Core drill output torque upper control limit drill rod

A core drilling rig and output torque technology, which is applied to drill pipes, drill pipes, drilling equipment, etc., can solve problems such as bottom hole drill pipe enlargement, bottom hole drill pipe breakage, bottom hole drill pipe breakage accidents, etc., and reduce construction costs. Cost, avoid bottom hole drilling accident, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

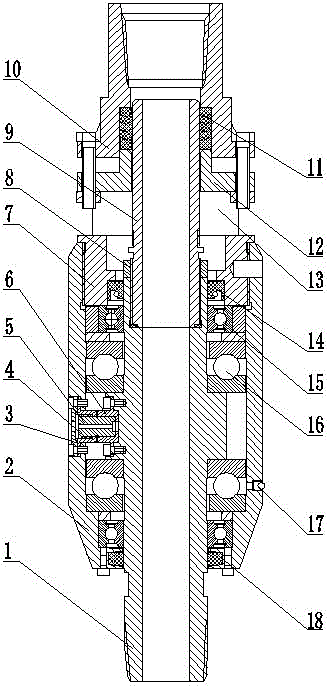

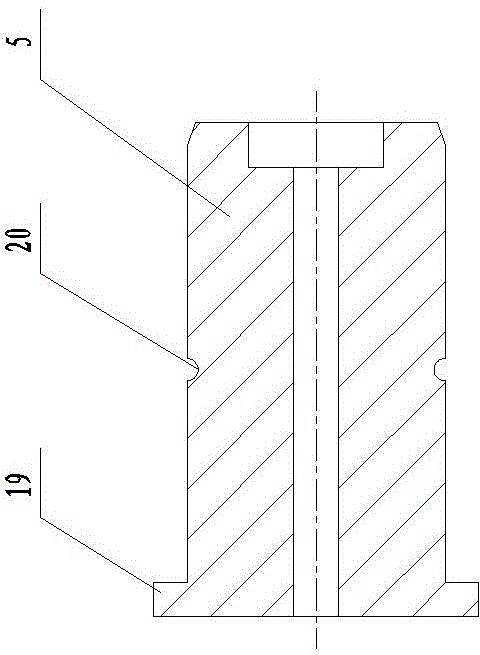

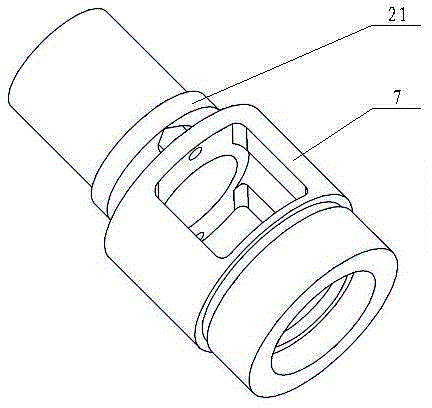

[0013] A drill rod for controlling the output torque upper limit of a core drilling rig, including a core tube, the outer wall of the lower part of the core tube is provided with an external thread for connecting the supporting drill rod of the core drilling rig, and the upper part of the core tube is provided with a fixed connection with the active drill rod of the core drilling rig. The joint 10 is covered with a rotating sleeve 2 in the middle of the core tube, and a torsion bar 5 that transmits torque from the rotating sleeve to the core tube is provided between the rotating sleeve 2 and the core tube. The axial direction of the core pipe is set vertically, and in the middle of the torsion bar 5, there is a circular arc groove 20 that is disconnected when the output torque of the core drilling rig is greater than the maximum torque of the bottom hole drill pipe. One end of the torsion bar passes through the inner ear plate 6 is fixedly connected with the core tube, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com