deep water conduit device

A catheter device and catheter technology, which is applied in the direction of drill pipe, casing, drill pipe, etc., can solve the problems of lateral bending deformation of the catheter, poor lateral load effect, drilling accidents, etc., and achieve enhanced bending deformation stiffness, reduced lateral displacement and all The effect of bending moment and avoiding drilling accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

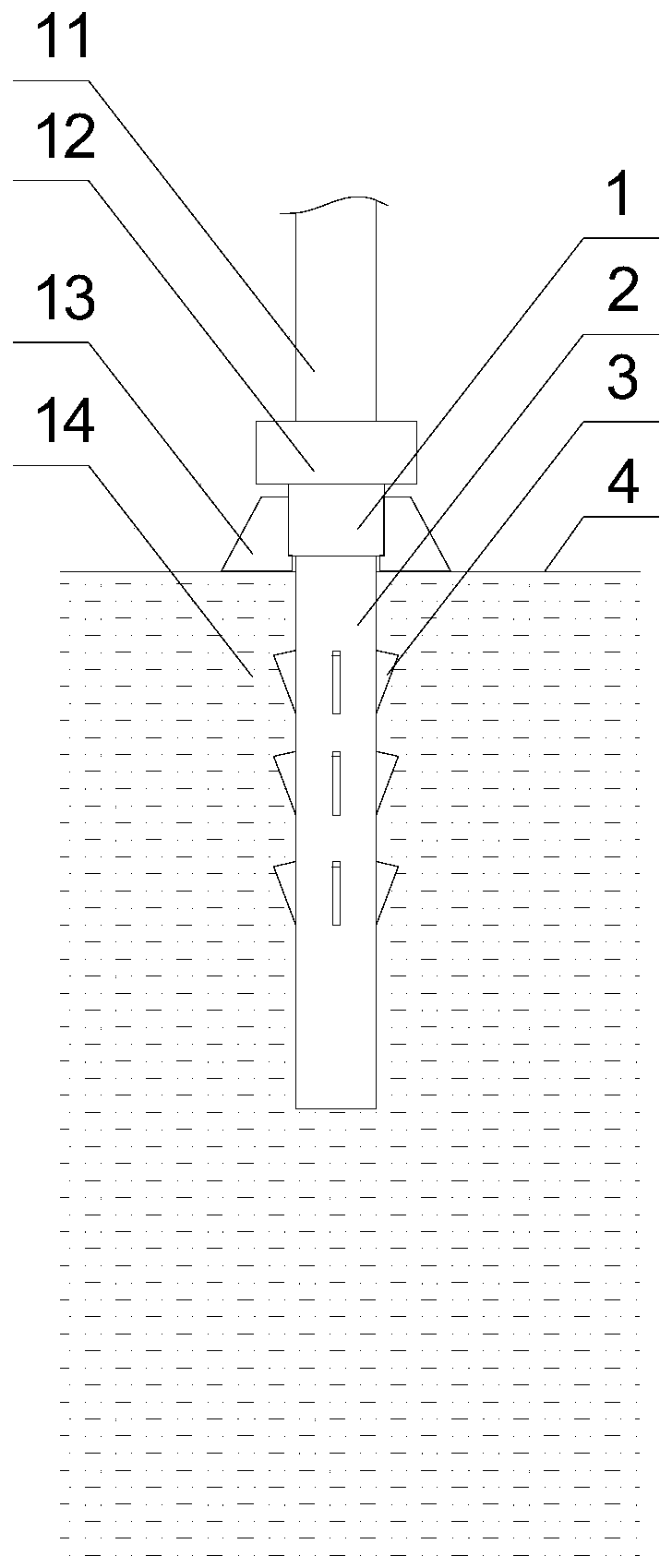

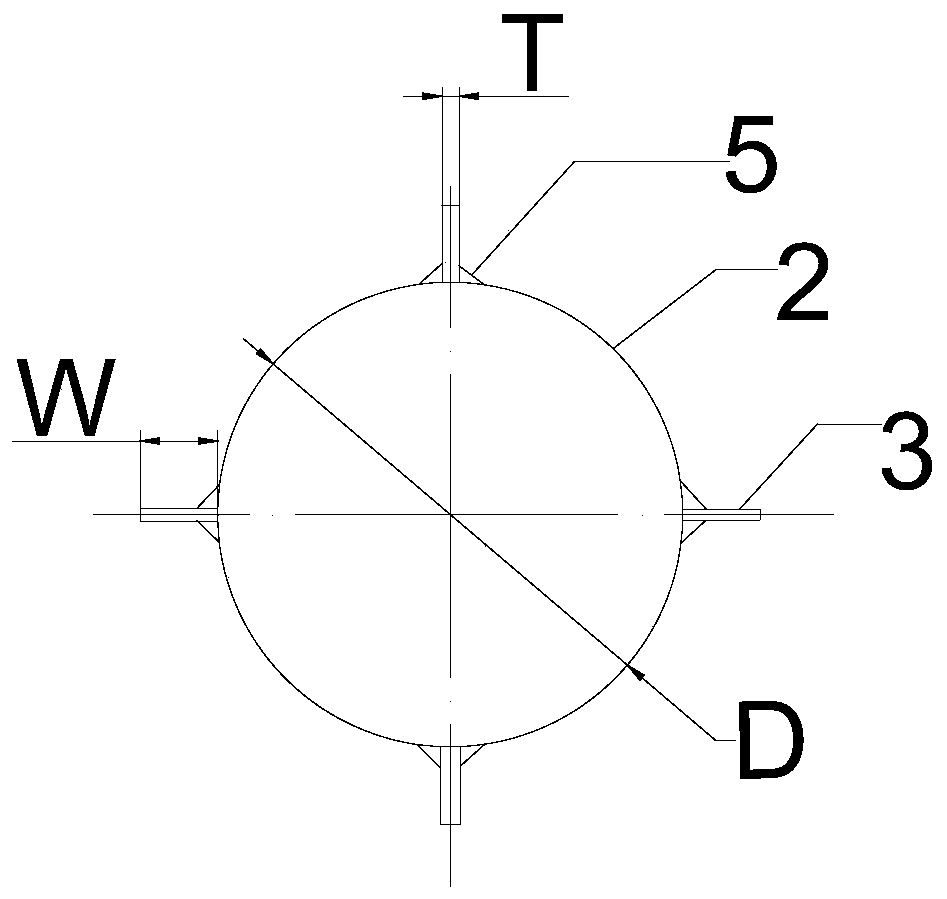

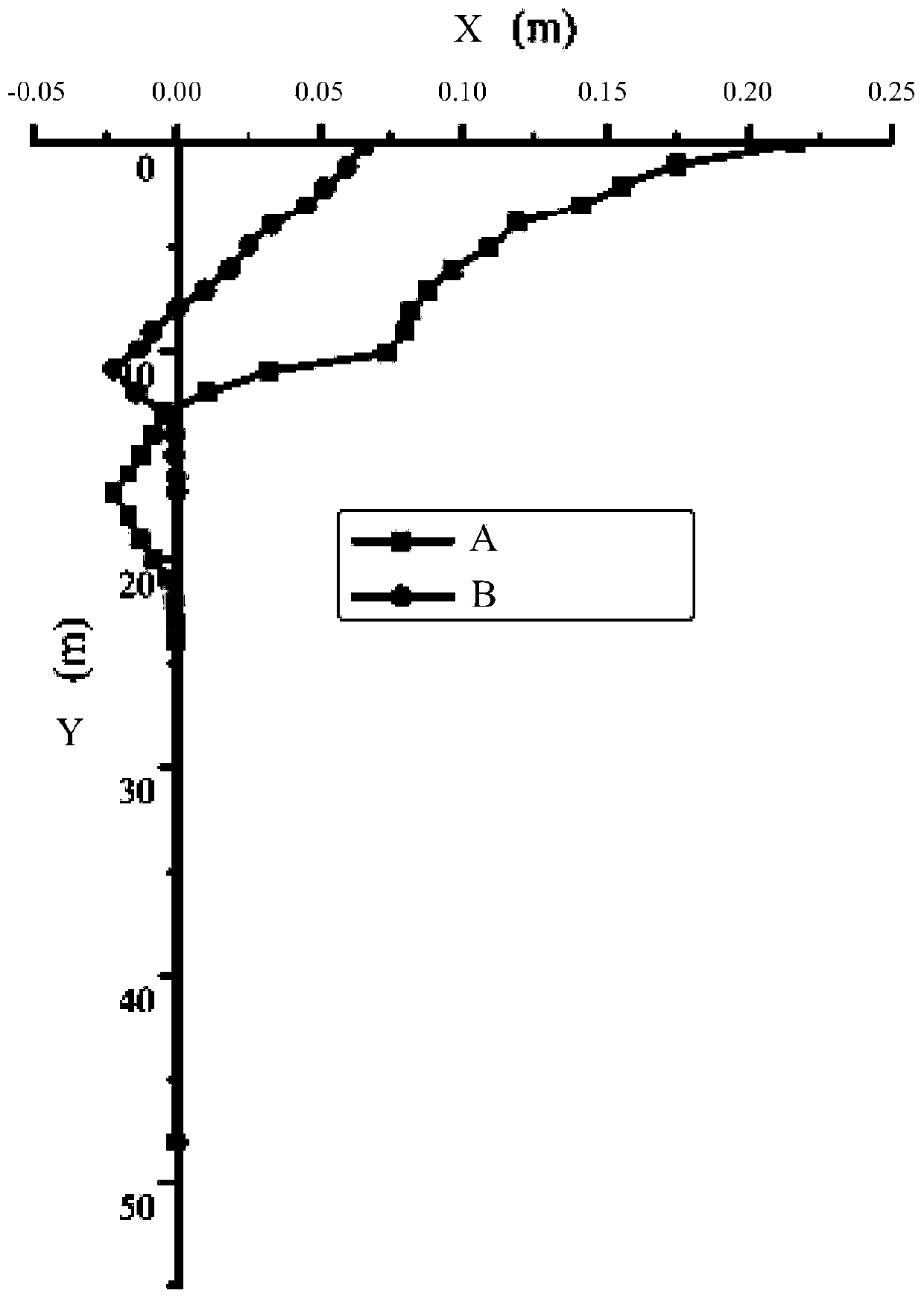

[0034] In the process of offshore deepwater drilling, the conduit is lowered into place, and after being connected with the underwater wellhead, blowout preventer and riser, it acts as a structural support. Good running and supporting effects can only be ensured if the conduit does not deflect when it is lowered to the design position below the seabed mud line. Since the upper end of the riser is connected to the drilling ship or drilling platform, under the dynamic action of wind, wave, current and other marine environmental loads, the drilling ship or drilling platform will deviate, and the complex power borne by the riser will be continuously transmitted to the pipe, resulting in The conduit is subjected to a huge lateral bending moment, and the large lateral force causes the conduit to bend and deform laterally. The axial deviation of the conduit head is too large, which may easily cause damage to the wellhead and cause large economic losses.

[0035] At present, the cathe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com