An in-situ observation test machine for simulating the sand cleaning process of drilling

A testing machine and in-situ technology, which is applied in measurement, earthwork drilling, wellbore/well components, etc., can solve the problem of starting rolling without comprehensive consideration of drilling fluid formula parameters, speed parameters, torque parameters, pressure parameters, drill pipe eccentricity parameters, etc. Problems such as moving and rotating are achieved to improve economic benefits and prevent drilling accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

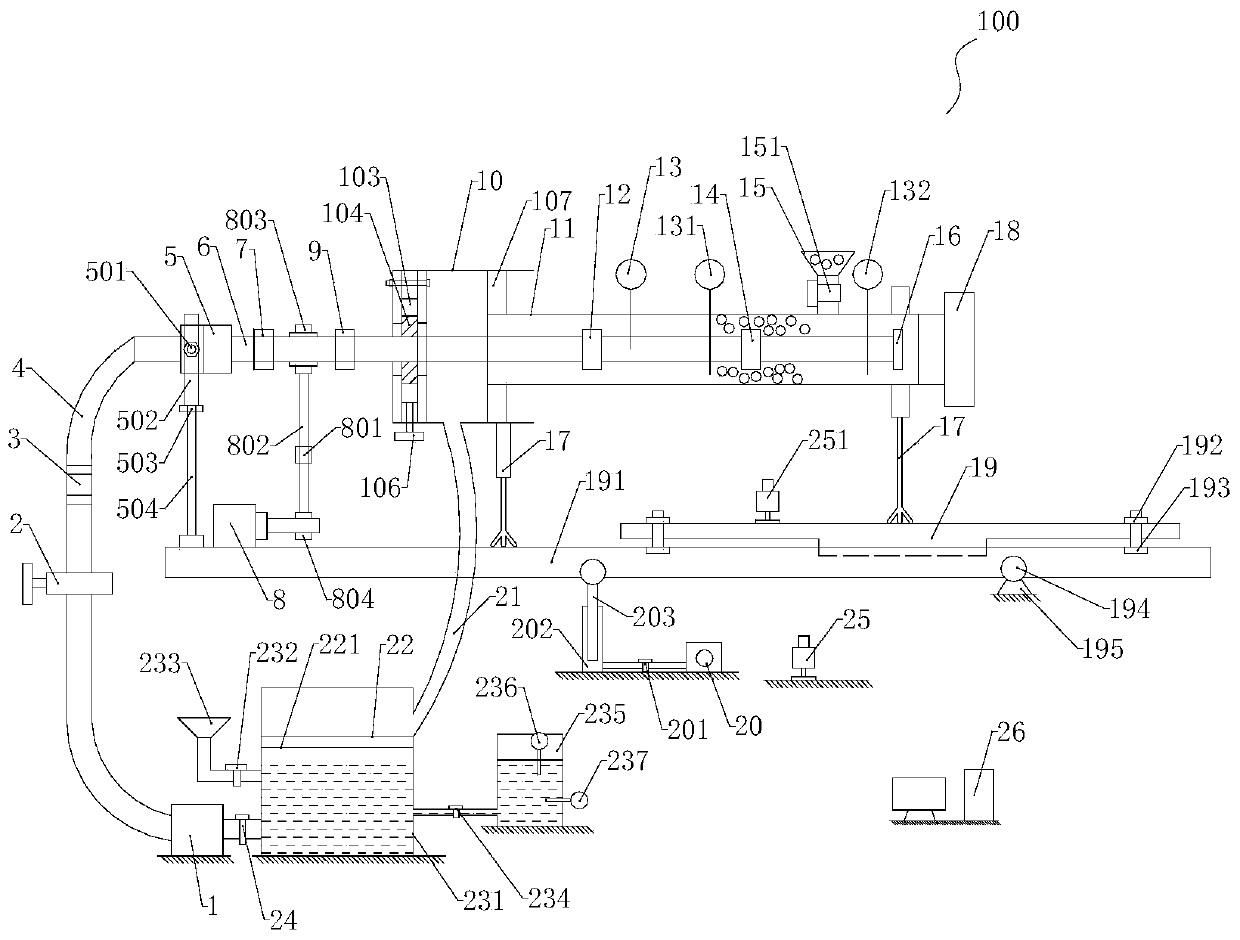

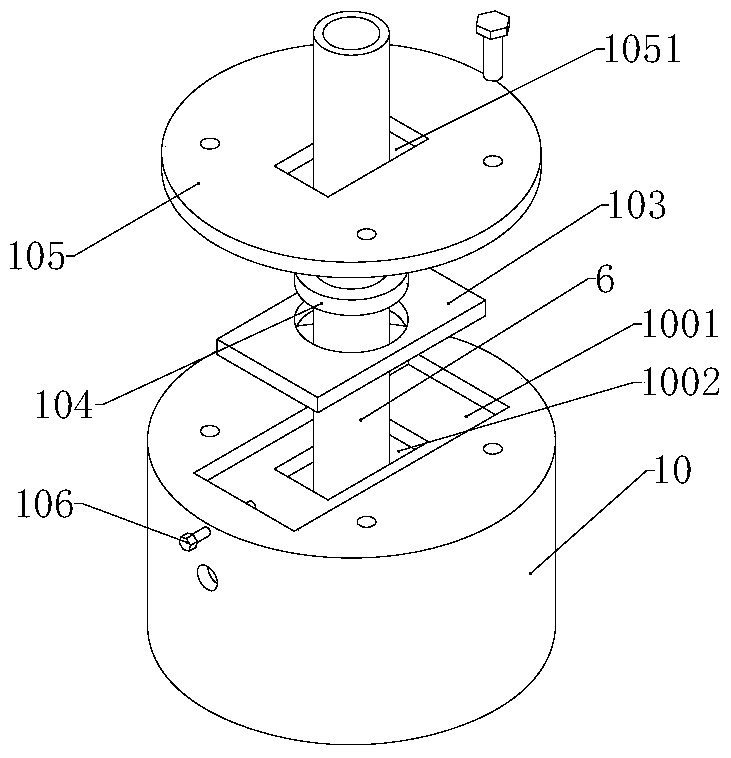

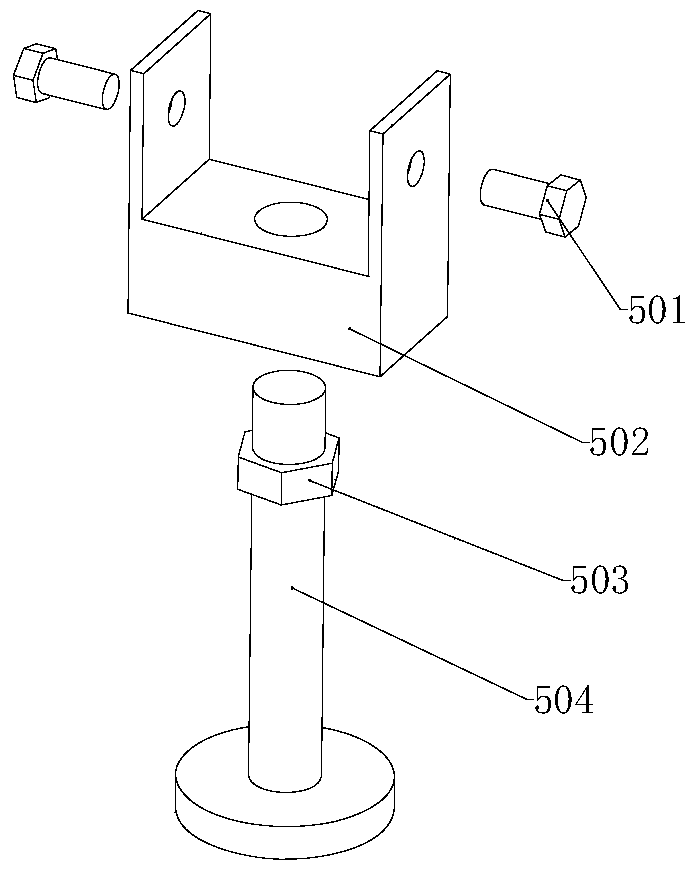

[0052] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

[0053] Such as figure 1 As shown, the present invention provides an in-situ observation test machine for simulating the sand removal process of drilling, including a bottom plate, a slide plate, a transparent simulated casing, a fixed cylinder liner, a simulated hollow drill pipe, a rotating drive mechanism for the drill pipe, and a drilling fluid circulation control device. and data acquisition and processing devices. The bottom plate extends along a longitudinal direction, assuming figure 1 The left end is the front end, and the right end is the rear end. The rear end of the bottom plate is hinged with the base, and the base is fixed. The bottom plate is connected with an inclination angle driving device. into different angle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com