Power-failure protection device used for drilling rig and power-failure protection type drilling rig drum device

A power-off protection device and drilling rig technology, which is applied in the direction of mechanical equipment, brake actuators, gear transmission mechanisms, etc., can solve the problems of slipping drills and stuttering drills, and achieve the advantages of avoiding slipping drills, convenient use, and reasonable structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

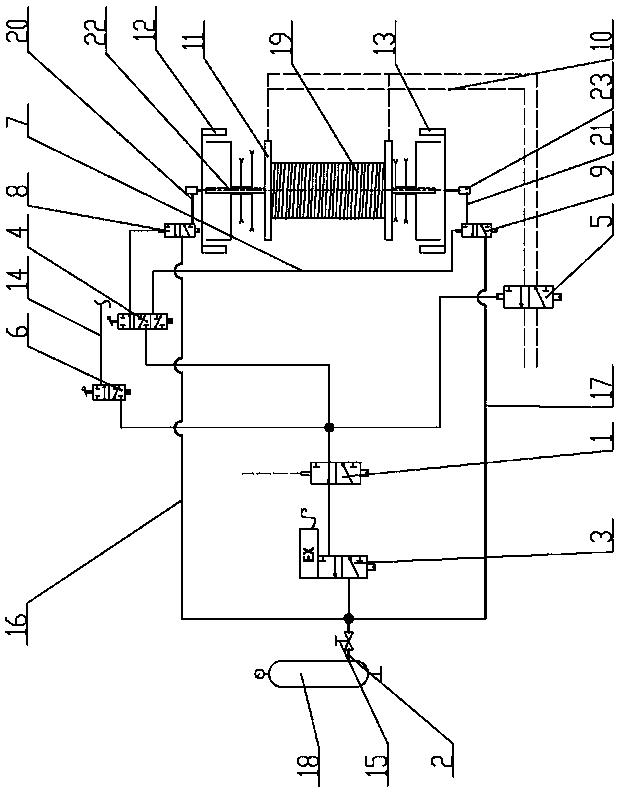

[0017] Embodiment 1: as attached figure 1 As shown, the power-off protection device for drilling rigs includes a normally open air control valve 1, an air source intake pipeline 2, a solenoid valve 3, a high and low speed air guide valve 4, an air-controlled hydraulic reversing valve 5, and a total clutch air guide valve 6 , the control air pipeline 7, the low-speed air control reversing valve 8 and the high-speed air control reversing valve 9, the air outlet of the air source inlet pipeline 2 communicates with the first normally open interface of the normally open air control valve 1 through the control air pipeline 7 , and a solenoid valve 3 is provided in the above-mentioned control air pipeline 7, and the control interface of the normally open air control valve 1 passes through the control air pipeline 7 and the high and low speed air guide valve 4, the air-controlled hydraulic reversing valve 5 and the total clutch air guide respectively. The valves 6 are connected, and t...

Embodiment 2

[0023] Embodiment 2: as attached figure 1 As shown, the power-off protection drilling rig drum device includes the above-mentioned power-off protection device for drilling rigs, the main drum 19, the hydraulic pipeline 10, the third main air pipeline 20, the fourth main air pipeline 21 and the central shaft 22, the central shaft 22 The outside of the middle part is provided with a main drum 19, the upper outer side and the lower outer side of the main drum 19 are respectively provided with a brake disc 11, the upper end of the central shaft 22 is provided with a low-speed pneumatic tire clutch 12, and the lower end of the central shaft 22 is provided with a high-speed pneumatic tire clutch 13, each The brake disc 11 is connected to the air-controlled hydraulic reversing valve 5 through the hydraulic pipeline 10, the low-speed air-controlled reversing valve 8 is connected to the low-speed pneumatic tire clutch 12 through the third main air pipeline 20, and the high-speed air-con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com