Method for improving foam well drilling efficiency by foam pre-evolution liquid device

A technology of foam and dry foam, which is applied in drilling compositions, chemical instruments and methods, and earthwork drilling and production, can solve the problems of inability to carry water, low foam dryness, and formation of liquid accumulation, and avoid drilling Accidents, increase foam dryness, and facilitate refitting effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

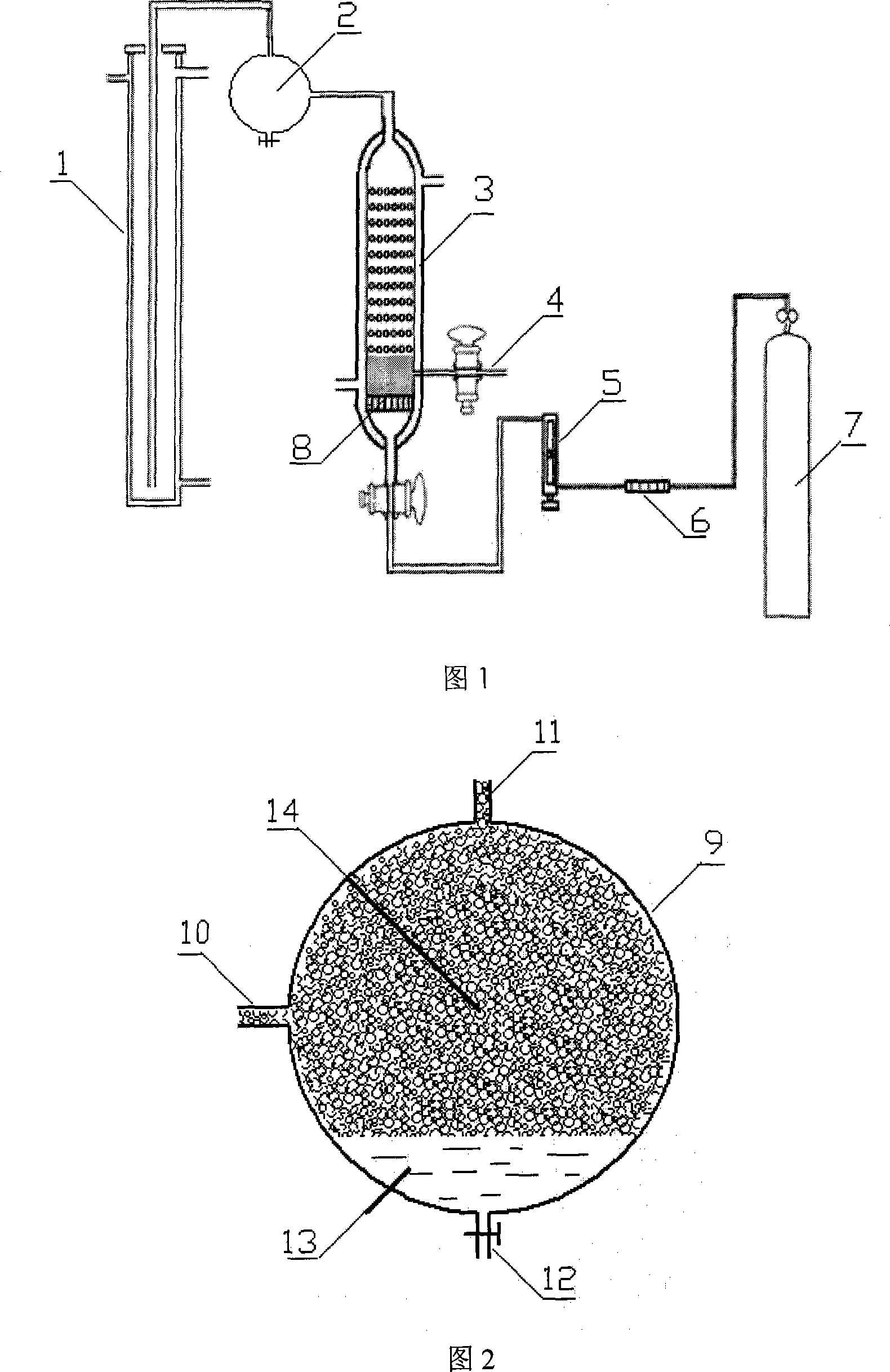

[0029] A kind of foam pre-analysis device, structure as shown in Figure 2, pre-analysis device 2 is a spherical container 9, is provided with semicircular dividing plate 14 and liquid level sensor 13 in the spherical container 9, is provided with on the spherical container 9 Foam inlet 10, dry foam outlet 11 and automatic control drain 12; the axis of foam inlet 10 and the axis of dry foam outlet 11 are perpendicular to each other, and dry foam outlet 11 and automatic control drain 12 are on the same axis; semicircle A shaped partition 14 is arranged on the inner wall of the spherical container 9 and is located between the foam inlet 10 and the outlet 11 ; the liquid level sensor 13 is arranged below the middle of the spherical container 9 .

[0030] The included angle between the semicircular partition 14 and the axis of the dry foam outlet 11 is 0°-90°.

[0031] The dry foam outlet 11 is located directly above the spherical container 9 .

[0032] The automatic control drain...

Embodiment 2

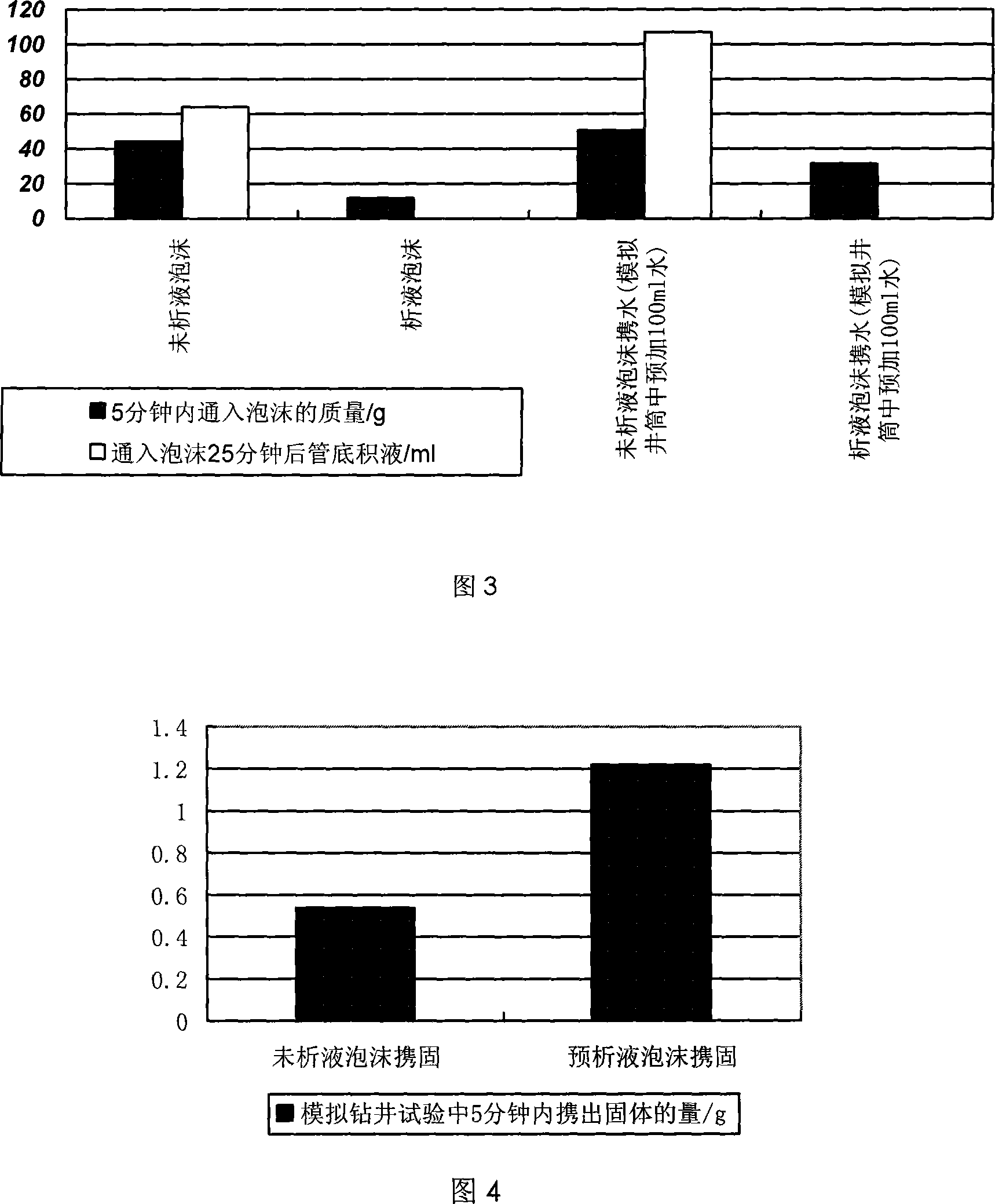

[0040] The foam pre-analysis device and the method of utilizing the foam pre-analysis device to improve the foam drilling efficiency are the same as in Example 1. The difference is that when betaine is used as a foam agent, the dryness of the betaine foam is 52% when the betaine foam is generated. The dryness of the pre-analysed liquid foam obtained by the device is 89%. Using this foam to simulate drilling, the non-separated foam will precipitate 50ml of liquid in the wellbore within 220s; the pre-separated foam will have no liquid precipitated in the wellbore, and can carry 50ml of pre-added water from the wellbore within 190s.

Embodiment 3

[0042] The foam pre-analysis device and the method of utilizing the foam pre-analysis device to improve the foam drilling efficiency are the same as in Example 1, and the difference is that when the alkyl ethoxy sodium sulfate is used as a foam agent, when the alkyl ethoxy sodium sulfate foam generates The dryness is 49%, and the dryness of the pre-analysis foam obtained by the pre-analysis device is 78%. Using this foam to simulate drilling, the unanalysed foam 14Os precipitates 50ml of liquid in the wellbore; the pre-dialysis foam has no liquid in the wellbore Precipitate, and can carry out from the wellbore within 510s all the pre-added 50ml turbid liquid containing 1.0% solid particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| dryness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com