Printing ink viscosity regulating device for printing machine

A technology of ink viscosity and adjustment device, which is applied in printing and other directions, can solve the problems that are difficult to achieve accuracy and affect the quality of printed products, and achieve clear and consistent patterns, good printing effects, and labor-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

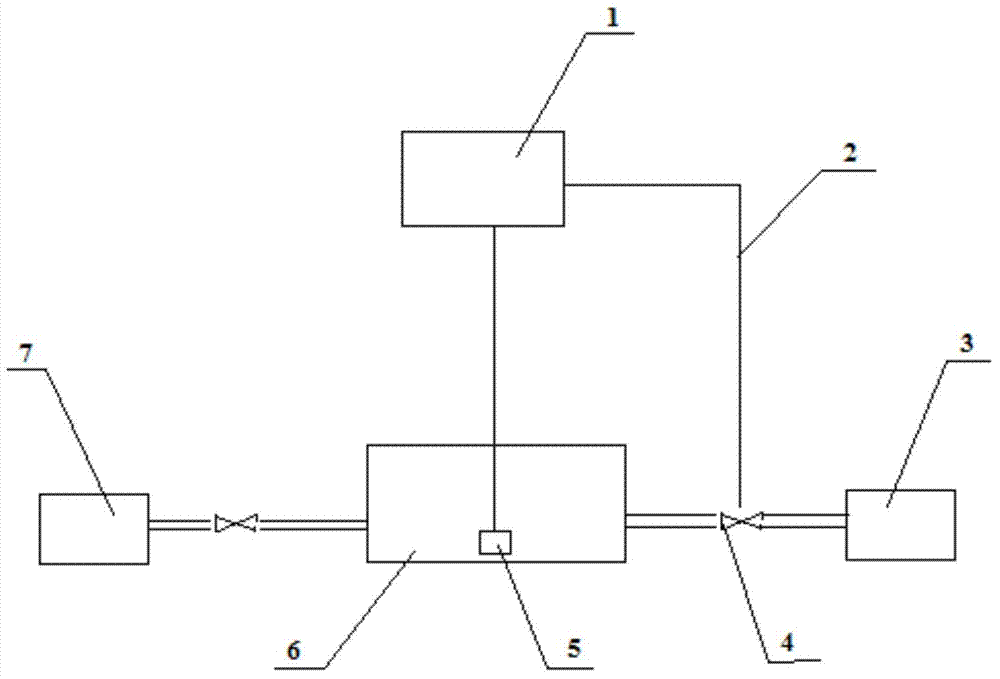

[0011] Such as figure 1 As shown, a printing machine ink viscosity adjustment device includes an electric controller 1 and an ink tank 6, the electric controller 1 is connected with a viscosity detection sensor 5 arranged in the ink tank 6, and the ink tank 6 is respectively connected to the storage tank through a pipeline. The ink tank 7 is connected with the solvent tank 3, and the pipeline connecting the ink tank 6 and the solvent tank 3 is provided with a solenoid valve 4, and the electric controller 1 is connected with the solenoid valve 4 through a wire 2 to control the amount of solvent injected into the ink tank 6 .

[0012] When the present invention is in use, the viscosity detection sensor 5 transmits the signal to the electric controller 1, and if the viscosity is lower than the predetermined viscosity, the electric controller 1 opens the electromagnetic valve 4 on the pipeline that the ink tank 6 is connected to the solvent tank 3, and the solvent flows from the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com