Patents

Literature

33results about How to "Avoid Drilling Accidents" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

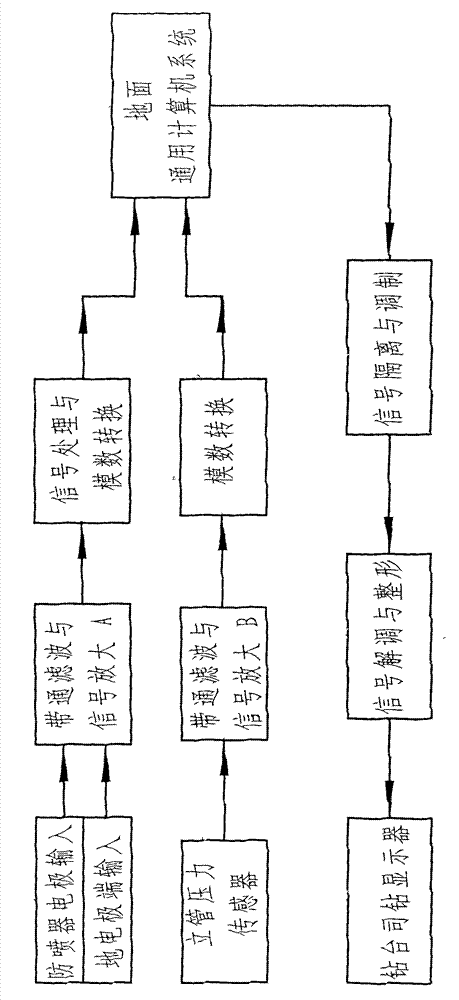

Petroleum drilling real-time monitoring system

InactiveCN102828747AViscosity is accurate in real timeAccurate viscositySurveyDisplay devicePetroleum

The invention provides a petroleum drilling real-time monitoring system which comprises a drilling liquid performance monitoring instrument, a geological logging monitoring instrument and a drilling engineering parameter monitoring instrument, wherein sensors are arranged on all the instruments; the sensors are used for transmitting a detecting signal to computer processing equipment through a wireless transmitting and receiving system, and the detecting signal is processed through the computer software and then converted into a chart to be displayed through a display in real time. With the adoption of the petroleum drilling real-time monitoring system, the shortcomings of the comprehensive logging instrument that only the geological logging and drilling engineering parameters can be monitored can be overcome; the drilling liquid performance can be monitored online in real time, so that the drilling liquid, the drilling engineering and the geological logging can be integrated and processed through a computer, and then a comprehensive system integrating the acquiring, displaying and processing of various data at a drilling site can be formed; the comprehensive system can meets the various demands of safely optimizing the drilling and comprehensively determining an oil-gas-water layer.

Owner:韩文峰

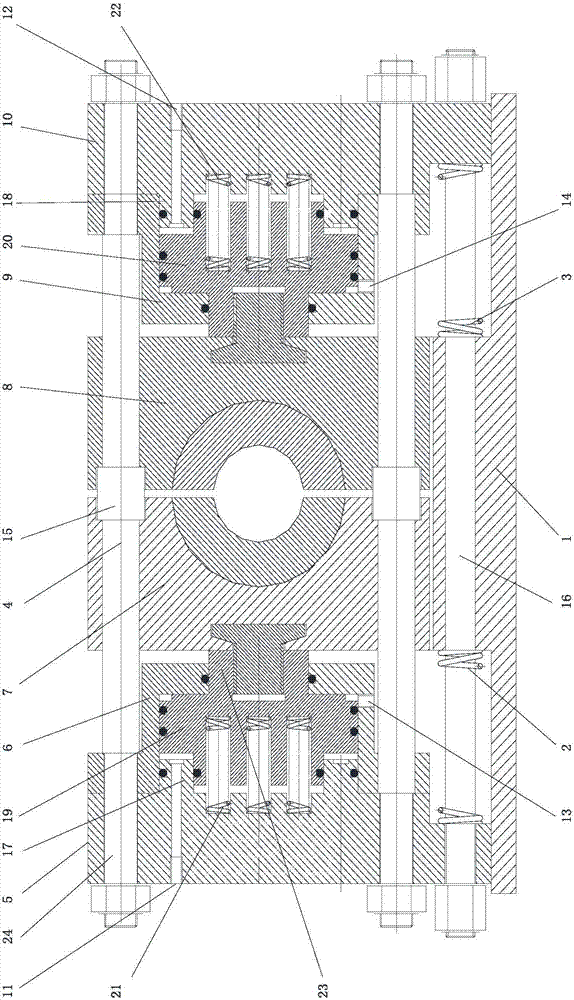

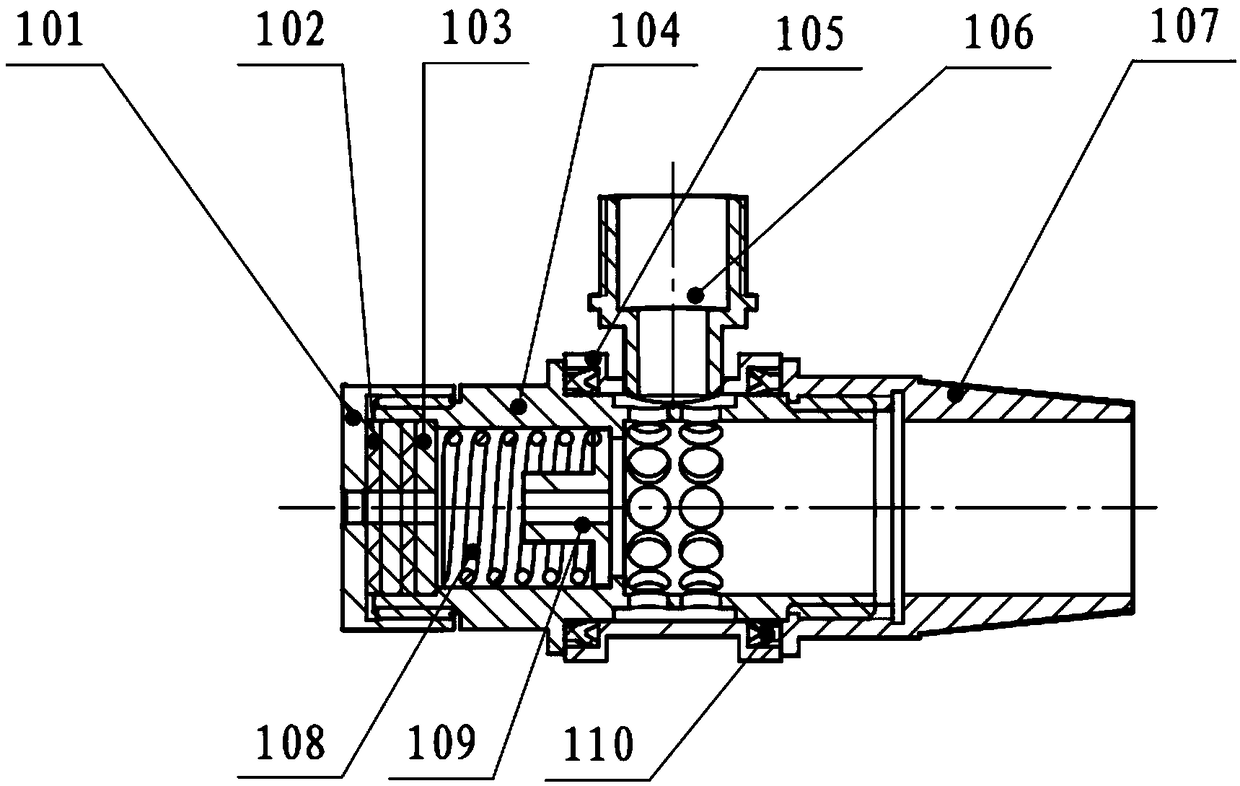

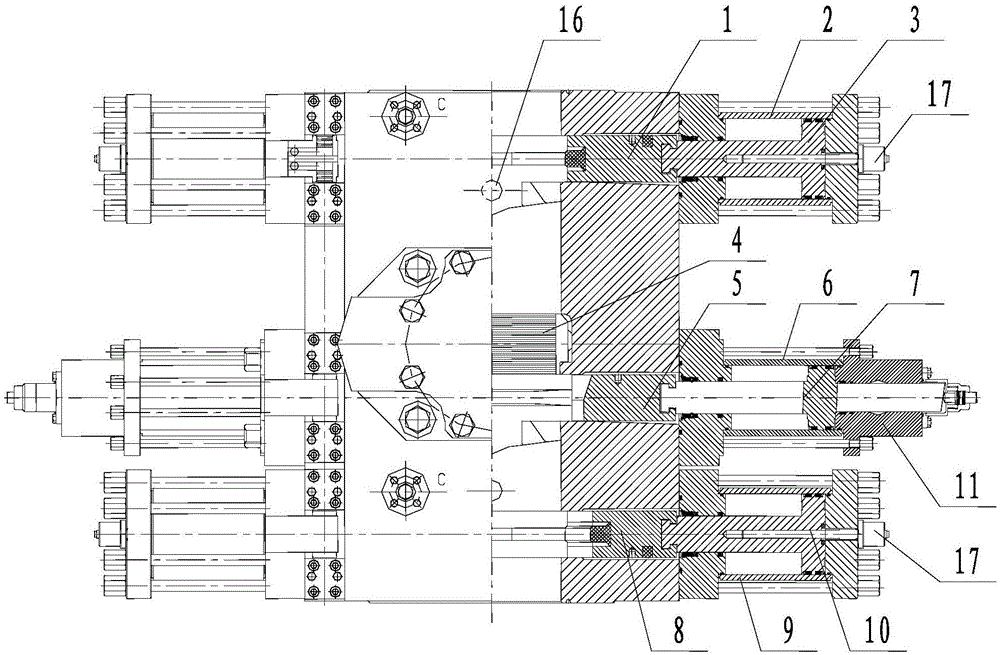

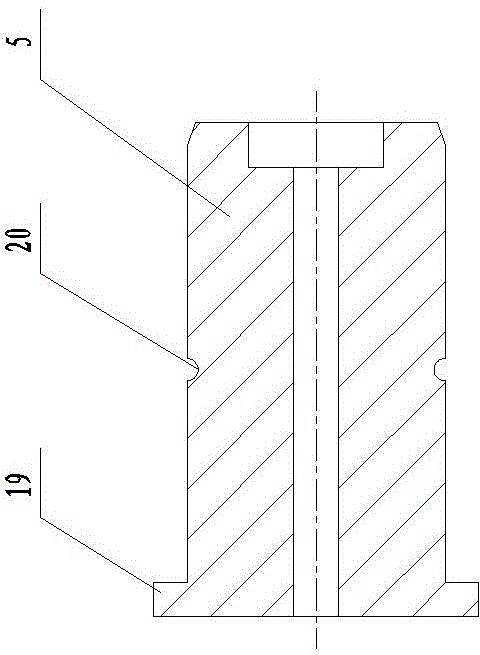

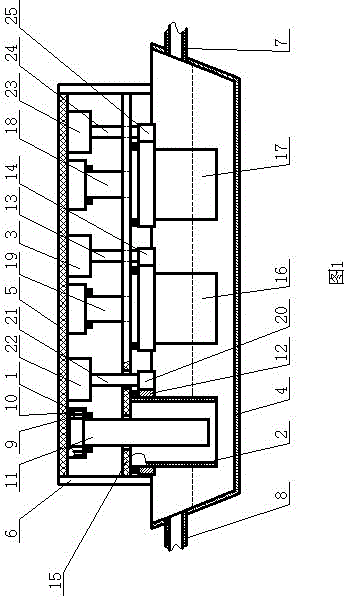

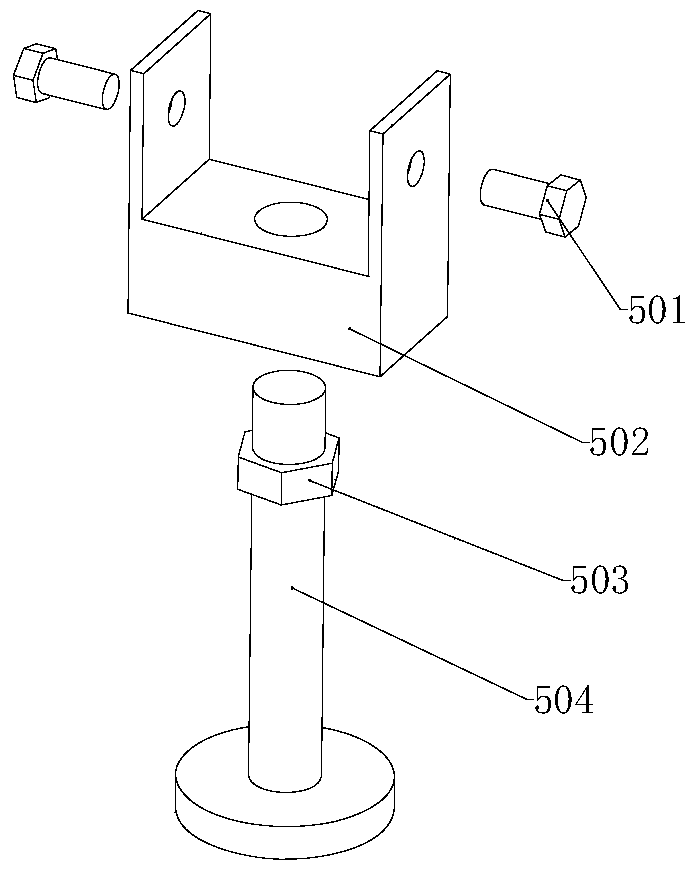

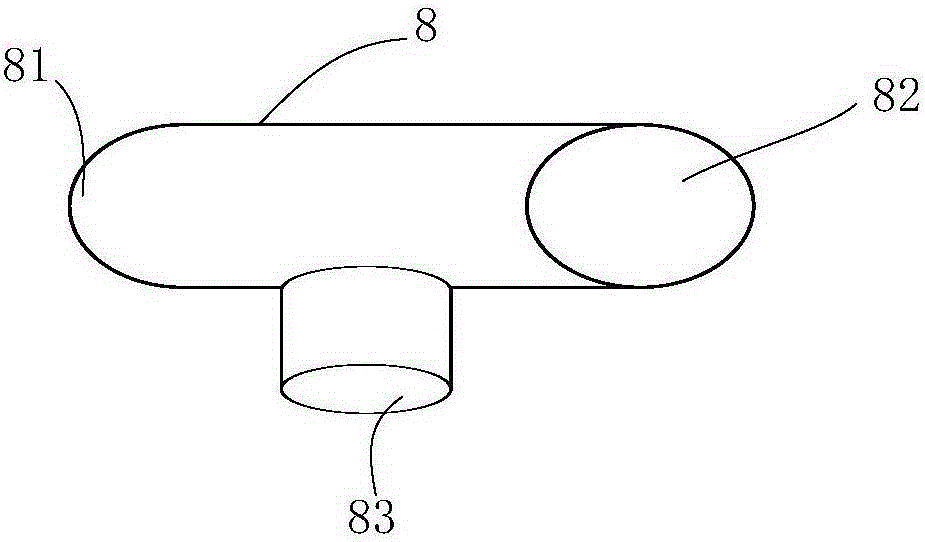

Automatic floating centering hydraulic clamp holder

PendingCN107420051AEliminate wear and tearHigh speedDrilling rodsDrilling casingsSingle degree of freedomEngineering

The invention discloses an automatic floating centering hydraulic clamp holder. The automatic floating centering hydraulic clamp holder comprises a clamping assembly used for clamping a drill rod and a base fixedly matched with a drilling machine rack and used for installing the clamping assembly. The clamping assembly is installed on the base in the radial swing direction of the drill rod in a single-degree-of-freedom sliding mode, and a fixing elastic part used for fixing the clamping assembly to avoid the situation that the clamping assembly slides under the gravity effect is arranged between the base and the clamping assembly in the single-degree-of-freedom sliding direction of the clamping assembly; external force floating centering can be increased, so that the situation that abrasion on the drill rod during clamp holder centering is guaranteed through force generated by rotating of the drill rod is avoided; and meanwhile in a lateral orientation drilling machine, the clamp holder can also be centered under the effect of floating external force, so that the eccentric problem of an existing clamp holder under the gravity effect or the problem that the initial position of the clamp holder is repeatedly adjusted to ensure centering in different orientations is avoided.

Owner:CHINA COAL TECH & ENG GRP CHONGQING RES INST CO LTD

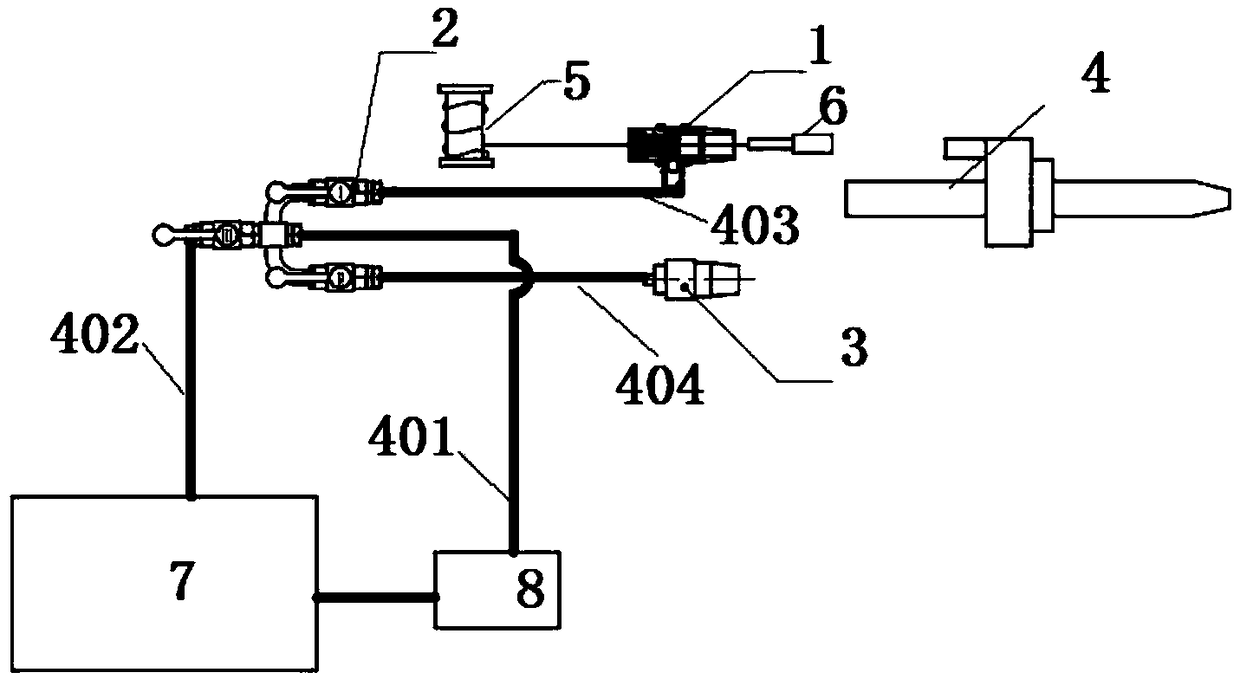

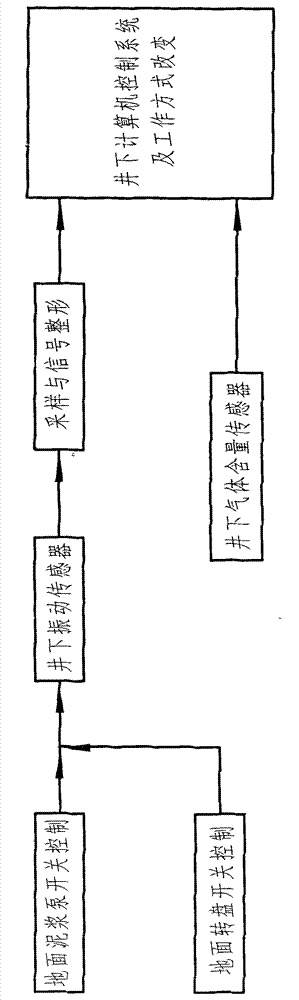

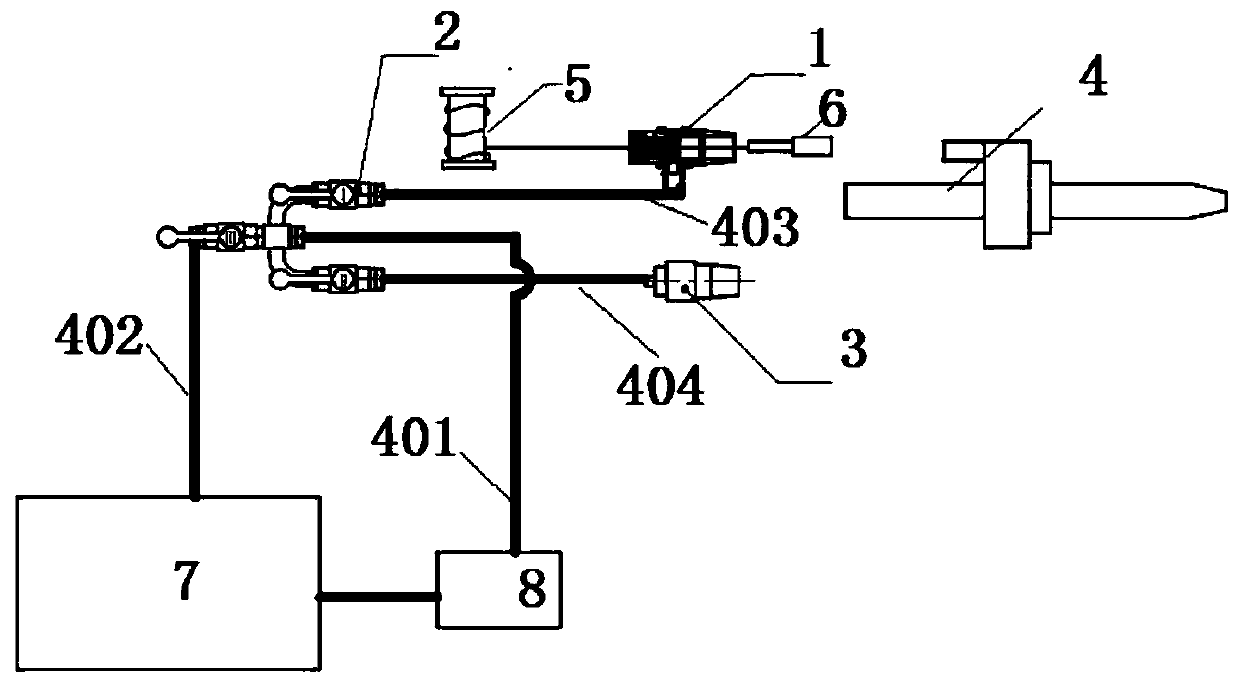

Directional drilling and back-pressure prevention electric rotating plate device and manipulating method thereof

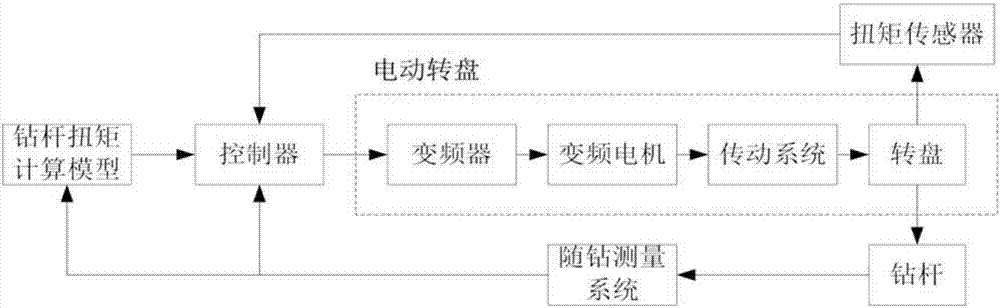

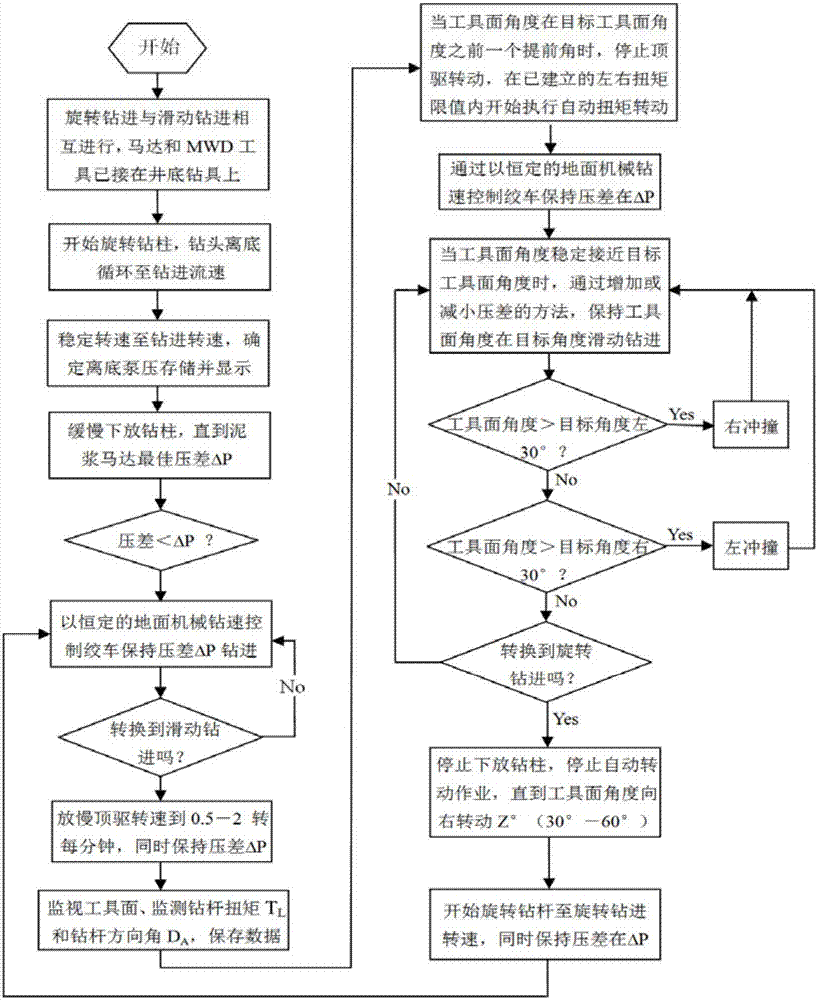

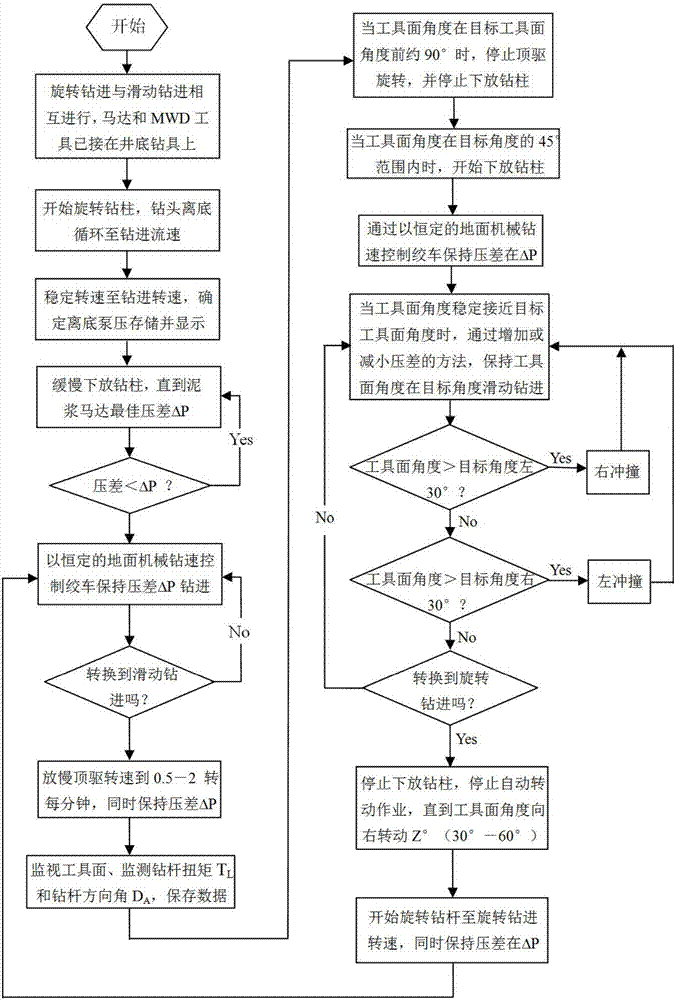

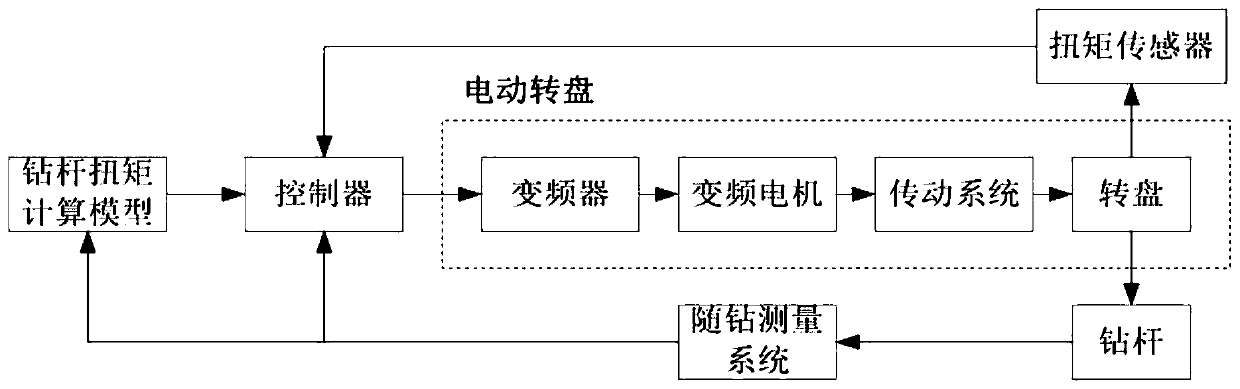

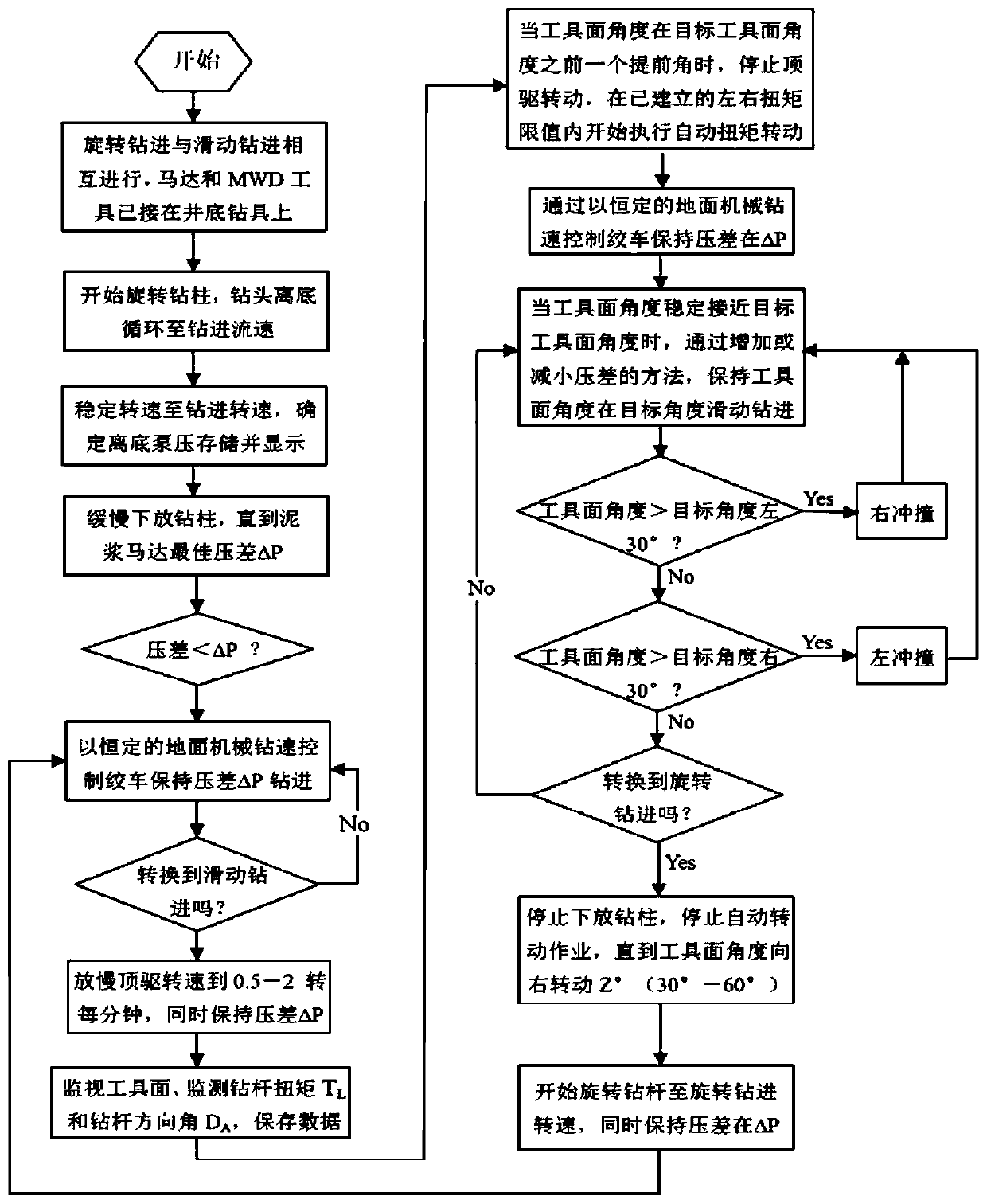

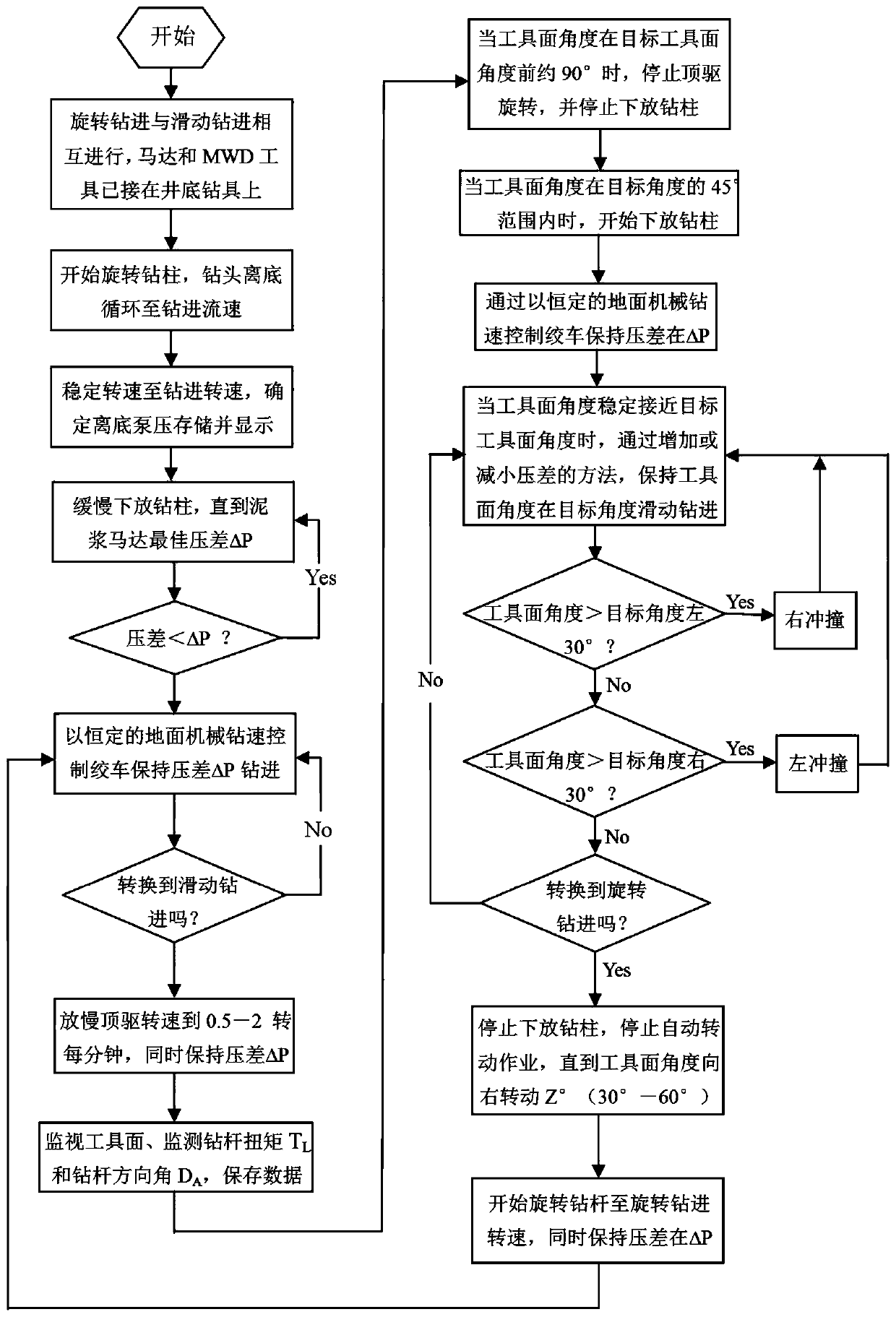

ActiveCN107013163AControl speed in real timeReal-time control of lapsConstructionsRotary drillingElectricityFrequency conversion

The invention relates to a directional drilling and back-pressure prevention electric rotating plate device composed of a rotating speed and torque sensor, a frequency conversion and speed regulation system, a rotating plate, a drilling rod, a measurement while drilling (MWD) system and a controller. The rotating speed and torque sensor can feed back the output torque of the rotating plate in the working process of the electric rotating plate. The torque values of the sections of the drilling rod are calculated according to a drilling rod torque calculation model and input to the controller. The speed, forward rotating, reverse rotation and the number of laps of rotation of the rotating plate are adjusted through the frequency conversion and speed regulation system. The MWD system can measure the angle of a tool face, and when the angle of the tool face is larger than a certain numerical value, rotating drilling is turned into sliding drilling, and the direction of sliding drilling is further controlled. The controller is electrically connected with a computer to store data, and communication with other equipment can be achieved. Directional drilling of the electric rotating plate can be achieved, friction resistance and back pressure are reduced, well drilling efficiency is improved, and the directional drilling and back-pressure prevention electric rotating plate device can be widely applied to the petroleum drilling industry.

Owner:QINGDAO JINJIANGYUAN IND EQUIP CO LTD

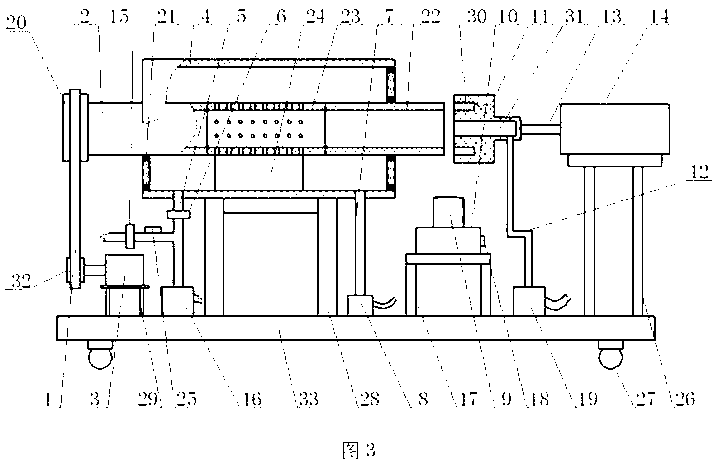

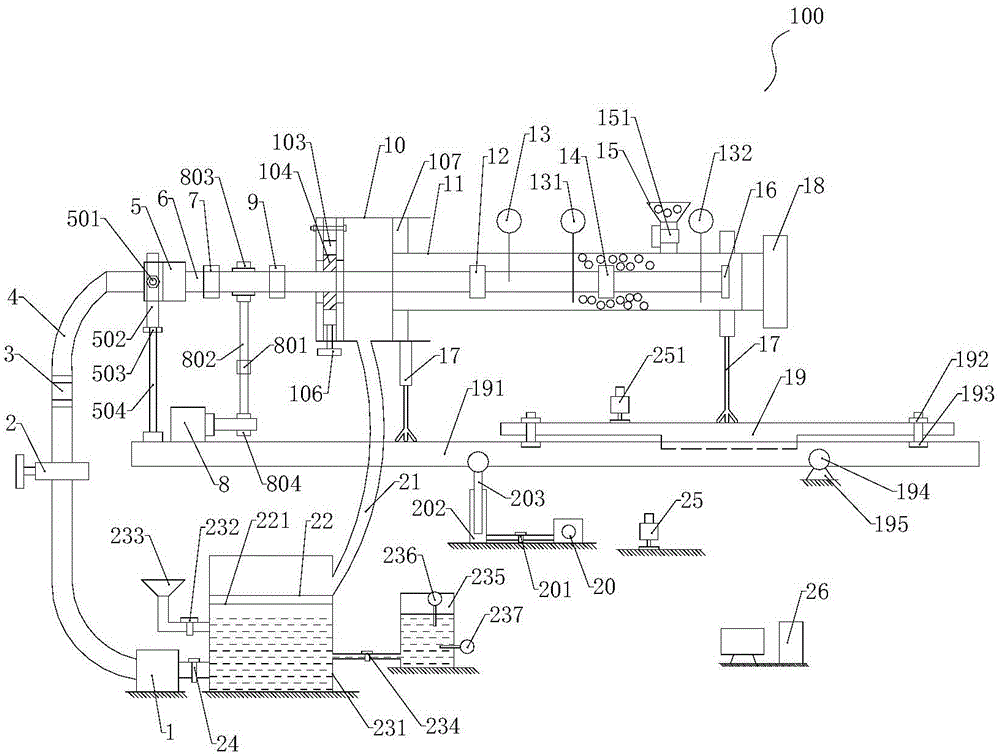

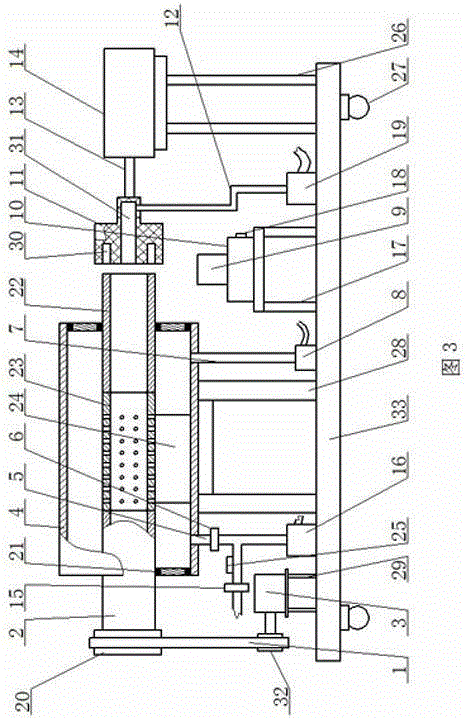

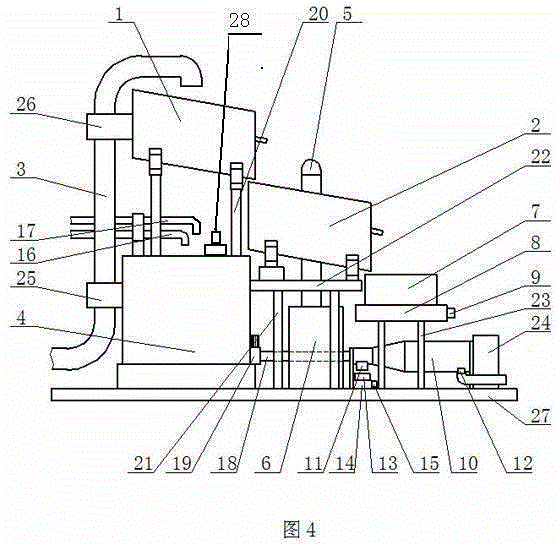

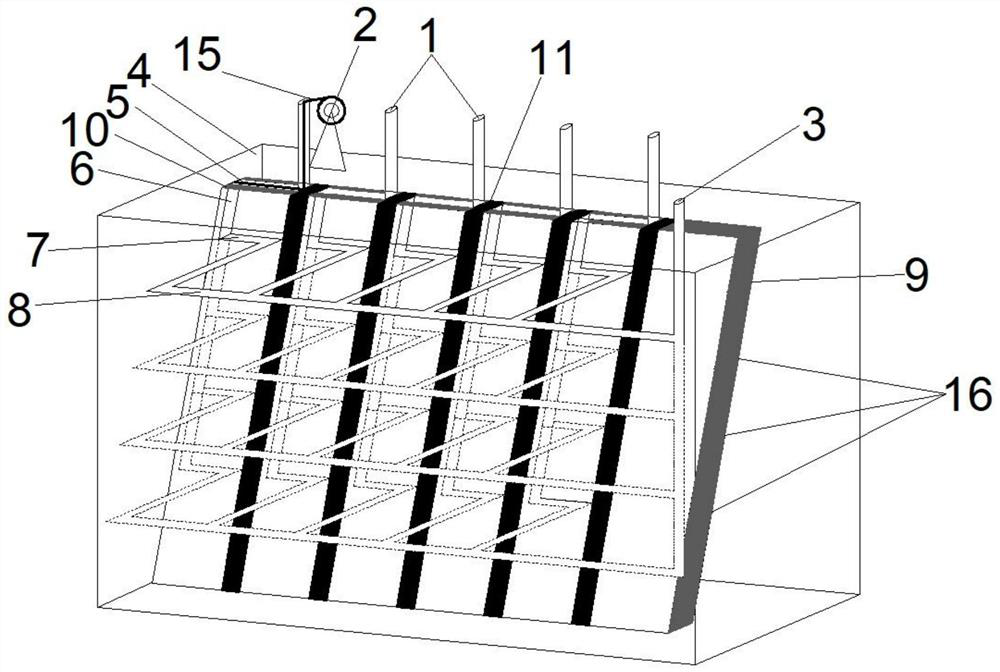

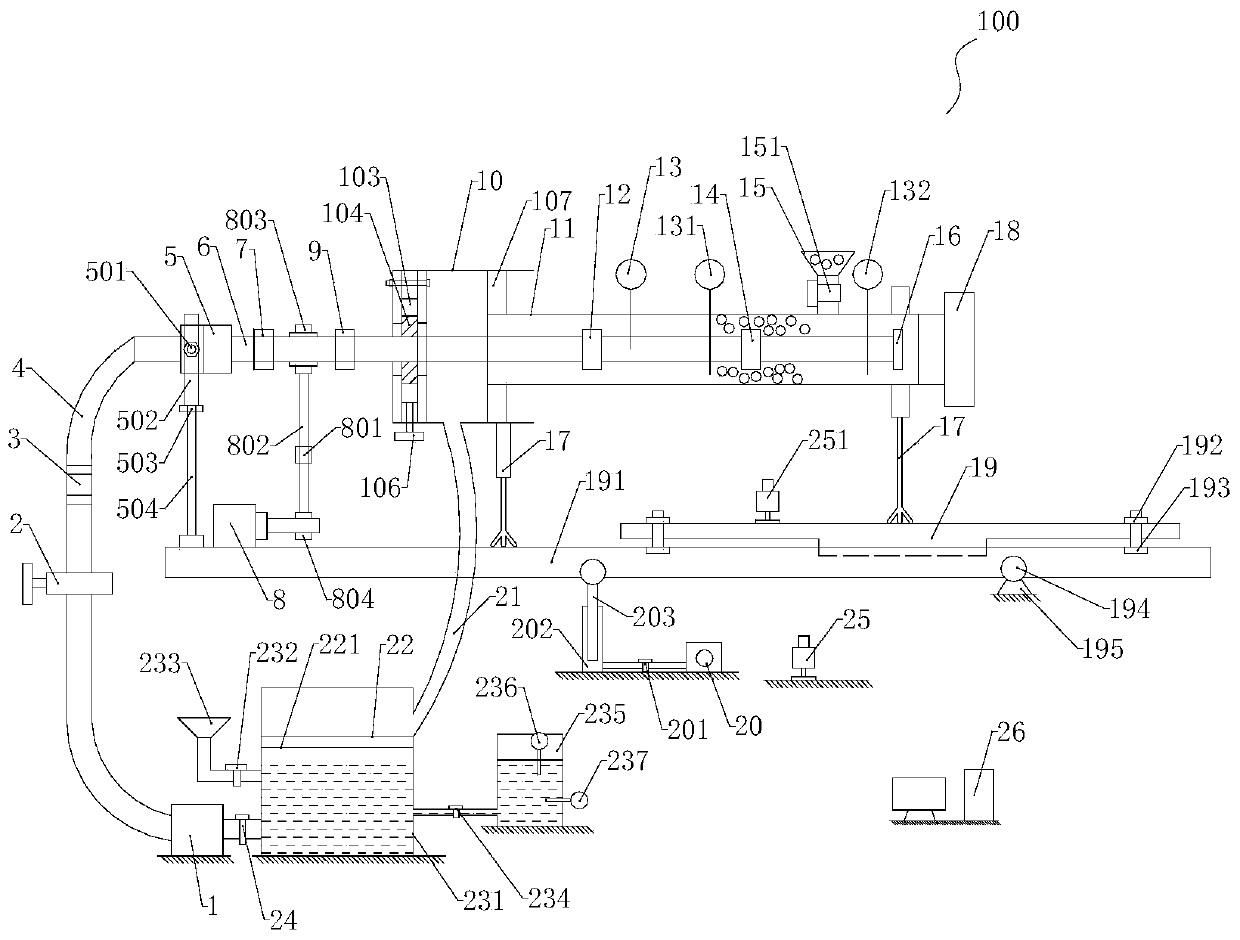

In-situ observation tester simulating sand cleaning process in drilling

The invention relates to an in-situ observation tester simulating a sand cleaning process in drilling, comprising a bottom plate, a slide plate, a transparent simulation sleeve, a fixing cylinder sleeve, a simulation hollow drill stem, a drill stem rotation drive mechanism, a drilling fluid cycle control device and a data acquisition device. In-situ observation in the sand cleaning process of drilling is tested by integrating parameter such as eccentricity, hole drift angle, drilling fluids of different features, pressure, flow, flow speed, torque, different sands, sand addition, sand-cleaning eyeholes and drilling stem sleeve surface roughness, and great significance is brought to sand cleaning mechanism of the drilling process, abrasion of the sleeve, sand cleaning features of drilling fluids and the like; the tester is simple in structure, has a clear principle and is convenient to operate.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

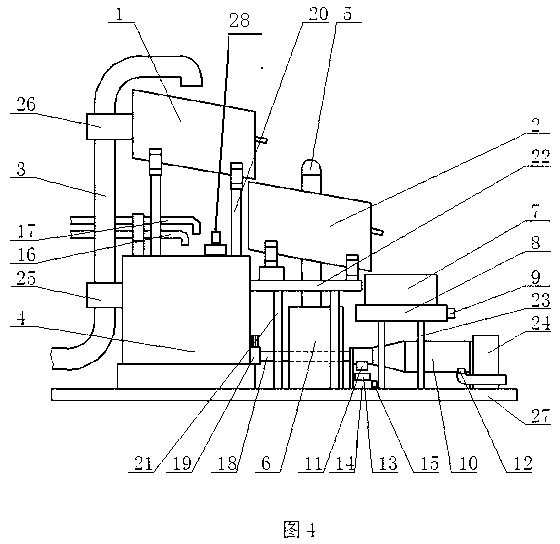

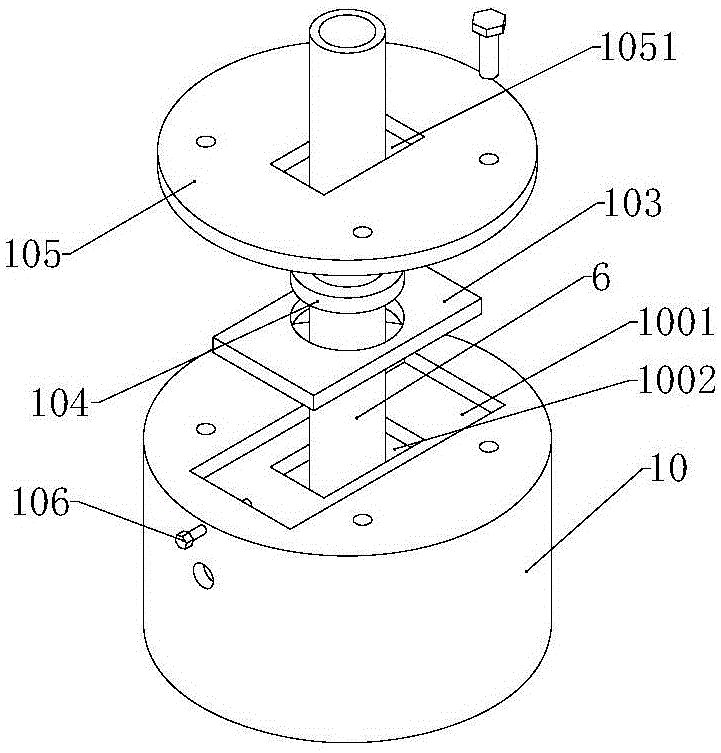

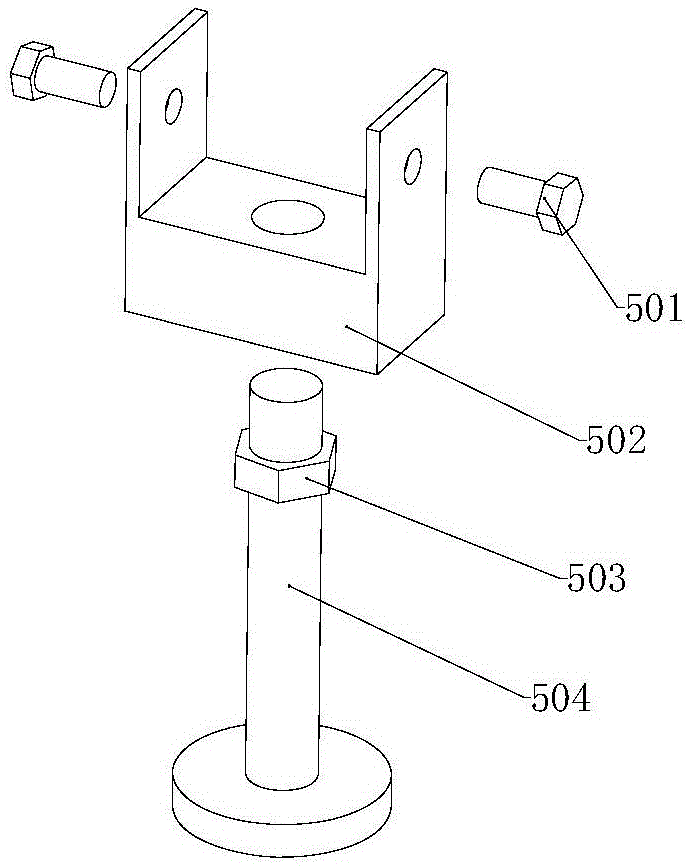

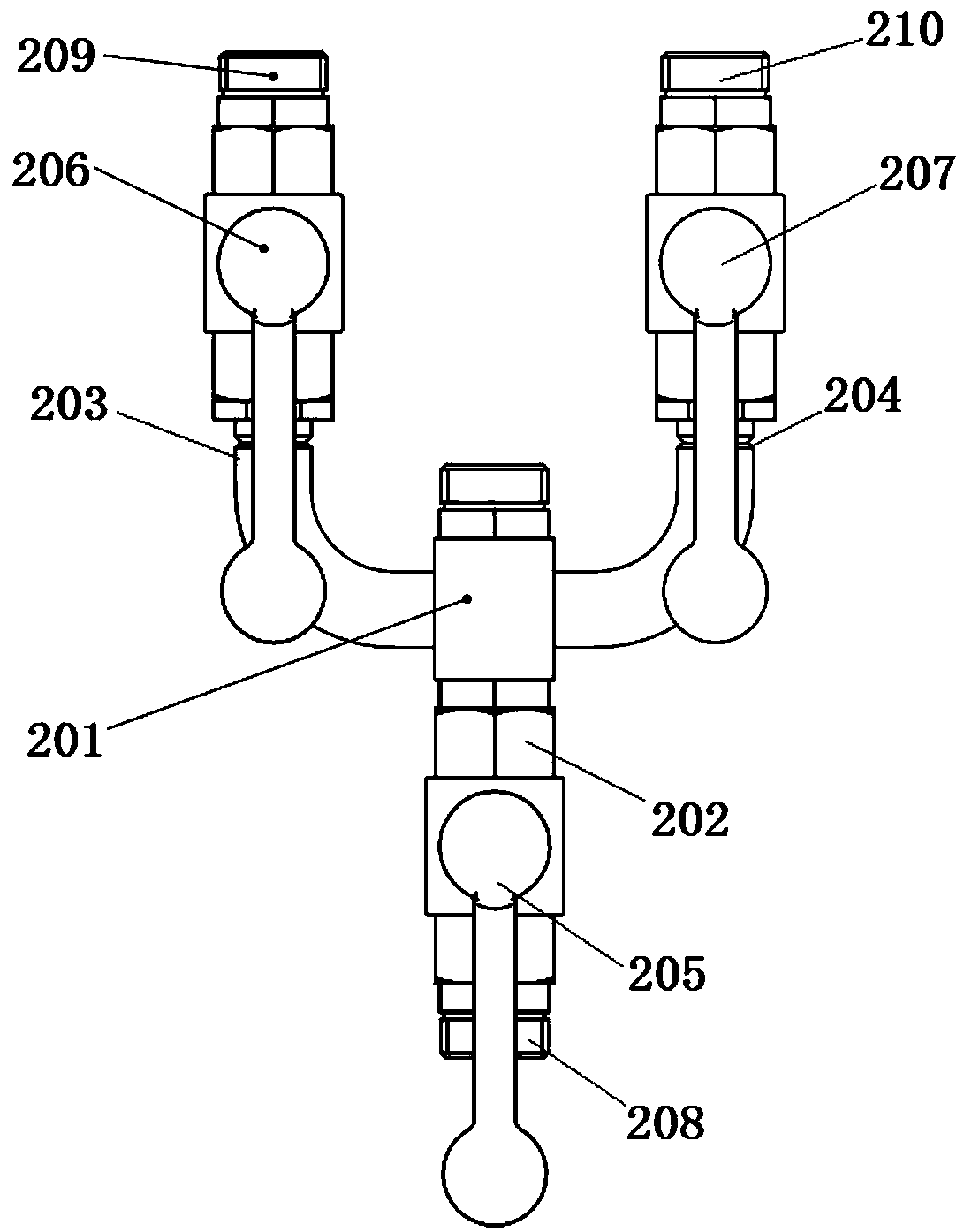

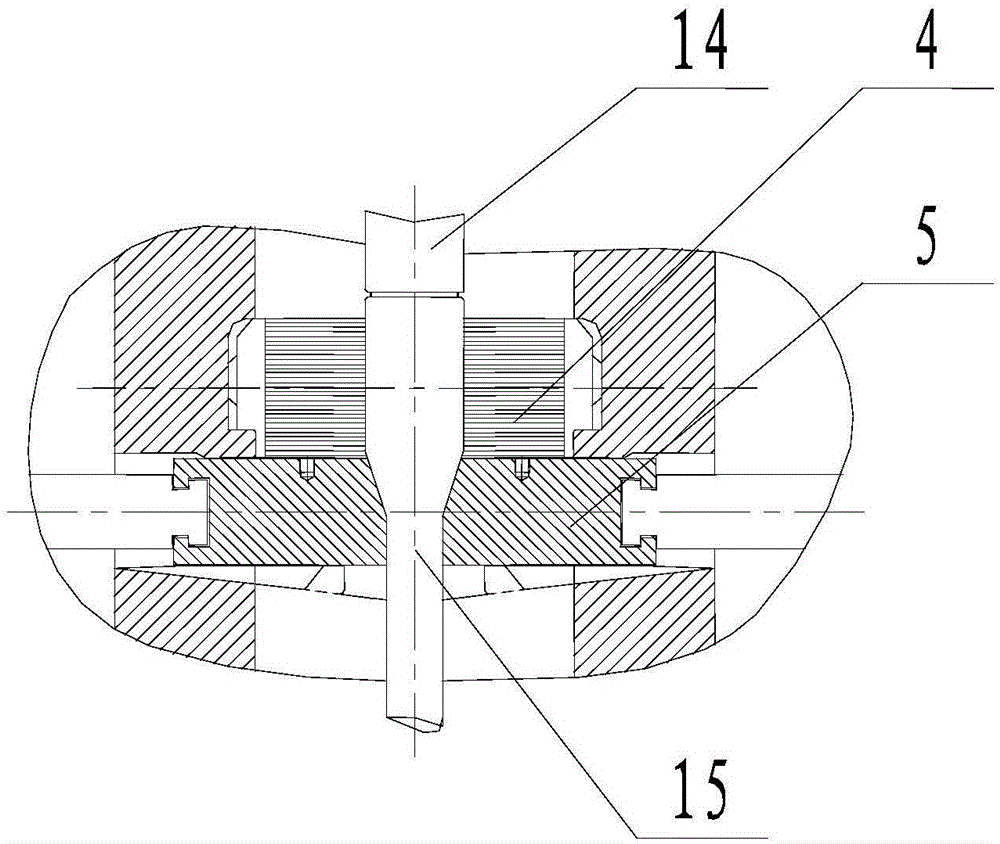

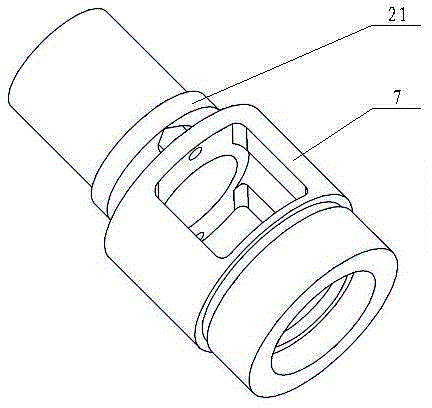

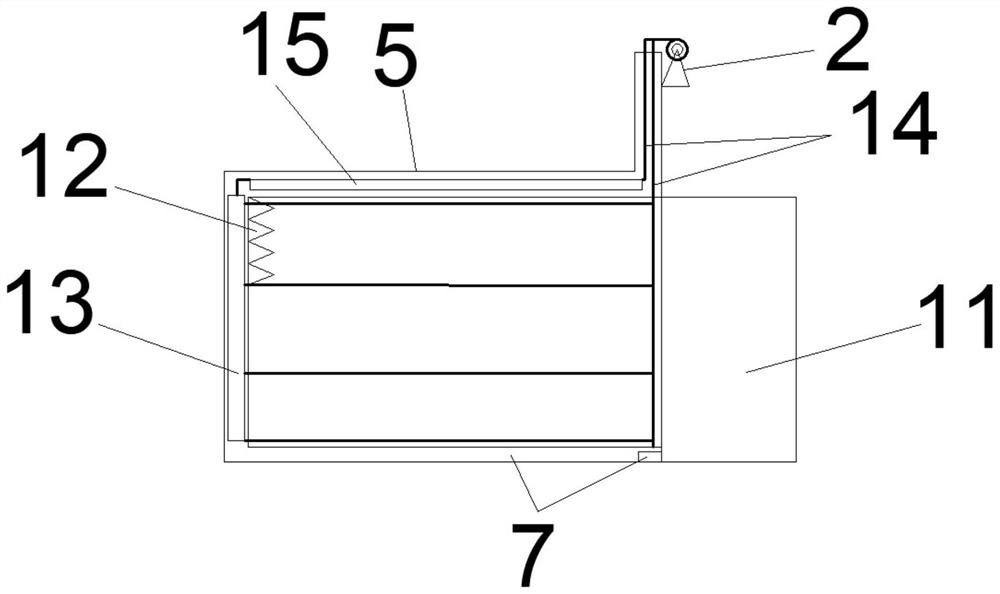

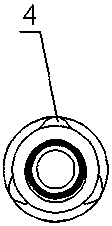

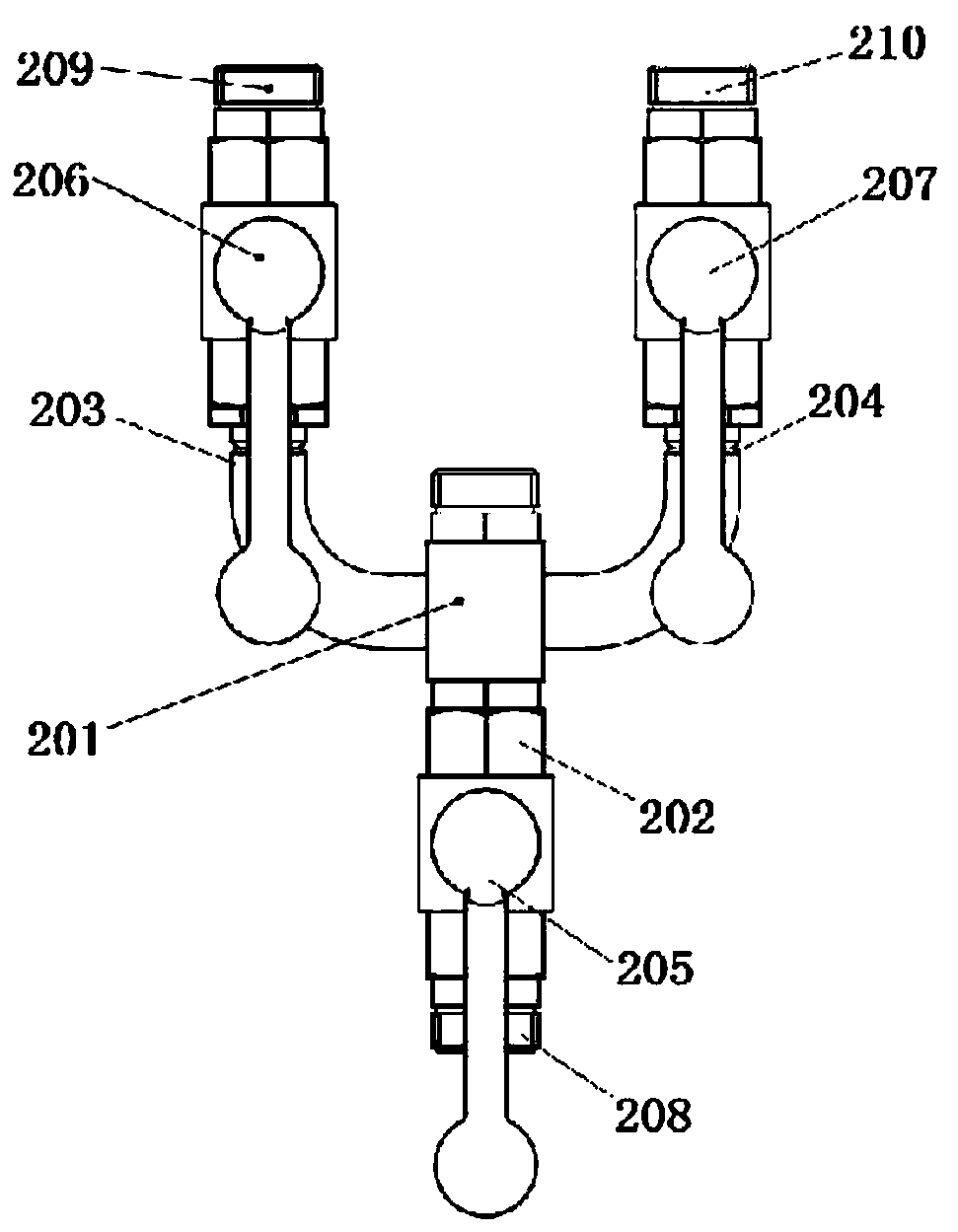

Waterway control assembly and method for rope core drilling rig

ActiveCN108756794AReduce connectivityReduce the number of disassemblyDrilling rodsFlushingControl valvesUltimate tensile strength

The invention discloses a waterway control assembly and method for a rope core drilling rig. The waterway control assembly comprises a rotatable through-cable water connector, a waterway control valveset, a conventional water connector and a connecting pipeline. The waterway control valve set is an intercommunication-type four-way pipe, corresponding three connecting openings are provided with two-way ball valves, the three two-way ball valves are opened and closed to control the connecting and disconnecting relation among the four connecting openings, and thus a waterway is controlled. The rotatable through-cable water connector comprises an end cover, a water sealing ring, a retaining ring, a mandrel, a rotating sleeve, a water pipe connector and a transition connector; the tail end ofthe mandrel is provided with a groove for allowing the water sealing ring and the retaining ring to be mounted in a spaced mode; the rotating sleeve is sleeved with the middle of the mandrel; and thewater pipe connector radially extending is connected to the rotating sleeve in a penetrating mode. Thus, according to the waterway control assembly and method, the structure is simple, operation is convenient, and the problems that in the prior art, the waterway control auxiliary time is long, and the labor intensity of workers and the personnel cost are high can be solved.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

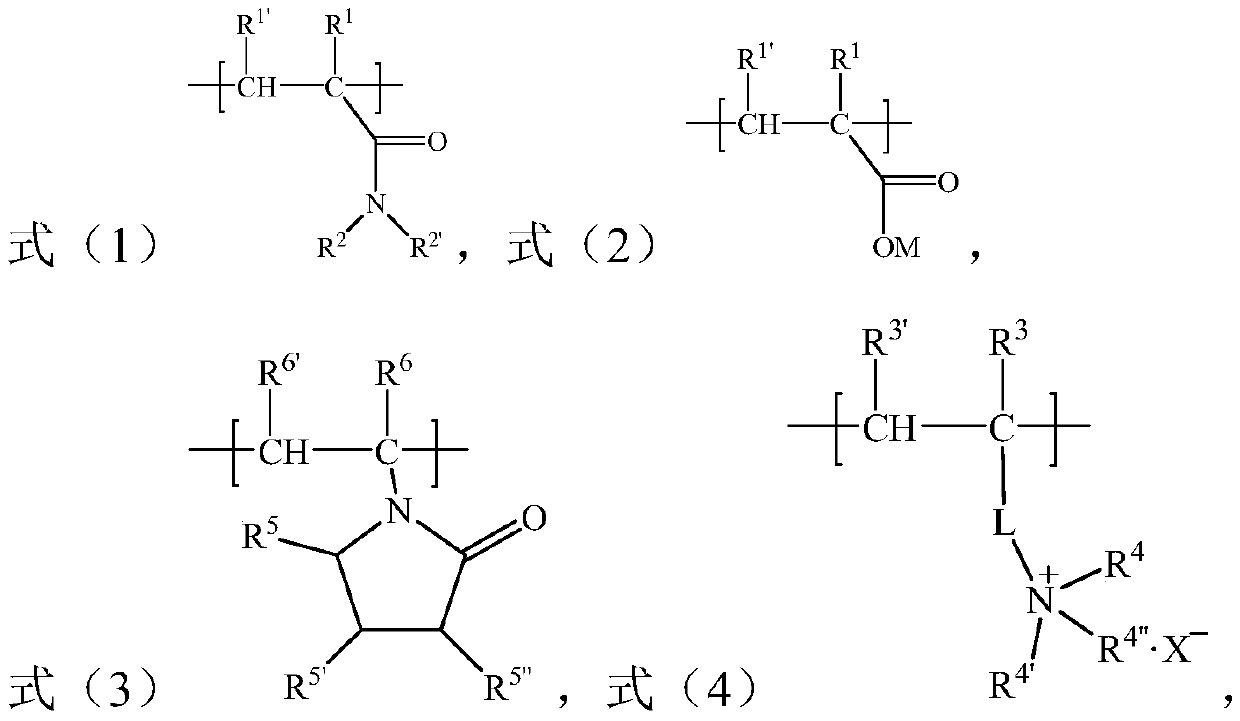

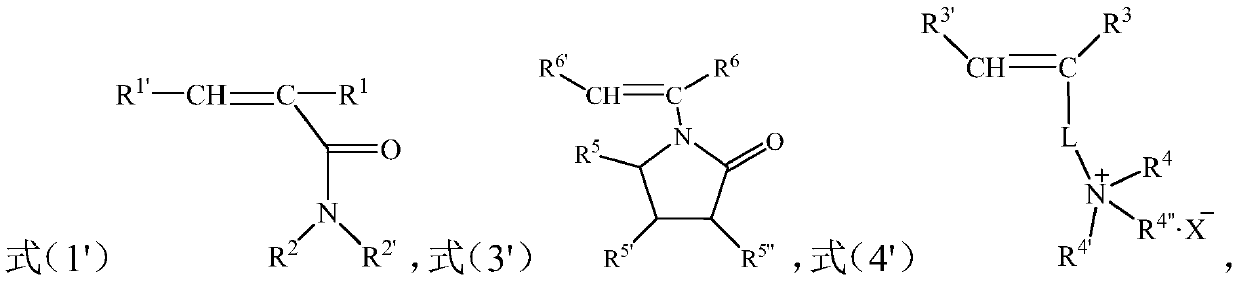

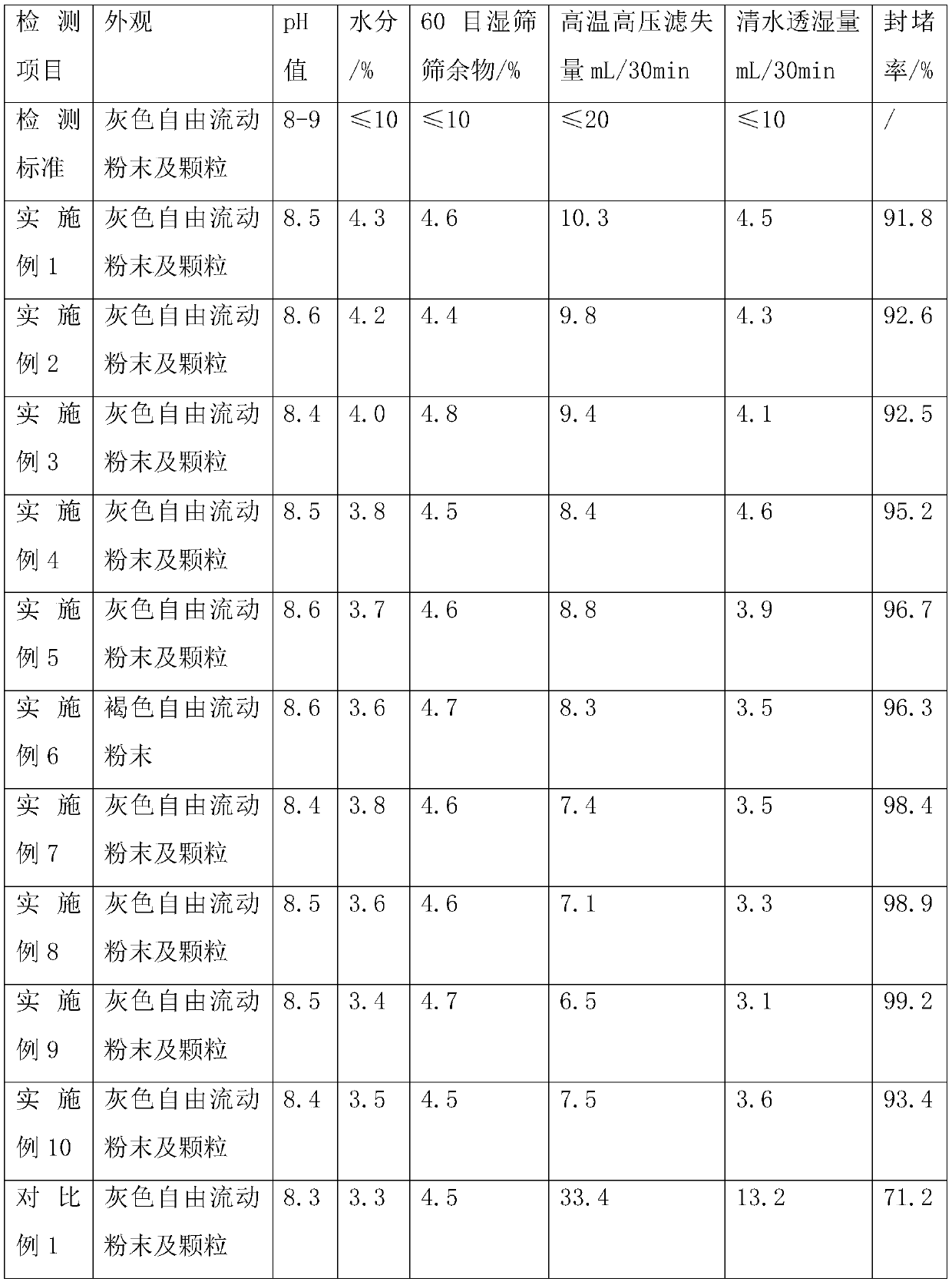

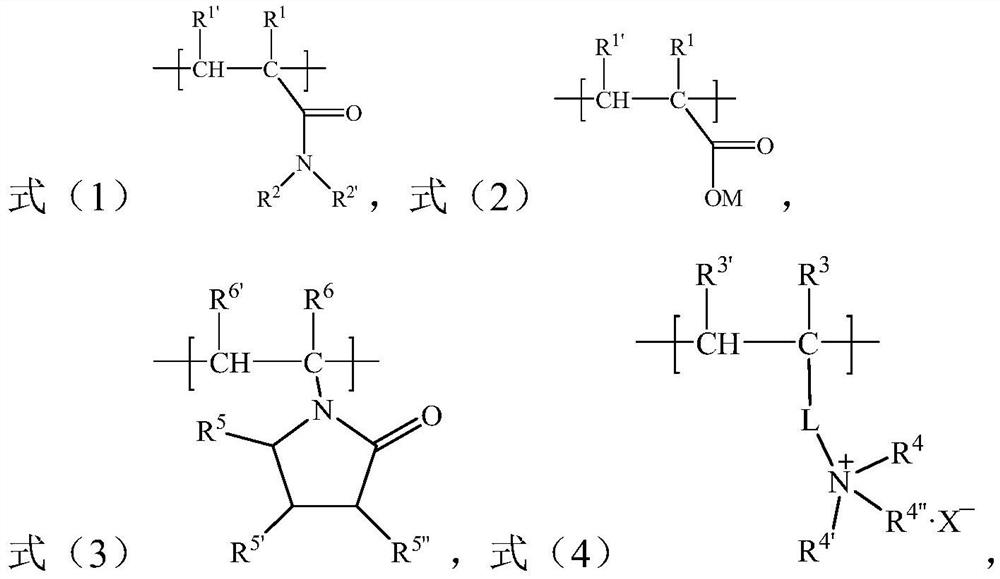

Hydrophobic modification polyacrylamide polymer as supermolecule shearing strength improving agent and application in water-based drilling fluid

ActiveCN110396152ASolving the problem of cuttings deposition in the horizontal sectionAvoid Drilling AccidentsDrilling compositionPetroleumPolyacrylamide

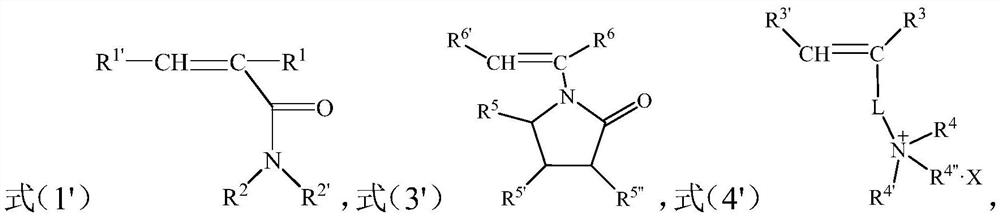

The invention relates to the field of well drilling of the petroleum industry and in particular to a hydrophobic modification polyacrylamide polymer as a supermolecule shearing strength improving agent and application in a water-based drilling fluid. Structure units forming the polymer are a structure unit of a formula (1) shown in the specification, a structure unit of a formula (2) shown in thespecification, a structure unit of a formula (3) shown in the specification and a structure unit of a formula (4) shown in the specification; and the number-average molecular weight of the polymer is1-6.5 million. The hydrophobic modification polyacrylamide polymer provided by the invention has a supermolecule-like structure, and a shearing strength improving agent with properties of shearing resistance and easily recovered structures can be provided by virtue of electrostatic force, hydrogen bonds, hydrophobic effects and the like of supermolecules.

Owner:中国石油集团川庆钻探工程有限公司钻井液技术服务公司 +1

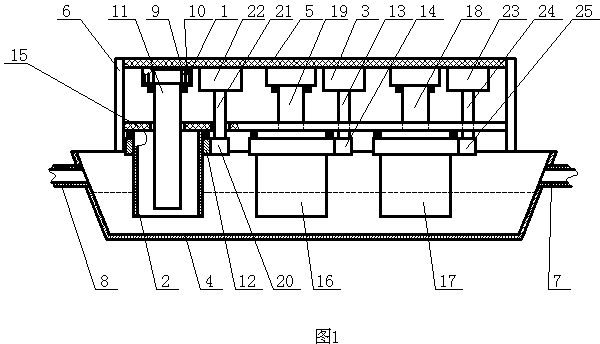

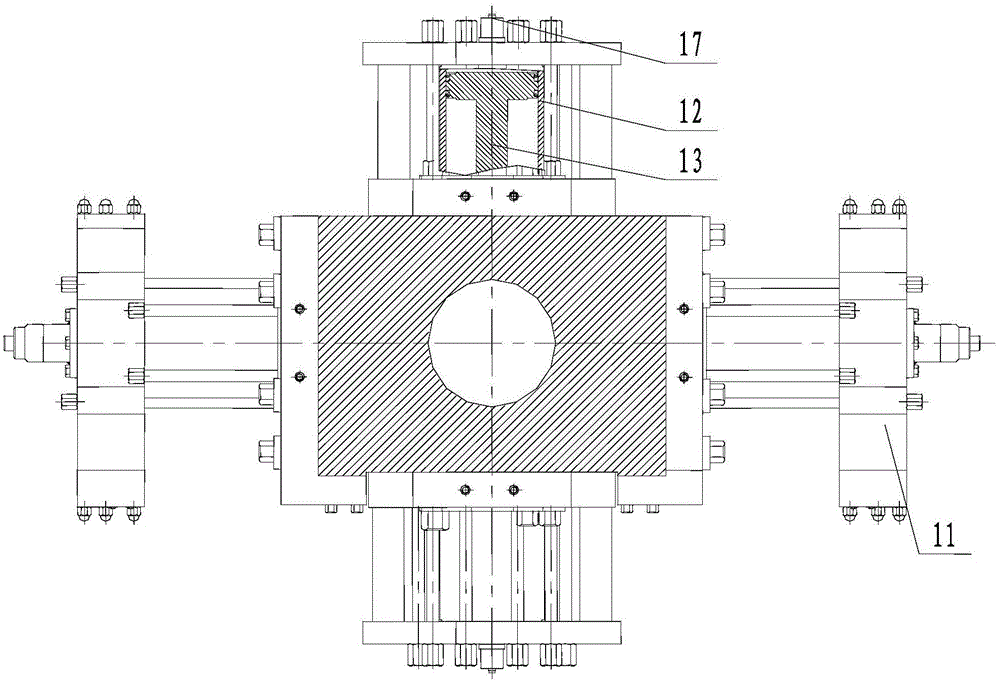

Pressure control device for continuous circulating drilling

InactiveCN106285528AStable pressureEliminate pressure fluctuationsFlushingHydraulic cylinderWell drilling

The invention discloses a pressure control device for continuous circulating drilling. The pressure control device for continuous circulating drilling comprises a body, a through hole for allowing a drill rod to penetrate through is formed in the middle of the body, four rams are further installed in the through hole of the body, each ram is formed by splicing two half rams of the symmetrical structure, and each half ram is driven by a hydraulic cylinder. The four rams comprise the blind ram, the slip ram, the bearing ram and the pipe ram sequentially from top to bottom, wherein the blind ram, the bearing ram and the pipe ram are arranged in parallel, and the slip ram and the bearing ram are crossed by 90 degrees. The pressure control device can reduce pressure fluctuation of a wellhead when single-joint unit or three-joint unit connection and disconnection circulation stops or starts, keep the pressure of the wellhead stable, and can ensure that the formed well wall does not collapse to the greatest extent, drilling accidents are greatly reduced, and the risks of circulation loss, stratum cracking, well kick, pressure differential sticking, and jamming of a drill bit or bottom drill combination are greatly reduced.

Owner:CNPC BOHAI DRILLING ENG

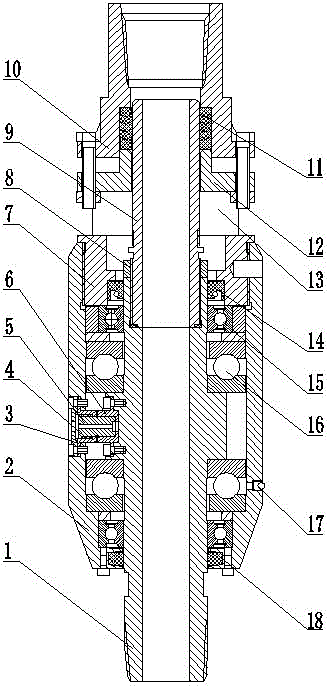

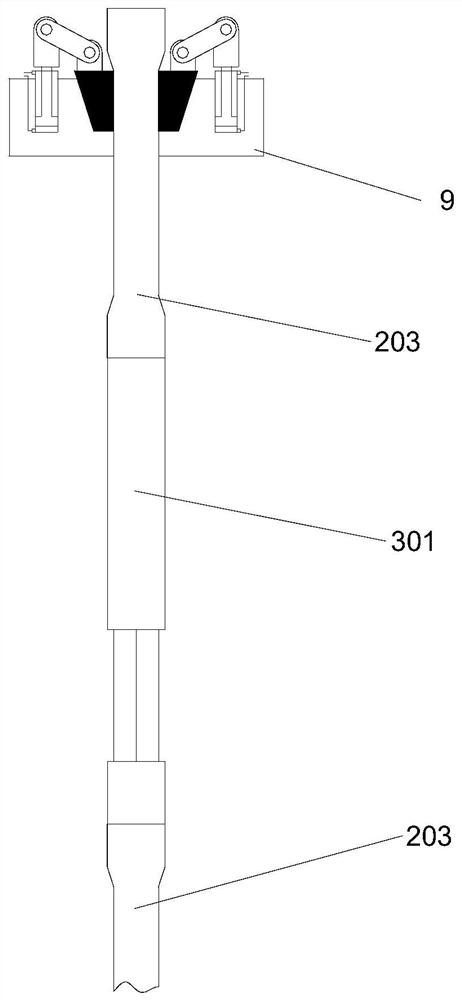

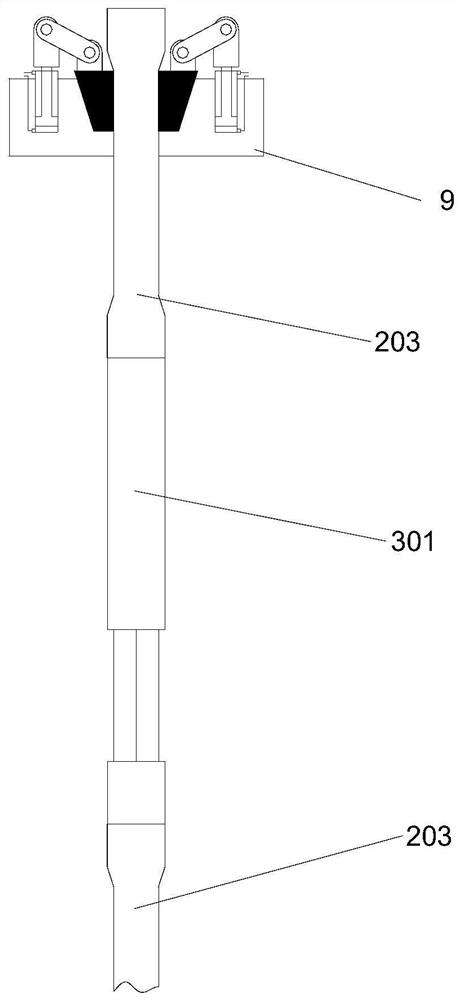

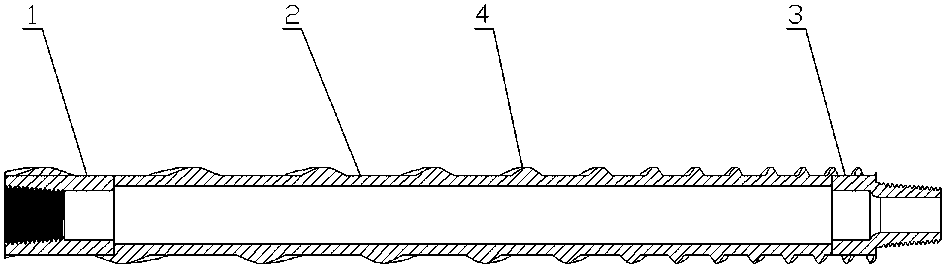

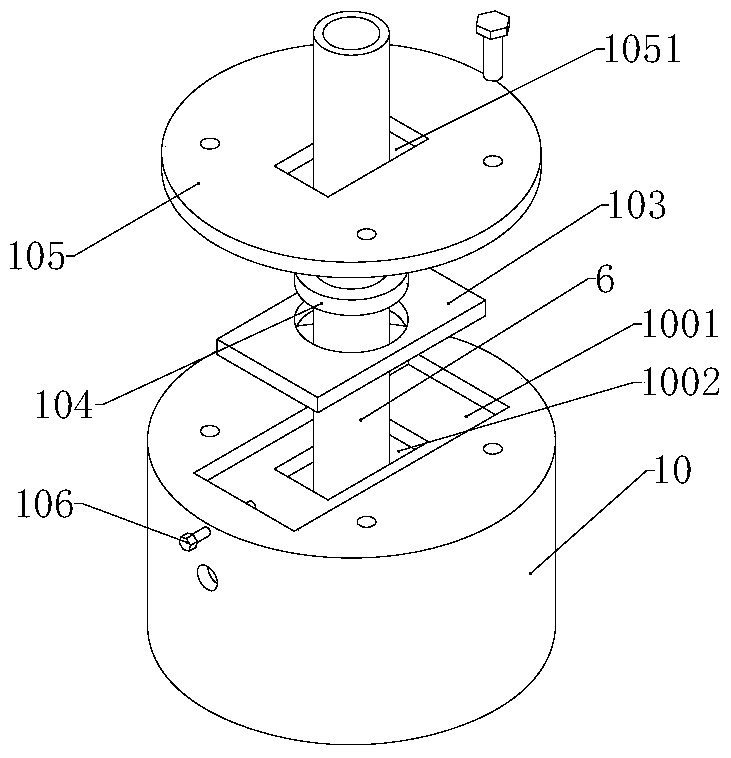

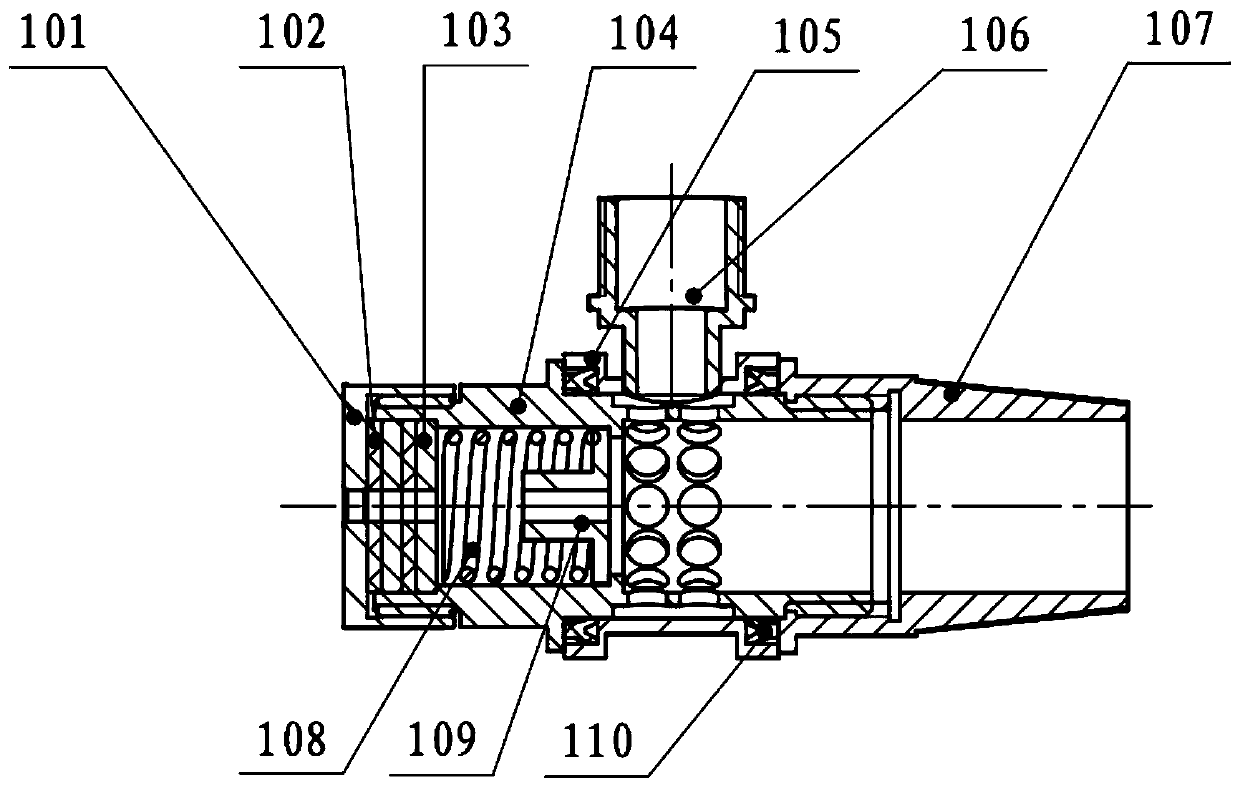

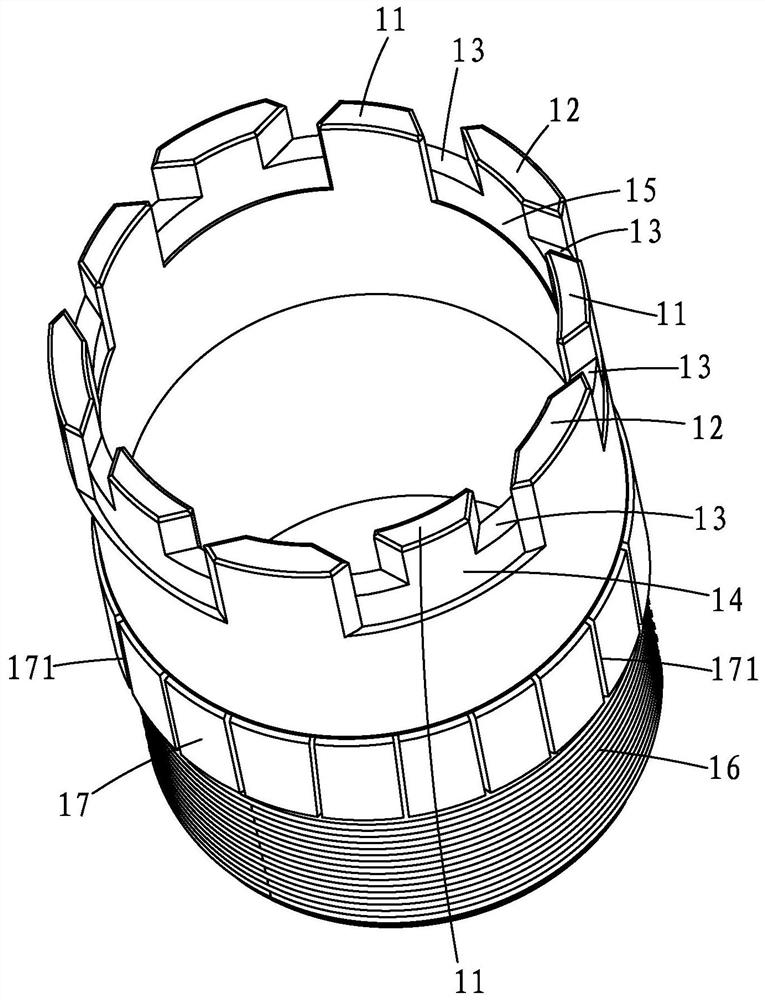

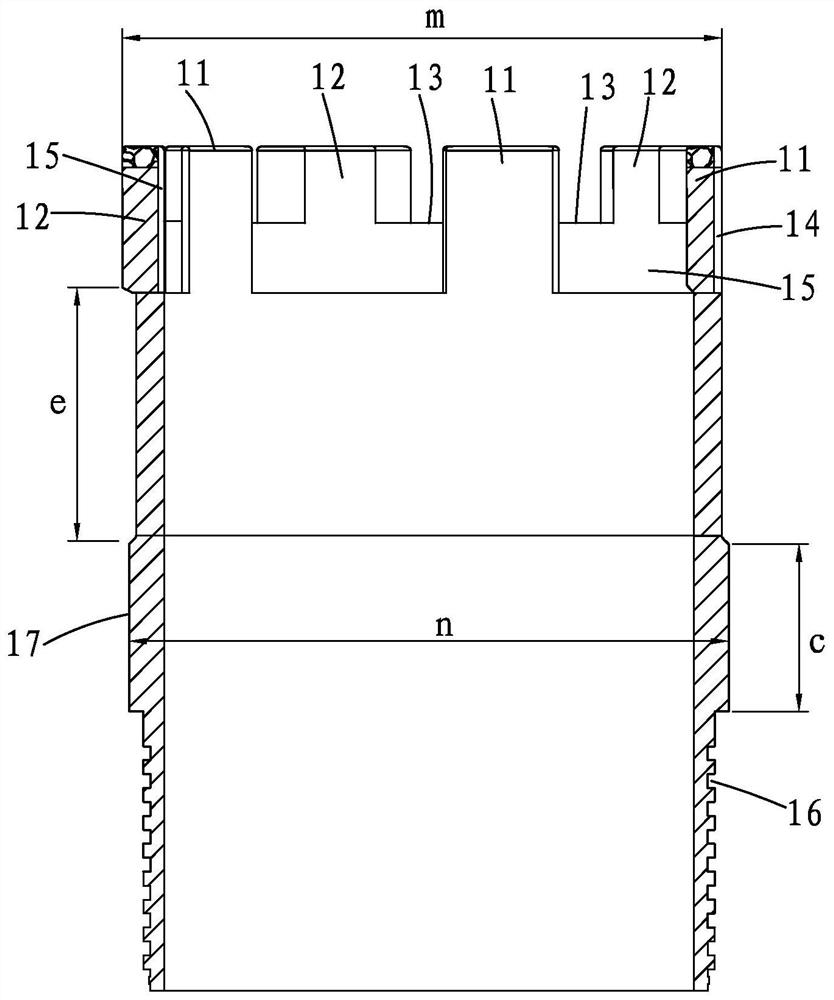

Core drill output torque upper control limit drill rod

ActiveCN104481418AReduce weightSimple structureDrilling rodsDrilling casingsGeological explorationTorque transmission

Disclosed is a core drill output torque upper control limit drill rod. The core drill output torque upper control limit drill rod comprises a core pipe, a joint is arranged on the upper portion of the core pipe, a rotating sleeve sleeves the middle of the core pipe, a torque transmission bar is disposed between the rotating sleeve and the core pipe, and a ring of circular arc groove which is used for disconnection when the core drill output torque is larger than the maximum bearing torque of a downhole drill rod is designed in the middle of the torque transmission bar. By means of the circular arc groove in the middle of the torque transmission bar, a torque transmission relation between a core drill active drill rod and the downhole drill rod is disconnected when the core drill output torque is larger than the maximum bearing torque of the downhole drill rod, the core drill active drill rod continues to rotate and the downhole drill rod stops rotating, and thereby, bearing torque overload protection of the downhole drill rod can be achieved. The core drill output torque upper control limit drill rod has the advantages that the weight is small, the structure is simple, assembly and disassembly are convenient, downhole drill rod breaking accidents caused by excessively large drill output torque can be effectively avoided, the construction costs are lowered, and the core drill output torque upper control limit drill rod is applicable to deep hole geological exploration engineering.

Owner:H H DRILL TECH DRILLING MACHINERY CO LTD

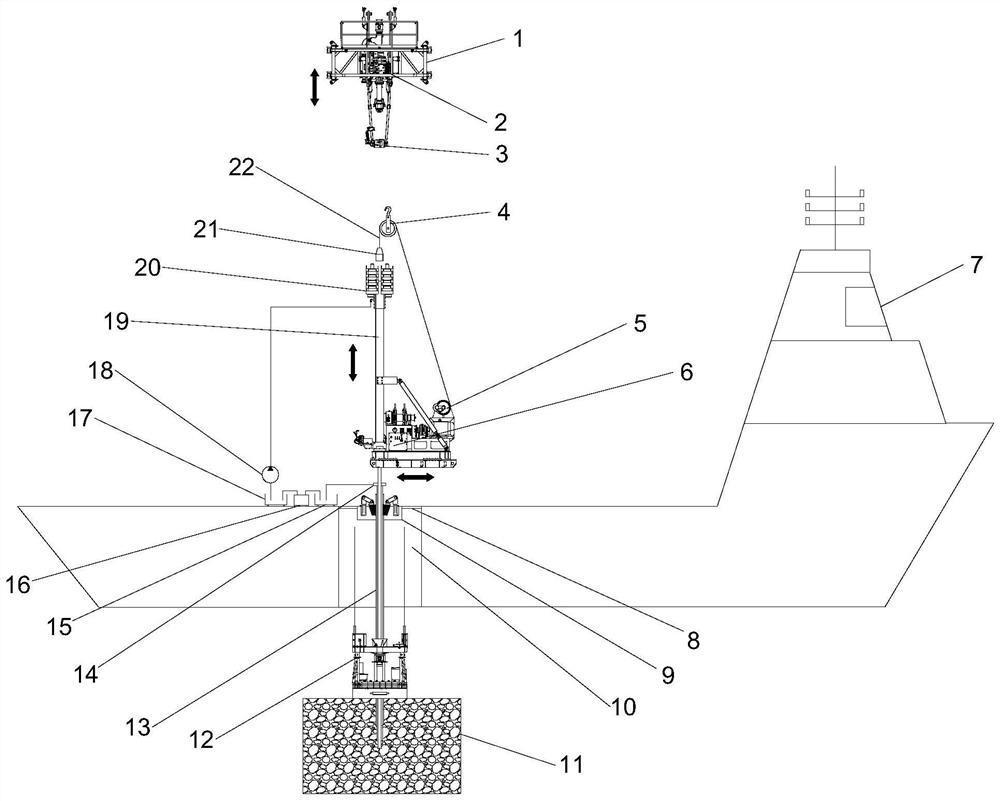

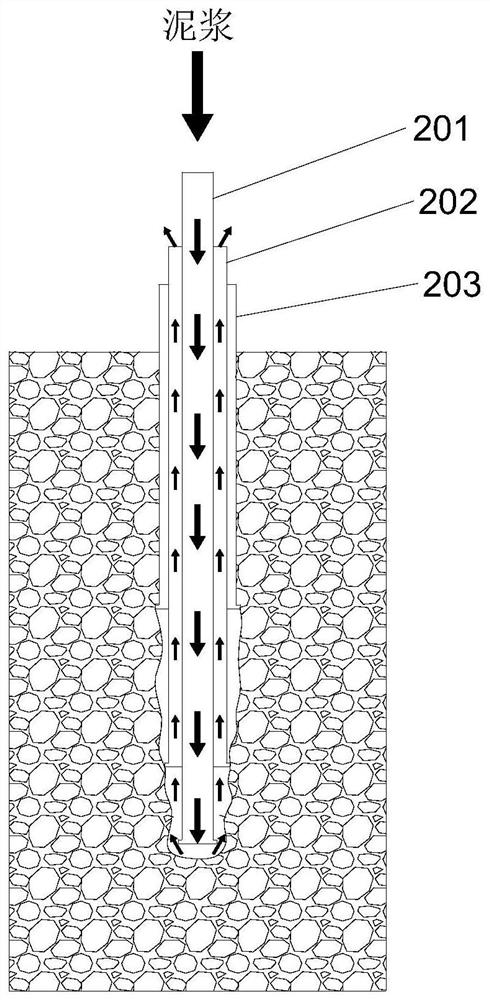

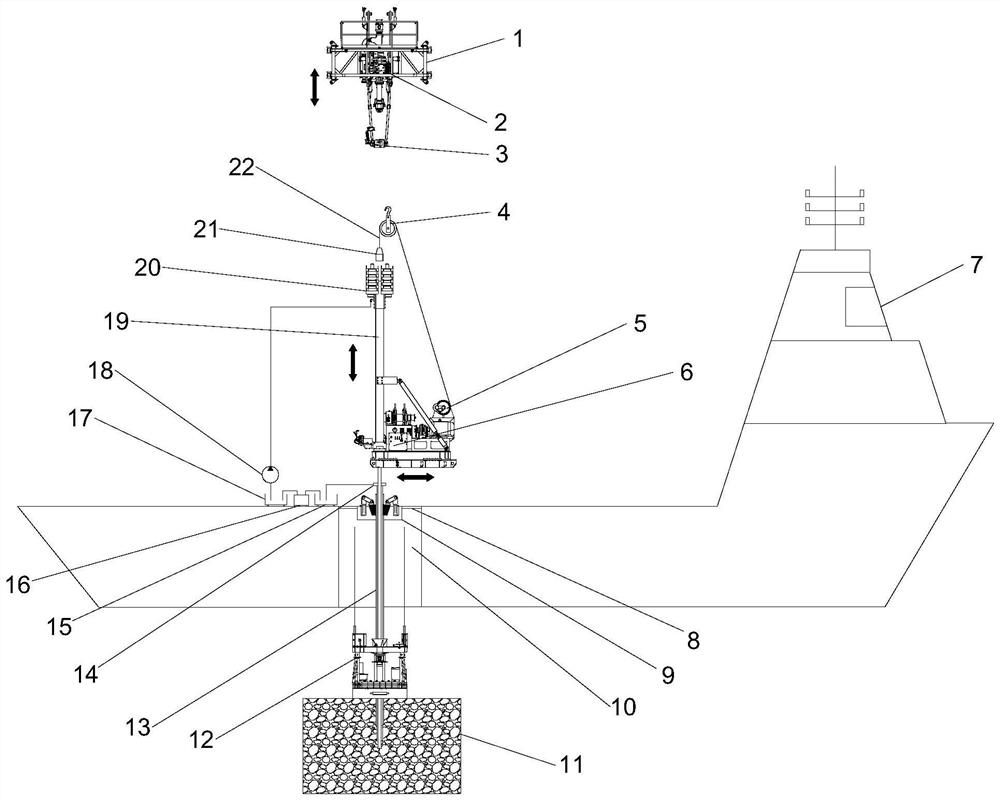

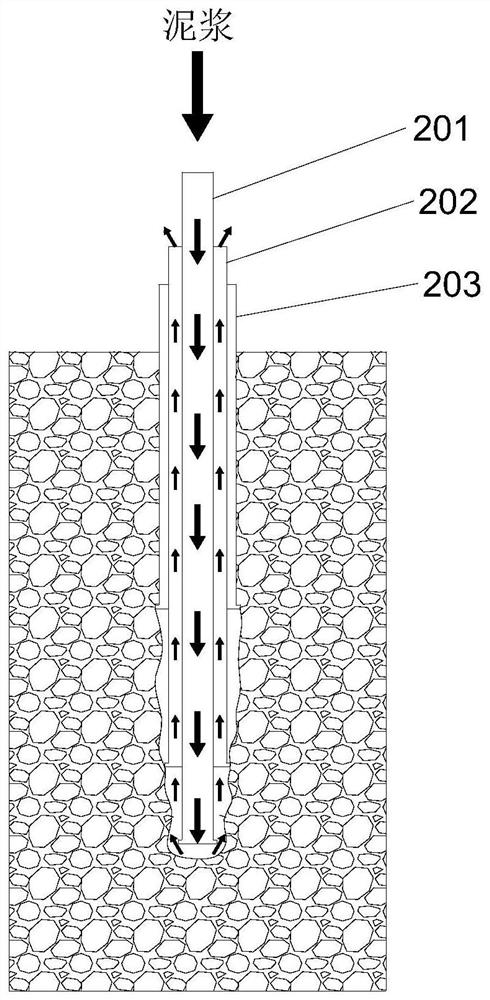

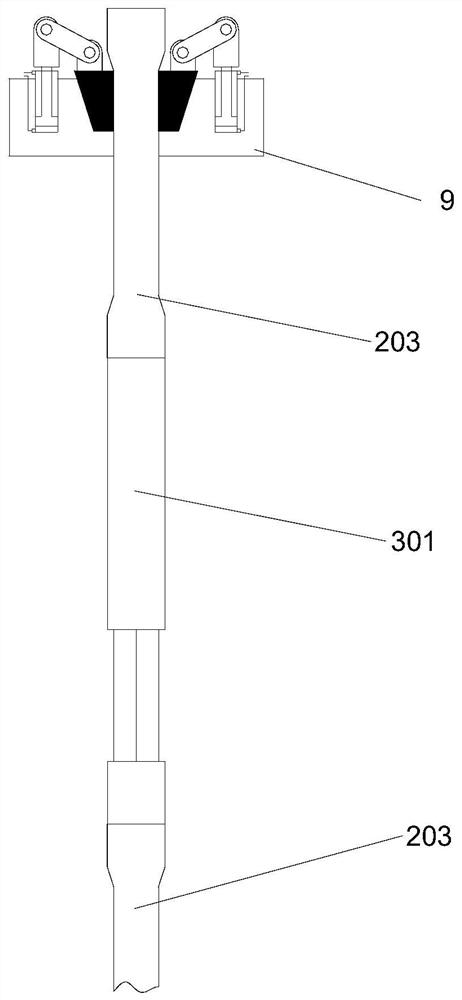

Offshore casing surge compensation dual-drive three-layer casing drilling and coring method

ActiveCN113914802AAvoid Drilling AccidentsDrilling is stable and reliableDrilling rodsFlushingWellheadSoil science

The invention discloses an offshore casing surge compensation dual-drive three-layer casing drilling and coring method. The method comprises the following steps that a drilling ship is positioned at set longitude and latitude coordinates through a dynamic positioning system, a drilling rod is stabilized through a seabed base plate, torque and drilling pressure are transmitted through wellhead casing surge compensation, and during casing drilling, water depth changes caused by rising tide, falling tide or surges can be compensated within a certain range through surge compensation, a sleeve is prevented from colliding with equipment, wellhead operation safety is guaranteed, three-layer sleeve drilling is achieved through double driving heads, the well wall is effectively protected, the drilling sampling coring rate is high, and the coring quality is good. Compared with a common drilling method, the method has the advantages of high drilling efficiency, high coring rate, simple equipment, high reliability, low cost and the like, and is not only suitable for shallow drilling of common sedimentary rock stratums, but also suitable for stratums difficult to core, such as reef limestone stratums and sandy soil stratums.

Owner:GUANGZHOU MARINE GEOLOGICAL SURVEY

Petroleum drilling real-time monitoring system

InactiveCN102828747BViscosity is accurate in real timeAccurate viscositySurveyDisplay devicePetroleum

The invention provides a petroleum drilling real-time monitoring system which comprises a drilling liquid performance monitoring instrument, a geological logging monitoring instrument and a drilling engineering parameter monitoring instrument, wherein sensors are arranged on all the instruments; the sensors are used for transmitting a detecting signal to computer processing equipment through a wireless transmitting and receiving system, and the detecting signal is processed through the computer software and then converted into a chart to be displayed through a display in real time. With the adoption of the petroleum drilling real-time monitoring system, the shortcomings of the comprehensive logging instrument that only the geological logging and drilling engineering parameters can be monitored can be overcome; the drilling liquid performance can be monitored online in real time, so that the drilling liquid, the drilling engineering and the geological logging can be integrated and processed through a computer, and then a comprehensive system integrating the acquiring, displaying and processing of various data at a drilling site can be formed; the comprehensive system can meets the various demands of safely optimizing the drilling and comprehensively determining an oil-gas-water layer.

Owner:韩文峰

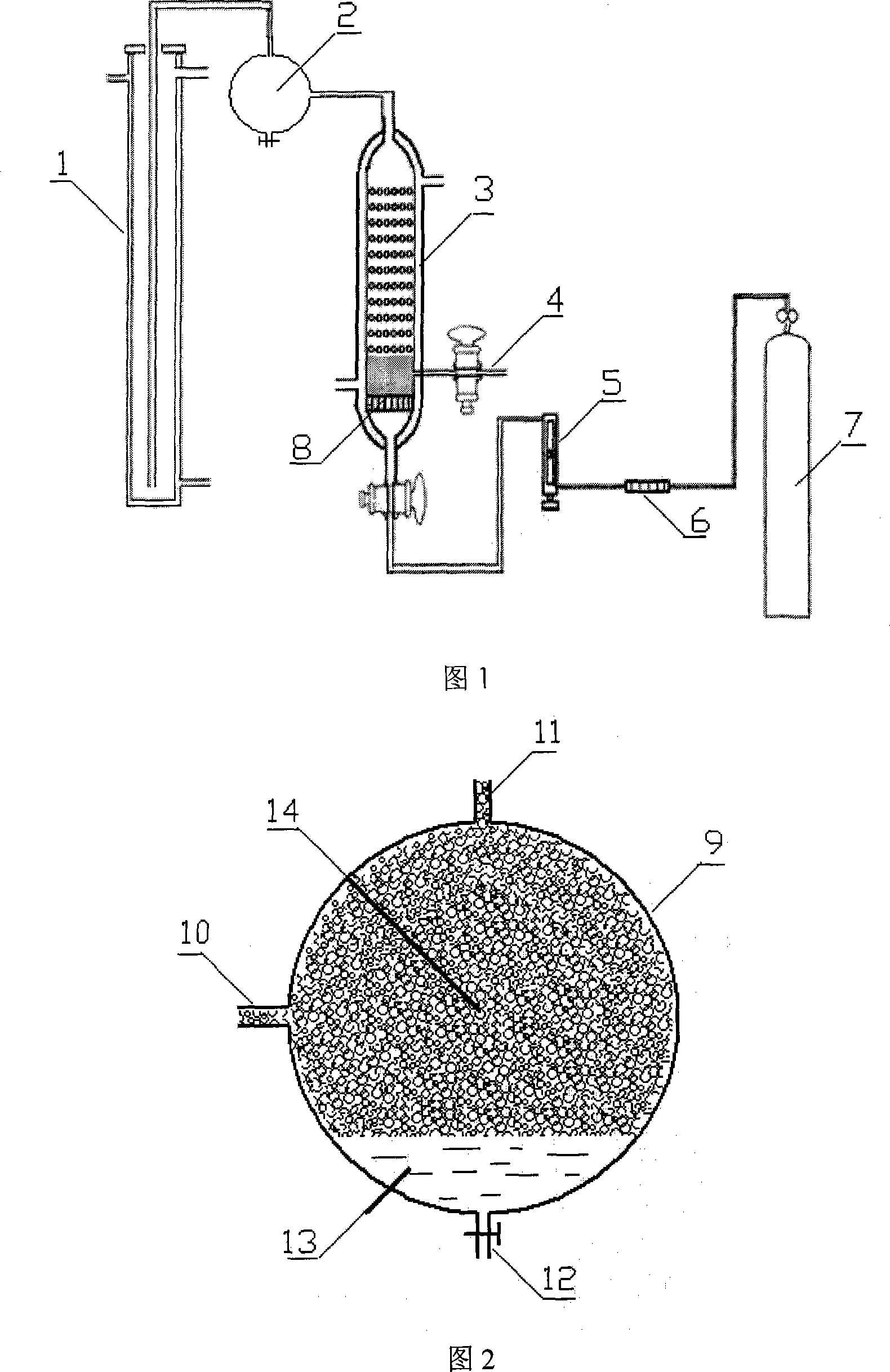

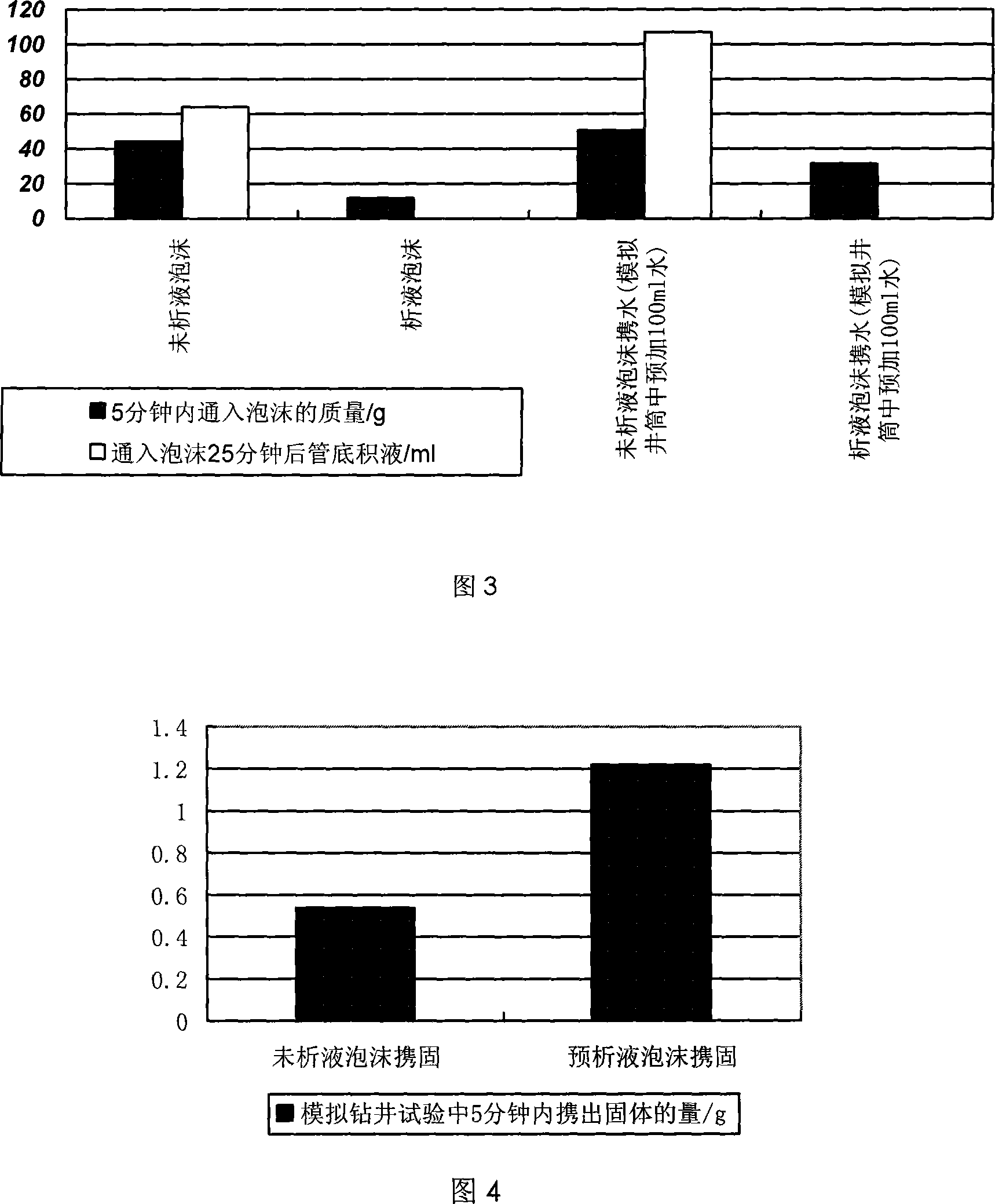

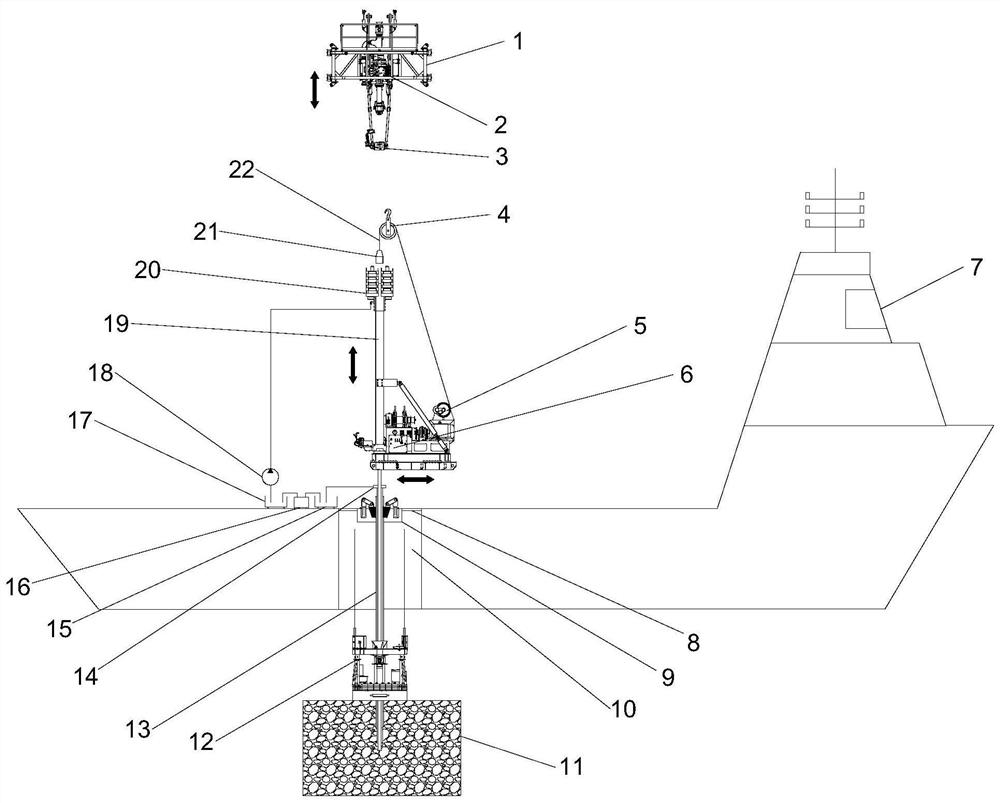

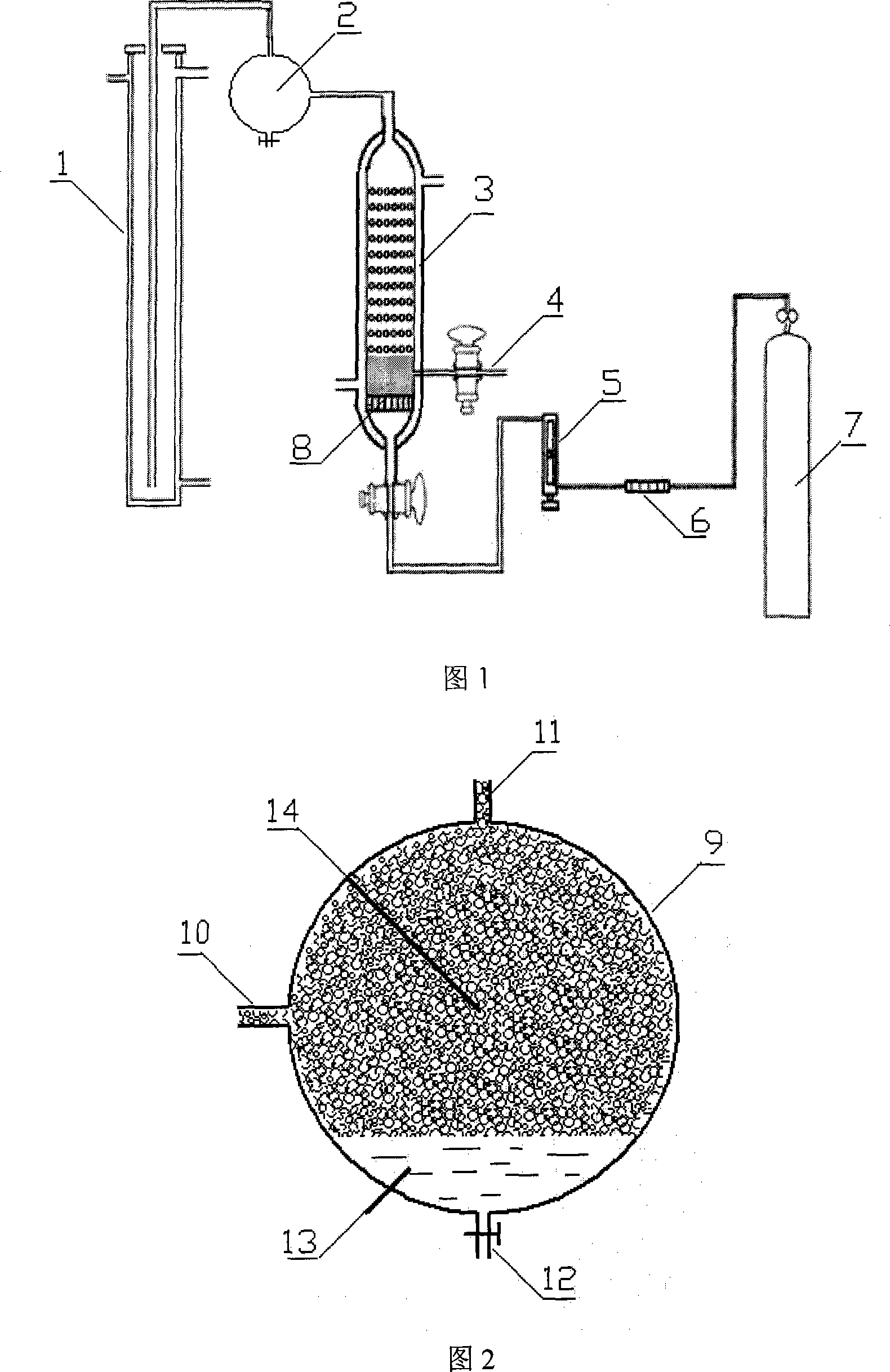

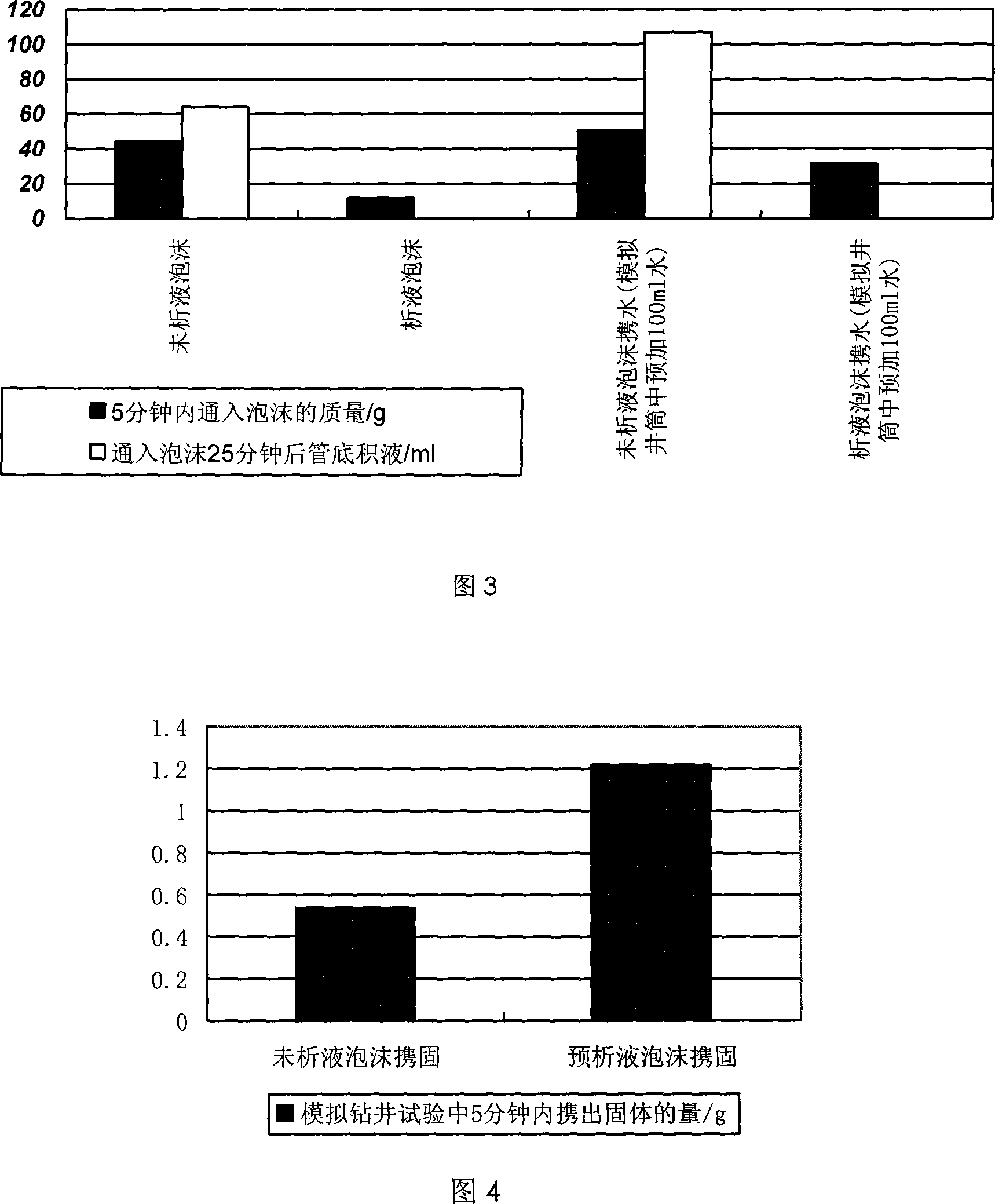

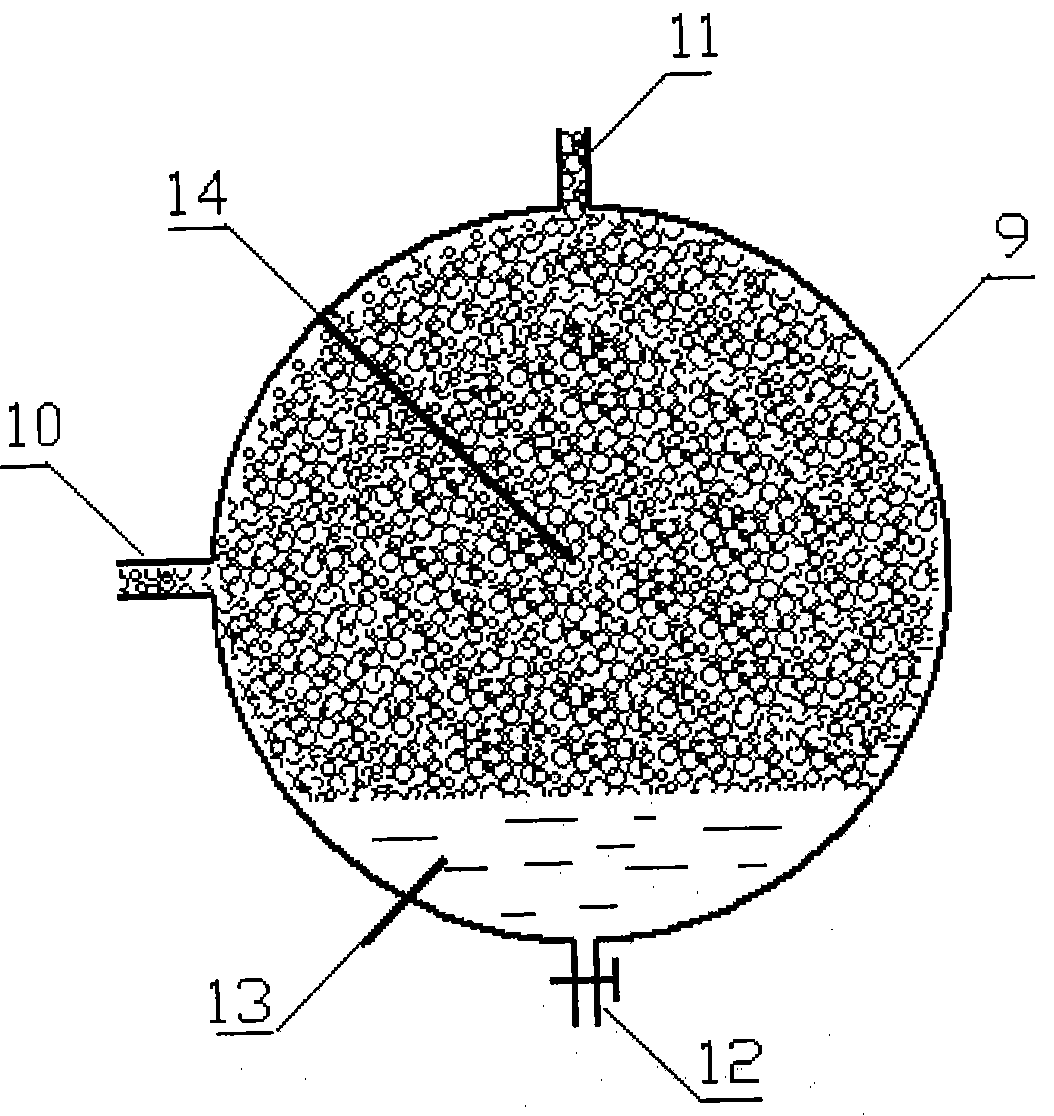

Method for improving foam well drilling efficiency by foam pre-evolution liquid device

InactiveCN101220733AQuick water carry outAvoid Drilling AccidentsFlushingDrilling compositionPorous mediumActive agent

The invention provides a method which utilizes a foam pre-dialyzing liquid device to improve the efficiency of foam drilling and belongs to the technical field of petroleum drilling. The concrete method is as follows: 1) nitrogen or air flow passes a porous medium sand core to mix with a foam base solution containing the active ingredient of interfacial active agent to produce continuous foam and get the fresh foam with the dryness of 45-60%; 2) the fresh foam with the dryness of 45-60% is sent into the pre-dialyzing liquid device, and the pre-dialyzing liquid device reduces the motion speed of the foam, and a large amount of mobile water carried in the foam is separated out by the gravity action and the pre-dialyzing liquid dry foam with the dryness of 75-95% is acquired; 3) the dry foam of the pre-dialyzing liquid is sent into a well bore to take out the water and the solid matters such as drill chips in the well bore. The invention can rapidly take out the strata water in the well, and the bottom of the well has no residual liquid, which can avoid the occurrence of drilling accidents.

Owner:SHANDONG UNIV

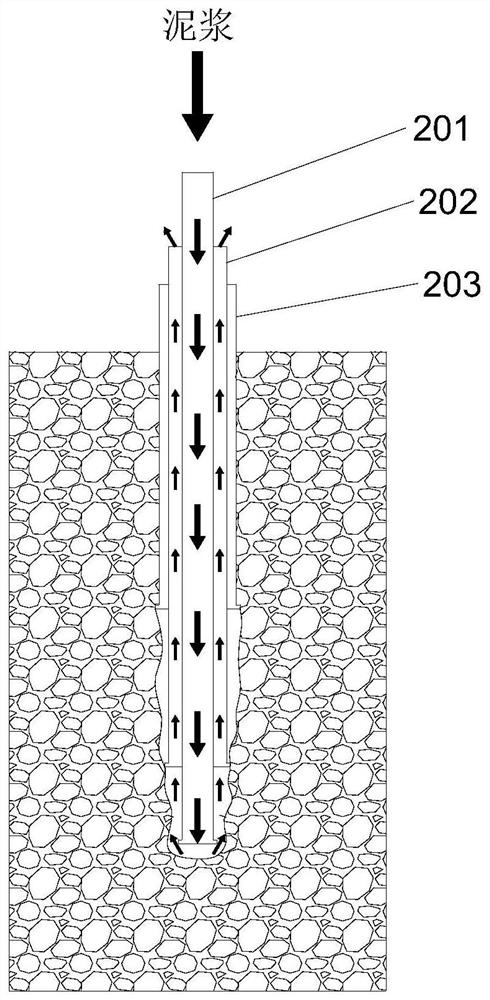

Offshore casing surge compensation dual-drive three-layer casing drilling and coring device

PendingCN113914803AAvoid Drilling AccidentsDrilling is stable and reliableDrilling rodsFlushingDrilling systemGeotechnical engineering

The invention discloses an offshore casing surge compensation dual-drive three-layer casing drilling and coring device. The device comprises a drilling ship with a dynamic positioning system, a drilling tool system, an outer casing drilling system, an inner sleeve and drill rod drilling system and a mud circulating system; the drilling tool system comprises an outer sleeve, an inner sleeve, a drilling rod and a surge compensator; the outer casing drilling system comprises a traveling block mounted on the tower, a top drive mounted on the traveling block and a hydraulic elevator mounted on the top drive; the inner sleeve and drill rod drilling system comprises a vertical shaft type drilling machine and a winch; and the mud circulating system comprises a mud recycling pool, a mud filter, a mud pool and a mud pump which are installed on a deck. The drilling and coring device has the advantages of being high in drilling efficiency, high in coring rate, simple in equipment, high in reliability, low in cost and the like, and is not only suitable for general sedimentary rock stratum shallow drilling, but also suitable for stratums difficult to core, such as reef limestone stratums and sandy soil stratums.

Owner:GUANGZHOU MARINE GEOLOGICAL SURVEY

An underground gasification method for steeply inclined coal seams with a dip angle greater than 70° and a coal thickness less than 5m

ActiveCN112963137BAvoid the danger of collapseMake up for the lack of miningConstructionsFluid removalThermodynamicsCoalbed methane

The invention discloses an in-situ underground gasification method for coal seams with a coal seam dip angle greater than 70° and a coal seam thickness less than 5 m; Arrangement of gasification pipeline and ignition device, underground gasification operation and other steps. The present invention drills and excavates the underground coal seam through the method of underground gasification, transforms the area to be mined into multiple coal gasifiers, and reduces a series of complicated problems caused by the huge inclination angle of the coal seam in traditional mechanized coal mining. The risk of the process and operation and the waste of coal resources, and the drilling technology can minimize the process of personnel going down the well, so as to achieve automatic coal mining; at the same time, through reasonable pipeline layout, the limitation of the coal seam dip angle caused by the underground gasification in the past has been improved to the greatest extent. It provides a new option for the mining method of steeply inclined coal seams with an inclination angle greater than 70° in the future.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

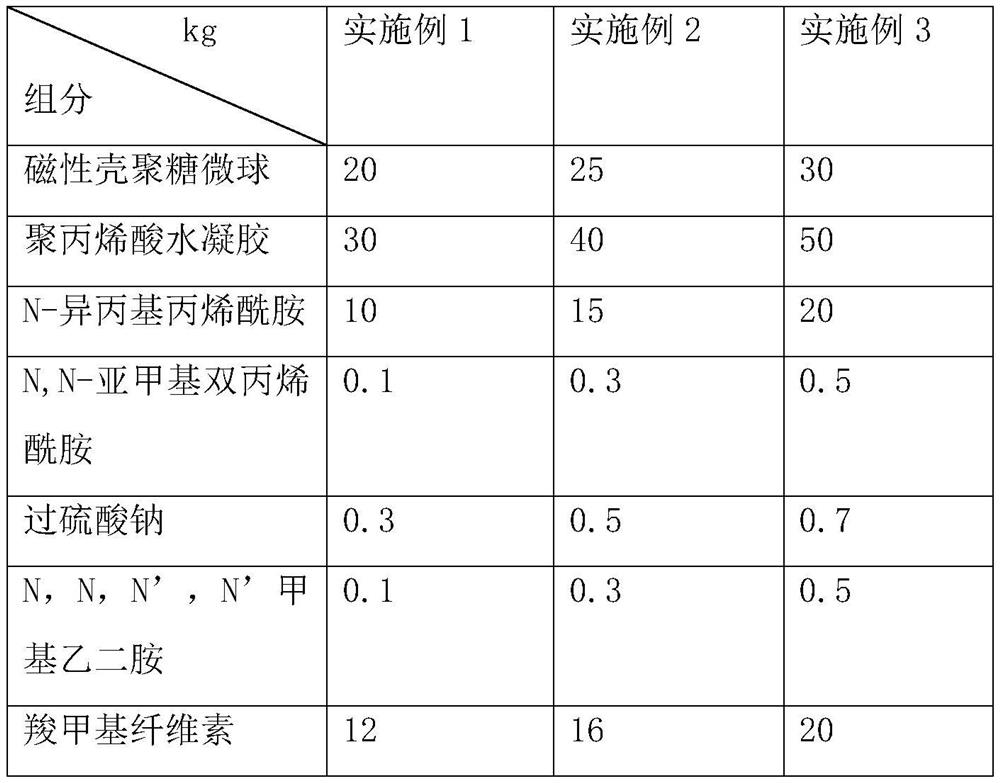

Hydroxyl film-forming plugging agent for drilling fluid and preparation method thereof

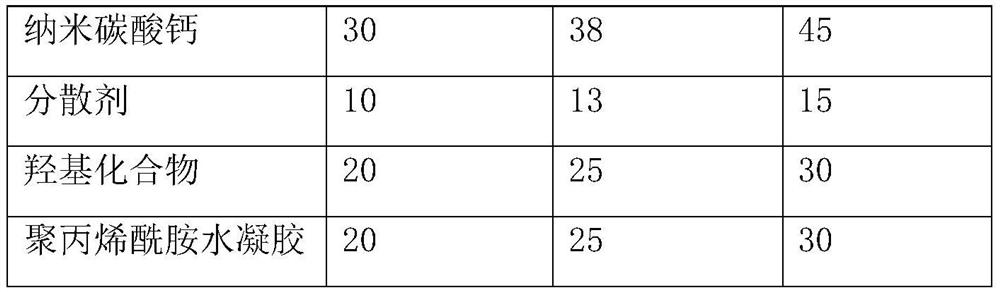

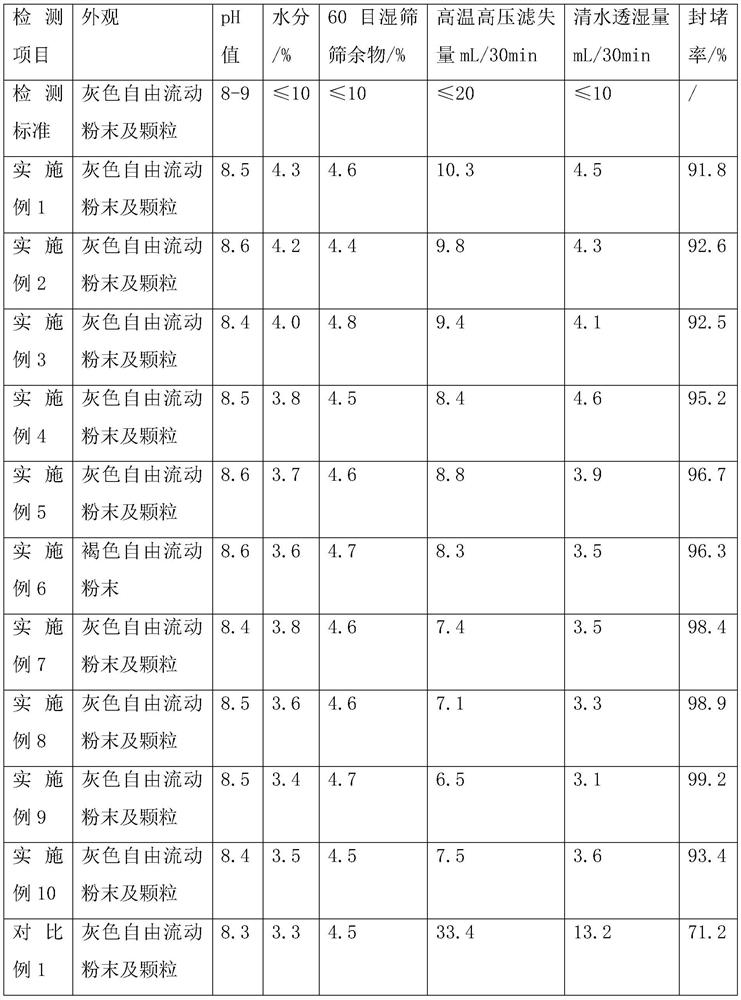

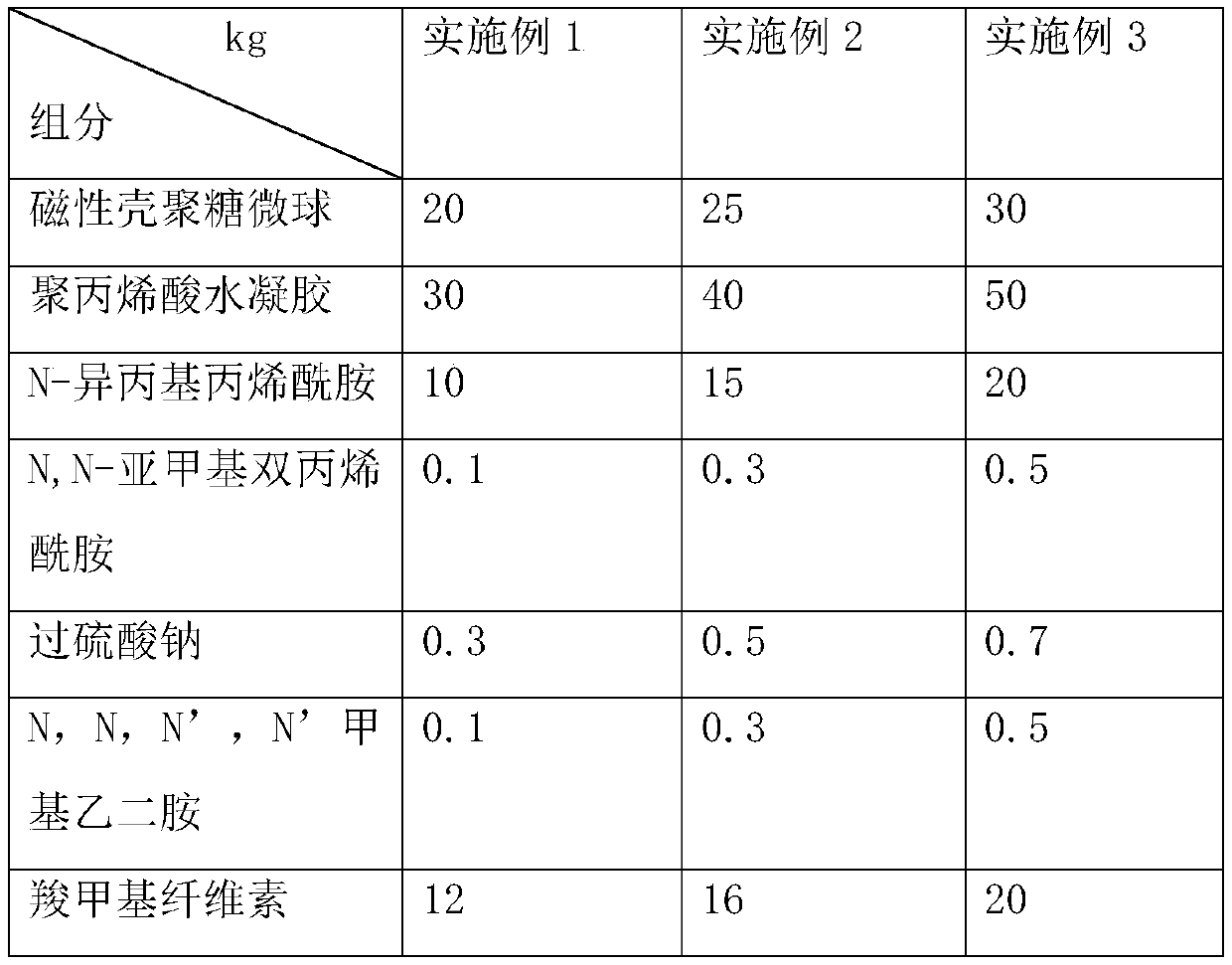

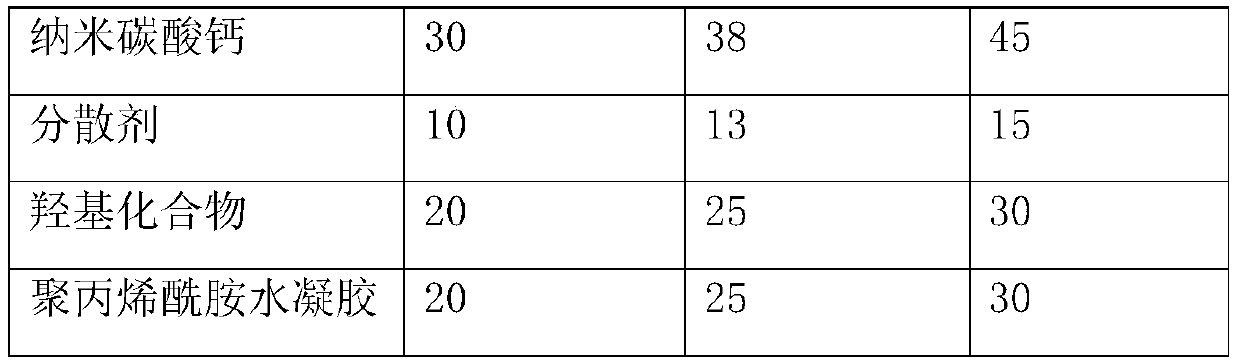

The invention discloses a hydroxyl film-forming plugging agent for drilling fluid and a preparation method thereof. Hydroxyl film-forming plugging agent for drilling fluid includes the following components: magnetic chitosan microspheres, polyacrylic acid hydrogel, N-isopropylacrylamide, N,N-methylenebisacrylamide, sodium persulfate, N, N, N', N'-tetramethylethylenediamine, carboxymethyl cellulose, nano calcium carbonate, dispersant, hydroxyl compound, polyacrylamide hydrogel; hydroxyl compound includes complex alcohol GPH‑II, Nano silica, polyhydroxy resin WN2‑1 and polyanionic cellulose. The hydroxyl film-forming plugging agent for drilling fluid of the present invention has the advantages of reducing fluid loss, stabilizing the well wall, avoiding pipe sticking due to pressure difference, strong ability to carry debris in suspension, good rheology and plugging effect, and capable of deforming and plugging nanopores of shale With micro-cracks, it is non-toxic, does not pollute the environment, does not pollute the formation, and has the advantages of good compatibility.

Owner:北京宏勤石油助剂有限公司

Hydroxyl film-forming plugging agent for drilling fluid and preparation method thereof

ActiveCN111471439APrevent infiltrationImprove salt toleranceDrilling compositionMeth-Polyacrylamide Hydrogel

The invention discloses a hydroxyl film-forming plugging agent for drilling fluid and a preparation method of the hydroxyl film-forming plugging agent. The hydroxyl film-forming plugging agent for thedrilling fluid is prepared from the following components: magnetic chitosan microspheres, polyacrylic acid hydrogel, N-isopropylacrylamide, N, N-methylene bisacrylamide, sodium persulfate, N, N, N ',N'-tetramethylethylenediamine, carboxymethyl cellulose, nano calcium carbonate, a dispersing agent, a hydroxyl compound and polyacrylamide hydrogel; wherein the hydroxyl compound is prepared from complexing alcohol GPH-II, nano silicon dioxide, polyhydroxy resin WN2-1 and polyanionic cellulose. The hydroxyl film-forming plugging agent for the drilling fluid has the advantages of reducing the filter loss, stabilizing the well wall, avoiding differential pressure jamming, being high in suspension chip-carrying capacity, good in rheological property and plugging effect, capable of deforming to plug shale nanopores and microcracks, non-toxic, free of environmental pollution, free of stratum pollution and good in compatibility.

Owner:北京宏勤石油助剂有限公司

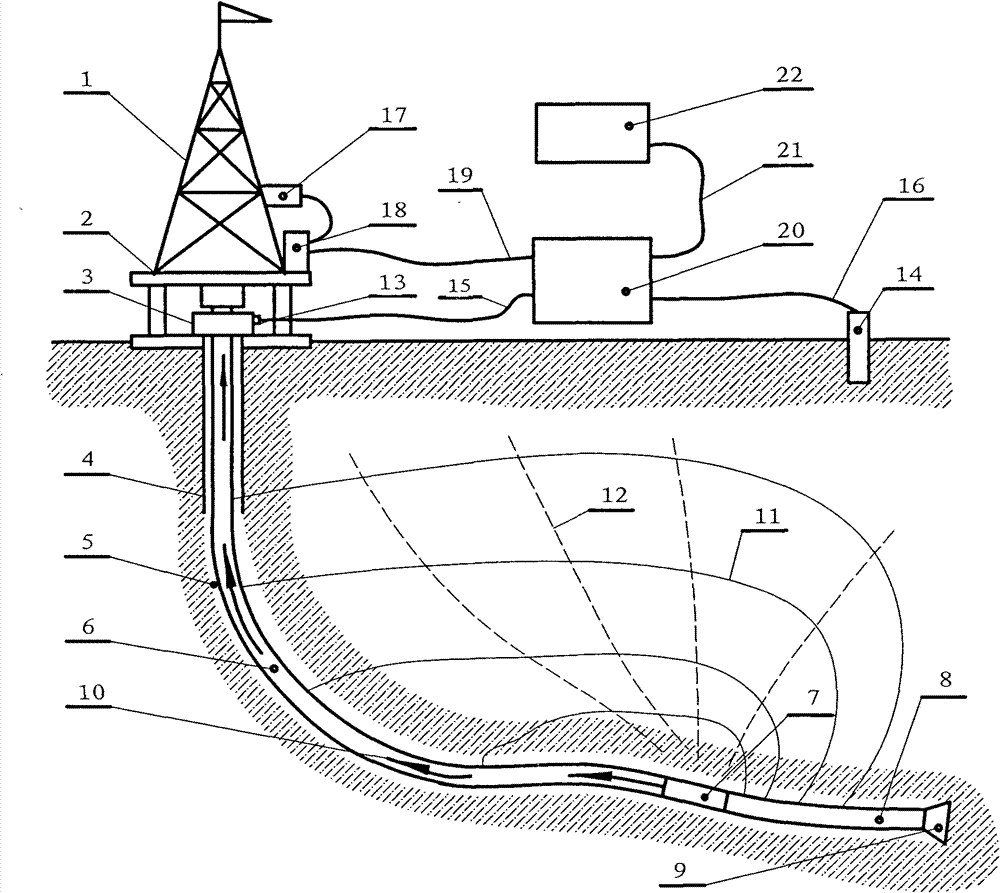

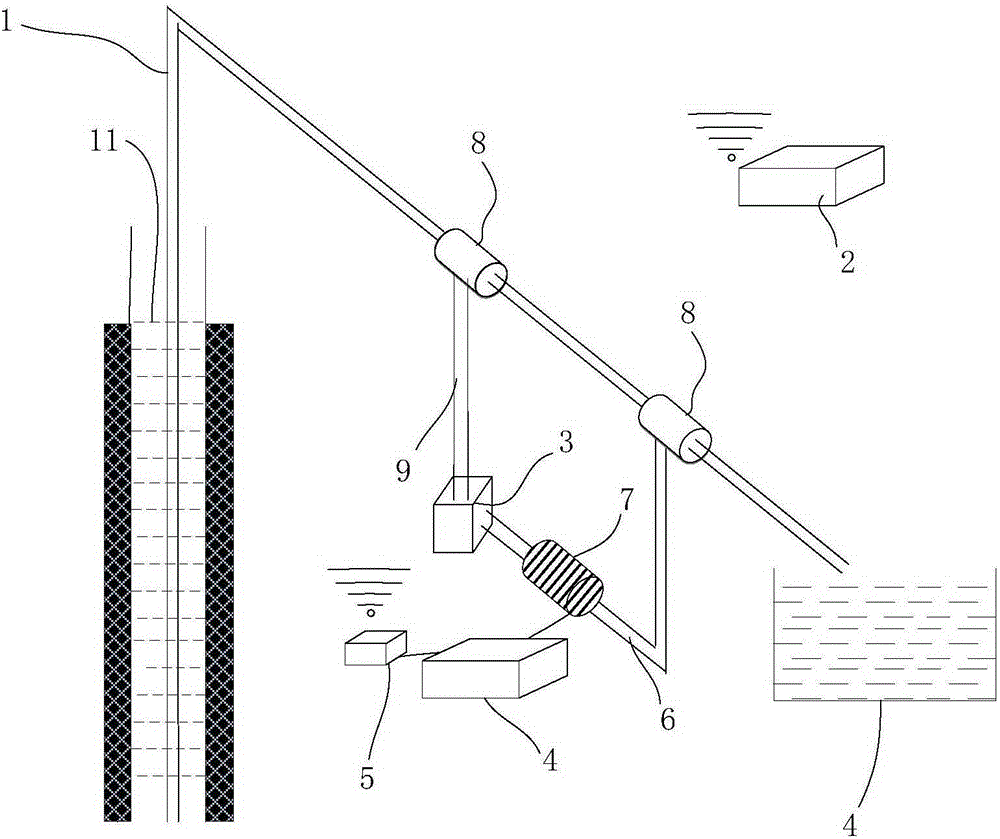

Geometry steerable drilling system driven by liquid and gas phase drilling media rotary disc

InactiveCN101737009BFacilitate the control of selective crossingAvoid formingSurveyConstructionsElectrical conductorGas phase

The invention relates to a geometry steerable drilling system driven by a liquid and gas phase drilling media rotary disc, which comprises two parts i.e. a ground part and an underground part, wherein the ground part consists of a derrick, a drilling floor, a blowout prevention device, a blowout prevention device electrode, a ground electrode, an electrical conductor, a vertical pipe pressure sensor, a drilling floor driller display, a drilling floor communication cable, a signal processing interface box, a standard serial communication cable and a universal computer system; and the underground part consists of an underground while-drilling directional tool and an underground while-drilling directional instrument. The geometry steerable drilling system driven by the liquid and gas phase drilling media rotary disc can use both a pure liquid phase and mixture media of a pure gas phase or the liquid phase, not only can be used for guide drilling of a rotary disc, but also can be used formeasuring a formation natural gamma and the resistivity of the rotary disc while drilling and is suitable for popularizing and applying in petroleum drilling engineering.

Owner:CNPC GREATWALL DRILLING ENG

An electric turntable device for directional drilling and anti-backup pressure and its control method

ActiveCN107013163BControl speed in real timeReal-time control of lapsConstructionsRotary drillingFrequency conversionWell drilling

The invention relates to a directional drilling and back-pressure prevention electric rotating plate device composed of a rotating speed and torque sensor, a frequency conversion and speed regulation system, a rotating plate, a drilling rod, a measurement while drilling (MWD) system and a controller. The rotating speed and torque sensor can feed back the output torque of the rotating plate in the working process of the electric rotating plate. The torque values of the sections of the drilling rod are calculated according to a drilling rod torque calculation model and input to the controller. The speed, forward rotating, reverse rotation and the number of laps of rotation of the rotating plate are adjusted through the frequency conversion and speed regulation system. The MWD system can measure the angle of a tool face, and when the angle of the tool face is larger than a certain numerical value, rotating drilling is turned into sliding drilling, and the direction of sliding drilling is further controlled. The controller is electrically connected with a computer to store data, and communication with other equipment can be achieved. Directional drilling of the electric rotating plate can be achieved, friction resistance and back pressure are reduced, well drilling efficiency is improved, and the directional drilling and back-pressure prevention electric rotating plate device can be widely applied to the petroleum drilling industry.

Owner:QINGDAO JINJIANGYUAN IND EQUIP CO LTD

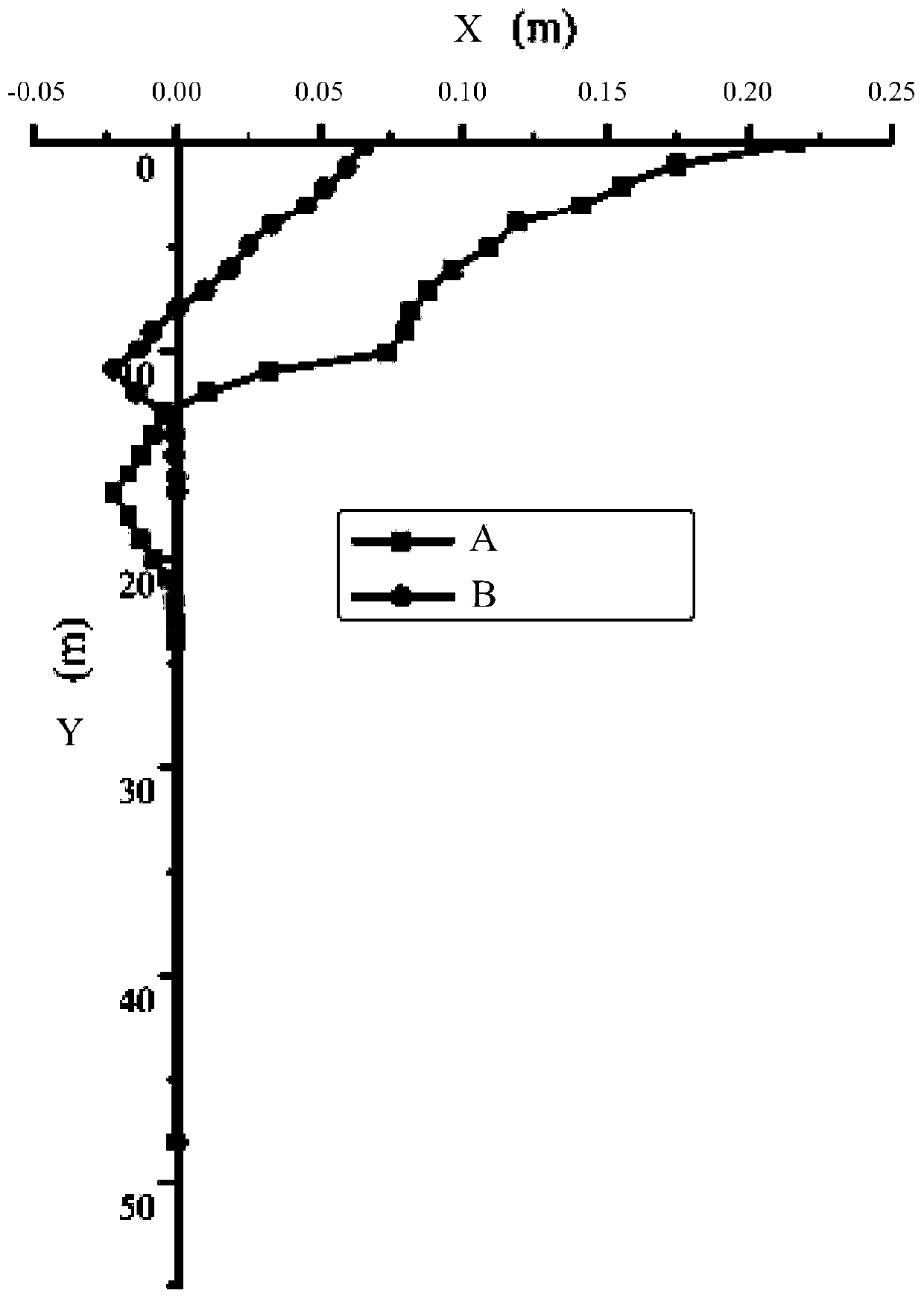

Drilling drill pipe and drilling method for bionic flow pattern resistance reduction in coal and rock formations under complex geological conditions

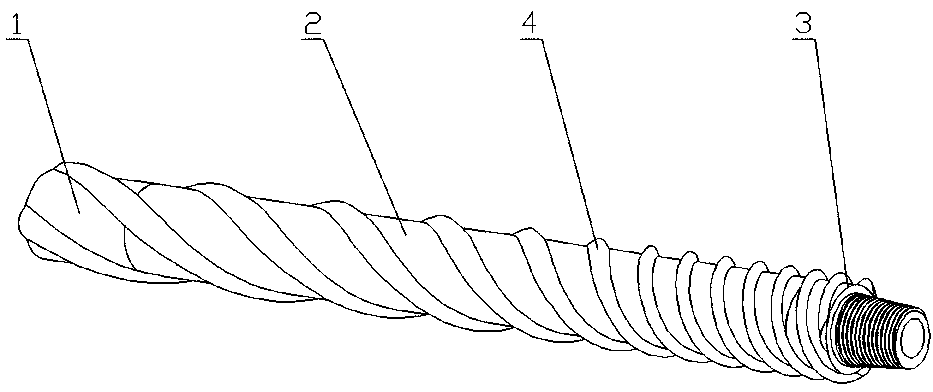

ActiveCN106761451BIncreased drilling depthImprove drilling efficiencyDrilling rodsDrilling casingsUltimate tensile strengthCoal

The invention discloses a bionic flow line resistance reducing drilling rod for coal rock stratum drilling under the complicated geologic condition. The bionic flow line resistance reducing drilling rod comprises a bionic concave connecting piece, a bionic hollow rod body and a bionic convex connecting piece. The surfaces of the bionic concave connecting piece, the bionic hollow rod body and the bionic convex connecting piece are convex bionic flow lines or concave bionic flow lines. The bionic flow lines are arranged to be multi-head variable lead helical structures. According to the rock strength of a construction site, based on the drilling method of the bionic flow line resistance reducing drilling rod for coal rock stratum drilling under the complicated geologic condition, the structure of the bionic flow line resistance reducing drilling rod and drilling process technical parameters are determined. By designing the bionic flow lines of the variable lead helical structure on the surface of the drilling rod, drilling resistance can be effectively reduced, the drilling efficiency and slagging efficiency are improved, drilling hole accidents caused by local heat accumulation in a drilled hole are prevented, and the drilling hole depth and drilling efficiency of a coal rock stratum under the complicated geologic condition are improved.

Owner:HENAN POLYTECHNIC UNIV +1

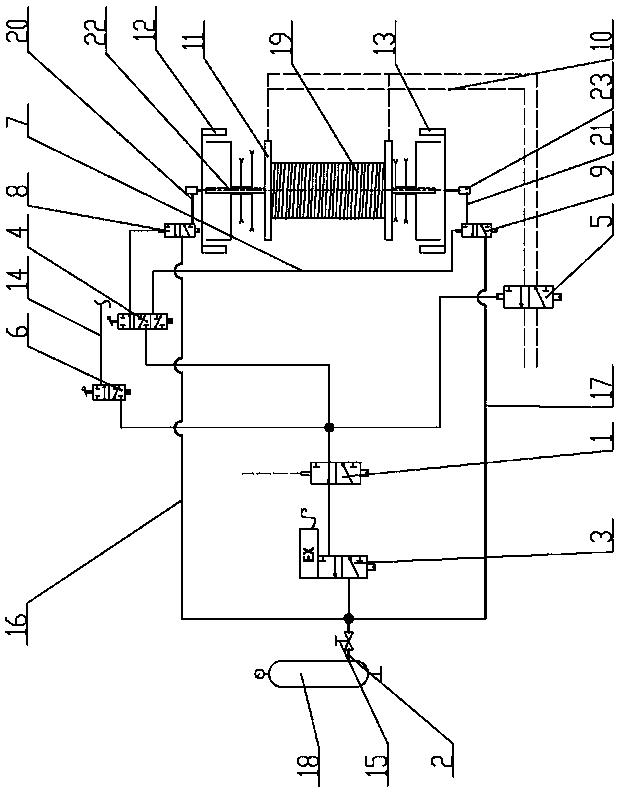

Power-failure protection device used for drilling rig and power-failure protection type drilling rig drum device

PendingCN108374855AImprove securitySimple structureBrake actuating mechanismsCoupling-brake combinationFree fallingLow speed

The invention relates to the technical field of protection devices, and provides a power-failure protection device used for a drilling rig and a power-failure protection type drilling rig drum device.The power-failure protection device used for the drilling rig comprises a normally-open pneumatic control valve, a source gas inlet pipeline, an electromagnetic valve, a high and low speed gas guidevalve, a pneumohydraulic reversing valve, a master clutch gas guide valve, a control gas pipeline, a low-speed pneumatic reversing valve and a high-speed pneumatic reversing valve, wherein an gas outlet of the source gas inlet pipeline is communicated with a first normally-open interface of the normally-open pneumatic control valve through the control gas pipeline, and the electromagnetic valve isarranged in the control gas pipeline. The power-failure protection type drilling rig drum device comprises the power-failure protection device used for the drilling rig, a main drum, a hydraulic pipeline, a third master gas guide pipeline, a fourth master gas guide pipeline and a central shaft. The power-failure protection device is reasonable and simple in structure and convenient to use, by arranging the electromagnetic valve in the control gas pipeline, the drilling rig can be quickly comprehensively braked in an unexpected power failure, drill string not-well braked and free-fall accidents are avoided, the operation safety of the drilling rig is improved, and the power-failure protection device has the advantages of being safe, simple and reliable, and saving labor.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Hydrophobic Modified Polyacrylamide Polymer Suitable as Supramolecular Shear Lifting Agent and Its Application in Water-based Drilling Fluid

ActiveCN110396152BSolving the problem of cuttings deposition in the horizontal sectionAvoid Drilling AccidentsDrilling compositionPolymer scienceStructural unit

The invention relates to the field of drilling in the petroleum industry, in particular to a hydrophobically modified polyacrylamide polymer suitable as a supramolecular cutting agent and its application in water-based drilling fluid. The structural units constituting the polymer are the structural units represented by the following formula (1), the structural units represented by the formula (2), the structural units represented by the formula (3), and the structural units represented by the formula (4); and The polymer has a number average molecular weight of 1 million to 6.5 million. The hydrophobically modified polyacrylamide polymer provided by the present invention has a supramolecular-like structure, and can provide a shearing agent with shear resistance and easy structure recovery by means of intermolecular electrostatic force, hydrogen bond, hydrophobic interaction, etc. .

Owner:中国石油集团川庆钻探工程有限公司钻井液技术服务公司 +1

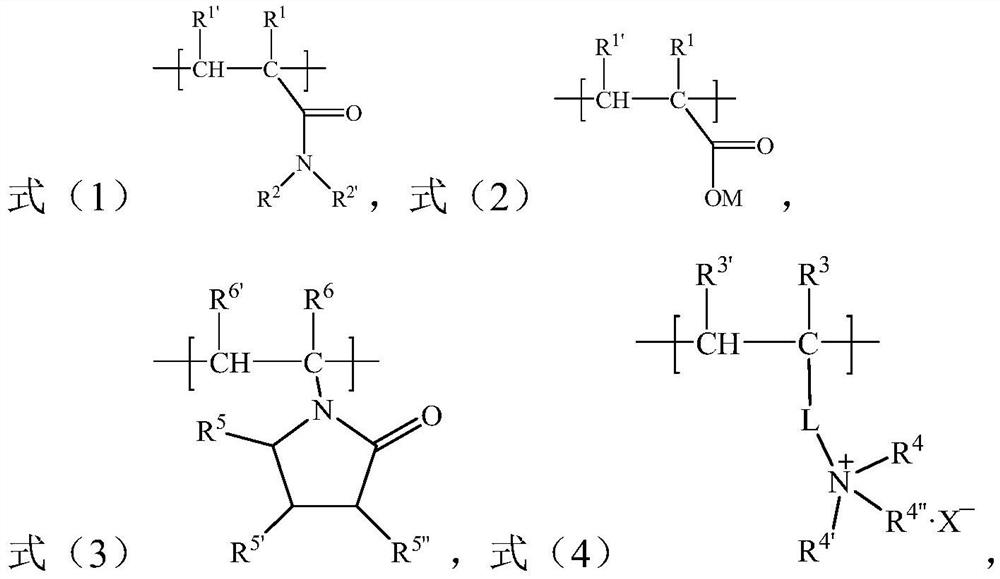

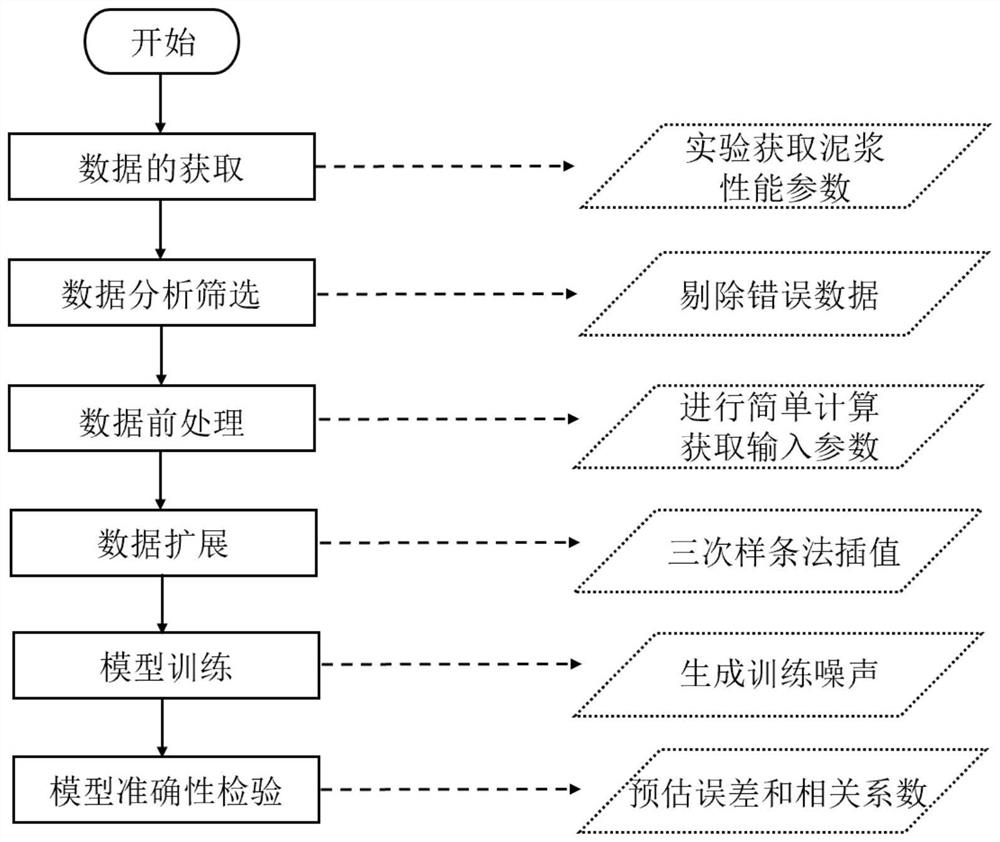

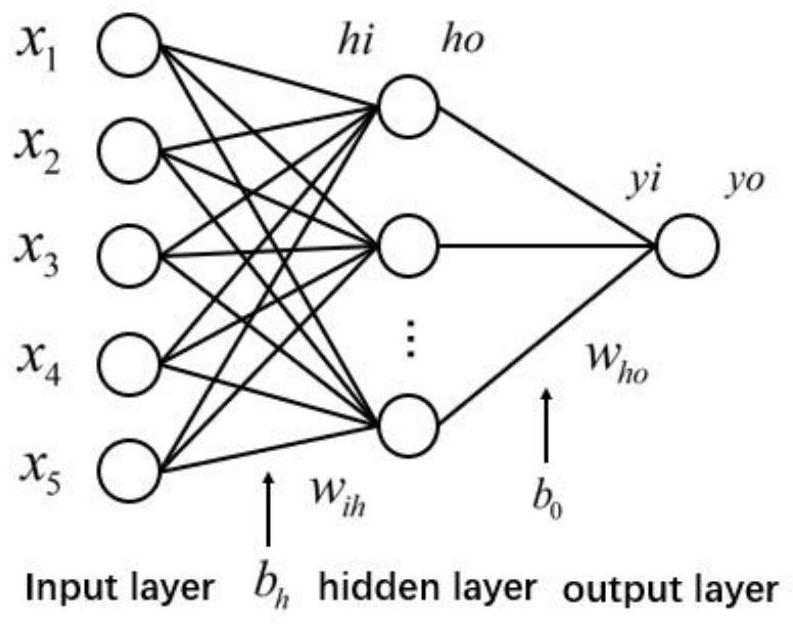

Method and equipment for measuring sand content of drilling fluid based on neural network

ActiveCN114279914AHigh precisionImprove practicalityFlow propertiesParticle suspension analysisData expansionEngineering

The invention provides a method for measuring the sand content of drilling fluid based on an artificial neural network. The method comprises the following steps: collecting performance parameters of a plurality of groups of mud with different sand contents; screening and analyzing performance parameters of the mud, calculating to obtain Heschell-Balkel three parameters according to the screened and analyzed performance parameters, and taking the screened and analyzed performance parameters and the Heschell-Balkel three parameters as input parameters; performing data expansion and division on the input parameters to obtain a training set, a verification set and a test set; constructing an ANN neural network model, and iteratively training and verifying the ANN neural network model by using the training set and the verification set; and evaluating the prediction effect of the trained neural network model by using the test set, and measuring the sand content of the drilling fluid by using the neural network model meeting the preset prediction effect. A small amount of limited existing data is analyzed, processed and expanded to obtain an accurate prediction model.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

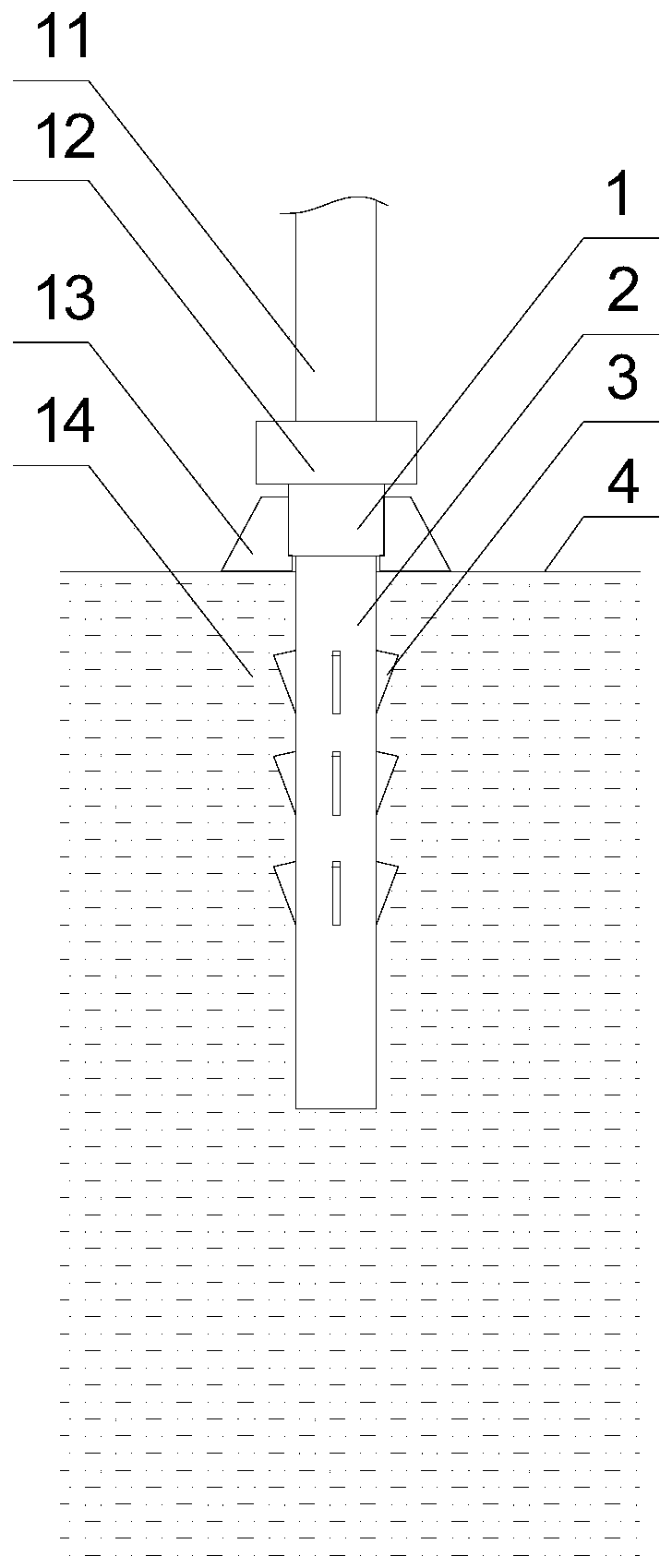

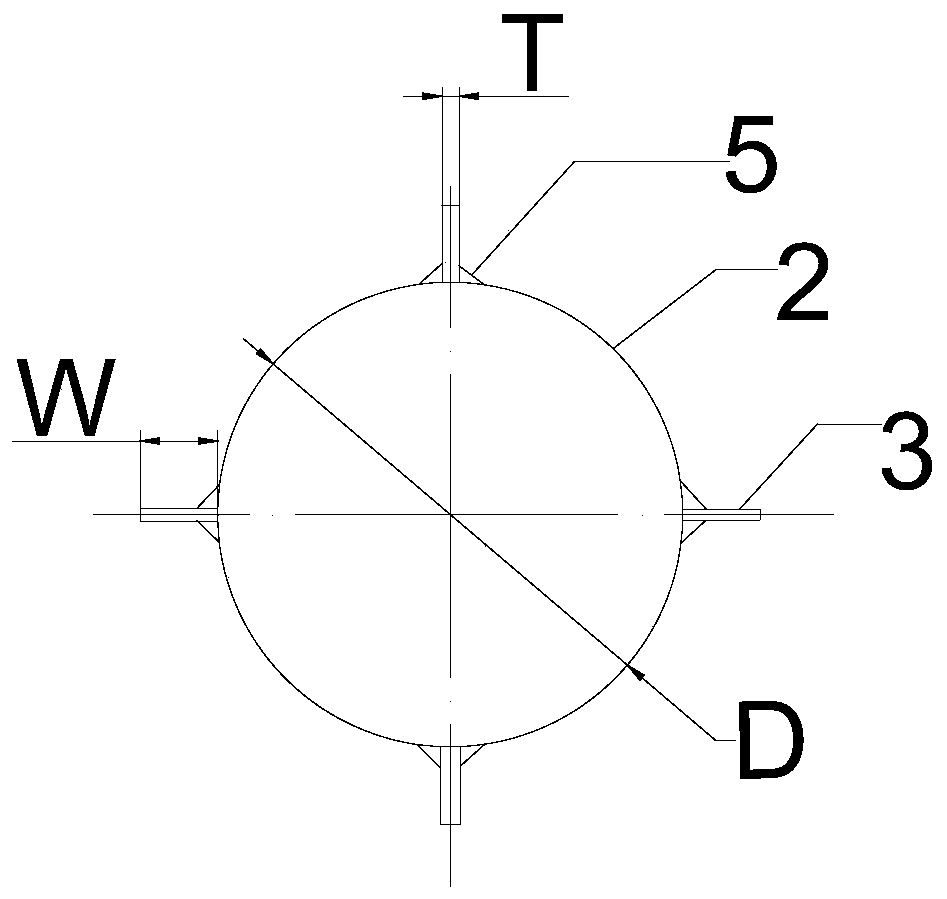

deep water conduit device

ActiveCN108661568BEnhanced bending deformation stiffnessImprove stabilityDrilling rodsDrilling casingsUnderwaterMarine engineering

The invention provides a deep water guiding pipe device. The deep water guiding pipe device comprises a guiding pipe, a guiding pipe head, a water insulation pipe, an underwater well head, a well headbase and a stable plate. The upper end of the guiding pipe is fixedly connected with the underwater well head through the guiding pipe head, the upper end of the underwater well head is connected with the water insulation pipe, and the well head base is arranged outside the connecting position of the guiding pipe and the guiding pipe head in a sleeving mode. The stable plate is arranged on the outer side face of the portion, below the well head base, of the guiding pipe. According to the deep water guiding pipe device, by means of the method that the stable plate is arranged on the outer sideface, below a seabed mud line, of the guiding pipe, the bending deformation rigidity of the guiding pipe is reinforced, the anti-transverse-load capacity of the guiding pipe is improved, the transverse displacement and borne bending moment of the guiding pipe are obviously lowered, the drilling accident is effectively avoided, meanwhile the stability and safety of the deep water guiding pipe areimproved, and economic benefits are increased.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

An in-situ observation test machine for simulating the sand cleaning process of drilling

The invention relates to an in-situ observation tester simulating a sand cleaning process in drilling, comprising a bottom plate, a slide plate, a transparent simulation sleeve, a fixing cylinder sleeve, a simulation hollow drill stem, a drill stem rotation drive mechanism, a drilling fluid cycle control device and a data acquisition device. In-situ observation in the sand cleaning process of drilling is tested by integrating parameter such as eccentricity, hole drift angle, drilling fluids of different features, pressure, flow, flow speed, torque, different sands, sand addition, sand-cleaning eyeholes and drilling stem sleeve surface roughness, and great significance is brought to sand cleaning mechanism of the drilling process, abrasion of the sleeve, sand cleaning features of drilling fluids and the like; the tester is simple in structure, has a clear principle and is convenient to operate.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Wireline core drilling rig waterway control assembly and method

ActiveCN108756794BReduce connectivityReduce the number of disassemblyDrilling rodsFlushingMarine engineeringControl valves

A waterway control assembly and method for a cable coring drilling rig, the control assembly includes a rotatable cable water joint, a waterway control valve group, a conventional waterway joint and connecting pipelines, the waterway control valve group is an intercommunicating four-way pipe fitting, three Each interface is provided with a two-way ball valve, through the opening and closing of the three two-way ball valves, to control the on-off relationship between the four interfaces, and realize the control of the waterway. The rotatable cable water joint includes an end cover, a water seal Ring, retaining ring, mandrel, rotating sleeve, water pipe joint and transition joint, the end of the mandrel is provided with a groove for the spaced installation of the sealing water ring and the retaining ring, the rotating sleeve fits in the middle of the mandrel, the The rotary sleeve is connected with a radially extending water pipe joint; thus, the present invention has a simple structure and is easy to operate, and can solve the problems of long auxiliary time for waterway control, high labor intensity and high personnel cost in the prior art.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

Foam pre-evolution liquid device

InactiveCN101220733BEasy to absorb water and expandEasy to collapseFlushingDrilling compositionActive agentPorous medium

The invention provides a method which utilizes a foam pre-dialyzing liquid device to improve the efficiency of foam drilling and belongs to the technical field of petroleum drilling. The concrete method is as follows: 1) nitrogen or air flow passes a porous medium sand core to mix with a foam base solution containing the active ingredient of interfacial active agent to produce continuous foam andget the fresh foam with the dryness of 45-60%; 2) the fresh foam with the dryness of 45-60% is sent into the pre-dialyzing liquid device, and the pre-dialyzing liquid device reduces the motion speed of the foam, and a large amount of mobile water carried in the foam is separated out by the gravity action and the pre-dialyzing liquid dry foam with the dryness of 75-95% is acquired; 3) the dry foamof the pre-dialyzing liquid is sent into a well bore to take out the water and the solid matters such as drill chips in the well bore. The invention can rapidly take out the strata water in the well,and the bottom of the well has no residual liquid, which can avoid the occurrence of drilling accidents.

Owner:SHANDONG UNIV

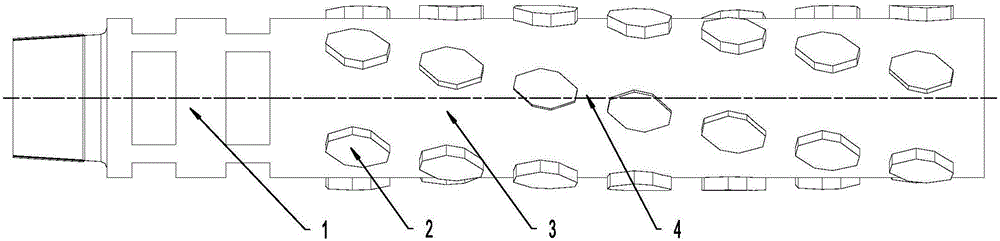

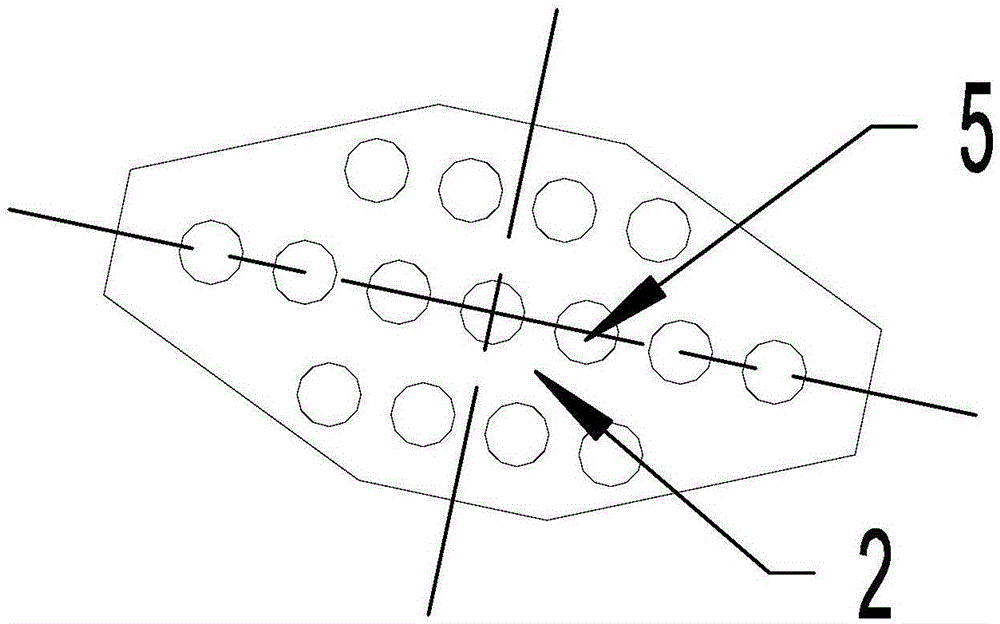

Stable drill pipe

InactiveCN105114006ACarry smoothlyAvoid drilling accidentsDrilling rodsDrilling casingsSlurryWellbore

The invention discloses a stable drill pipe. The stable drill pipe comprises a pipe body and stabilization blocks fixedly installed on the outer cylindrical face of the pipe body. A discharging channel is formed between every two adjacent stabilization blocks. The stabilization blocks are polygonal arc-shaped plates. On the outer cylindrical surface of the pipe body, the inner arc faces of the polygonal arc-shaped plates are fixedly connected with the outer cylindrical surface of the pipe body. The stable drill pipe is suitable for different rotation speeds under different geological conditions and can guarantee that rock residues can be smoothly carried to the ground in flushing fluid and avoid that when slurry leaks suddenly in a shaft, a wedging accident occurs.

Owner:BEIJING CHINA COAL MINE ENG CO LTD

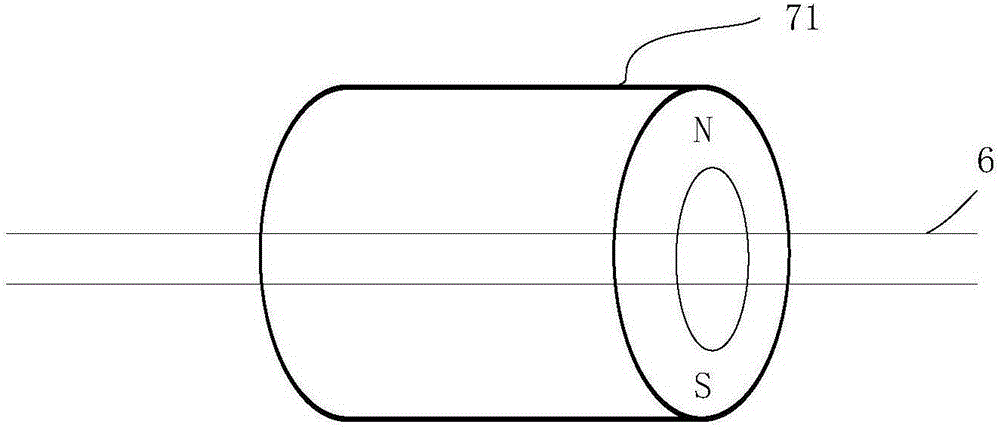

Nuclear magnetic resonance logging system

ActiveCN105275465AImprove adaptabilityImprove stabilityConstructionsBorehole/well accessoriesWired communicationComputer module

The invention provides a nuclear magnetic resonance logging system, which comprises a mud pipe, a controller, a controllable pump, a spectrometer, a wireless transmitting and receiving module, a detection pipe and a detection device, wherein the mud pipe is used for extracting downhole drilling fluid; one end of the mud pipe extends to the downhole and the other end is connected with a drilling fluid pool; one end of the detection pipe is communicated with the mud pipe and the other end is communicated with the outlet of the controllable pump; the inlet of the controllable pump is communicated with the mud pipe; the detection pipe is sleeved with the detection device; the detection device is connected with the spectrometer; and the spectrometer and the controllable pump communicate with the controller via the wireless transmitting and receiving module. According to the nuclear magnetic resonance logging system, real-time drilling fluid detection and remote drilling fluid detection control are realized, defects that wiring of wired communication is complicated, fault points are hard to find when fault happens and the like are overcome, and adaptability and stability of the nuclear magnetic resonance logging system are enhanced.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

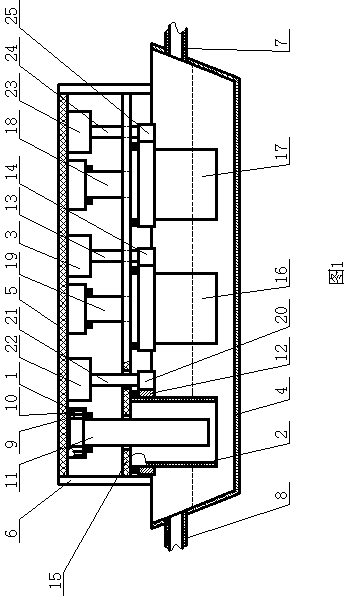

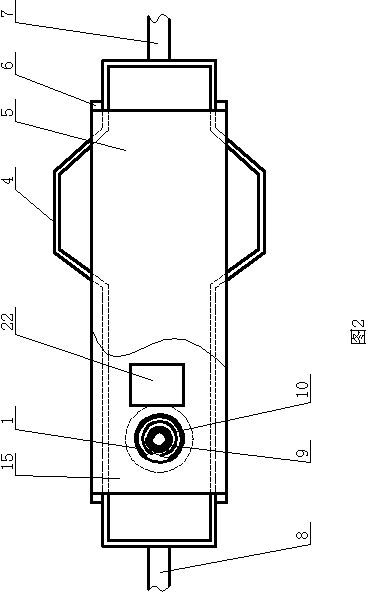

Viscometer used for real-time monitoring in petroleum drilling

InactiveCN102830044BMonitor viscosity in real timeReal-time monitoring of shear forceFlow propertiesDrive shaftLiquid tank

The invention provides a viscometer used for real-time monitoring in petroleum drilling. The viscometer comprises a drilling liquid tank, wherein at least two rotary viscosimeters of different rotational speeds are installed inside the drilling liquid tank; the rotary viscosimeters are suspended inside the drilling liquid tank through a bracket; a drilling liquid inlet is formed at one end of the drilling liquid tank; a drilling liquid outlet is formed at the other end of the drilling liquid tank; the rotary viscosimeters are provided with outer cylinders; an inner cylinder is installed at each outer cylinder; an angle sensor is installed at the upper end of each inner cylinder; a power transmission member is installed at the outer wall of the upper part of each outer cylinder; and the power transmission member is connected with a motor through a transmission shaft. With the adoption of the viscometer, the viscosity of the drilling liquid can be monitored in real time, and thus the purpose of safely monitoring the drilling in real time is achieved.

Owner:韩文峰

An offshore casing surge compensation double-drive three-layer casing drilling coring method

ActiveCN113914802BProtection boreholeAvoid Drilling AccidentsDrilling rodsFlushingSoil scienceDynamic positioning

The invention discloses an offshore casing surge compensation double-drive three-layer casing drilling coring method. The drilling vessel is positioned at the set latitude and longitude coordinates through a dynamic positioning system, the drill pipe is stabilized through the seabed base, and the wellhead casing is used to stabilize the drill pipe. Pipe surge compensation can transmit torque and WOB during casing drilling. During sampling drilling, surge compensation can compensate for water depth changes caused by rising tide, ebb tide or surge within a certain range, preventing casing from colliding with equipment and ensuring that The wellhead operation is safe, and three-layer casing drilling is realized by double driving heads, which effectively protects the well wall, so that the drilling sampling coring rate is high, and the coring quality is good. Compared with the common drilling method, the invention has the advantages of high drilling efficiency, high coring rate, simple equipment, high reliability, low cost, etc., and is not only suitable for shallow drilling in general sedimentary rock formations, but also suitable for difficult-to-core formations, such as Reef limestone formation, sandy soil layer.

Owner:GUANGZHOU MARINE GEOLOGICAL SURVEY

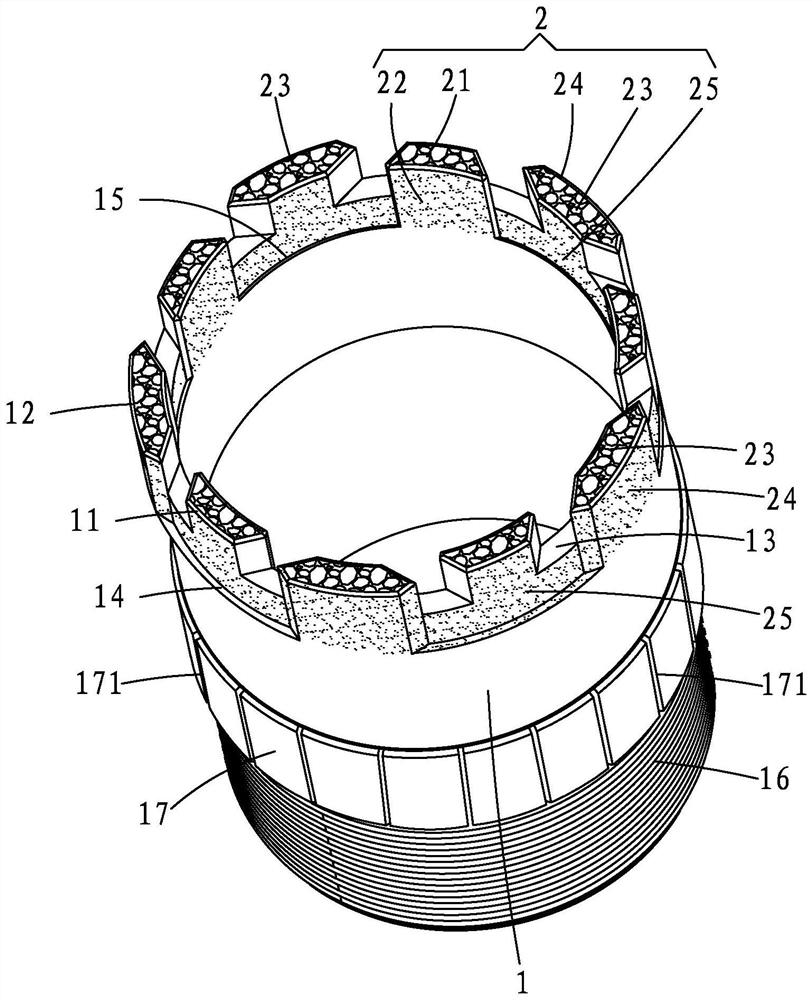

Diamond drill bit with splayed convergent alternate waterways

PendingCN111677453ASpeed up the edgeIncrease working areaDrill bitsDrilling rodsMining engineeringStructural engineering

The invention provides a diamond drill bit with splayed convergent alternate waterways. According to the diamond drill bit, cutting teeth and the splayed convergent alternate waterways are arranged atthe upper end of the head of the diamond drill bit along the circumference, the splayed convergent alternate waterways comprise a plurality of end face water gaps, outer water grooves and inner watergrooves, outer side walls of inner working teeth are concave inwards to form the outer water grooves, inner side walls of outer working teeth are concave inwards to form the inner water grooves, theend face water gaps comprise forward flow water gaps and reverse flow water gaps which are obliquely arranged, adjacent forward flow water gaps and reverse flow water gaps are reversely arranged and distributed in a splayed shape or an inverted splayed shape, the splayed shape and the inverted splayed shape are alternately arranged, outer side ports of the forward flow water gaps and the reverse flow water gaps communicate with the ends of the outer water grooves correspondingly, and inner side ports of the forward flow water gaps and the reverse flow water gaps communicate with the ends of the inner water grooves correspondingly. According to the diamond drill bit, a working mode of the diamond drill bit can be changed, the working efficiency of the diamond drill bit is improved, the service life of the diamond drill bit is prolonged, drill burning accidents are prevented, and jumping and vibration of the diamond drill bit in the working process are avoided.

Owner:福建省华力勘测设计有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com