Viscometer used for real-time monitoring in petroleum drilling

A real-time monitoring and oil drilling technology, applied in the direction of instruments, measuring devices, scientific instruments, etc., can solve the problems of drilling safety threats, affecting the accuracy of drilling fluid viscosity indicators, and performance changes that cannot be detected in time, so as to avoid drilling accidents and structural Reasonable and accurate signal transmission effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

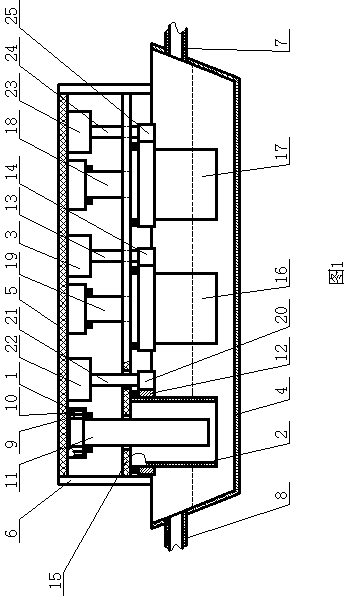

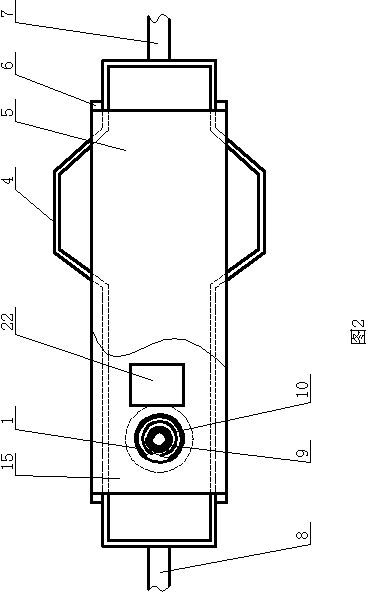

[0007] The present invention will be further described with reference to the accompanying drawings.

[0008] The viscometer for real-time monitoring of petroleum drilling according to the present invention comprises a drilling fluid tank 4, at least two rotational viscometers with different rotating speeds are installed in the drilling fluid tank 4, and the rotational viscometer is suspended in the drilling fluid tank 4 by a bracket, and the drilling One end of the tank 4 is provided with a drilling fluid inlet 8, and the other end is provided with a drilling fluid outlet 7. Both the drilling fluid inlet 8 and the drilling fluid outlet 7 are arranged in the middle of the drilling fluid tank 4 to further ensure the fluid flow. Uniform; the rotational viscometer is provided with an outer cylinder, and an inner cylinder is installed at each outer cylinder, an angle sensor 10 is installed at the upper end of each inner cylinder, and a power transmission component is installed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com