Pressure control device for continuous circulating drilling

A pressure control and drilling technology, which is applied in earthwork drilling, wellbore flushing, wellbore/well components, etc., can solve the problems of prolonging drilling operation time, unstable wellbore pressure, and wellbore collapse, etc., so as to maintain the wellbore The effect of stable pressure, shortening drilling operation time and reducing drilling cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

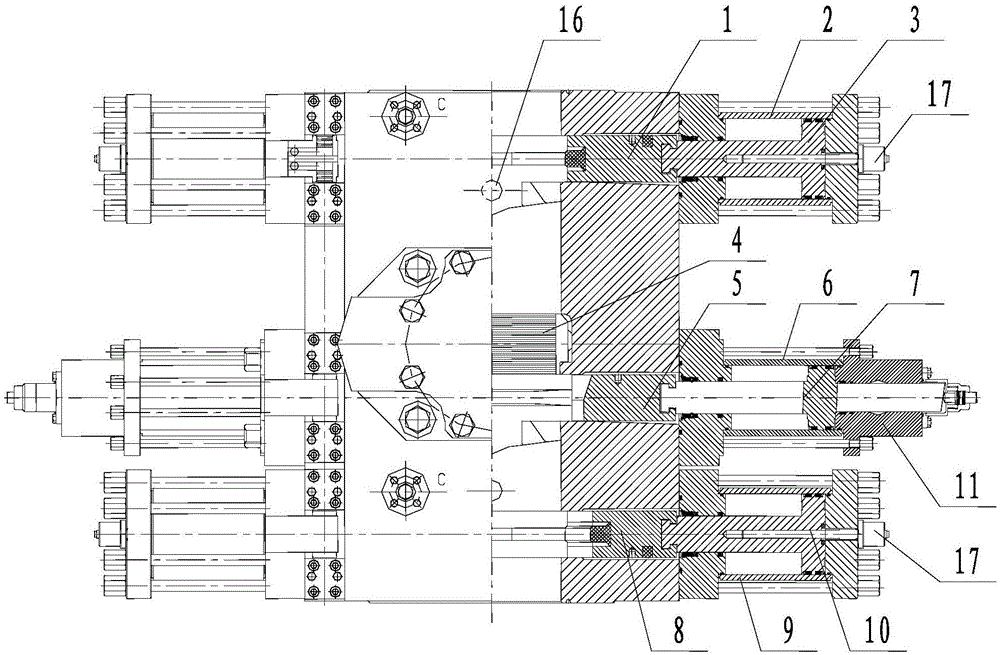

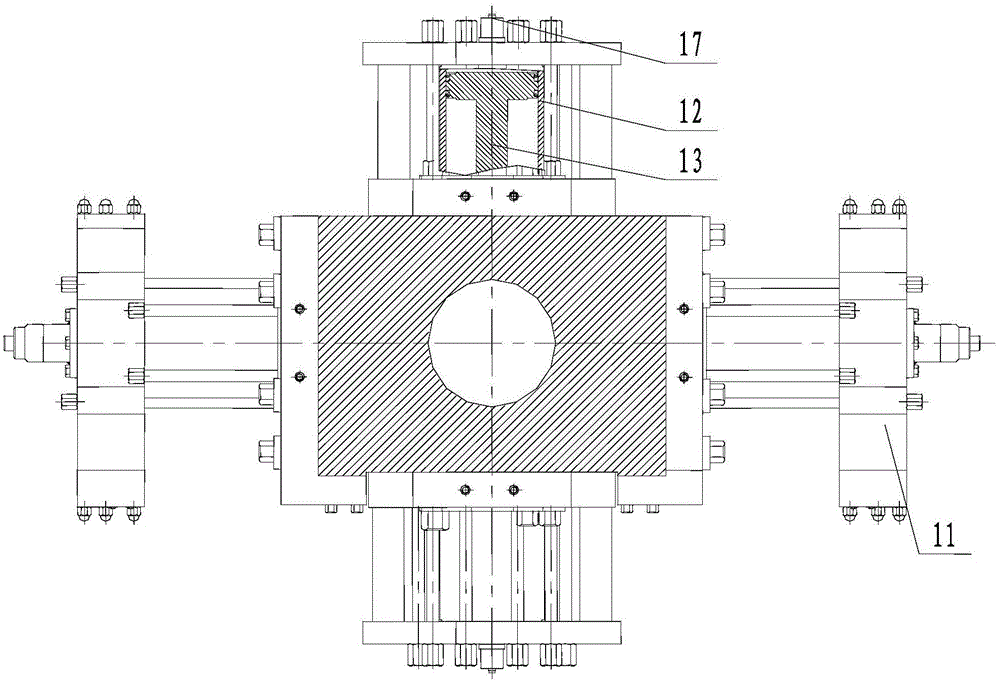

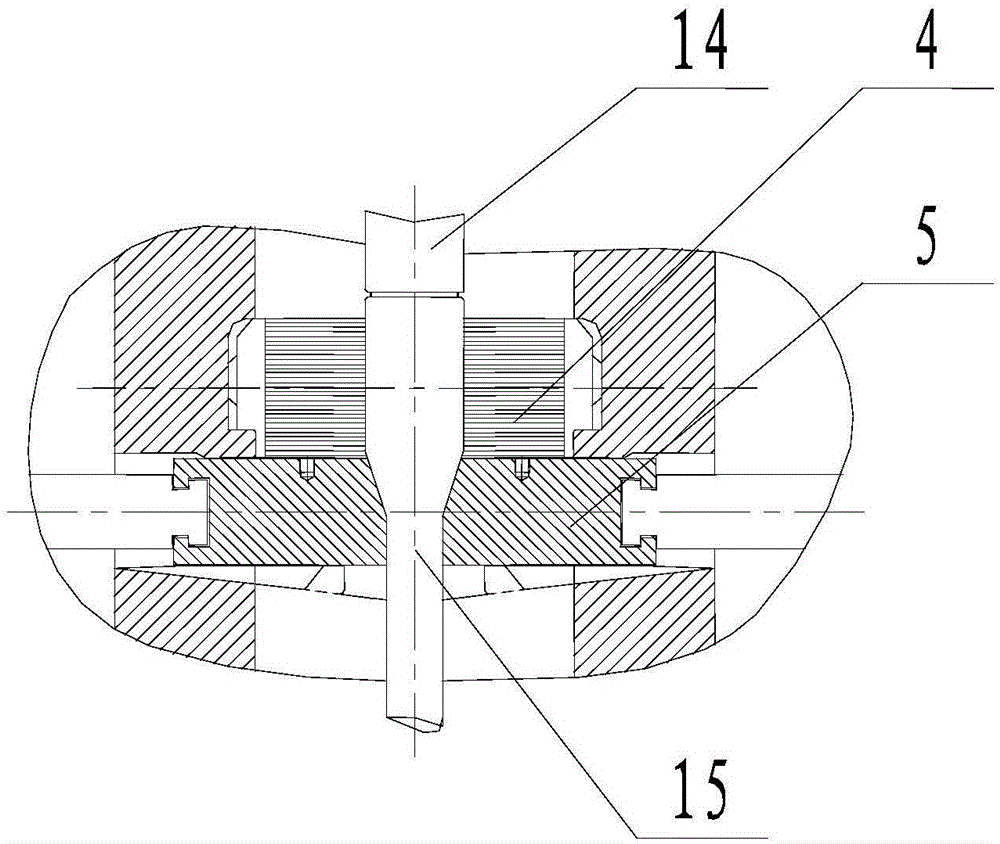

[0017] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

[0018] see Figure 1 to Figure 6 , the pressure control device for continuous circulation drilling of the present invention includes a body, the middle part of the body is vertically penetrated to form a through hole for the drill pipe to pass through, and four rams are installed in the through hole of the body, each of which The rams are respectively spliced by two semi-rams with symmetrical structures, and each of the half rams is driven by a hydraulic cylinder.

[0019] The four rams are respectively a full-sealing ram 1, a slip ram 4, a load-bearing ram 5 and a pipe ram 8 arranged in sequence from top to bottom, wherein the full-sealing ram 1, the load-bearing ram 5 and the pipe ram The rams 8 are arranged in parallel, and the slip rams 4 and the load-bearing rams 5 are staggered at 90° horizontally.

[0020] The full-sealing ram 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com