An electric turntable device for directional drilling and anti-backup pressure and its control method

A technology of directional drilling and anti-support pressure, applied in the automatic control system of drilling, drilling equipment and methods, rotary drilling, etc. Effects of drilling accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

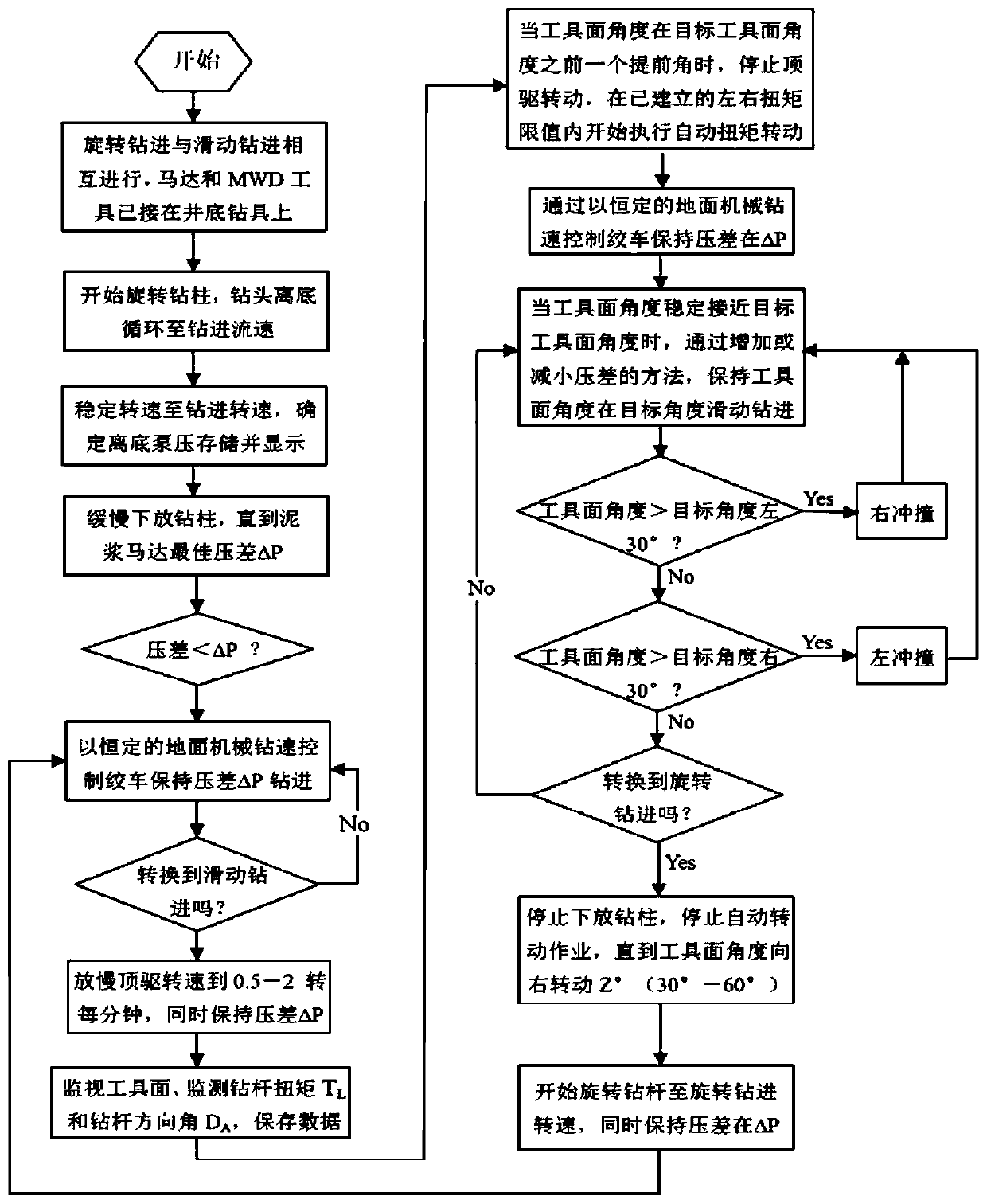

Embodiment 1

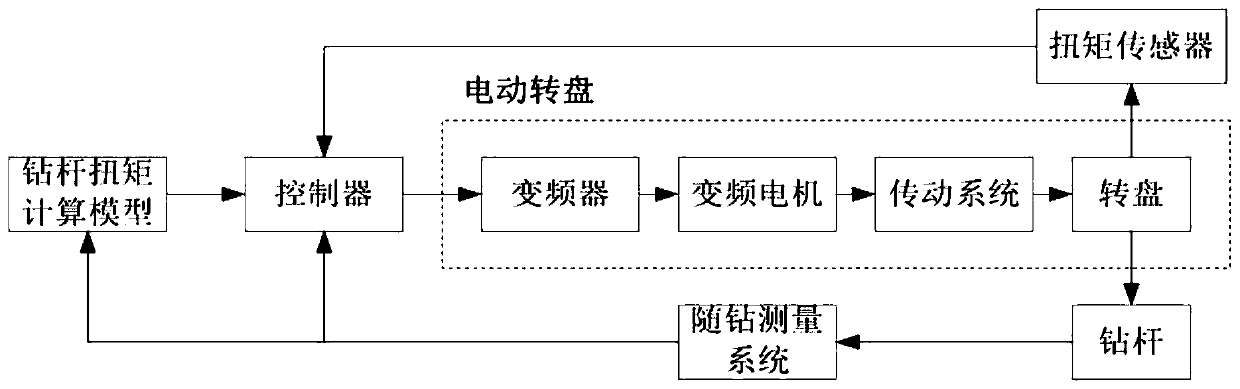

[0024] An electric turntable device for directional drilling and anti-backup pressure, including a rotational speed torque sensor (4), a frequency conversion speed regulation system (6), a turntable (2), a drill pipe (1), a measurement-while-drilling system (5) and a controller (3).

[0025] The controller (3) is electrically connected to a computer to store data. The controller (3) is also equipped with a rotary table and a drill pipe torque calculation model, using neural network (ANN) algorithm model and predictive control (MPC) Combining algorithms to control the relationship between speed and rotation angle to achieve directional drilling and reduce friction and back pressure;

[0026] The rotational speed torque sensor (4) adopts a strain gauge sensor, which is composed of an elastic shaft, a measuring bridge, an instrument amplifier, and an interface circuit. The elastic shaft is made of a material that is prone to deformation, and the slight deformation of the torque w...

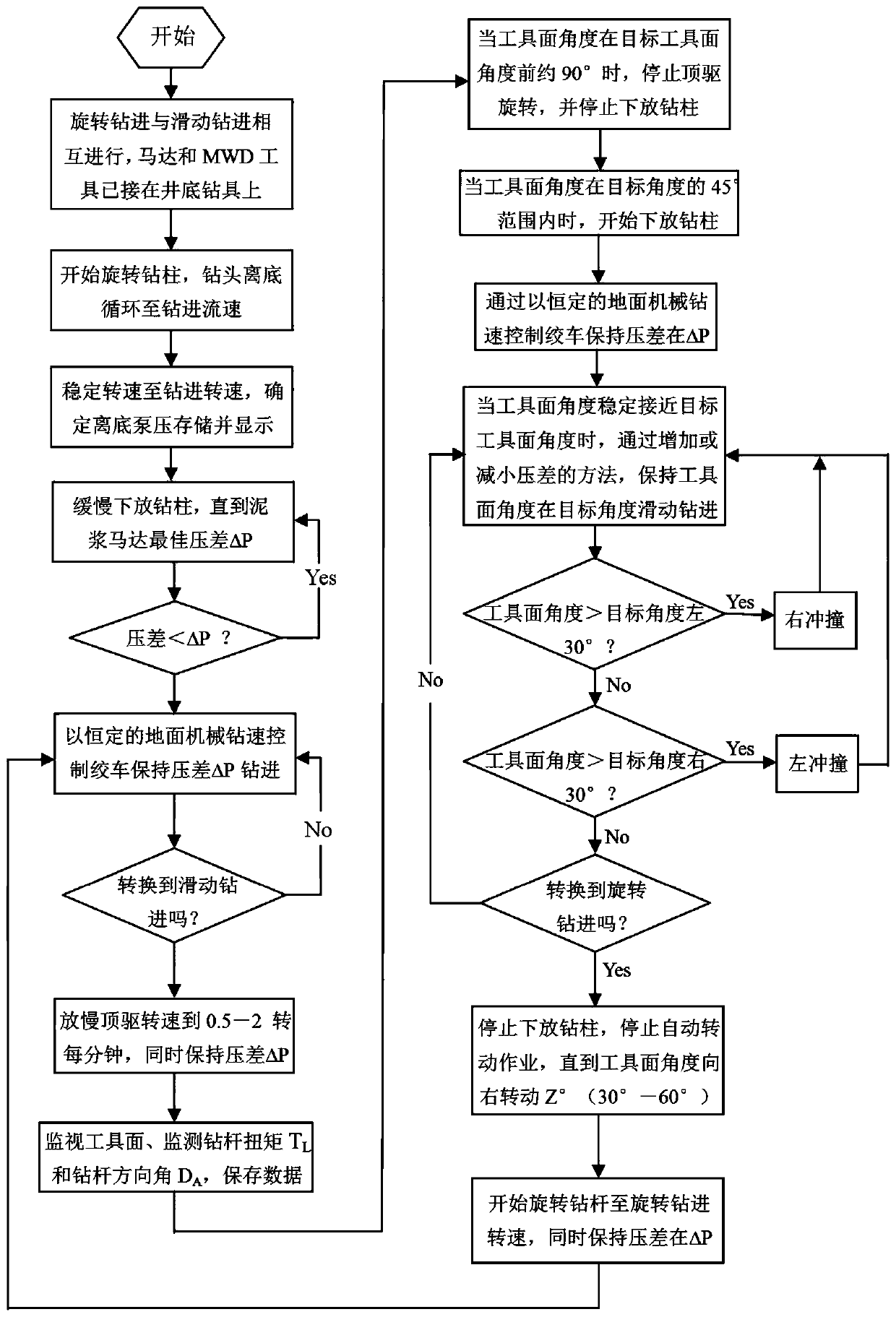

Embodiment 2

[0033] An electric turntable device for directional drilling and anti-backup pressure, including a rotational speed torque sensor (4), a frequency conversion speed regulation system (6), a turntable (2), a drill pipe (1), a measurement-while-drilling system (5) and a controller (3).

[0034] The controller (3) is electrically connected to a computer to store data. The controller (3) is also equipped with a rotary table and a drill pipe torque calculation model, using neural network (ANN) algorithm model and predictive control (MPC) Combining algorithms to control the relationship between speed and rotation angle to achieve directional drilling and reduce friction and back pressure;

[0035] The rotational speed torque sensor (4) adopts a strain gauge sensor, which is composed of an elastic shaft, a measuring bridge, an instrument amplifier, and an interface circuit. The elastic shaft is made of a material that is prone to deformation, and the slight deformation of the torque w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com