Petroleum drilling real-time monitoring system

A real-time monitoring system and oil drilling technology, which is applied in the directions of measurement, earthwork drilling, wellbore/well components, etc., can solve the problem that the oil drilling system cannot realize real-time monitoring, the drilling fluid cannot realize real-time monitoring, and the medium pressure loss of water detection index Inaccurate and other problems to achieve the effect of avoiding drilling accidents, reasonable structure and accurate monitoring data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

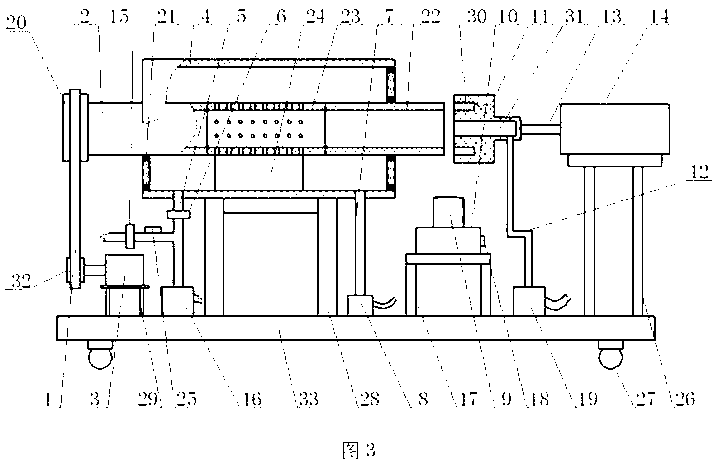

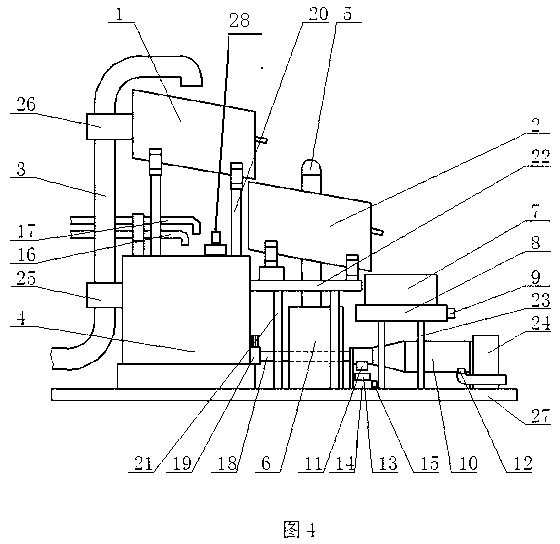

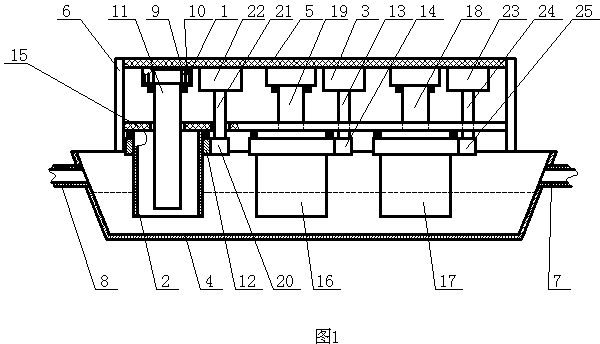

[0011] The oil drilling real-time monitoring system of the present invention includes a drilling fluid performance monitoring instrument, a geological logging monitoring instrument and a drilling engineering parameter monitoring instrument. Sensors are installed on each instrument, and the sensor transmits the detection signal to the computer through a wireless transmitting and receiving system. Processing equipment, and then processed by computer software, converted into charts and displayed on the monitor in real time. Wherein the geological logging monitoring instrument and the drilling engineering parameter monitoring instrument are prior art, for these prior art, the present embodiment only describes the name of each part and related parameters used in the oil drilling real-time monitoring system: geological logging real-time monitoring part , consisting of spectrometer, fluorescence content measuring instrument, hydrogen flame chromatograph, thermal conductivity chromatog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com