A Real-time Monitoring Method of Wing Shear Force Based on Fiber Bragg Grating Measured Strain

A technology of optical fiber grating and actual strain measurement, which is applied in the measurement of force, the measurement of the change force of the optical properties of the material when it is stressed, and the measurement device. Calibration, cumbersome calibration process and other issues, to achieve the effect of health management, strong anti-electromagnetic interference ability, and aircraft safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

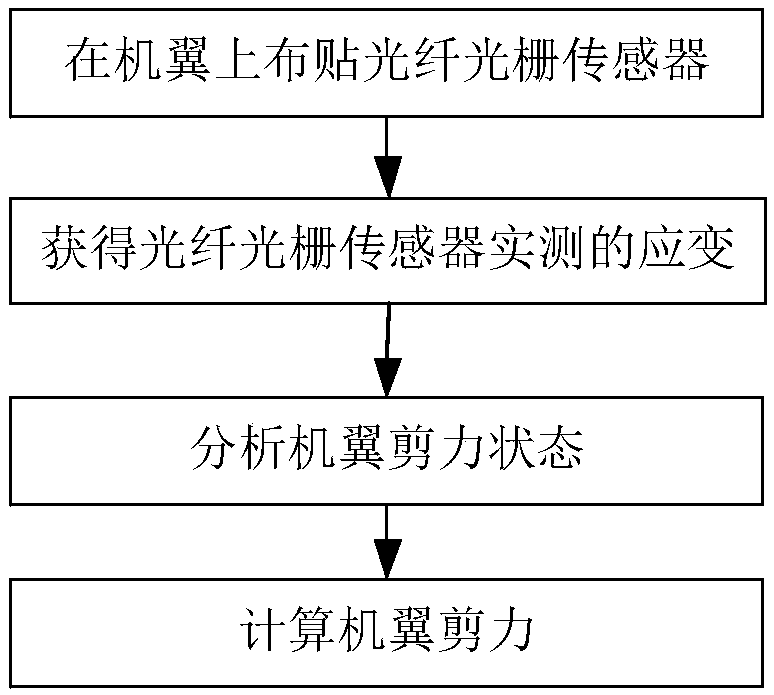

[0047] A real-time monitoring method for aircraft wing shear force based on fiber grating measured strain provided by the present invention, see figure 1 As shown, it is realized through the following steps:

[0048] Step 1: Paste the fiber grating sensor on the wing;

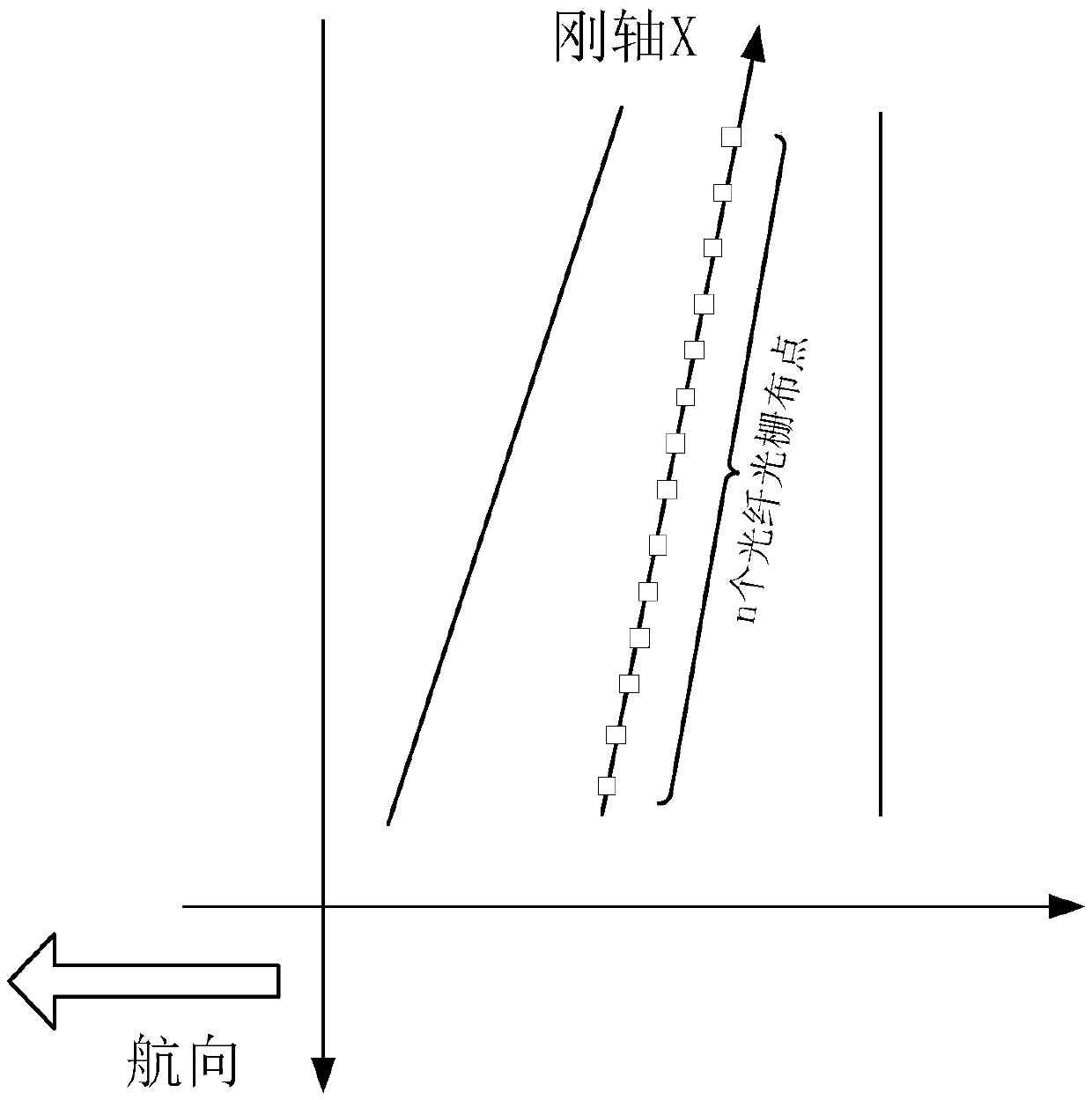

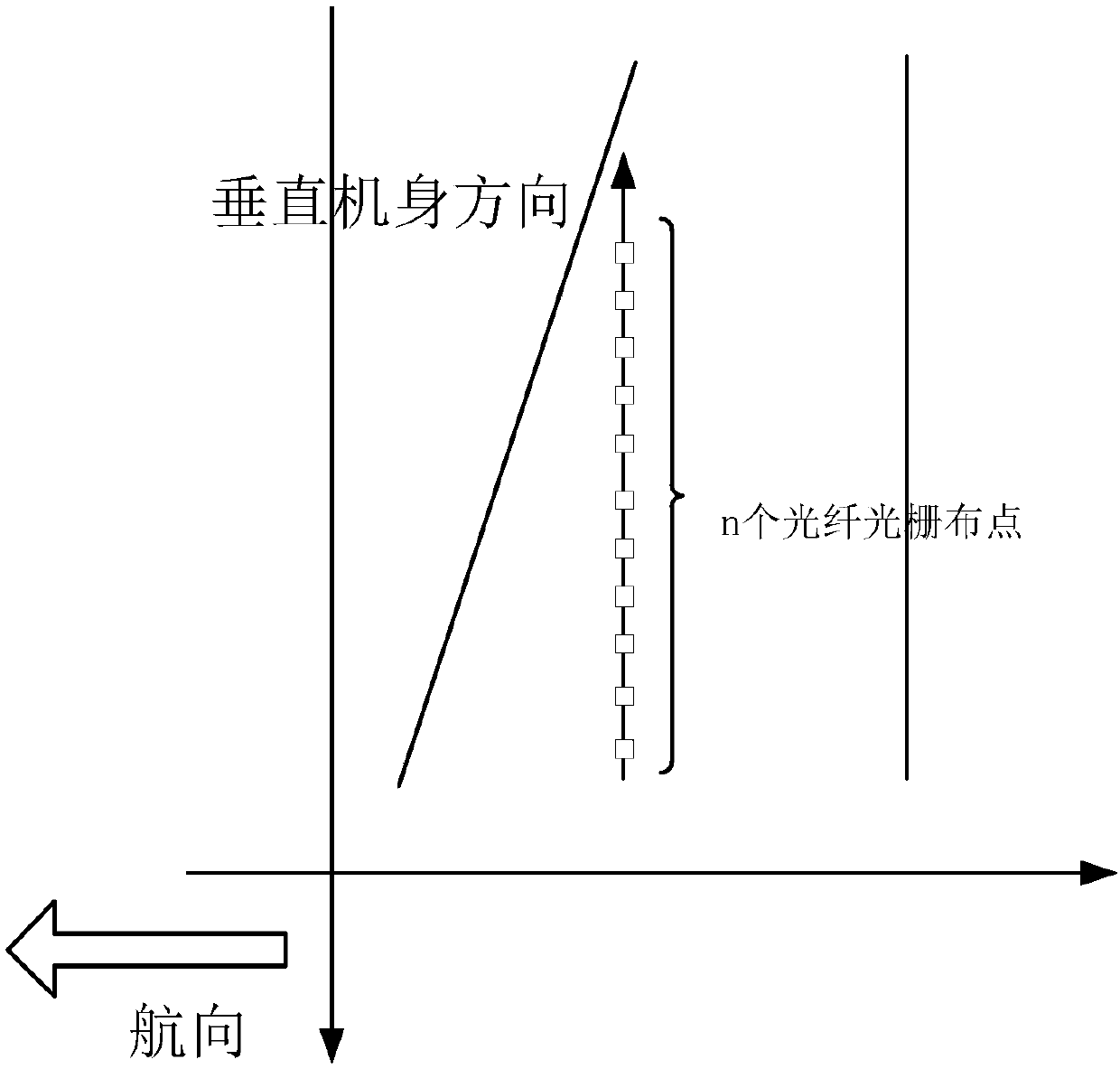

[0049]On the surface of the wing, deploy n points of fiber grating sensor measuring points along the direction of the rigid axis of the wing until it is close to the end of the wing, such as figure 2 as shown; or, deploy n points of FBG sensor measuring points on the surface of the wing along the direction perpendicular to the fuselage, until it is close to the end of the wing, such as image 3 shown;

[0050] Among them, no matter whether the fiber grating sensor is placed along the direction of the rigid axis of the wing or along the direction perpendicular to the fuselage, the position of the last one or several fiber grating sensor measuring points will be close to the position of the pressure center of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com