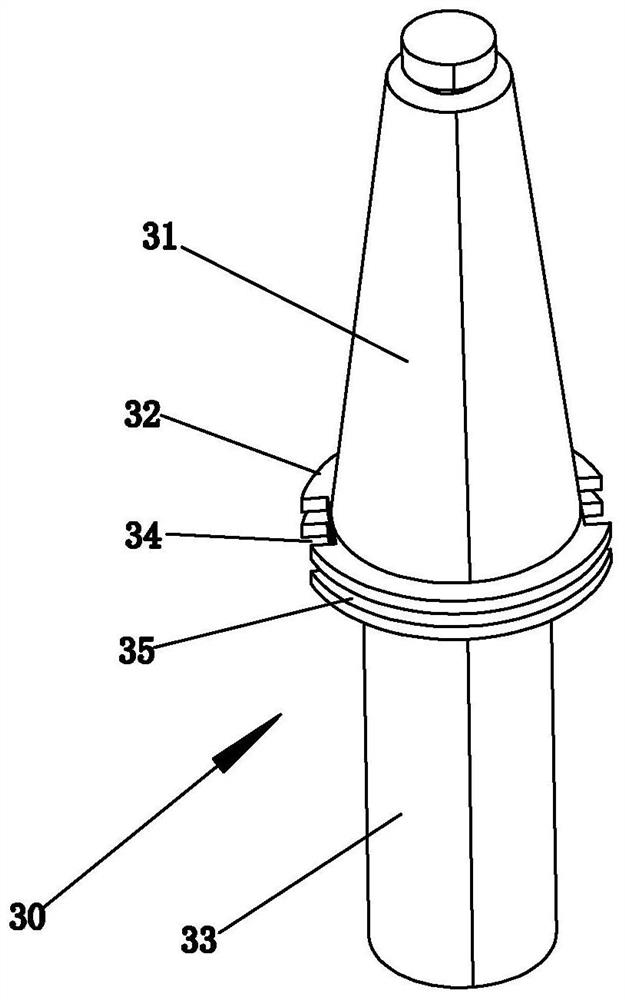

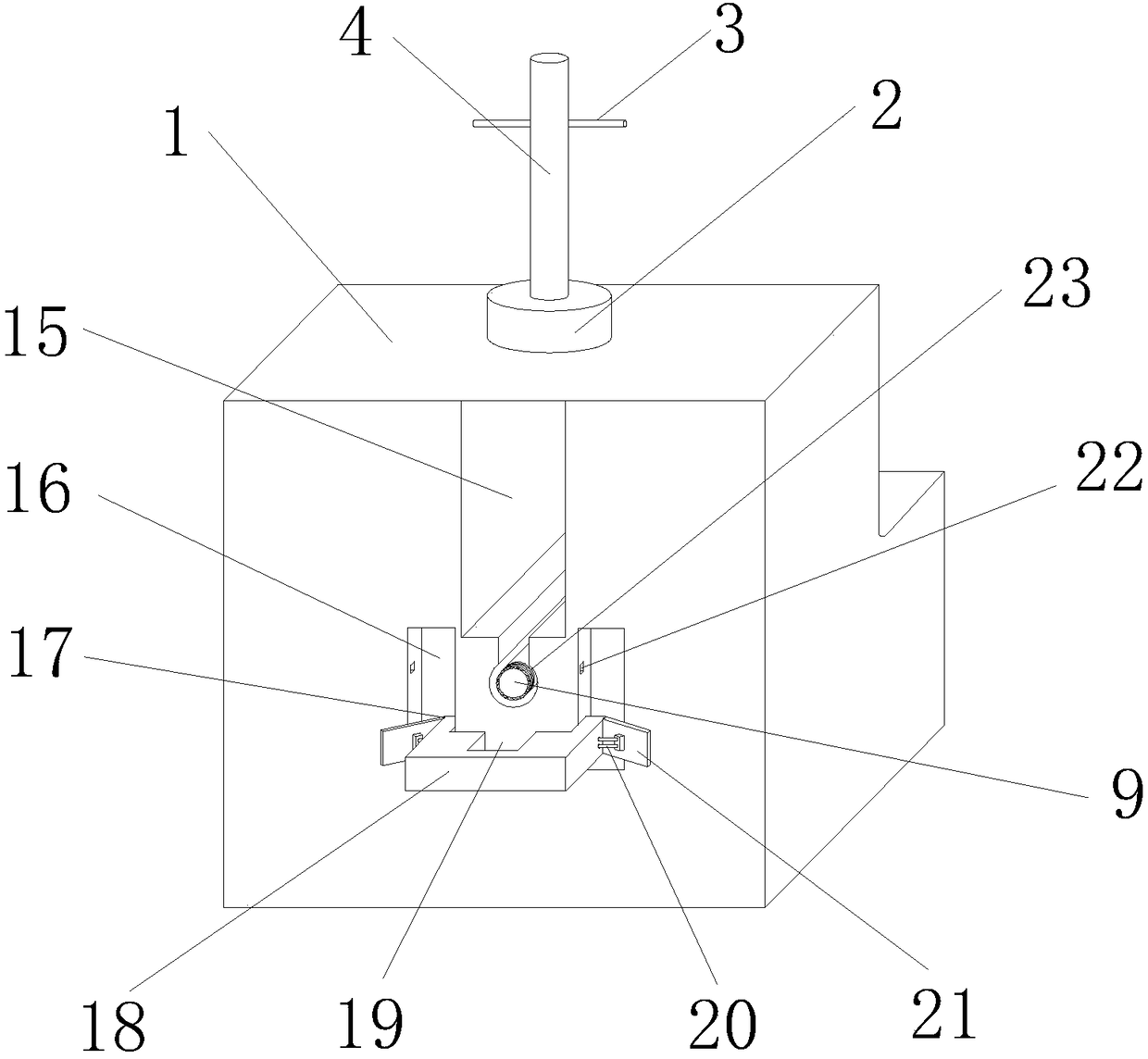

Automatic tool changing device of engraving machine and tool changing method of automatic tool changing device

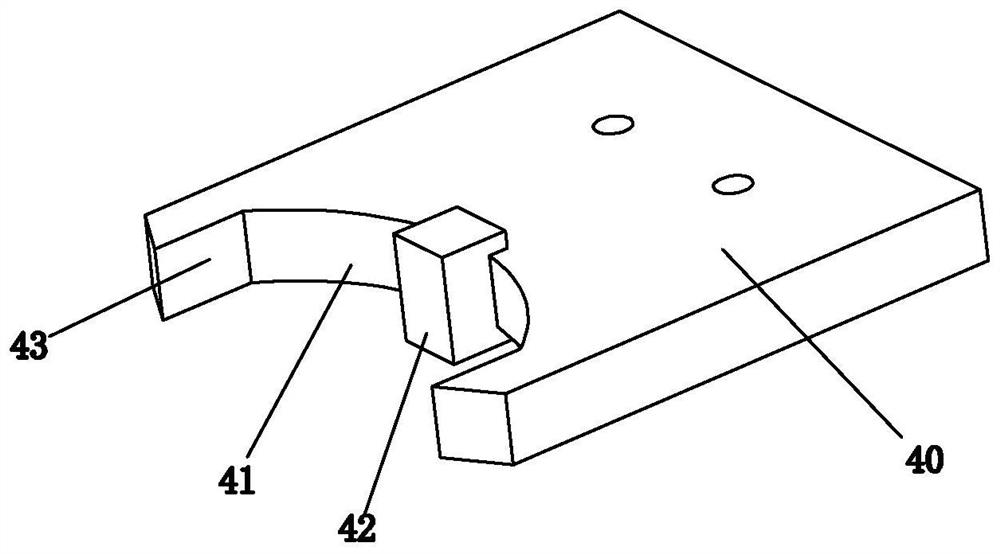

PendingCN113442632AEliminate manual controlImprove automated processing efficiencyWorking accessoriesModel makingMachineMachining

The invention discloses an automatic tool changing device of an engraving machine and a tool changing method of the automatic tool changing device. The automatic tool changing device comprises a six-axis mechanical arm and a tool magazine, wherein the six-axis mechanical arm is provided with a main shaft, and the tool magazine comprises a support, a plurality of tool stations capable of storing tools and at least one tool disassembling station capable of disassembling the tools on the main shaft; the tool stations and the tool disassembling station are all arranged on the support, and if no tool is arranged on the main shaft, the six-axis mechanical arm drives the main shaft to move to the corresponding tool station for tool installation; and if the tool is arranged on the main shaft, the six-axis mechanical arm drives the main shaft to move to the tool disassembling station for tool disassembling operation and then move to the corresponding tool station for tool installation. The automatic tool changing device has the advantages that through the combination of the six-axis mechanical arm and the tool magazine, automatic tool changing operation can be carried out, the tedious manual control link is omitted, and the automatic machining efficiency is improved.

Owner:HUAQIAO UNIVERSITY

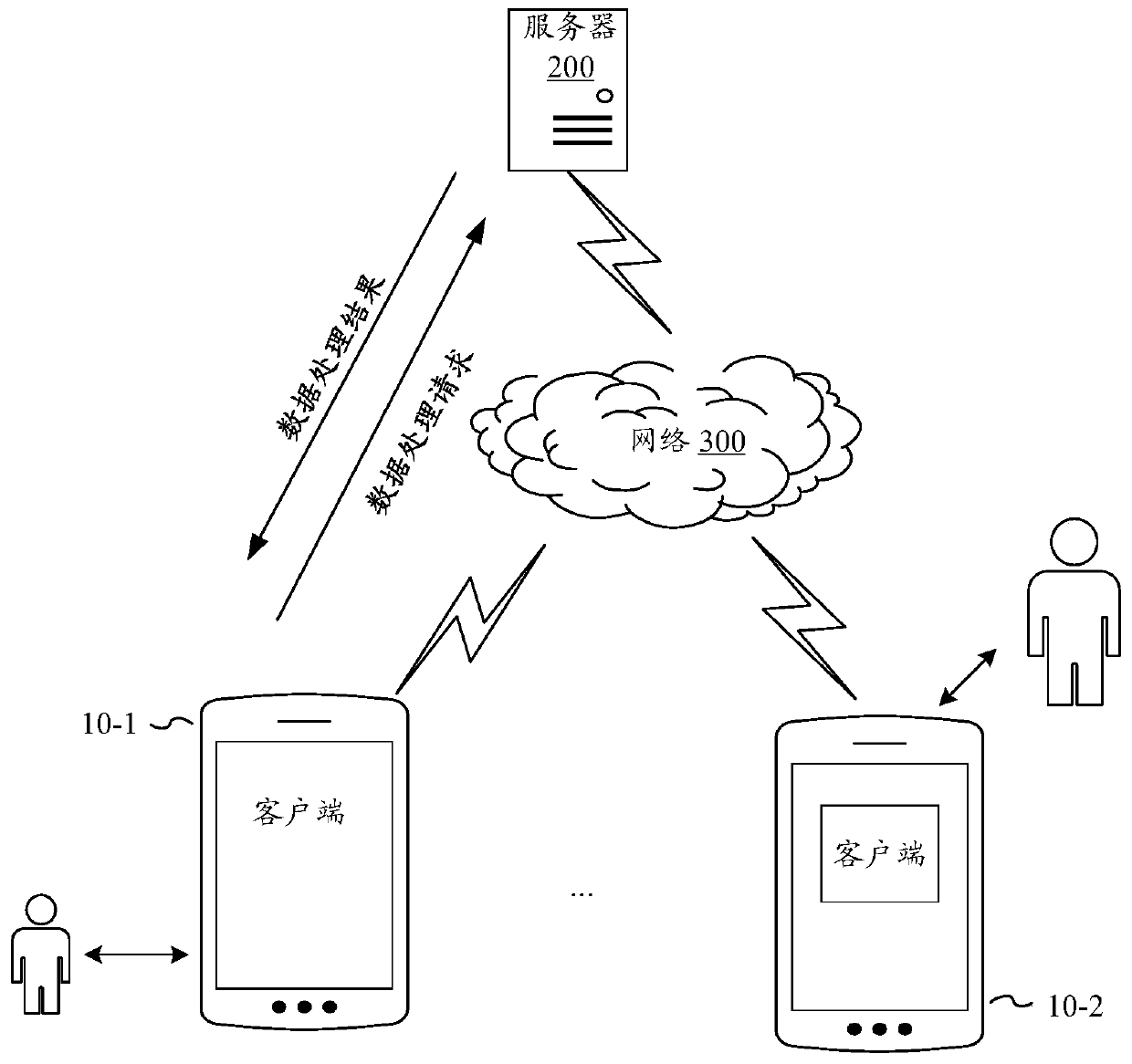

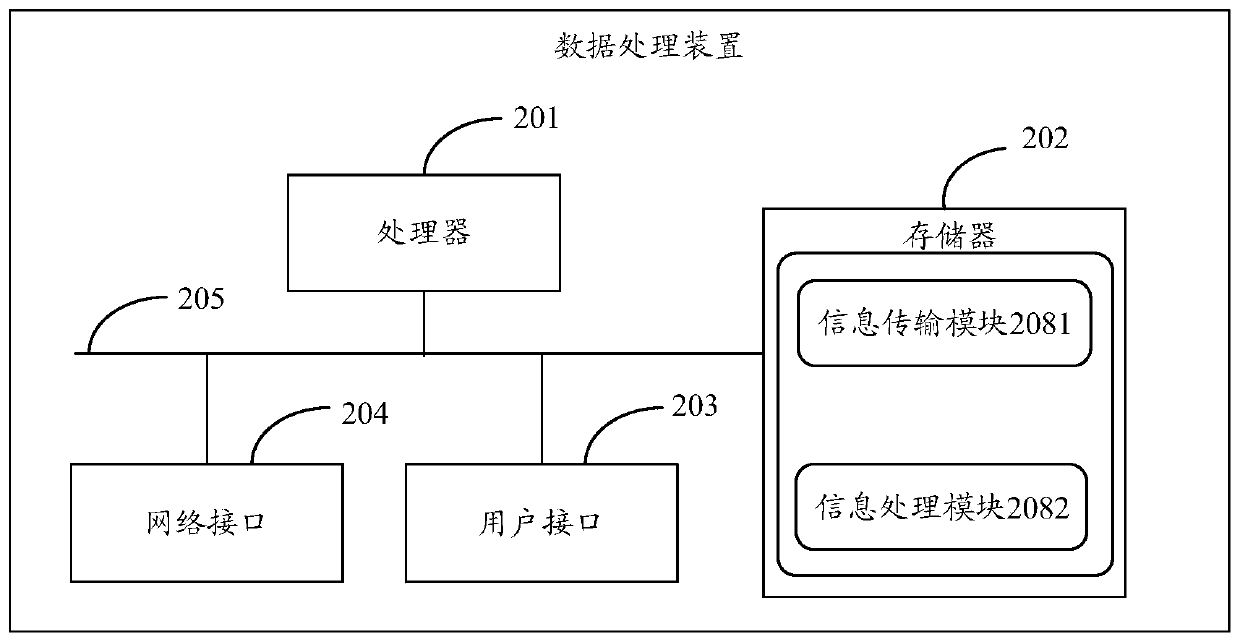

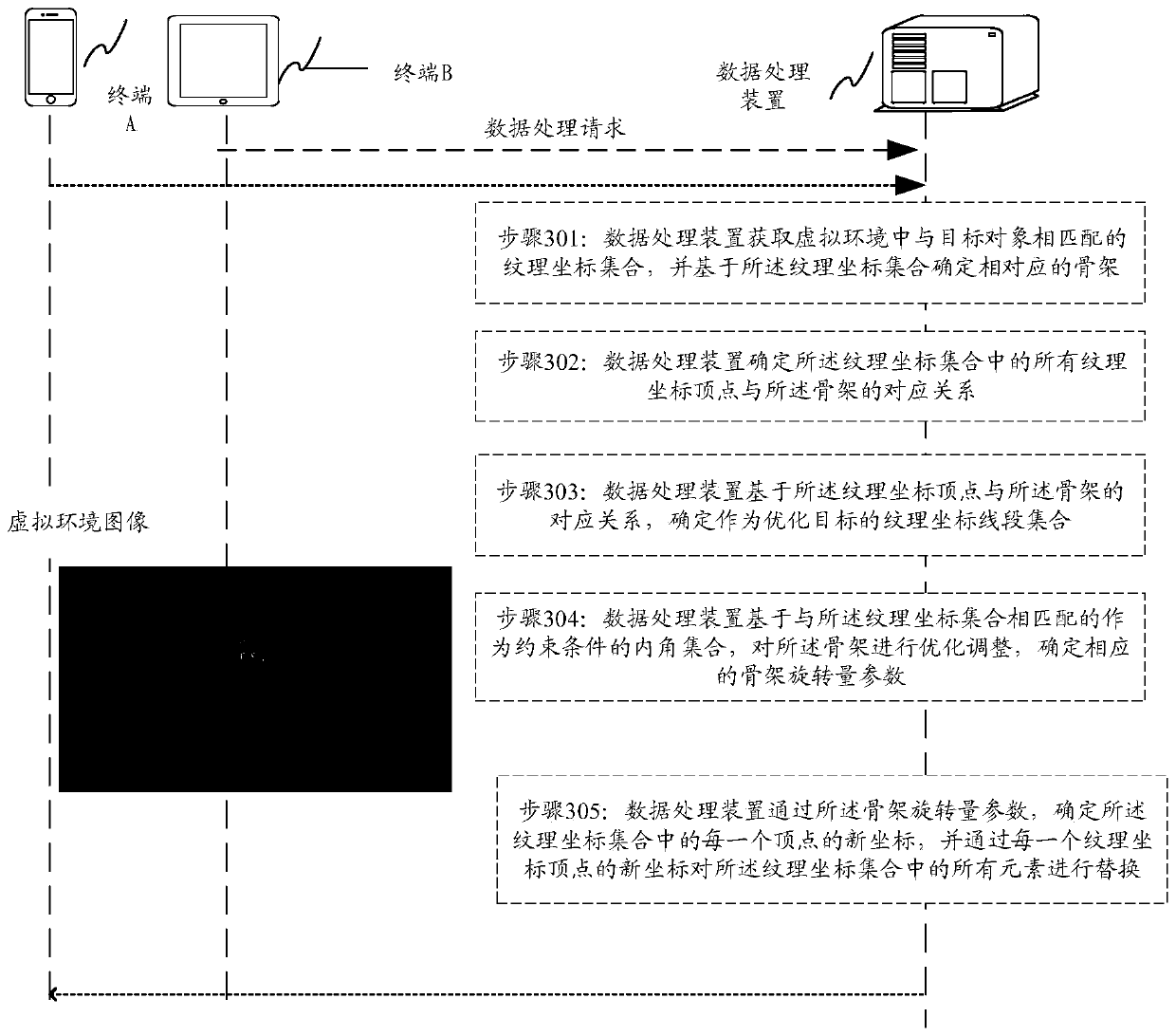

Data processing method and device, electronic equipment and storage medium

ActiveCN111462343AAchieve regulationImprove automated processing efficiencyImage data processingPattern recognitionImaging processing

The invention provides a data processing method. The data processing method comprises the steps of determining a corresponding skeleton based on a texture coordinate set; determining a corresponding relationship between all texture coordinate vertexes in the texture coordinate set and a skeleton; determining a texture coordinate line segment set to be optimized; based on an interior angle set matched with a texture coordinate set, optimizing and adjusting the skeleton, determining a new coordinate of each vertex in the texture coordinate set, and replacing all elements in the texture coordinate set through the new coordinate of each texture coordinate vertex. The invention further provides a data processing device, electronic equipment and a storage medium. According to the invention, thetarget object in the virtual environment can be automatically adjusted, the efficiency of automatically processing the image data of the virtual environment by a machine is improved, and the waiting time of image processing is also reduced.

Owner:TENCENT TECH (SHENZHEN) CO LTD

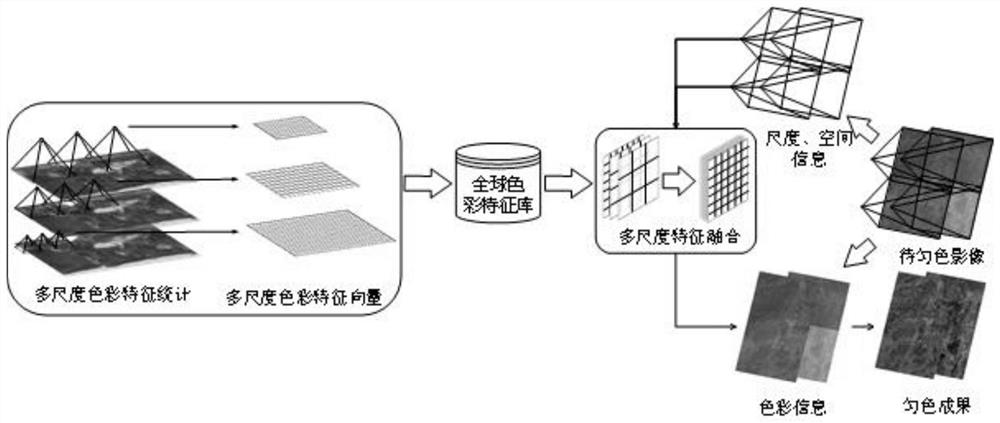

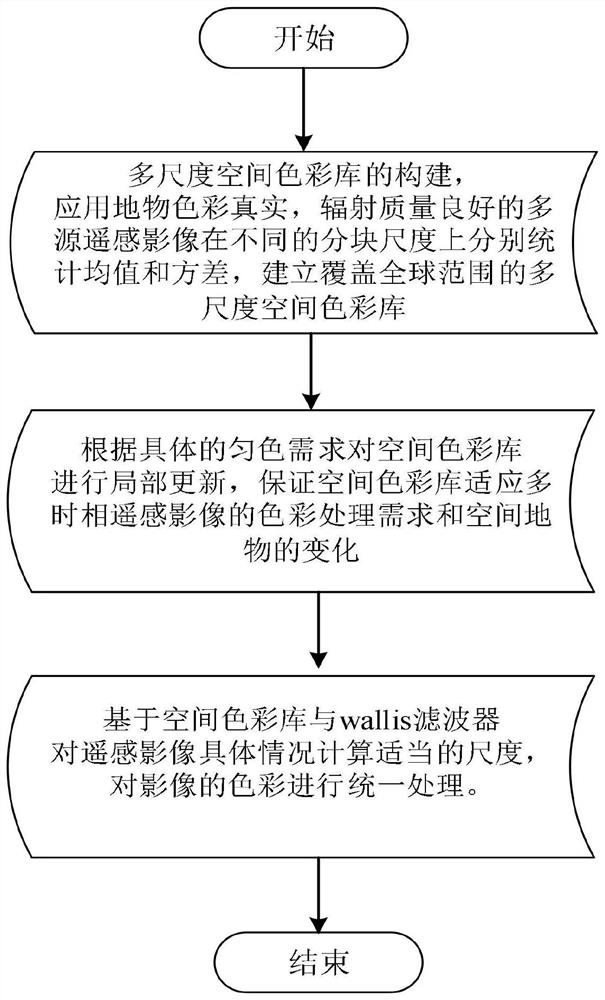

Remote sensing image automatic color uniformizing method based on global color feature library

PendingCN111754590AAvoid workloadSatisfy the needs of color uniformityImage enhancementImage analysisImage resolutionSingle image

The invention discloses a remote sensing image automatic color uniformizing method based on a global color feature library. The method comprises the following steps: S1, constructing a multi-scale space color library: respectively counting mean values and variances of multi-source remote sensing images with real ground object colors and good radiation quality on different block scales, and establishing a multi-scale space color feature library covering a global range in combination with ground object textures and spectral features; and S2, locally updating the space color library according tospecific color uniformizing requirements; and S3, carrying out automatic color uniformizing processing on the remote sensing image based on a space color library and a wallis filter. The invention hasthe beneficial effects that the invention provides an automatic color uniformizing technology based on a multi-scale space color library, the workload of manufacturing a color uniformizing template in large-scale remote sensing image production is effectively avoided, and the color uniformizing requirements of the interior of a single image, the multiple images and large-range mosaic images are met at the same time; multi-scale statistical information is beneficial to meeting color consistency processing of images with different data sources and different resolutions.

Owner:BEIJING GEOWAY SOFTWARE

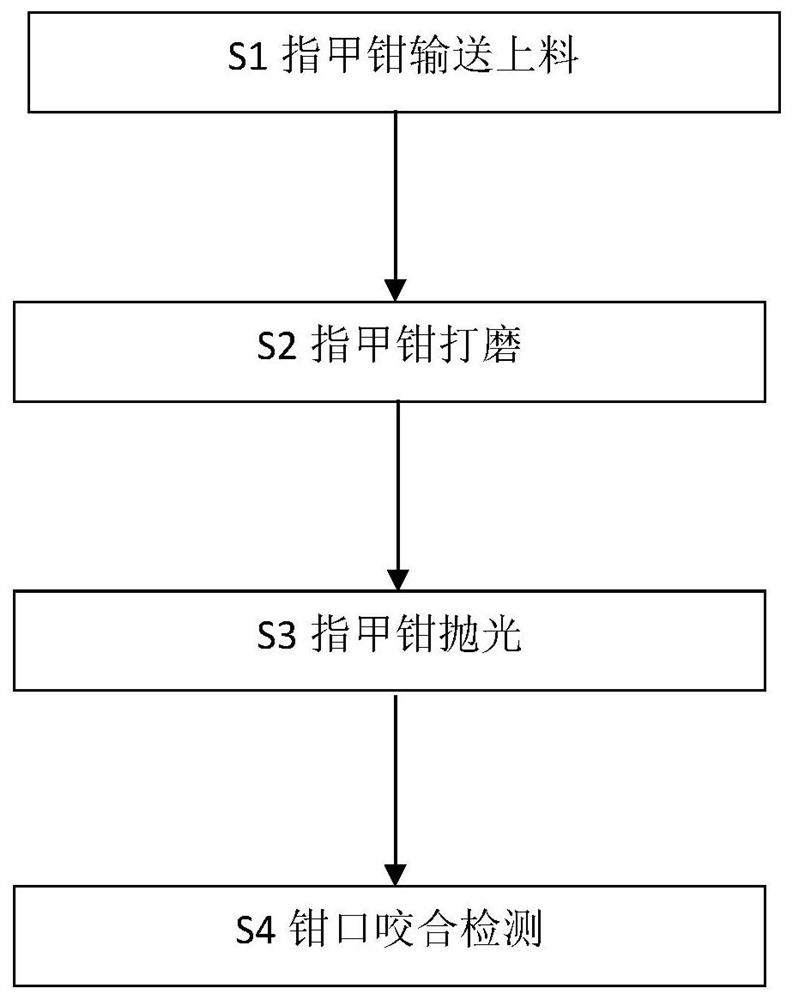

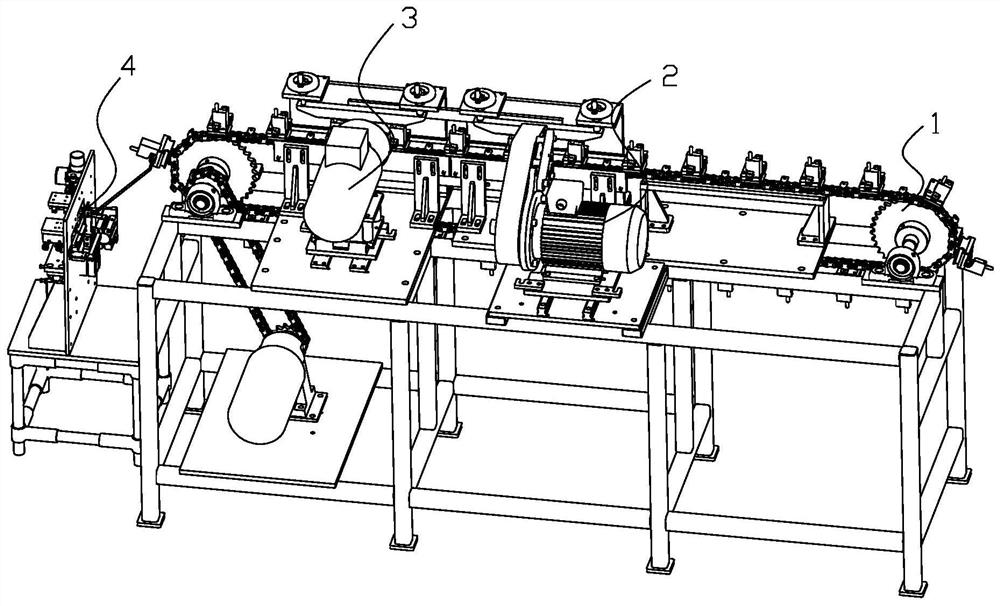

Automatic production method for nail clippers

ActiveCN113231894AEasy to adjustImprove stabilityMachine part testingGrinding carriagesIndustrial engineeringAutomatic processing

The invention belongs to the technical field of automatic production of nail clippers, and discloses an automatic production method of nail clippers. Equipment adopted by the method comprises a rack, a conveying device, a jaw grinding device, a jaw polishing device and a jaw gripping detection device, wherein the conveying device, the jaw grinding device, the jaw polishing device and the jaw gripping detection device are arranged on the rack; the conveying device is transversely and circularly arranged on the rack, and the conveying device is used for conveying the nail clippers; the jaw grinding device is located on the front side of the conveying device, and the jaw grinding device is used for grinding upper clippers and lower clippers of the nail clippers; the jaw polishing device is located on the front side of the conveying device and located on the discharging end side of the jaw grinding device, and the jaw polishing device is used for polishing the upper clippers and the lower clippers of the nail clippers; and the jaw gripping detection device is located on the discharging end side of the conveying device, and the jaw gripping detection device is used for carrying out gripping detection on the upper clippers and the lower clippers of the ground and polished nail clippers. In conclusion, the automatic production method has the advantages that the automatic processing efficiency and the automatic processing precision of the nail clippers are further improved.

Owner:萧县步强新型建材科技有限公司

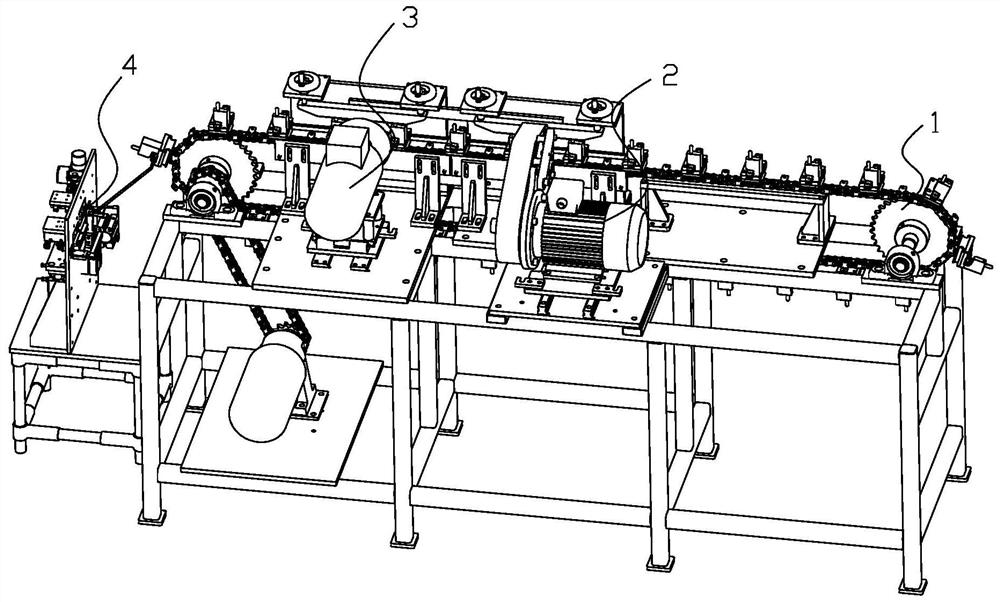

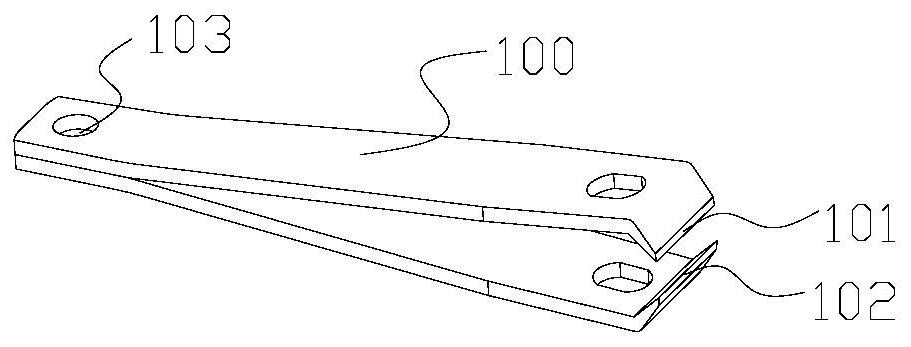

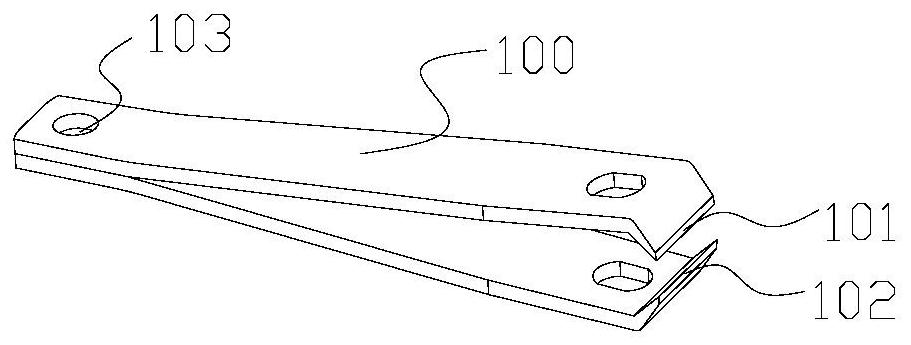

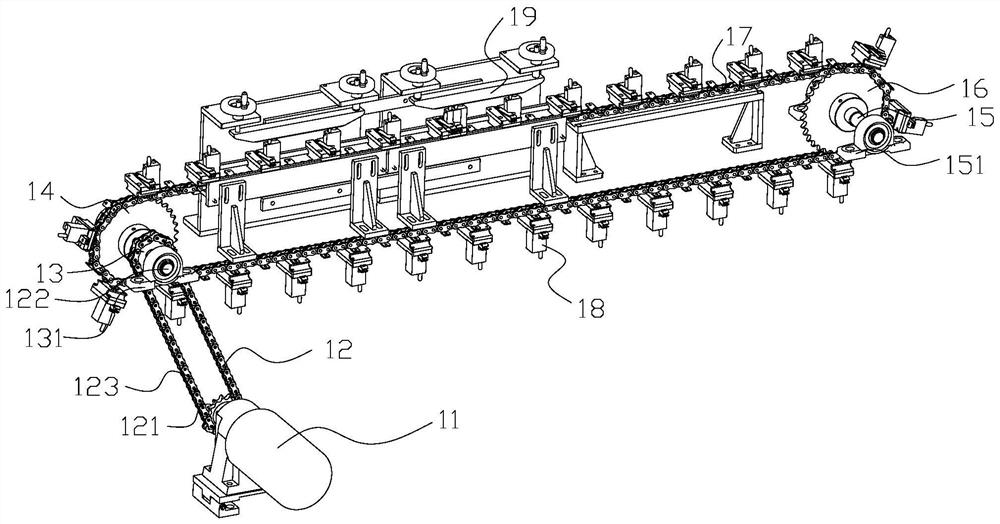

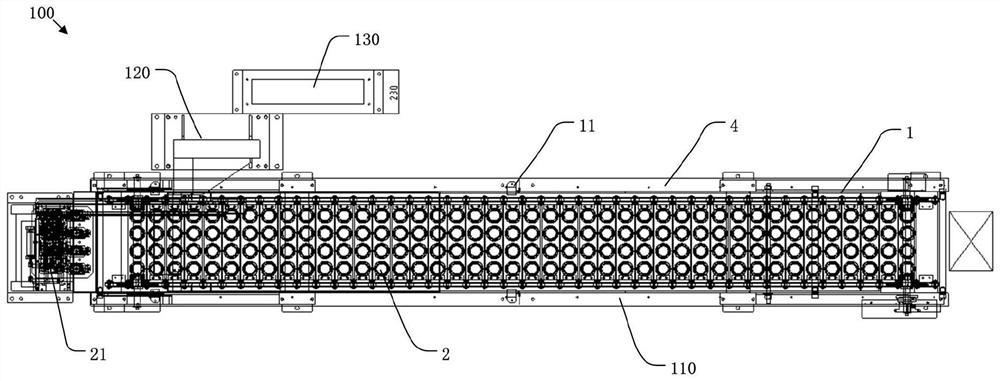

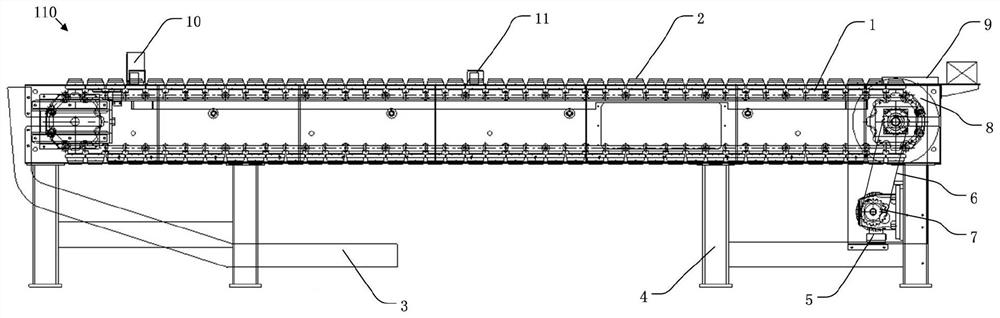

Nail clipper conveying device and method and automatic production device

ActiveCN113086521AImprove connection strength and stabilityImprove automated processing efficiencyMachine part testingConveyorsNail clipperElectric machinery

The invention belongs to the technical field of automatic production of nail clippers, and discloses a nail clipper conveying device and method. The device comprises a conveying motor, a conveying transmission set, a conveying driving rotating shaft, a conveying driving gear, a conveying driven rotating shaft, a conveying driven gear, a conveying chain, a plurality of conveying carriers and two jaw pressing assemblies; the conveying driving rotating shaft is arranged at the discharging end of a rack, and the lower end of the conveying transmission set is matched with the conveying motor; the upper end of the conveying transmission set is matched with the conveying driving rotating shaft; the conveying driving gear is arranged on the conveying driving rotating shaft in a sleeving manner; the conveying driven rotating shaft is arranged at the feeding end of the rack, and the conveying driven gear is arranged on the conveying driven rotating shaft in a sleeving manner; the conveying chain is connected to the conveying driving gear and the conveying driven gear in a tensioning manner; the multiple conveying carriers are regularly arranged on the conveying chain, and the two jaw pressing assemblies are transversely arranged on the rear side of the conveying chain in an aligned manner. The nail clipper conveying device and method and an automatic production device have the beneficial effects that the nail clipper conveying efficiency is further improved, and the nail clippers are prevented from falling off in the conveying process.

Owner:萧县步强新型建材科技有限公司

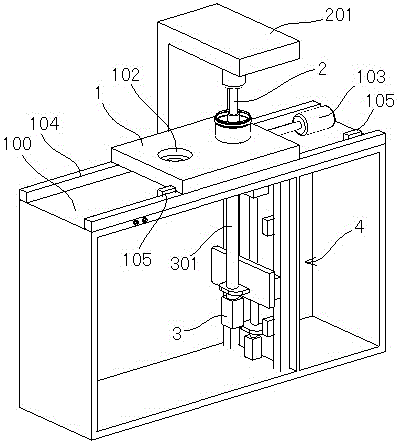

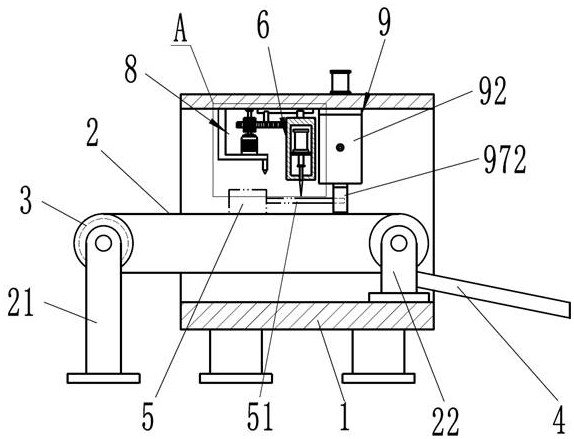

Sheet material thickness measurement device

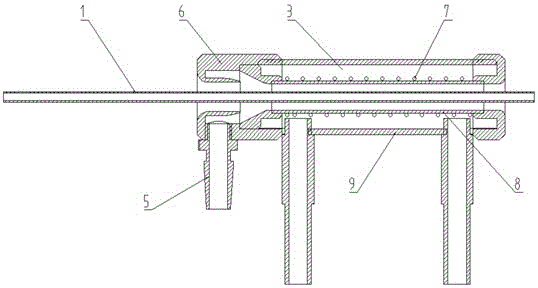

InactiveCN107504937AImprove automated processing efficiencyImprove securityMeasurement devicesMeasurement deviceAutomatic processing

The invention relates to a plate thickness measuring device, which includes a guiding cylinder, a sensor and a material retrieving device. The material retrieving device is arranged on a support. One end of the support is provided with a clamping measuring support, and the other end is provided with a guiding cylinder through an air steel support. The top end of the piston rod of the guide cylinder is provided with a connecting positioning bracket, and the connecting positioning bracket is connected to the rotary clamping cylinder through a sensor, and a displacement sensing bracket is arranged under the sensor. The material retrieving device comprises several suction cup rods and suction cups arranged at the bottom of the suction cup rods, and the several suction cup rods are arranged on the support in an S shape. The clamping measurement bracket is movable at one end of the bracket. It provides technical support for the layering of the board, ensures that the subsequent processing of the board is single-layer processing, improves the safety and reliability of the system processing, and improves the efficiency of the automatic processing of the board.

Owner:扬州安特自动化科技有限公司

Automatic gate milling machine

ActiveCN103801742BClamp firmlySimple structureFeeding apparatusMilling equipment detailsMilling cutterEngineering

The invention discloses an automatic gate milling machine, comprising a compressing cylinder, a spindle motor and a feeding mechanism, wherein the compressing cylinder is arranged above a work-piece locating plate; the spindle motor is arranged below the work-piece locating plate; the feeding mechanism drives the spindle motor to feed; an avoiding hole is formed in the work-piece locating plate; a spindle and a milling cutter are orderly connected to the spindle motor; the avoiding hole overlaps with the axis of the spindle; the axis of the spindle, the axis of the compressing cylinder and the feeding mechanism are parallel in direction. The work-piece locating plate is arranged on the automatic gate milling machine, a locating groove is formed inside the locating plate, and the device is clamped by adopting the compressing cylinder, so that the automatic gate milling machine is reliable to clamp and high in automatic processing efficiency, and the labor intensity of a worker is reduced.

Owner:泰成半导体精密(苏州)有限公司

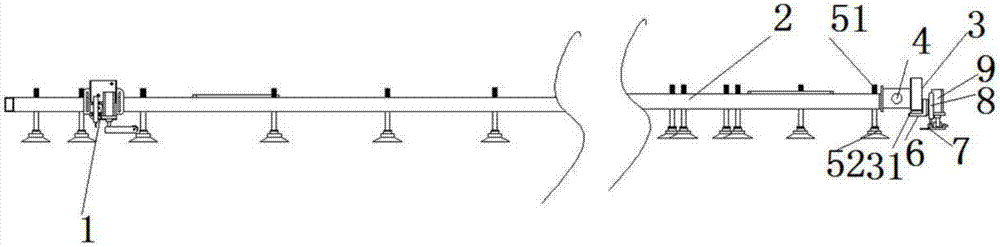

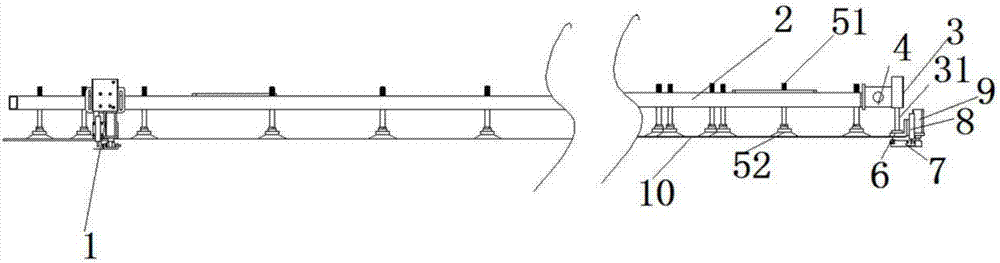

Transmission device at production front end of transformer

ActiveCN114162566AAutomatically adjust the positionImprove automated processing efficiencyConveyorsConveyor partsTransformerEngineering

The invention relates to a transmission device at the front end of transformer production, which comprises a transmission assembly on which a carrier is circularly transmitted; the workpiece conveying line body is used for conveying the transformer element to the carrier of the conveying assembly; the blanking line body is used for transferring the transformer element on the carrier; wherein the transformer element comprises two corresponding side surfaces, namely a surface to be processed and a boss surface, the transformer element is transferred between the conveying assembly and the workpiece conveying line body through a feeding assembly, and a turnover mechanism is arranged between the discharging line body and the conveying assembly; the overturning mechanism comprises a grabbing component for rotating the transformer element on the carrier and an overturning driving part for driving the grabbing component to rotate; and after the grabbing component grabs the transformer element on the carrier, the transformer element is overturned to the discharging line body from the conveying assembly under the driving of the overturning driving part, and the to-be-machined face of the transformer element is overturned to the downward direction from the upward direction.

Owner:JIANGSU ELECTRIC POWER CO +3

Foxing strip slicing device and packaging box processing equipment

PendingCN112549634AImprove accuracyImprove efficiencyPaper-makingBox making operationsStructural engineeringPackaging Case

The invention is suitable for the technical field of packaging equipment, and discloses a foxing strip slicing device and packaging box processing equipment. The foxing strip slicing device comprisesa supporting platform, a feeding assembly, a moving assembly, a cutting plate and suction cups. A concave face matched with foxing strips is arranged on the lower portion of the cutting plate, a gap is formed between the concave face and the supporting platform and used for allowing the cut foxing strips to penetrate through, a plurality of mounting holes are evenly formed in the concave face, andthe suction cups are movably arranged in the mounting holes and can extend out of the mounting holes to be used for adsorbing the foxing strips. By the adoption of the suction cups capable of stretching out and drawing back in the mounting holes, the obliquely-standing foxing strips can be attracted easily, each foxing strip is attracted to the concave face of the cutting plate in a straight lineshape, the foxing strip separation accuracy is improved, the foxing strips are separated through the foxing strip slicing device by means of the packaging box processing equipment, and the automaticprocessing efficiency of packaging boxes can be greatly improved.

Owner:东莞市韦安自动化科技有限公司

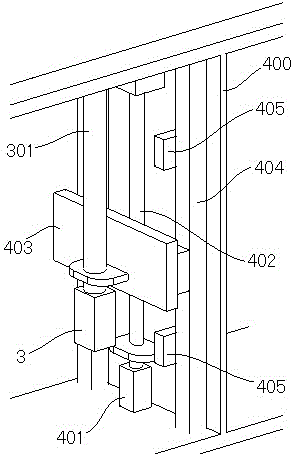

Quantitative plate feeding system

InactiveCN107570619AImprove automated processing efficiencyMeet single-layer processing requirementsMetal-working feeding devicesMetal working apparatusPiston rodAutomation

The invention relates to a quantitative plate feeding system which comprises a quantitative plate dosing device and a plate feeding device. The quantitative plate dosing device comprises a guide air cylinder, a sensor and a first taking device. The first taking device is arranged on a support, one end of the support is movably provided with a clamping measuring support, and the guide air cylinderis arranged at the other end of the support through an air cylinder support; a connecting and positioning support is arranged at the top end of a piston rod of the guide air cylinder and connected with a rotary clamping air cylinder through the sensor; and a displacement induction support is arranged under the sensor. The plate feeding device comprises a second taking device and a fork teeth tooling. The fork teeth tooling comprises fork teeth and fork teeth supports; the fork teeth supports are movably arranged on supporting frames through a fork teeth drive device and are arranged in parallel in a staggered mode left and right; lifting air cylinders are arranged on the supporting frames; the second taking device is arranged under piston rods of the lifting air cylinders; and plate baffles are arranged under the supporting frames. According to the quantitative plate feeding system provided by the invention, both the requirement for full automation and the requirement for single-layermachining are met.

Owner:扬州安特自动化科技有限公司

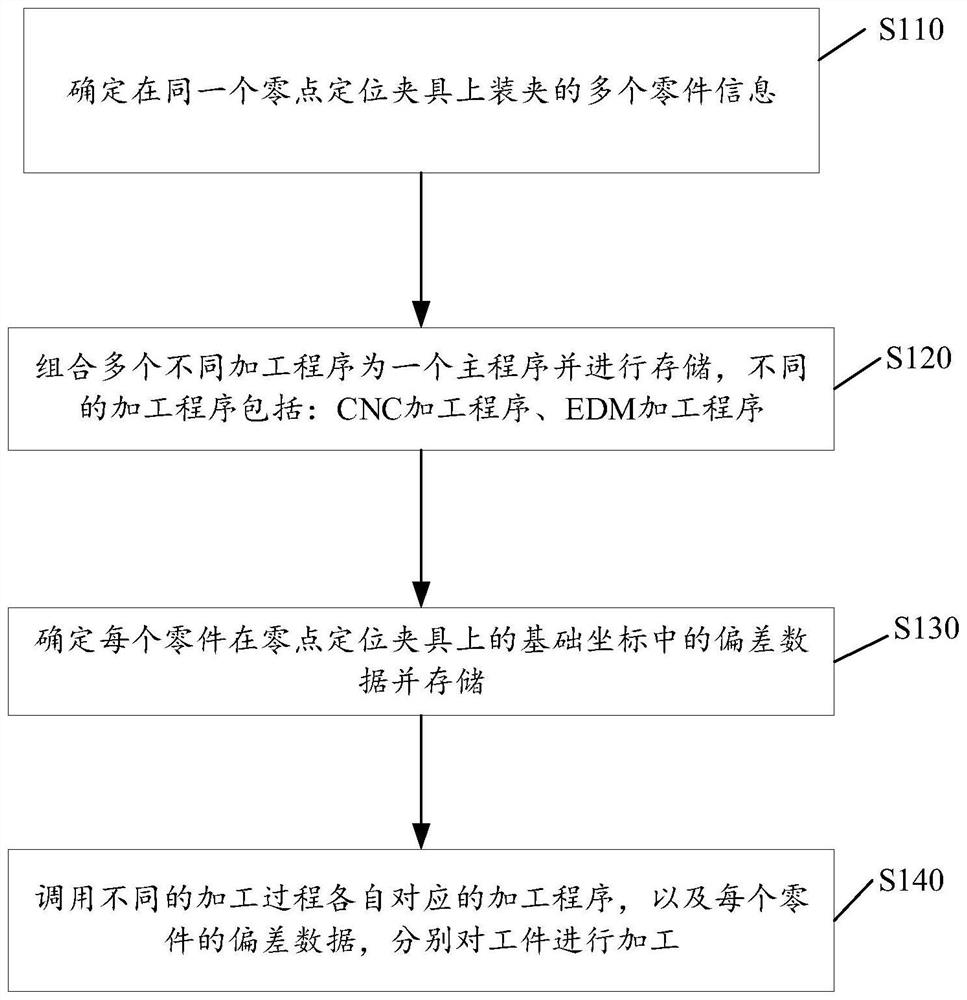

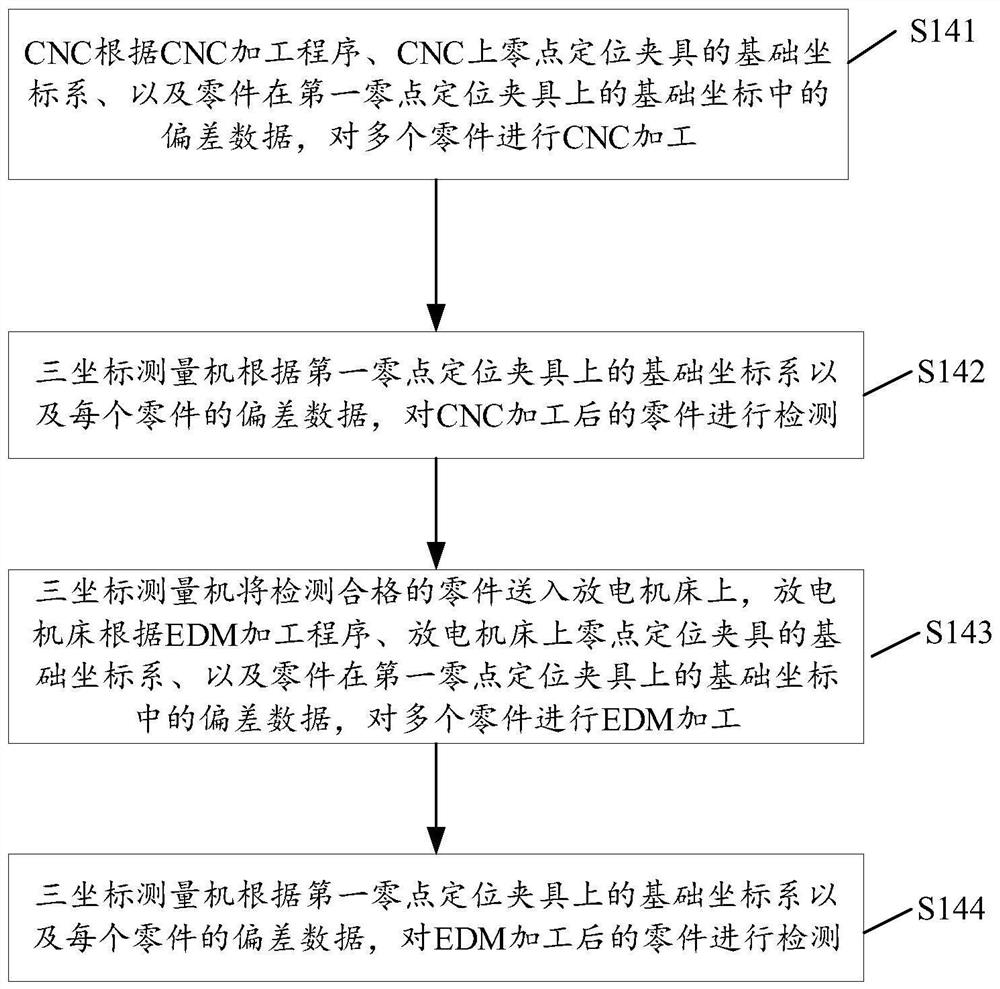

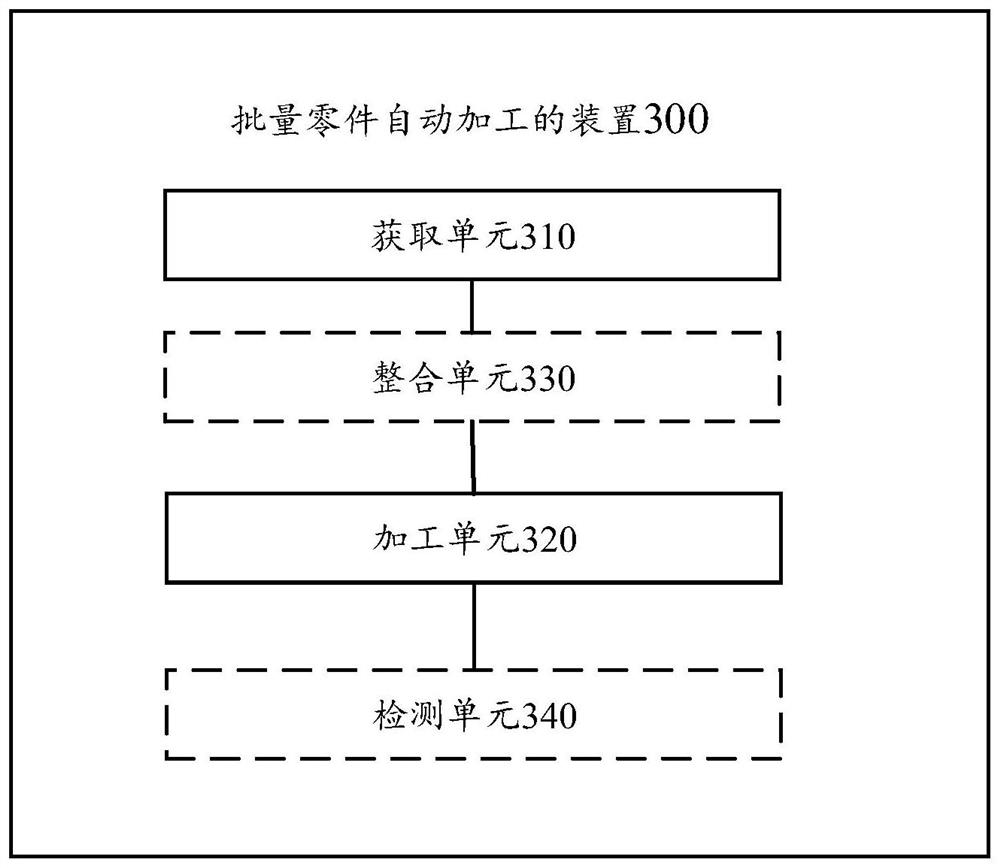

Method and device for automatically machining parts in batches

PendingCN114425643AImprove automated processing efficiencyReduce the frequency of computer useElectrical-based auxillary apparatusProcess engineeringMachine tool

The invention provides a method and a device for automatically processing batch parts, which are characterized in that a plurality of same parts are clamped on a zero-point positioning clamp, deviation data of each part on the zero-point positioning clamp are corrected and determined through a three-coordinate measuring machine, and the deviation data are stored in a system; and the CNC machining program and the EDM machining program are integrated and then stored in the system. When the parts enter the CNC equipment for machining and enter the discharge machine tool for EDM machining, the corresponding machining equipment obtains the deviation data, the position of each part on the zero point positioning clamp is determined according to the deviation data, and a corresponding machining program is called for machining. Repeated manual part clamping can be reduced, the human input is reduced, the part on-machine frequency is reduced, the input cost of a zero-point positioning clamp is reduced, and the automatic machining efficiency of batch parts is improved.

Owner:深圳模德宝科技有限公司

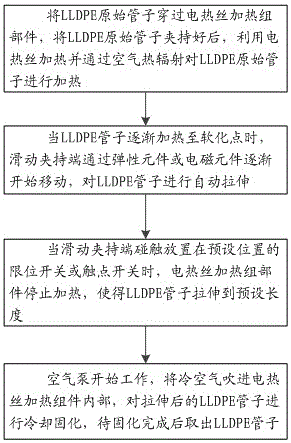

A method for automatic hot drawing and reprocessing of lldpe pipes

InactiveCN104943153BComply with batch automation production requirementsEnsure consistencyCold airElectricity

The invention discloses an automatic hot stretching reprocessing method of a LLDPE pipe. The method comprises the following steps: a LLDPE original pipe penetrates through an electric heating wire heating part; after the LLDPE original pipe is clamped, the LLDPE original pipe is heated through the heating of an electric heating wire and the air heat radiation; when the LLDPE pipe is gradually heated to a softening point, a slide clamping end gradually moves through an elastic element or an electromagnetic element to automatically stretch the LLDPE pipe; when the slide clamping end touches a limiting switch or a touch switch placed in a preset position, the electric heating wire heating part stops heating, so that the LLDPE pipe is stretched to a preset length; an air pump begins to work to blow cold air into the electric heating wire heating part for cooling and curing the stretched LLDPE pipe; after the curing is finished, the LLDPE pipe is taken out; and the method realizes automatic processing, is higher in effect, is convenient to control the product quality, and facilitates the technical effect of batch production.

Owner:CHENGDU TME SOFTWARE

Automatic processing equipment for small-diameter copper tubes with inner and outer cones and thin-walled circles

ActiveCN104440112BQuality improvementSimple structureOther manufacturing equipments/toolsEngineeringDrive motor

The invention discloses automatic processing equipment for a small-diameter copper pipe with inner and outer cones and a thin-wall cylinder. The automatic processing equipment comprises matched equipment, a pipe inner cone spinning executing mechanism, an integral cone spinning die for spinning a pipe outer cone, a die washing swivel head and a pipe loading and unloading device, wherein the matched equipment comprise a spindle box, a transverse guide rail, a longitudinal guide rail, a sliding carriage and a servo motor; the pipe inner cone spinning executing mechanism comprises a tapered spindle assembly and a driving motor thereof, and the tapered spindle assembly is arranged on a fixed slider in an oblique slider assembly; the integral cone spinning die for spinning the pipe outer cone is arranged on a water-cooling base; the die washing swivel head is connected with a stepper motor shaft; the pipe loading and unloading device comprises a loading mechanism and an unloading mechanism; an inner cone washing swivel head of the integral cone spinning die, an oil nozzle and a pipe collecting box are mounted on the spindle box body of the equipment. The automatic processing equipment is reasonable and simple in structure and convenient to operate, spins the inner and outer cones at high quality, improves the wall thickness evenness by the methods of drilling, precise boring and non-spindle thin-wall cylinder finish turning, is high in automatic processing efficiency and is low in cost.

Owner:CHINA NUCLEAR TIANJIN TECH DEV

Print head state detection method, print head detection system and 3D printer

ActiveCN111421957BImprove automated processing efficiencyEasy to compareMaterial analysis by optical meansStructural/machines measurementComputer printingProcess engineering

The invention relates to a printing head state detection method, a printing head detection system and a 3D printer. The 3D printer includes the print head detection system, and the print head state detection method includes the following steps: the print head prints test paper according to preset specifications; obtains a print image of the print test paper; performs noise reduction processing on the print image Select a number of detection areas for the print image after noise reduction processing; count the total number of print lines in each detection area; compare the total number of print lines in each detection area with the total number of preset qualified lines; judge whether the print head needs to be repaired or not according to the above comparison results replace. The print head state detection method, the print head detection system and the 3D printer can realize automatic detection, thereby helping to improve the print head state detection efficiency.

Owner:NINGXIA KOCEL MOLD

A non-point source pollution treatment device for livestock and poultry breeding waste

InactiveCN111296302BEfficient recyclingImprove the living environmentClimate change adaptationWaste water treatment from animal husbandryLiquid wasteSewage

The invention provides a non-point source pollution treatment device for livestock and poultry breeding waste, which belongs to the technical field of breeding sewage and is used to solve the technical problems that existing devices cannot effectively recycle waste, have low processing efficiency, and low resource utilization. Including breeding room and biogas digester, the breeding room is equipped with a dung leakage board, the bottom of the breeding room is equipped with a pit body, and a belt bracket, a separation block and a guide rod are fixed in the pit body, belts are set at both ends of the belt bracket, and the guide rod is slidingly set There is a scraper, the bottom of the breeding room is fixed with a cylinder, the end of the cylinder is fixed with a hinged joint, the joint is hinged with a connecting rod, the end of the connecting rod is hinged on the scraper, the end of the belt bracket is fixed with a feeding channel, and the separation block Sewage treatment mechanism is installed at the end of the sewage treatment system; the solid waste and liquid waste are treated separately in the present invention, the automatic treatment efficiency is high, it can prevent the waste from being difficult to clean up after accumulation, reduce peculiar smell, improve the living environment of people and poultry, and can effectively recycle Use waste to improve resource utilization.

Owner:INST OF SOIL FERTILIZER & WATER SAVING AGRI GANSU ACAD OF AGRI SCI

Automatic metal wire cutting structure for carbon brush forming machine

InactiveCN114865420AImprove processing qualityNo human interventionBrushes manufactureMolding machineWire cutting

The invention discloses an automatic metal wire cutting structure for a carbon brush forming machine, and the structure comprises a rack, the top of which is provided with a sliding rail; the conveying mechanism is mounted on the rack and used for conveying a carbon brush body to be cut; the adjusting mechanism is mounted at the top of the rack; the cutting mechanism is connected to the right end of the adjusting mechanism and is in sliding fit with the sliding rail; according to the metal wire cutting device, the length of a metal wire can be accurately cut, the machining efficiency is high, and therefore the overall benefit is better.

Owner:ZHEJIANG IND & TRADE VACATIONAL COLLEGE

Sheet material quantitative pushing device

InactiveCN107598004AImprove automated processing efficiencyReduce labor intensityMetal-working feeding devicesMetal working apparatusEngineeringSmall range

The invention relates to a sheet material quantitative pushing device. The sheet material quantitative pushing device comprises a material taking device, a quantitative device and a pushing device. The quantitative device comprises a guide air cylinder and a sensor. The material taking device is arranged on a movable tooling frame, one end of the movable tooling frame is provided with a clamping measuring support, and the other end is provided with the guide air cylinder through an air cylinder support. The top end of a piston rod of the guide air cylinder is provided with a connecting positioning support, the connecting positioning support is connected with a rotary clamping cylinder through the sensor, and a displacement induction support is arranged under the sensor. The pushing devicecomprises a driving air cylinder and the movable tooling frame, the driving air cylinder is arranged on the movable tooling frame, a connecting seat is arranged on a connecting bottom frame, and the connecting bottom frame is arranged on the movable tooling frame through a linear guide rail. The size of a sheet material changes in a small range, the development of a sheet material machining automation technology is promoted through driving of the movable tooling frame by the driving air cylinder, the safety and the reliability of system machining are improved, and the efficiency of sheet material automation machining is improved.

Owner:扬州安特自动化科技有限公司

Non-point source pollution treatment device for livestock and poultry breeding waste

InactiveCN111296302AEfficient recyclingImprove the living environmentClimate change adaptationGas production bioreactorsLiquid wasteAgricultural science

The invention discloses a non-point source pollution treatment device for livestock and poultry breeding waste, belongs to the technical field of breeding pollution discharge, and is used to solve thetechnical problems of the existing device with low treatment efficiency and low resource utilization rate that cannot effectively recycle and utilize the waste. The device comprises a feeding room and a biogas digester, wherein a fecal leakage board is arranged in the feeding room, a pit body is arranged below the feeding room, a belt support, separation blocks and a guide rod are fixed inside the pit body, belts are arranged at two ends of the belt support in a sleeving manner, scraper boards are arranged on the guide rod in a sliding manner, an air cylinder is fixed to the bottom of the feeding room, a hinge head is fixed to the end of the air cylinder, a connecting rod is hinged on the hinge head, the end of the connecting rod is hinged on the scraper boards, a feeding channel is fixedto the end of the belt support, and sewage treatment mechanisms are arranged at the ends of the separation blocks. According to the device, solid waste and liquid waste are treated separately, the automatic treatment efficiency is high, the waste difficult to clean after accumulation is prevented, the odor is reduced, the living environment of human, livestock and poultry is improved, the waste is effectively recycled and utilized, and the resource utilization rate is improved.

Owner:INST OF SOIL FERTILIZER & WATER SAVING AGRI GANSU ACAD OF AGRI SCI

Anti-clogging device, control method and sewage pump

ActiveCN110173433BReduce the likelihood of cloggingImprove work efficiencySpecific fluid pumpsPump componentsImpellerGear wheel

The invention provides an anti-blocking device, a control method and a sewage pump. The anti-blocking device comprises at least two water inlet pipes, a sundry discharging pipe, impellers, a motor shaft, filter screens, pressure sensors, first valves, second valves, gear clutches and a controller. The impellers are arranged at the water inlet ends of the water inlet pipes, and the water inlet endsof the water inlet pipes are connected. Each impeller is connected with one end of an impeller shaft, and the other ends of the impeller shafts are connected with a gear train at the output end of the motor shaft through the gear clutches. The filter screens are mounted at the water inlet ends of the water inlet pipes and located behind the impellers. The first valves are arranged between the filter screens and the impellers. The sundry discharging pipe is provided with a water inlet and a water outlet, the water inlet is connected with the positions, between the filter screens and the firstvalves, on the water inlet pipes, and the second valves are arranged at the joints correspondingly. By means of the anti-blocking device, the blocked water inlet pipe can be subjected to back washingthrough water of the water inlet pipe at the normal working end, danger brought by pump body demounting is avoided, the service life of the pump body is prolonged, and therefore the work efficiency ofthe pump is improved.

Owner:JIANGSU UNIV

Automatic processing method and equipment for small-diameter copper pipe with inner and outer cones and thin-walled circles

Owner:CHINA NUCLEAR TIANJIN TECH DEV

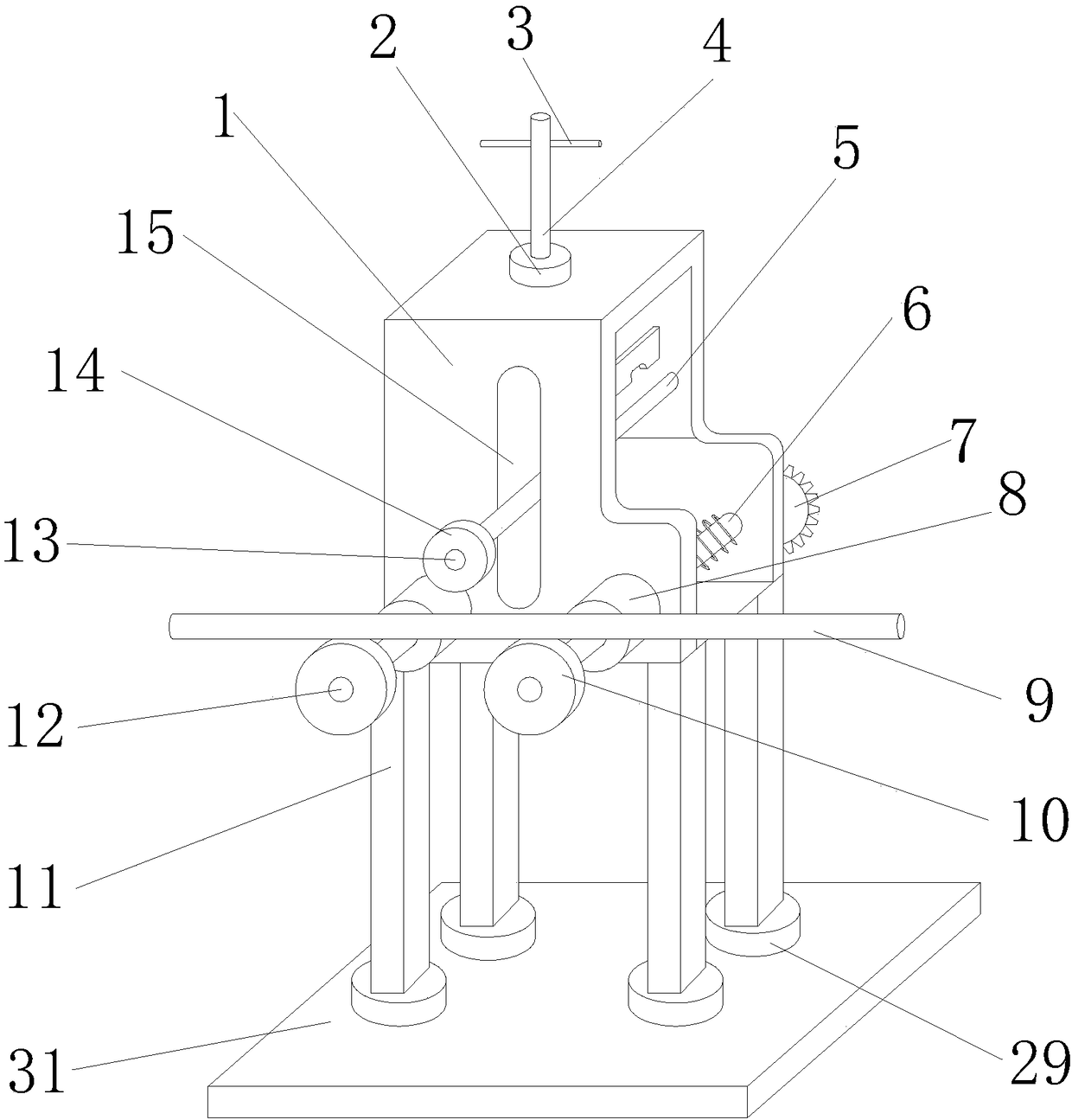

Cylinder sleeve conveying and carrying mechanism

PendingCN114377990AImprove automated processing efficiencySortingDelivery systemAutomatic processing

The invention discloses a cylinder sleeve conveying and carrying mechanism. The cylinder sleeve conveying and carrying mechanism comprises a cylinder sleeve conveying system and a two-shaft cylinder sleeve carrying and detecting system. The cylinder sleeve conveying system comprises a conveying chain, a plurality of cylinder sleeve positioning blocks are arranged on the outer side face of the conveying chain, and cylinder sleeves are fixed to the cylinder sleeve positioning blocks and driven by the conveying chain to be conveyed. The two-shaft cylinder sleeve carrying and detecting system comprises a cylinder sleeve positioning device. The cylinder sleeve positioning device comprises a mounting bracket, a vertical driving device, a gripper and a cylinder sleeve detection device; the vertical driving device is provided with a stroke reader, whether the cylinder sleeves exist or not can be judged according to the read stroke values of the stroke reader, the height of the cylinder sleeves can be judged based on the difference of the read stroke values so as to distinguish the types of the cylinder sleeves, and when the cylinder sleeves have different read stroke values in the forward and reverse placement directions, the cylinder sleeves can be driven by the stroke reader. And the forward and reverse placing directions of the cylinder sleeve can be further judged, and the automatic processing efficiency is improved.

Owner:SHANGHAI PRAXAIR AUTOMATIC EQUIP MFG CO LTD

Automatic processing equipment for sanitary water pipe

ActiveCN108067853AImprove automated processing efficiencyActive connectionMetal working apparatusArchitectural engineeringLap joint

The invention discloses automatic processing equipment for a sanitary water pipe. The automatic processing equipment for the sanitary water pipe comprises a body, wherein a connecting block is mountedat the bottom end of the body; a rotary rod is arranged at the bottom end of the connecting block; the rotary rod penetrates through the connecting block and the body; a cavity is formed in the body;a water pipe is arranged at the bottom end in the cavity; a thread is arranged at the top end of the outer wall of the water pipe; the water pipe is connected to the rotary rod in lap joint; and slots are formed in the left and right sides of the bottom end in the front surface of the body. According to the automatic processing equipment for the sanitary water pipe disclosed by the invention, a clamping plate is pressed, so that a baffle plate squeezes a compression spring in a bump, a locking rod on the clamping plate is locked into the bump to connect a pipe sleeve in the groove to the water pipe oppositely, the water pipe and the pipe sleeve are effectively connected, the problems that the manually mounted pipe sleeve on the water pipe is inconvenient in a time- and labor-wasting manner, and the production efficiency is reduced are solved, and meanwhile, the automatic processing efficiency of the sanitary water pipe is enhanced, and the demand on the market is met.

Owner:WUHU HUIYU TRADING CO LTD

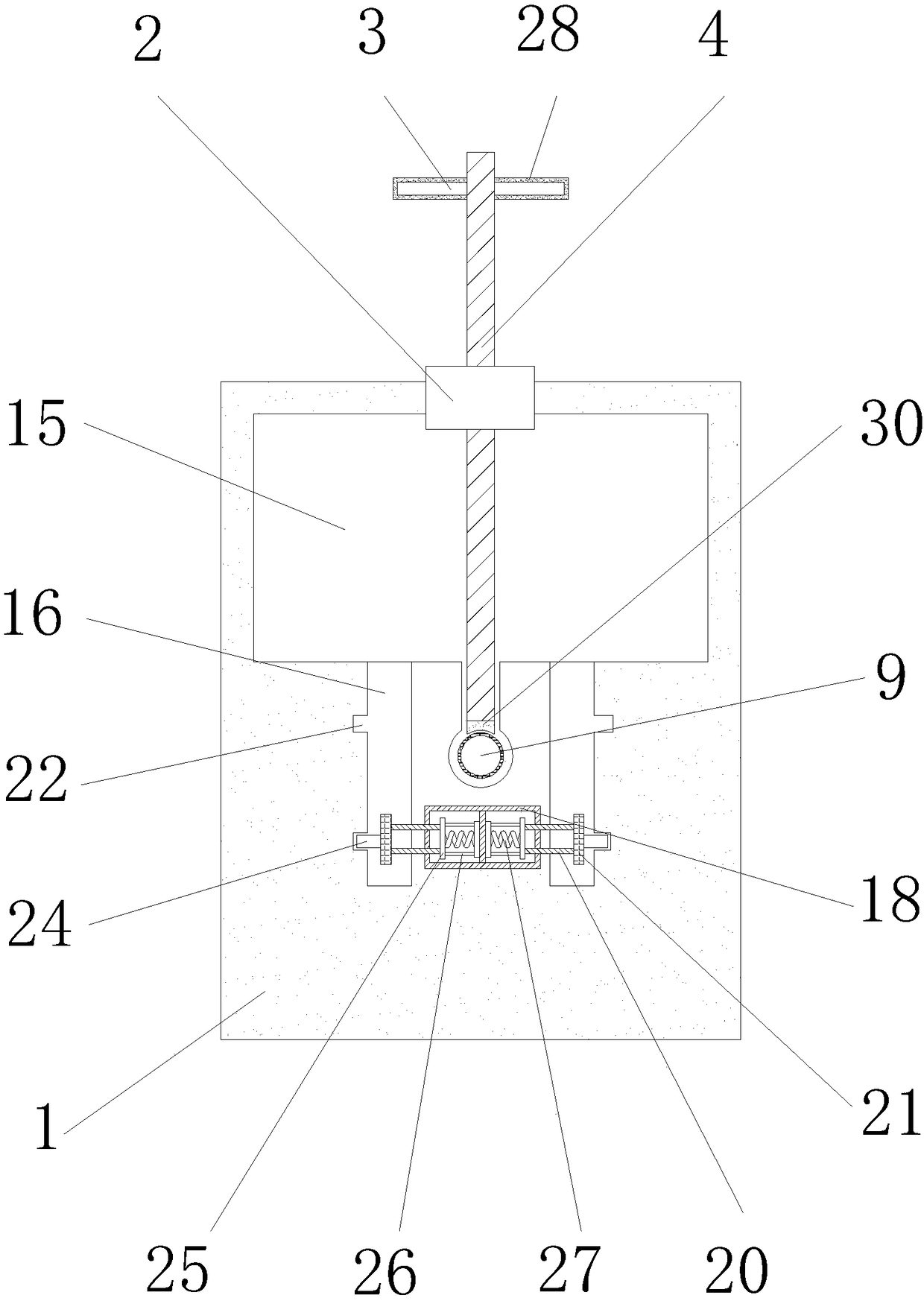

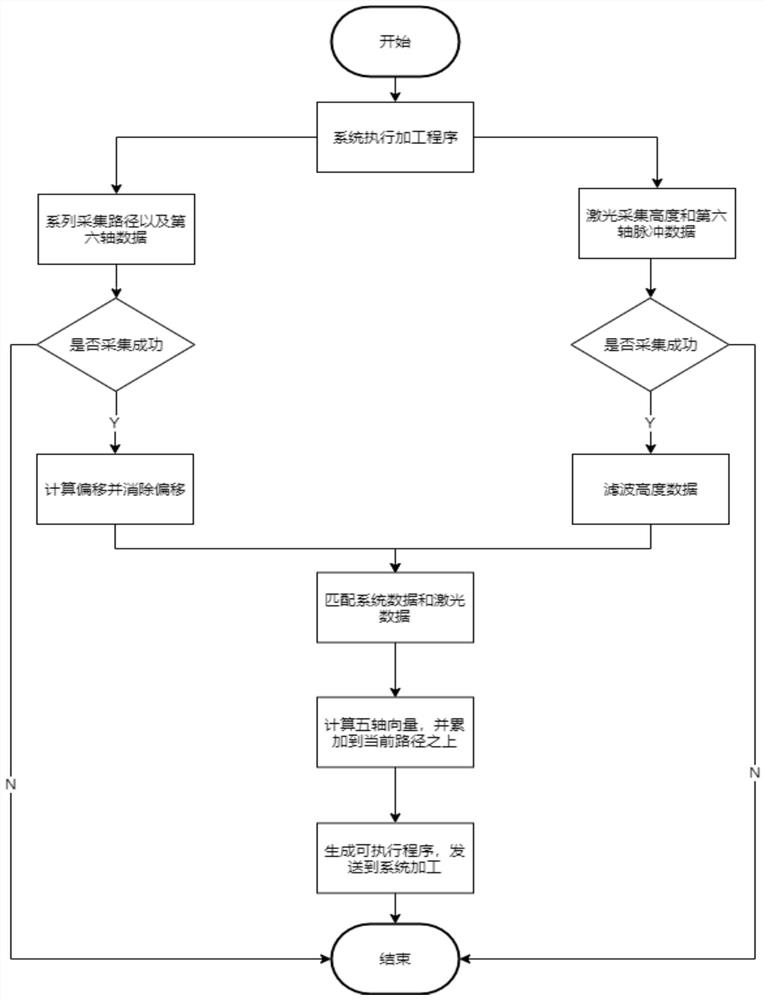

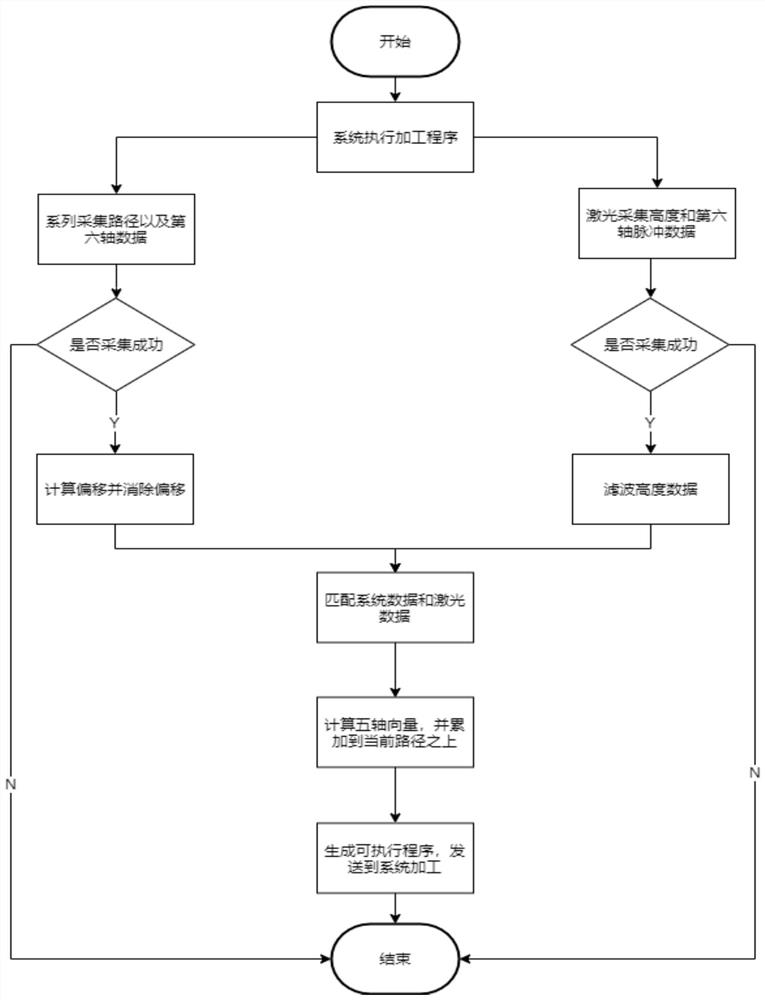

Laser measurement compensation method for realizing five-axis RTCP system

ActiveCN113031515AImprove efficiencyReduce manpower consumptionProgramme controlComputer controlMachining toolpathReal-time computing

The invention discloses a laser measurement compensation method for realizing a five-axis RTCP system. The method comprises the following steps: configuring a laser height acquisition system and a five-axis controller system to synchronously run an executable processing file; virtualizing a sixth axis and a signal thereof beyond five axes, wherein the signal value of the sixth axis is defined as an increment signal capable of describing the motion trail of the fifth axis; preprocessing the laser height data; calculating the offset of the delay between the signal of the sixth axis and the five-axis data; matching five-axis data with laser height data based on the calculated offset of the delay; and compensating and correcting a machining path based on a matching result. According to the laser measurement compensation method for achieving the five-axis RTCP system, accurate synchronization of the laser measurement system and the five-axis controller system can be achieved, compensation for an executed machining path is accurately calculated according to the accurate synchronization, and the efficiency, accuracy and reliability of automatic machining can be improved.

Owner:SHANGHAI LYNAC NUMERICAL CONTROL TECH CO LTD

Laser measurement compensation method for realizing five-axis rtcp system

ActiveCN113031515BFast processingImprove processing efficiencyProgramme controlComputer controlAutomatic processingElectrical and Electronics engineering

The invention discloses a laser measurement and compensation method for realizing a five-axis RTCP system. The method includes: configuring a laser height acquisition system and a five-axis controller system to synchronously run an executable processing file; virtualizing a sixth axis other than the five axes And its signal, the signal value of the sixth axis is defined as an incremental signal that can describe the motion trajectory of the five-axis; preprocess the laser height data; calculate the offset of the delay between the signal of the sixth axis and the data of the five-axis; The offset based on the calculated delay matches the five-axis data and the laser height data; based on the matching result, the processing path is compensated and corrected. According to the laser measurement compensation method for realizing the five-axis RTCP system of the present invention, it is possible to realize the precise synchronization of the laser measurement system and the five-axis controller system, and accordingly accurately calculate the compensation for the executed processing path, which helps to improve automatic processing efficiency, precision and reliability.

Owner:SHANGHAI LYNAC NUMERICAL CONTROL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com