Offshore casing surge compensation dual-drive three-layer casing drilling and coring device

A coring device and dual-drive technology, which is applied in the extraction of undisturbed core devices, casings, drill pipes, etc., can solve problems such as immaturity, and achieve the effects of simple and reliable device, strong operability and high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

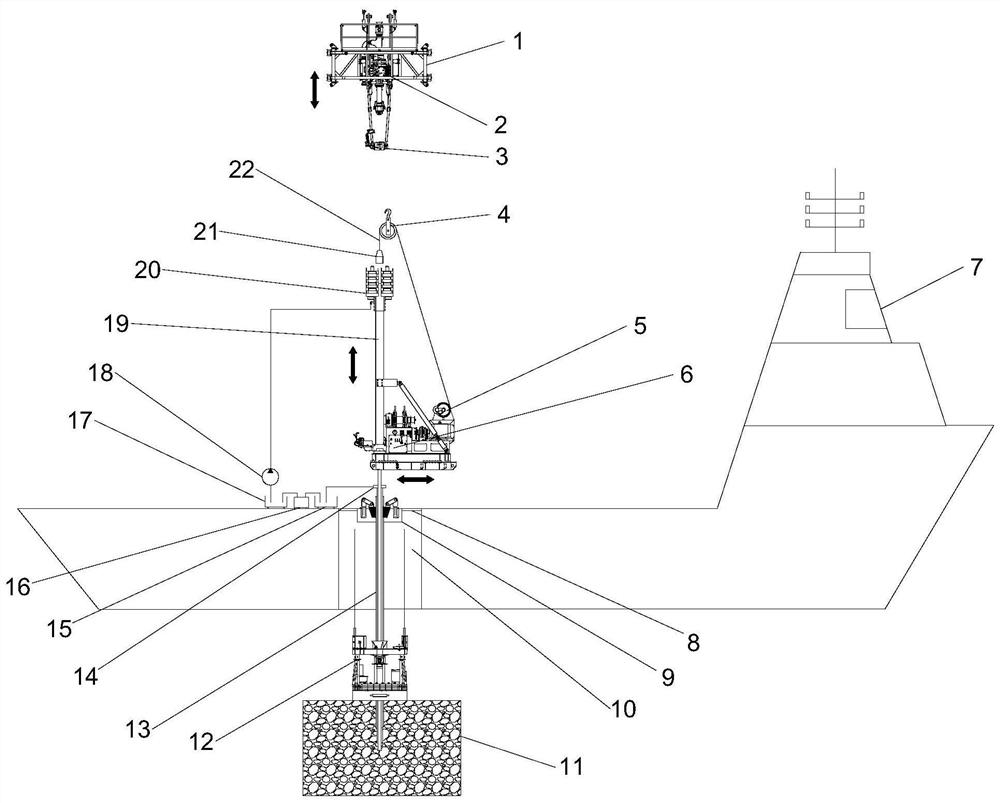

[0033] Such as figure 1 As shown, an offshore casing surge compensation dual-drive three-layer casing drilling and coring device in this embodiment mainly includes a drilling ship 7 and a drilling tool system arranged on the drilling ship 7, an outer casing drilling system, an inner Casing and drill pipe drilling systems and mud circulation systems.

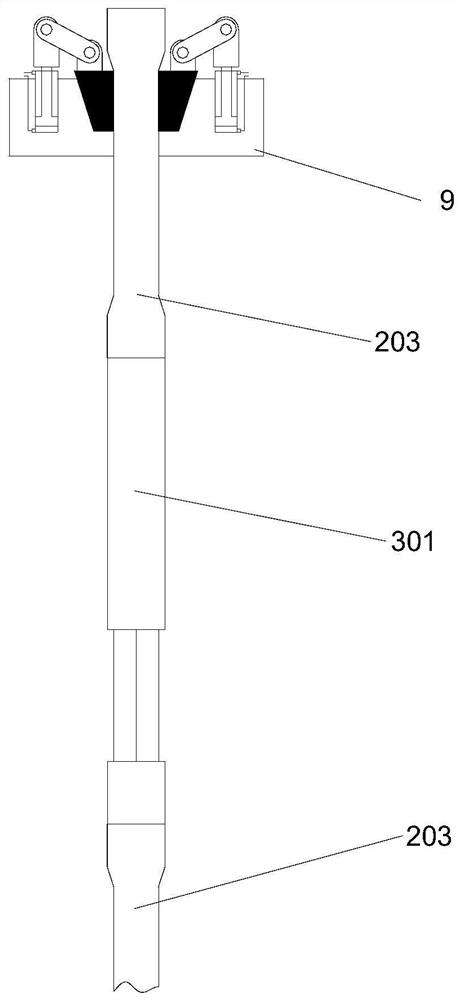

[0034] The drilling ship 7 includes a dynamic positioning system, and when the dynamic positioning is turned on, the wellhead position can be positioned at the specified coordinates. The deck of the drilling ship 7 is provided with a moon pool 10 and a tower (not shown in the figure), the top of the moon pool 10 is provided with a moon pool cover 8, and the center of the moon pool cover 8 is provided with a pneumatic slip 9. A liftable subsea base plate 12 is suspended.

[0035] The pneumatic slip 9 is a wedge connected to the pneumatic piston, which can move the outer casing up and down when opened, and can clamp the outer cas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com