Hydrophobic Modified Polyacrylamide Polymer Suitable as Supramolecular Shear Lifting Agent and Its Application in Water-based Drilling Fluid

A polyacrylamide, water-based drilling fluid technology, applied in drilling compositions, chemical instruments and methods, etc., can solve the problems of high flexibility, weakened rock-carrying performance, and the grid structure is not easy to recover again. , The effect of promoting the problem of drilling cuttings deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] A second aspect provides a method for preparing a hydrophobically modified polyacrylamide polymer suitable for a cutting agent, the method comprising:

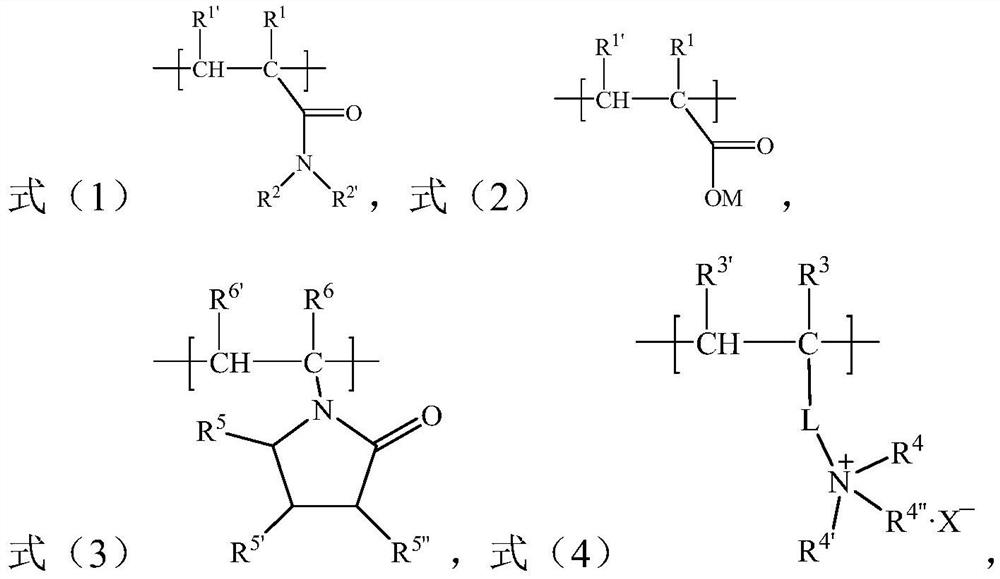

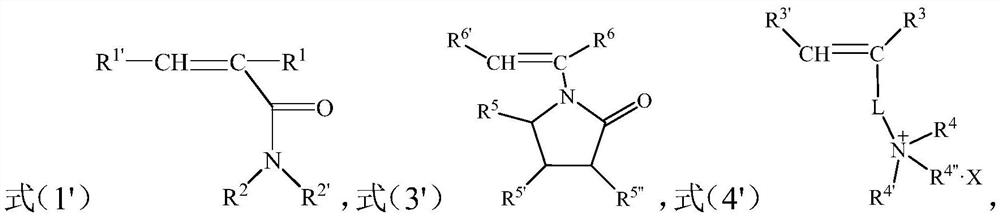

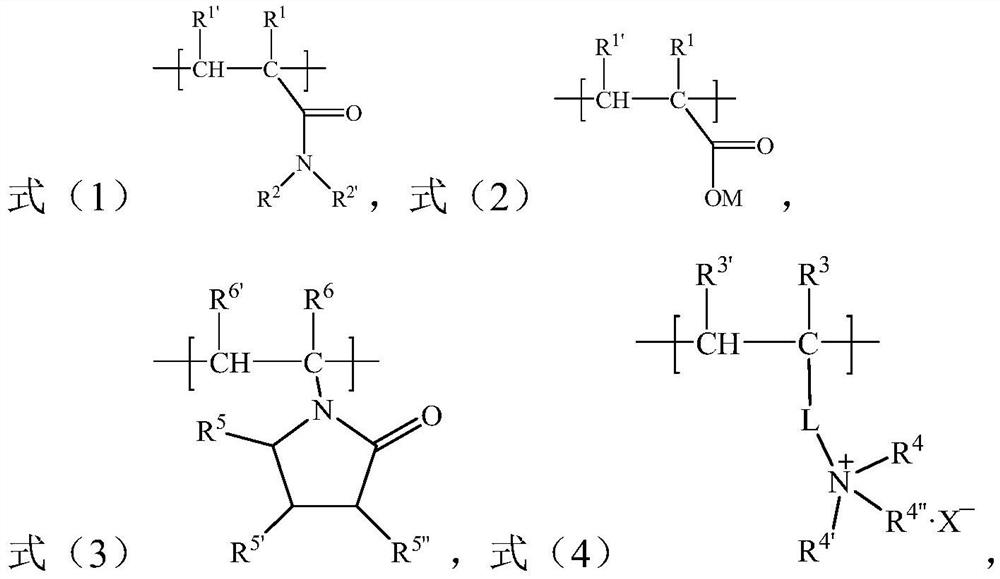

[0035] (1) The compound represented by the formula (1'), the compound represented by the formula (3'), and the compound represented by the formula (4') are freed in an aqueous solvent in the presence of an oxidative-epoxy initiator base polymerization;

[0036] (2) in an aqueous solution of alkali metal hydroxide, hydrolyzing the product of the radical polymerization reaction to obtain a hydrophobically modified polyacrylamide polymer;

[0037] Wherein, the method makes the number-average molecular weight of the obtained hydrophobically modified polyacrylamide polymer to be 1 million-6.5 million;

[0038]

[0039] where R 1 , R 1' , R 2 , R 2' , R 3 , R 3' , R 5 , R 5' , R 5” , R 6 and R 6' Each is independently selected from H and C1-C6 alkyl; M is selected from H or alkali metal element; R 4 and R 4' ...

Embodiment 1

[0099] This example is used to illustrate the hydrophobically modified polyacrylamide polymer of the present invention and its preparation method.

[0100] (1) 380 mmol of acrylamide, 45 mmol of N-vinylpyrrolidone and 9.5 mmol of tetradecyldimethylallyl ammonium chloride (purchased from Annagy) were dissolved in 100 mL of deionized water under magnetic stirring, The oxygen was removed by passing nitrogen for 10 minutes, and 0.37 mmol potassium persulfate and 0.4 mmol sodium bisulfite were added, and the polymerization reaction was carried out at 25 °C for 6 hours to obtain a solid gel product;

[0101] (2) Cut the obtained solid gel-like product into pieces with scissors, add 100 mL of 1 mol / L sodium hydroxide solution, place it in a water bath at 90°C for 8 hours, and then dry and grind the obtained product to obtain a hydrophobically modified polymer Acrylamide polymer, denoted as supramolecular cutting agent SV-1.

[0102] It was determined that the number average molecula...

Embodiment 2

[0104] This example is used to illustrate the hydrophobically modified polyacrylamide polymer of the present invention and its preparation method.

[0105] According to the method described in Example 1, the difference is that an equimolar amount of cetyldimethylallyl ammonium chloride (purchased from Annagy) is used instead of cetyldimethylallyl ammonium chloride, and finally a hydrophobically modified polyacrylamide polymer is obtained, which is denoted as supramolecular cutting agent SV-2.

[0106] It was determined that the number average molecular weight of the hydrophobically modified polyacrylamide polymer was 5 million, and the molecular weight distribution index was 2.9.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com