Diamond drill bit with splayed convergent alternate waterways

A diamond drill bit, staggered technology, applied in the direction of drill bits, drill pipes, drill pipes, etc., can solve problems such as imperfect structural design, rapid wear on the inside and outside, and easy jumping of drill bits, so as to reduce the risk of burning drill and reduce contact area, the effect of avoiding drilling accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

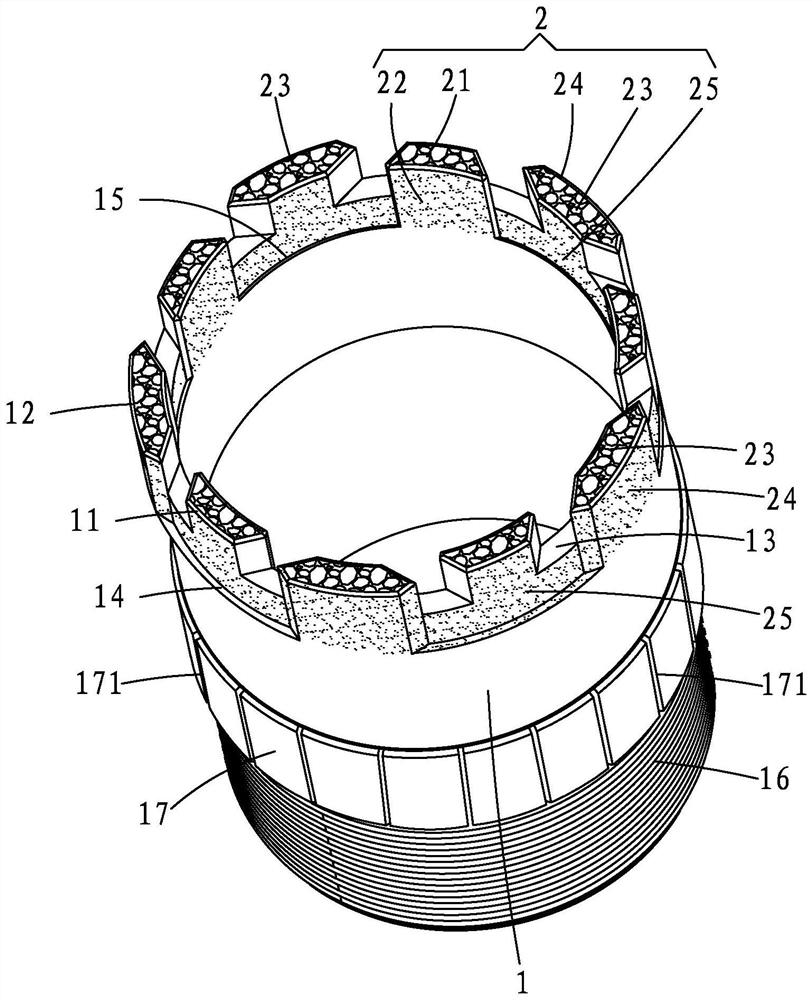

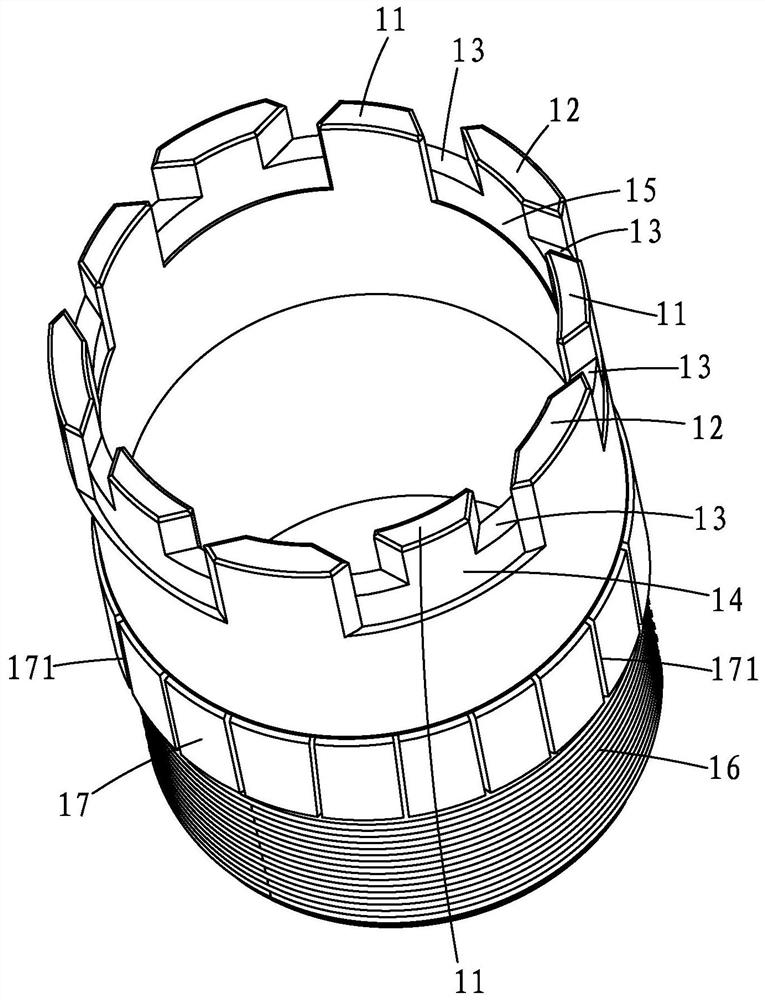

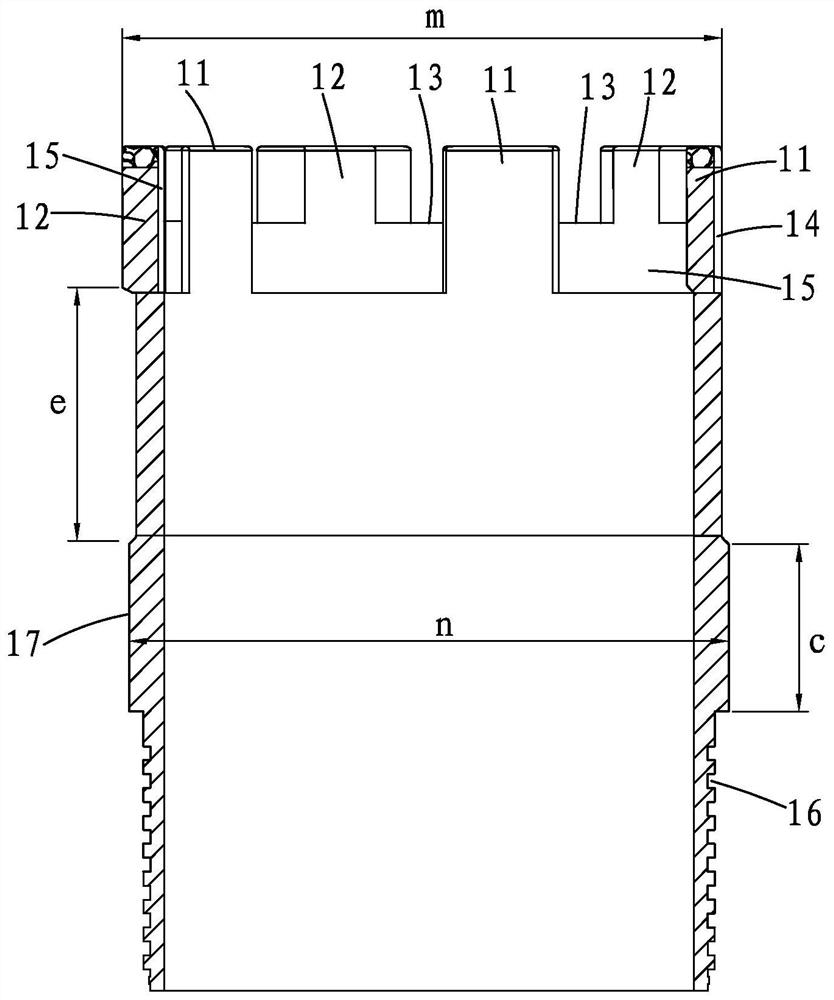

[0029] refer to Figure 1-6 As shown, the present invention relates to a diamond drill bit with eight-shaped converging staggered waterways, the diamond drill bit includes a drill bit steel body 1 and a drill bit working layer 2, and the upper end of the head of the drill bit steel body 1 is provided with cutting teeth along the circumference and the horoscope-shaped interlaced waterway, the cutting teeth are composed of several inner working teeth 11 and outer working teeth 12, and the horoscope-shaped interlaced waterway includes several end surface nozzles 13, outer water tanks 14 and inner water tanks 15;

[0030] The inner working teeth 11 and the outer working teeth 12 are alternately arranged along the circumference of the steel body, and the end surface nozzles 13 are arranged at intervals. The outer wall of the inner working teeth 11 is concave to form the outer water tank 14. The inside wall of the working tooth 12 is concave to form the inner water groove 15;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com